The Daily Production Log Excel Template for Manufacturing is a vital tool designed to track and record daily production activities efficiently. It helps monitor output, machine performance, and workforce productivity, ensuring consistent quality and timely delivery. Using this template supports data-driven decision making and enhances operational transparency in manufacturing processes.

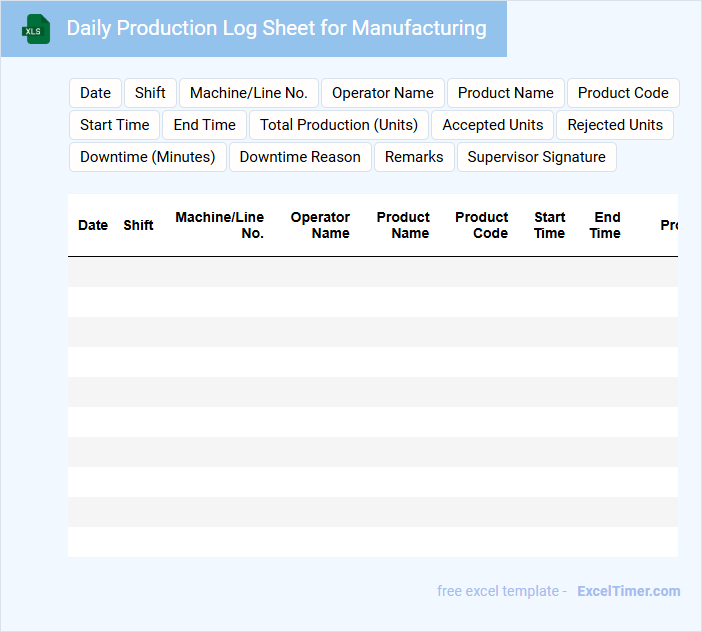

Daily Production Log Sheet for Manufacturing

What information is typically recorded in a Daily Production Log Sheet for Manufacturing? This document usually contains details such as production quantities, machine performance, and operator shifts. It helps track daily output and identify any issues or delays in the manufacturing process.

Why is accurate record-keeping important in a Daily Production Log Sheet? Precise logs ensure accountability and enable management to analyze productivity trends. This information is crucial for continuous improvement and meeting production targets efficiently.

Excel Template for Daily Production Output Tracking

An Excel template for daily production output tracking is typically used to record, monitor, and analyze the daily productivity of manufacturing or production processes.

- Production Data: It includes detailed entries of daily output quantities and production rates.

- Performance Metrics: Key performance indicators such as efficiency, downtime, and defects are tracked.

- Summary Reports: The template often features automated summaries and charts for quick review.

Manufacturing Daily Production Report with Shift Details

The Manufacturing Daily Production Report typically contains detailed information about the production output, including quantities produced, machine utilization, and downtime during each shift. It tracks shift-specific data such as operator performance and any issues encountered to ensure precise monitoring of the manufacturing process.

Such reports are crucial for identifying inefficiencies and improving overall productivity across shifts. Including accurate shift details like start/end times, personnel, and specific incidents can greatly enhance the value of the report.

For best results, always ensure timely data entry and clear documentation of any deviations or disruptions in production to maintain reliable records.

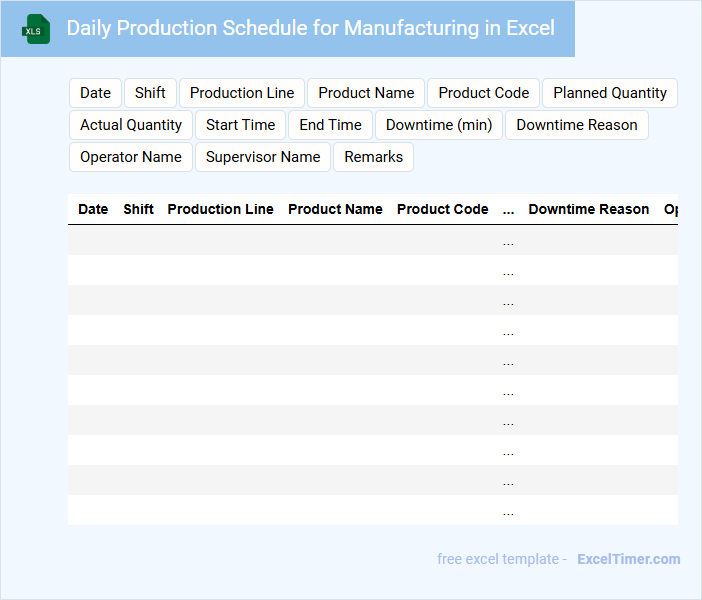

Daily Production Schedule for Manufacturing in Excel

What information does a Daily Production Schedule for Manufacturing in Excel typically include? This document usually contains detailed data on the production tasks scheduled for each day, including assigned workstations, operator names, and estimated completion times. It helps streamline workflow, manage resources efficiently, and ensure timely order fulfillment in a manufacturing setting.

What are the important elements to consider when creating such a schedule? Key factors include accurate demand forecasting, clear task prioritization, real-time updates for tracking progress, and flexibility to accommodate unexpected changes or delays. Incorporating color coding and formulas in Excel can enhance visibility and automate calculations, promoting better production management.

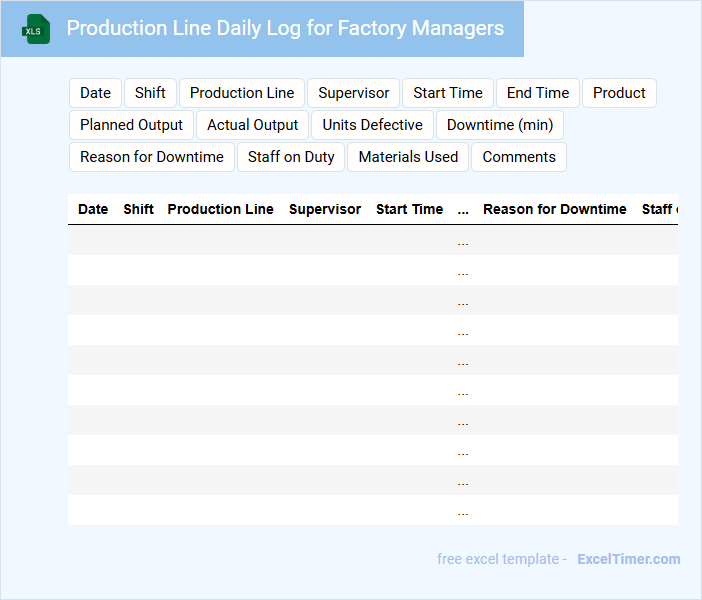

Production Line Daily Log for Factory Managers

The Production Line Daily Log is a crucial document for factory managers, capturing detailed records of daily manufacturing activities. It usually contains data on machine performance, worker shifts, and product output. Maintaining this log helps in identifying production bottlenecks and ensuring quality control.

Daily Manufacturing Output Tracker with Downtime

What information is typically included in a Daily Manufacturing Output Tracker with Downtime? This document usually contains detailed records of daily production quantities along with the corresponding downtime periods. It helps in monitoring manufacturing efficiency and identifying issues affecting productivity.

Why is it important to track both output and downtime in manufacturing? Tracking these ensures timely detection of bottlenecks and machine failures, enabling rapid response and maintenance. It also supports data-driven decision-making to optimize production processes.

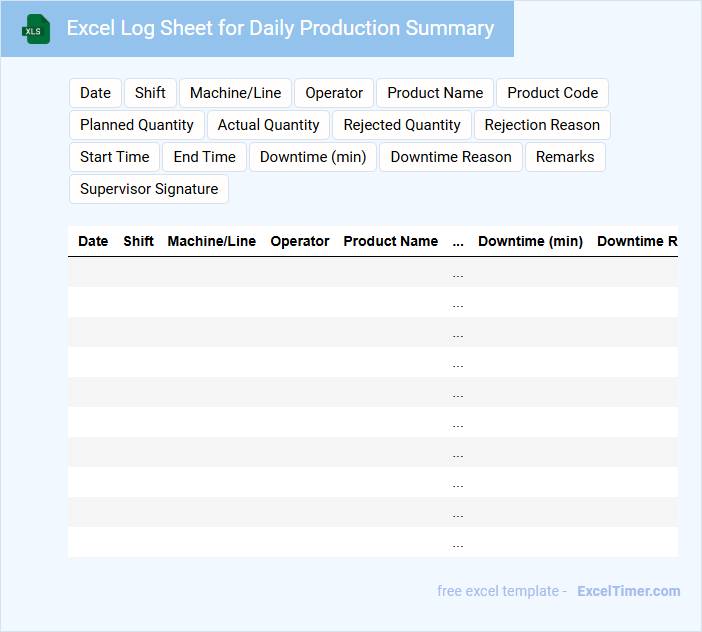

Excel Log Sheet for Daily Production Summary

An Excel Log Sheet for Daily Production Summary typically contains detailed records of daily outputs, machine performance, and labor inputs. It helps track production efficiency and identify bottlenecks during the manufacturing process.

This document usually includes columns for date, shift, production quantity, downtime, and remarks. Ensuring data accuracy and consistency is crucial for reliable analysis and reporting.

Including visual charts and automated formulas can enhance understanding and speed up decision-making.

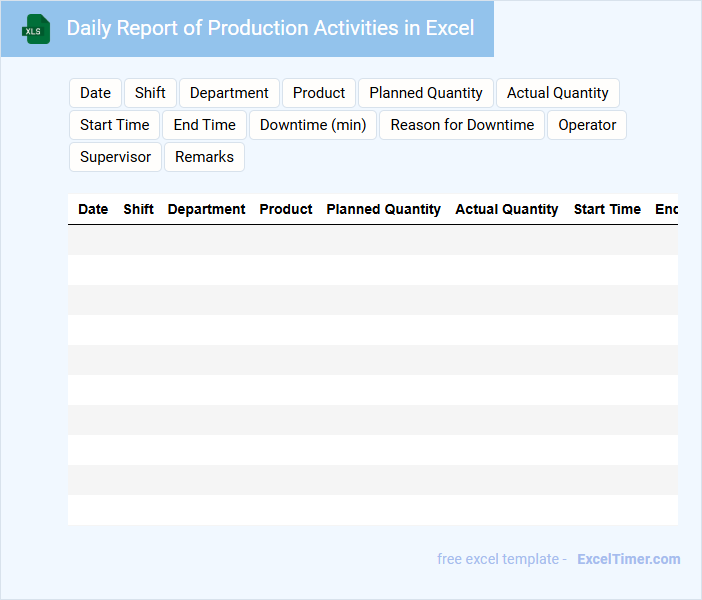

Daily Report of Production Activities in Excel

A Daily Report of Production Activities in Excel typically contains detailed logs of tasks completed, materials used, and workforce attendance. It helps in tracking production efficiency and identifying any issues promptly. Key elements usually include production targets, actual output, and downtime reasons.

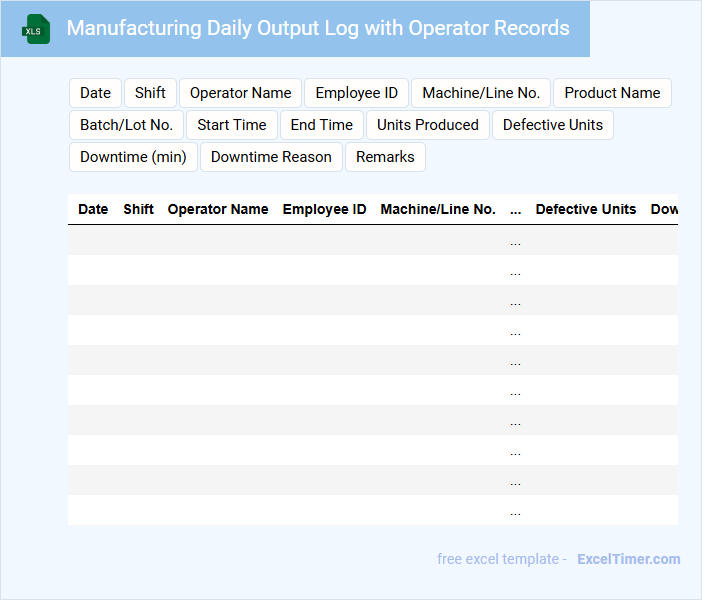

Manufacturing Daily Output Log with Operator Records

What information does a Manufacturing Daily Output Log with Operator Records typically contain? This document records daily production quantities, machine or process status, and any anomalies encountered. It also includes detailed operator information such as shift times, operator names, and specific tasks performed to ensure accountability and traceability in the manufacturing process.

Why is it important to include operator records in the daily output log? Including operator records helps track performance and identify any issues linked to specific shifts or personnel. It also facilitates effective communication between shifts and supports continuous improvement by analyzing operator-related production data.

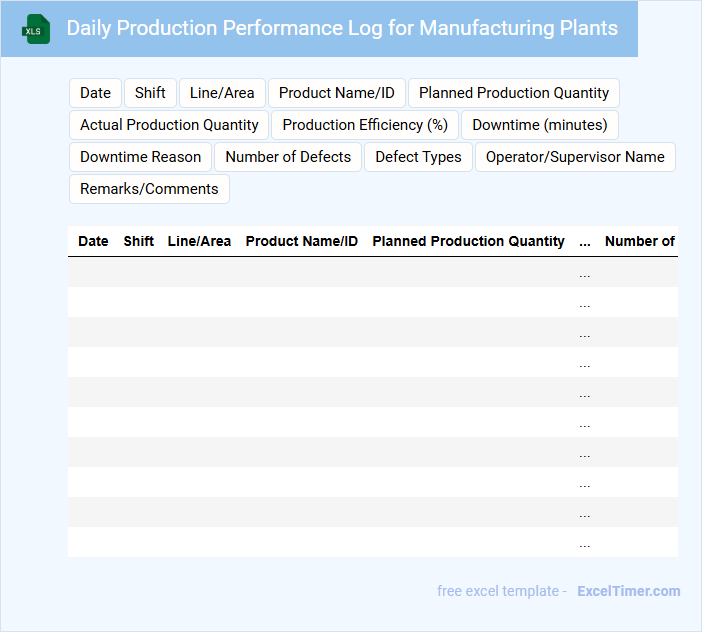

Daily Production Performance Log for Manufacturing Plants

The Daily Production Performance Log is a vital document used in manufacturing plants to record daily output, machine efficiency, and any operational issues encountered. It helps track productivity trends and identify areas needing improvement. Consistent and accurate entries ensure reliable data for management decisions.

Important elements to include are production volume, downtime reasons, quality defects, and shift details. Including notes on maintenance activities and safety observations can further enhance the log's usefulness. Regular review and analysis of the log promote continuous process optimization.

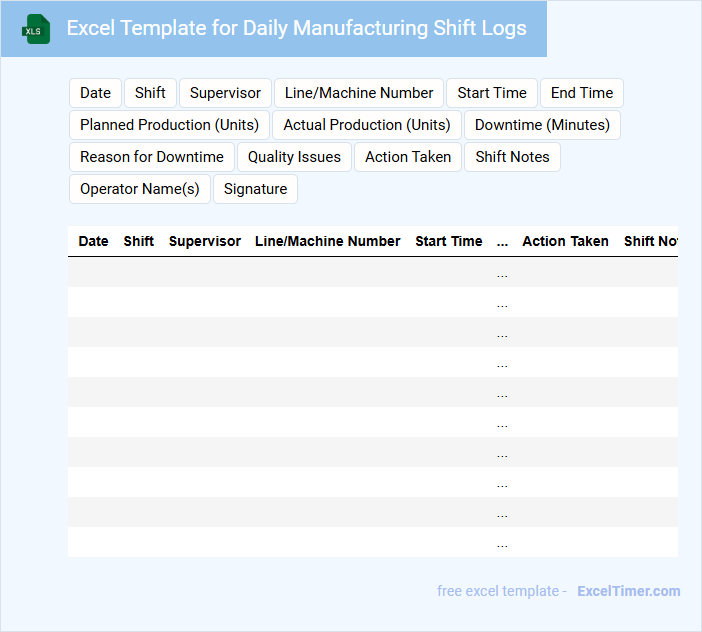

Excel Template for Daily Manufacturing Shift Logs

What information is typically included in an Excel Template for Daily Manufacturing Shift Logs? This type of document usually contains detailed records of production activities, equipment status, and workforce attendance during each shift. It helps in tracking productivity, identifying issues, and ensuring smooth operations in manufacturing processes.

What important elements should be included in this template? Key components include date and shift times, operator names, machine performance data, quantity produced, downtime reasons, quality control notes, and safety observations to maintain accurate and actionable records.

Daily Production Record Sheet with Defect Tracking

The Daily Production Record Sheet with Defect Tracking is a crucial document used in manufacturing and production environments to monitor daily output and identify quality issues. It typically contains data on the quantity of products made, the number of defects detected, and the types of defects categorized for analysis. Keeping such detailed records helps improve process efficiency and maintain product quality over time.

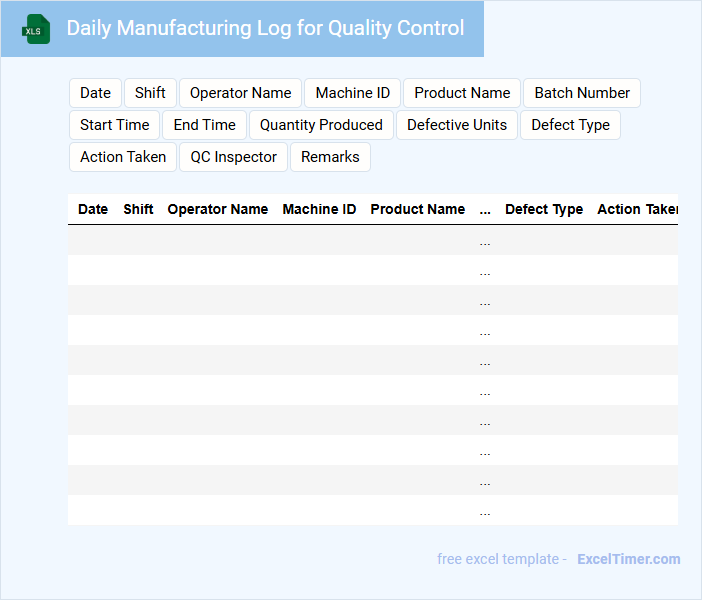

Daily Manufacturing Log for Quality Control

The Daily Manufacturing Log is a crucial document that records detailed information about the production process each day. It typically contains data on equipment status, batch numbers, raw material usage, and environmental conditions.

For Quality Control, this log helps track deviations, monitor compliance, and ensure product consistency. Maintaining accurate and timely entries is essential to quickly identify and resolve potential issues.

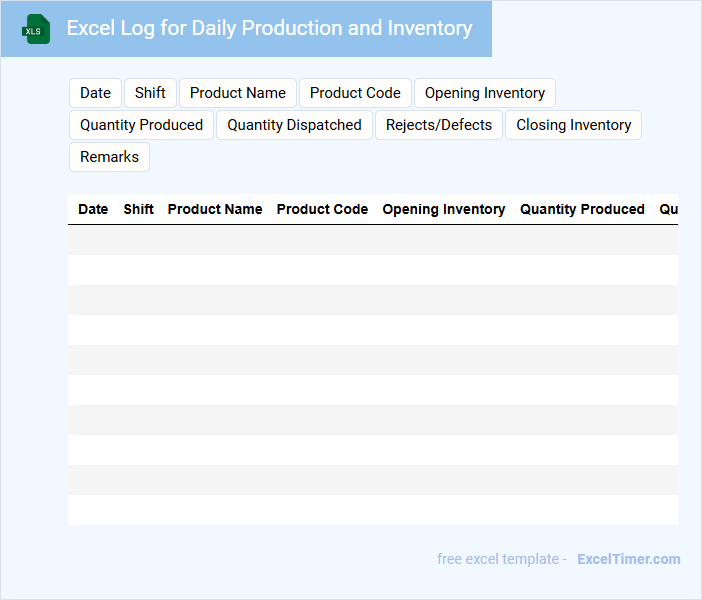

Excel Log for Daily Production and Inventory

An Excel Log for Daily Production and Inventory is a structured document used to record and track daily manufacturing output and stock levels. It typically contains columns for dates, product details, quantities produced, and inventory on hand. This log helps in monitoring productivity trends and managing supply chain efficiency.

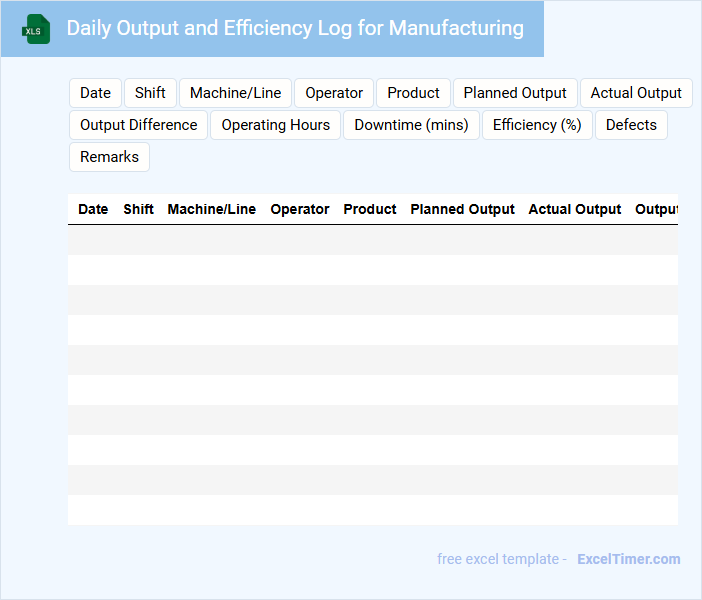

Daily Output and Efficiency Log for Manufacturing

The Daily Output and Efficiency Log is a critical document used in manufacturing to record the daily production quantities and monitor operational efficiency. It typically contains data such as unit output, machine performance, downtime, and labor hours. This log helps in identifying production bottlenecks and optimizing resource utilization.

What key data fields should be included in a Daily Production Log for manufacturing in Excel?

Your Daily Production Log in Excel should include key data fields such as Date, Shift, Operator Name, Machine ID, Product Code, Quantity Produced, Defects Count, and Production Downtime. Tracking these metrics ensures accurate monitoring of manufacturing efficiency and quality control. Incorporating Time Started and Time Ended also helps analyze productivity trends daily.

How can formulas track and summarize total daily output, downtime, and scrap rates?

Formulas in your Daily Production Log automatically calculate total daily output by summing completed units, track downtime by aggregating inactive machine hours, and determine scrap rates through dividing defective units by total production. Using Excel functions like SUM, SUMIF, and simple division, these metrics update in real-time for accurate monitoring. This enables efficient production analysis and quick decision-making to optimize manufacturing performance.

Which features in Excel (such as Data Validation or Conditional Formatting) help ensure data accuracy for production entries?

Excel features like Data Validation restrict input to specific ranges or lists, preventing incorrect production entries in a Daily Production Log. Conditional Formatting highlights anomalies or outliers in production data, enabling quick identification of errors or inconsistencies. Drop-down lists and timestamp formulas further enhance accuracy by standardizing entries and recording production times automatically.

How can Excel charts and PivotTables visualize production trends and bottlenecks over time?

Excel charts and PivotTables transform daily production log data into clear visual summaries, highlighting trends in output and identifying bottlenecks by comparing production volumes across time periods. PivotTables enable dynamic filtering and grouping of manufacturing metrics such as machine performance and downtime, facilitating quick detection of inefficiencies. Interactive charts provide intuitive views of production patterns, supporting data-driven decisions to optimize manufacturing workflows.

What methods can secure and archive Daily Production Logs for compliance and historical analysis?

Securing and archiving Daily Production Logs in manufacturing involves using encrypted cloud storage solutions like Microsoft OneDrive or Google Drive with restricted access controls. Implementing automated backup systems coupled with version control software ensures data integrity and easy retrieval for compliance audits. Employing compliant document management systems such as SAP Document Management or SharePoint enhances long-term archival security and regulatory adherence.