The Daily Production Schedule Excel Template for Manufacturing Plants streamlines production planning by organizing tasks, resources, and timelines efficiently. It enhances operational productivity by providing real-time tracking and visual representation of daily manufacturing activities. This template is essential for minimizing downtime, optimizing resource allocation, and ensuring timely order fulfillment.

Daily Production Schedule Template for Manufacturing Plants

A Daily Production Schedule Template for Manufacturing Plants is a document used to plan and track daily manufacturing activities. It ensures that production goals are met efficiently by organizing tasks and resources.

- Include start and end times for each production task to maintain workflow clarity.

- List assigned personnel and machinery to ensure accountability.

- Incorporate sections for tracking progress and noting any delays or issues.

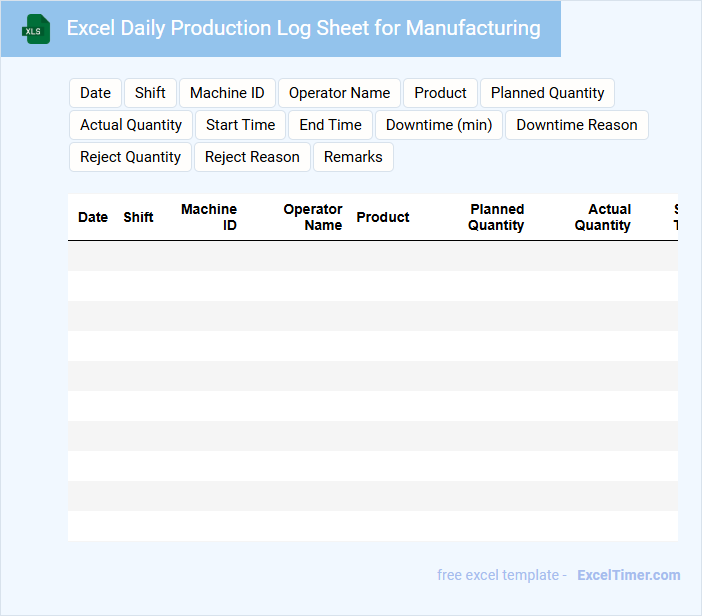

Excel Daily Production Log Sheet for Manufacturing

An Excel Daily Production Log Sheet is typically used to record and monitor the daily output and efficiency of a manufacturing process. It includes details such as production quantities, machine performance, and operator notes to ensure accurate tracking.

These sheets are essential for identifying production trends, managing inventory, and improving operational workflows. An important suggestion is to incorporate automatic calculations and drop-down menus to minimize errors and enhance data consistency.

Daily Production Tracking Template for Plant Operations

What information is typically included in a Daily Production Tracking Template for Plant Operations? This document usually contains data on daily output, machine performance, and labor efficiency to monitor production progress. It helps identify bottlenecks and ensures that operations meet targets for quality and quantity.

What is an important consideration when using this template? Accuracy in recording actual production figures and timely updates are crucial to provide real-time insights. Additionally, integrating metrics for downtime and maintenance helps improve overall plant efficiency and decision-making.

Production Planning Schedule with Daily Shift Tracking

Production Planning Schedule with Daily Shift Tracking is a document used to organize and monitor production activities on a daily basis across different shifts. It helps ensure efficiency and timely completion of manufacturing tasks by tracking progress and resource allocation.

- Include clear timelines and assigned tasks for each shift to avoid confusion.

- Incorporate real-time updates for accurate tracking and adjustments.

- Ensure it allows space for noting issues or delays for immediate resolution.

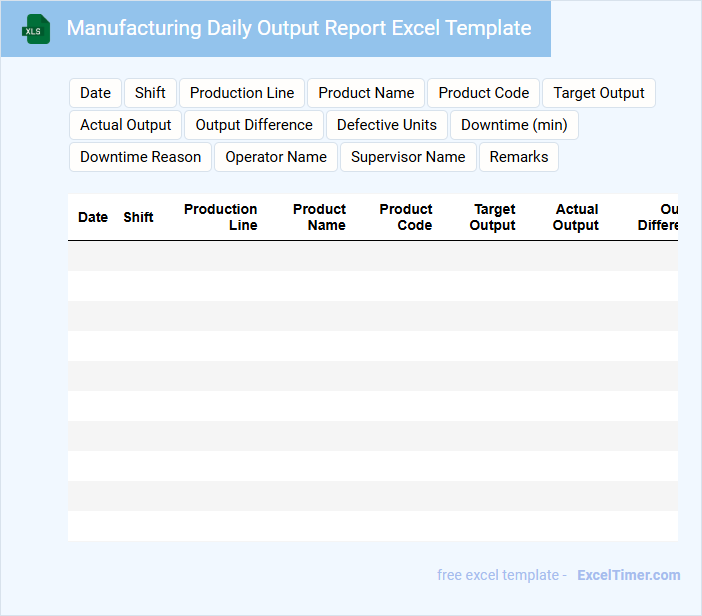

Manufacturing Daily Output Report Excel Template

What information is typically included in a Manufacturing Daily Output Report Excel Template? This type of document usually contains detailed records of production metrics such as quantities produced, machine performance, and downtime incidents. It helps in tracking daily manufacturing efficiency and identifying areas for process improvement.

What is an important aspect to consider when using a Manufacturing Daily Output Report Excel Template? Ensuring accurate and timely data entry is crucial to maintain the reliability of the report. Additionally, including clear headers and standardized formats enhances readability and facilitates data analysis.

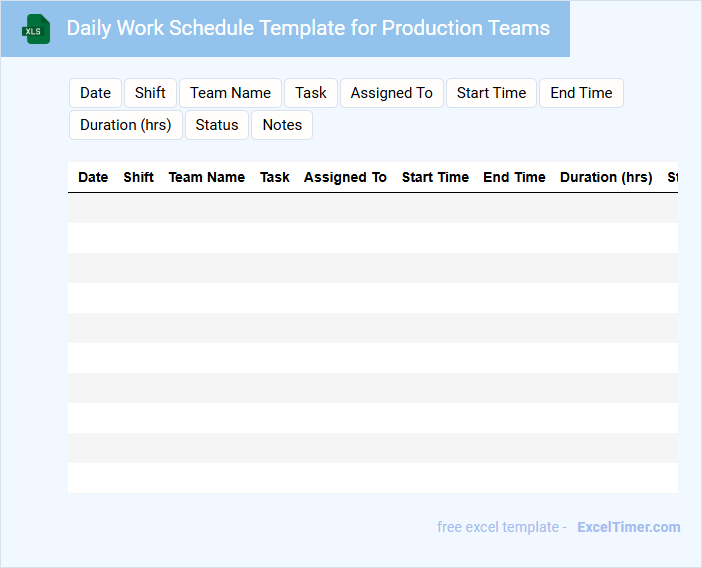

Daily Work Schedule Template for Production Teams

A Daily Work Schedule Template for Production Teams typically contains detailed task assignments and time allocations to ensure efficient workflow management.

- Clear task descriptions help team members understand their responsibilities and priorities.

- Time slots allocation allows for proper scheduling and tracking of production activities.

- Status indicators provide updates on task progress to facilitate communication and adjustments.

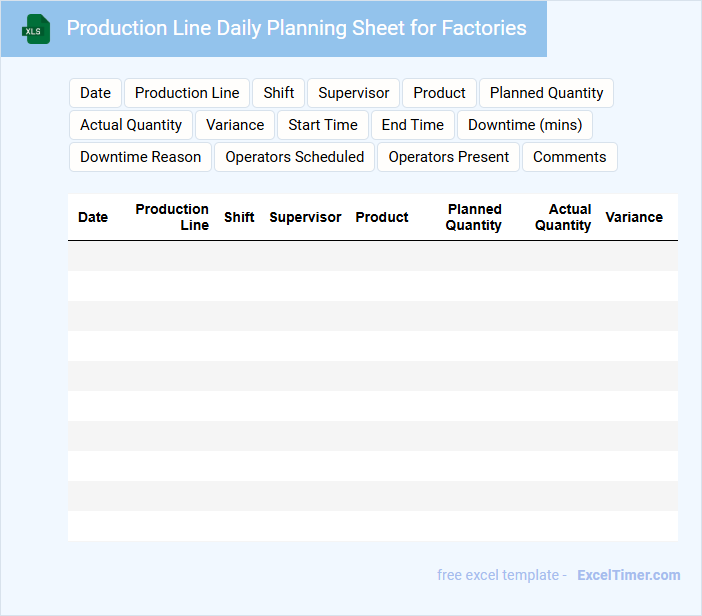

Production Line Daily Planning Sheet for Factories

What information is typically contained in a Production Line Daily Planning Sheet for factories? This document usually includes daily production targets, machine assignments, and workforce allocation. It helps ensure efficient workflow by clearly outlining tasks and schedules for each production line.

What is an important element to include in the Production Line Daily Planning Sheet? Including real-time updates on production status and potential bottlenecks is crucial. This allows quick adjustments and minimizes downtime, enhancing overall productivity.

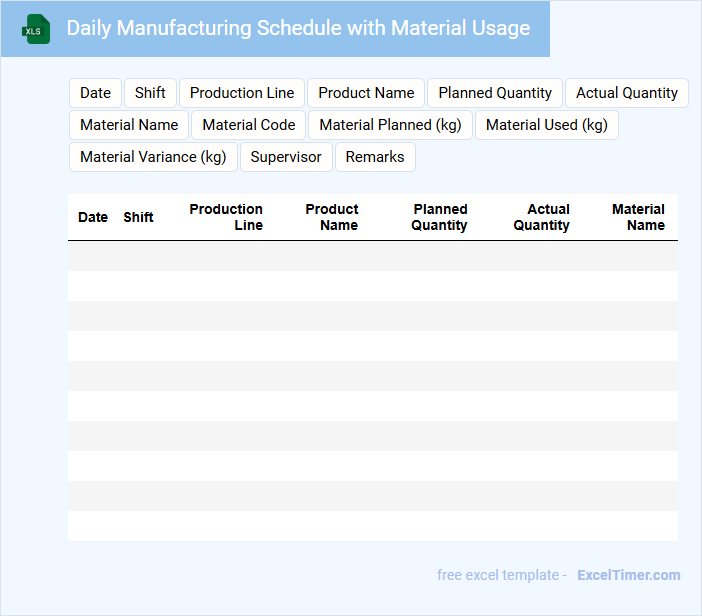

Daily Manufacturing Schedule with Material Usage

A Daily Manufacturing Schedule with Material Usage document typically outlines the planned production activities and the corresponding materials required for a given day to ensure efficient workflow and resource management.

- Production Tasks: Clearly list all manufacturing operations scheduled for the day.

- Material Requirements: Specify the exact materials and quantities needed for each task.

- Timing and Deadlines: Include start and end times for each task to maintain schedule adherence.

Excel Template for Daily Plant Production Monitoring

An Excel Template for Daily Plant Production Monitoring typically includes sections for recording daily output, equipment status, and workforce attendance. It helps in tracking production efficiency and identifying bottlenecks promptly.

This document often features charts and summary tables for quick analysis of trends and performance metrics. Ensuring accurate data entry and regular updates are crucial for reliable monitoring and decision-making.

Shift-wise Daily Production Record for Factories

A Shift-wise Daily Production Record for Factories is a document that tracks the production output and activities for each shift during a single day. It provides detailed insights into operational efficiency and helps identify issues in real-time.

- Include accurate start and end times for each shift to monitor productivity.

- Record the quantity of goods produced and any downtime experienced.

- Note any quality control issues or incidents that occurred during the shift.

Daily Production Dashboard with KPI Tracking

What information does a Daily Production Dashboard with KPI Tracking typically contain?

This type of document usually includes real-time data on production output, efficiency rates, and key performance indicators (KPIs) such as machine uptime, defect rates, and workforce productivity. It provides a visual summary to help managers monitor daily performance and identify areas needing immediate improvement.

For optimal use, it is important to ensure the dashboard is updated frequently, uses clear visual charts, and highlights critical KPIs that align with the company's operational goals. Consistent tracking and quick access to actionable insights enable better decision-making and enhanced production management.

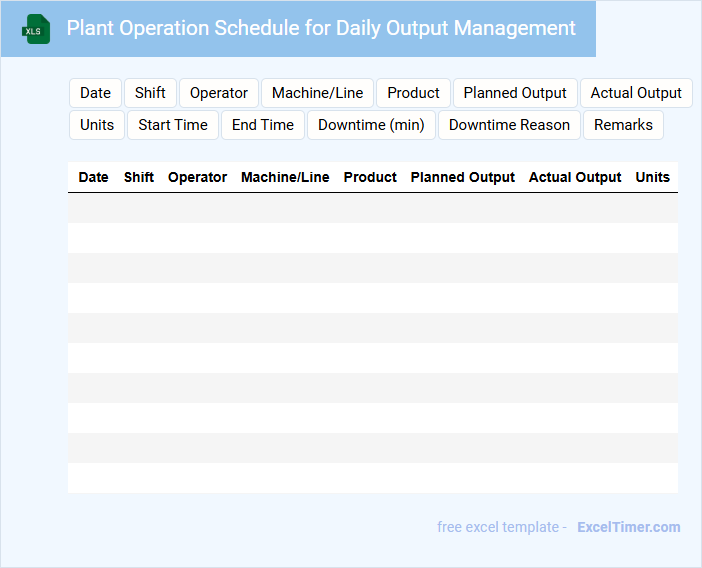

Plant Operation Schedule for Daily Output Management

A Plant Operation Schedule for Daily Output Management is a detailed document outlining the planned activities and production targets for a manufacturing plant within a single day. It typically contains information about machinery usage, shift timings, and resource allocation to ensure smooth operation and maximum productivity. An important suggestion is to include real-time monitoring and contingency plans to quickly address any unexpected disruptions.

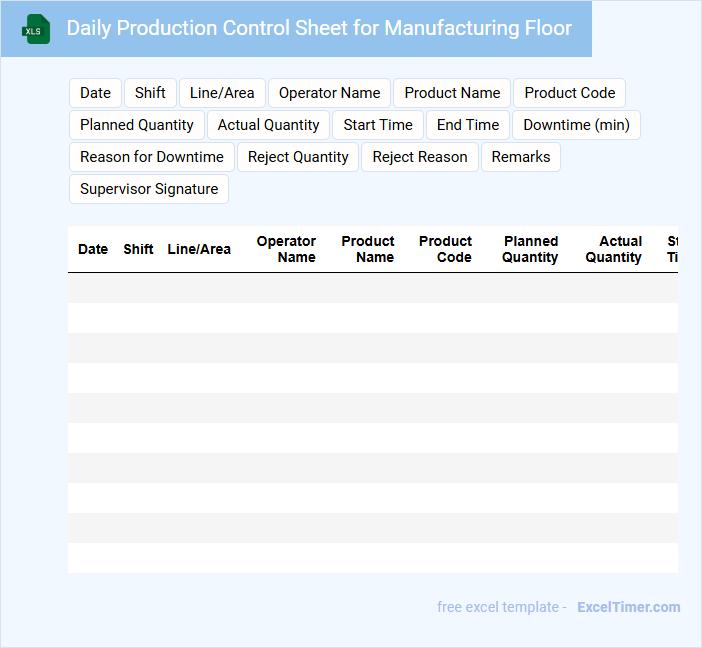

Daily Production Control Sheet for Manufacturing Floor

A Daily Production Control Sheet for the manufacturing floor is a document used to monitor and track daily production activities and output. It helps in maintaining quality control and ensuring that production targets are met efficiently.

- Record the quantity of products produced and compare it against the target for the day.

- Note any machine breakdowns or production delays with timestamps for immediate attention.

- Include quality inspection results to ensure compliance with manufacturing standards.

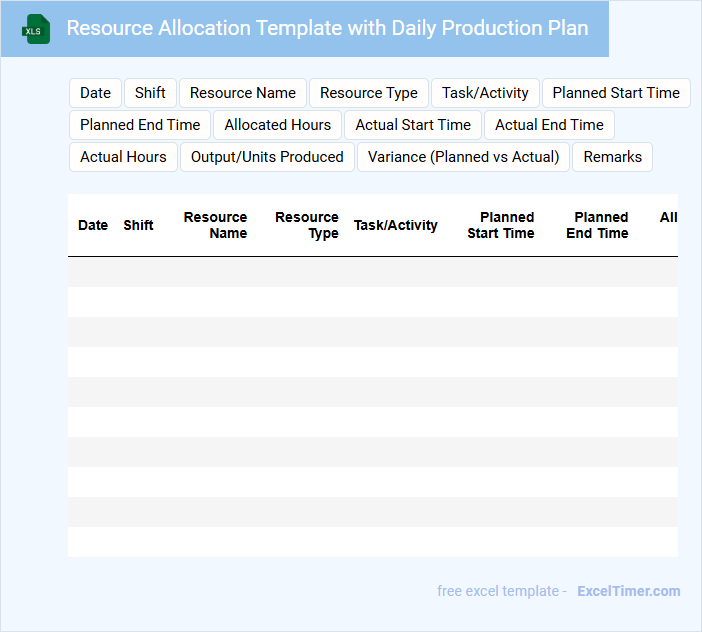

Resource Allocation Template with Daily Production Plan

A Resource Allocation Template with Daily Production Plan typically contains schedules and assignments to optimize resource use and manage daily production activities efficiently.

- Clear resource identification: List all resources including personnel, equipment, and materials involved in production.

- Detailed daily schedule: Outline specific tasks with start and end times for each production phase.

- Performance tracking metrics: Include measurements to monitor productivity and resource utilization effectively.

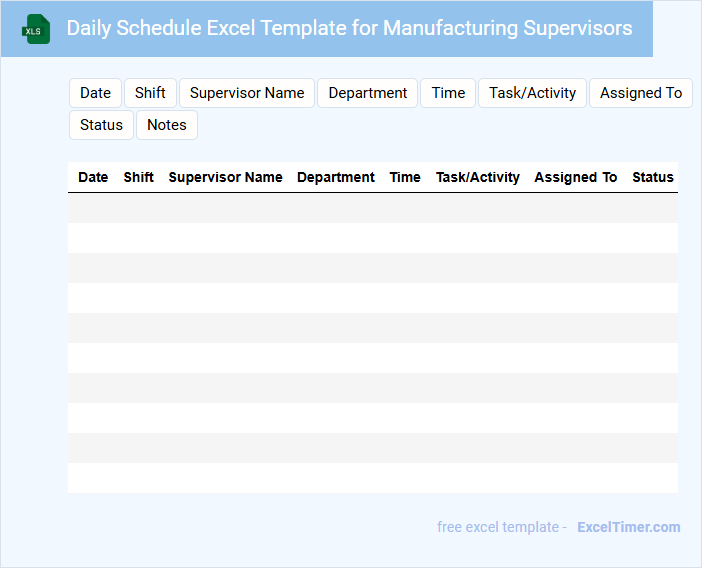

Daily Schedule Excel Template for Manufacturing Supervisors

A Daily Schedule Excel Template for Manufacturing Supervisors typically contains organized tasks, timelines, and resource allocations to streamline production activities and enhance oversight.

- Task Management: Clearly defines and organizes daily tasks to ensure efficient workflow and accountability.

- Resource Allocation: Tracks employee assignments and equipment usage to optimize productivity and minimize downtime.

- Performance Monitoring: Includes real-time updates and status checks to identify bottlenecks and maintain quality control.

What critical data fields must be included in a daily production schedule Excel document for manufacturing plants?

A daily production schedule Excel document for manufacturing plants must include critical data fields such as production date, shift timings, machine assignments, product codes, quantities planned versus produced, and operator names. These fields enable accurate tracking of output, resource allocation, and downtime analysis to optimize efficiency. Ensure your schedule also captures quality status and deadline adherence to maintain seamless manufacturing operations.

How does the schedule align production capacity with order deadlines in the Excel document?

The Daily Production Schedule in the Excel document aligns production capacity with order deadlines by matching available manufacturing resources and shift hours to the volume of orders due each day. It uses formulas to calculate workload distribution, ensuring no machine or labor exceeds its capacity while prioritizing urgent orders. Conditional formatting highlights potential bottlenecks, enabling proactive adjustments to meet delivery timelines efficiently.

What methods are used to track and adjust inventory levels within the daily production schedule?

Your Daily Production Schedule in Excel uses real-time inventory tracking and automated reorder point calculations to maintain optimal stock levels. Barcode scanning and batch tracking methods ensure accurate material usage monitoring. Dynamic adjustment algorithms align inventory with production demands to minimize shortages and overstock situations.

How are machine and labor availability integrated and visualized in the Excel schedule?

The Excel Daily Production Schedule integrates machine and labor availability using dynamic tables and conditional formatting to highlight resource allocation. Your schedule displays real-time utilization rates and available capacity through visual dashboards and color-coded grids. This approach ensures efficient planning by aligning production tasks with available machines and workforce.

What mechanisms are included for recording deviations or delays in the daily production process?

The Daily Production Schedule for Manufacturing Plants includes real-time deviation logging features that capture delays and production anomalies. Automated timestamping and reason code entry enable precise tracking of disruptions during the manufacturing process. Integrated alert systems notify supervisors instantly to ensure prompt corrective actions.