The Daily Shift Schedule Excel Template for Manufacturing Teams streamlines workforce management by organizing shifts, tracking attendance, and ensuring optimal coverage on the production floor. This template enhances communication and reduces scheduling conflicts, promoting operational efficiency and productivity. Easy to customize and update, it supports manufacturing teams in maintaining smooth daily operations.

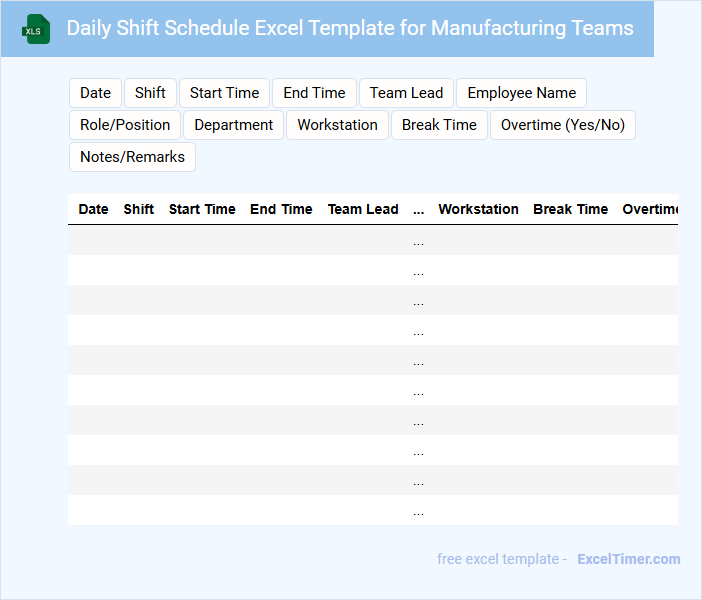

Daily Shift Schedule Excel Template for Manufacturing Teams

Daily Shift Schedule Excel Templates for Manufacturing Teams typically contain structured tables outlining employee shifts, tasks, and timings to ensure smooth operational workflows.

- Accurate Shift Timings: Ensure precise start and end times for each shift to avoid overlap and confusion.

- Task Assignments: Clearly assign specific roles and responsibilities to each team member for accountability.

- Real-time Updates: Incorporate features that allow quick adjustments to shift changes or absences.

Shift Assignment Tracker for Manufacturing Employees

What information is typically included in a Shift Assignment Tracker for Manufacturing Employees? This document usually contains details such as employee names, assigned shifts, dates, and specific job roles to ensure smooth workflow management. It helps supervisors monitor attendance, manage staffing levels, and optimize shift scheduling for operational efficiency.

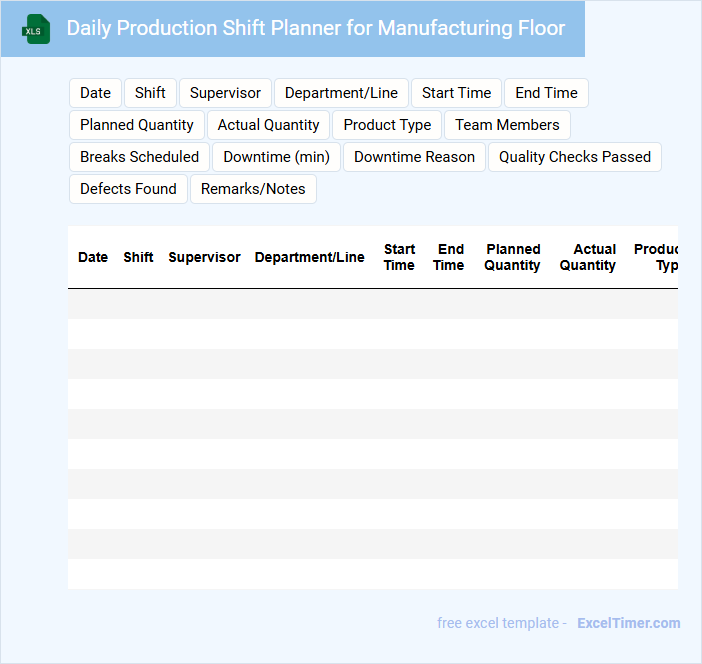

Daily Production Shift Planner for Manufacturing Floor

A Daily Production Shift Planner for the manufacturing floor is a critical document that outlines the scheduled tasks and responsibilities for each shift. It typically contains information about machine assignments, operator duties, and production targets to ensure smooth operations.

This planner also includes notes on maintenance schedules, safety reminders, and quality checks necessary during the shift. To optimize efficiency, it is important to update the planner in real-time and clearly communicate any changes to the team.

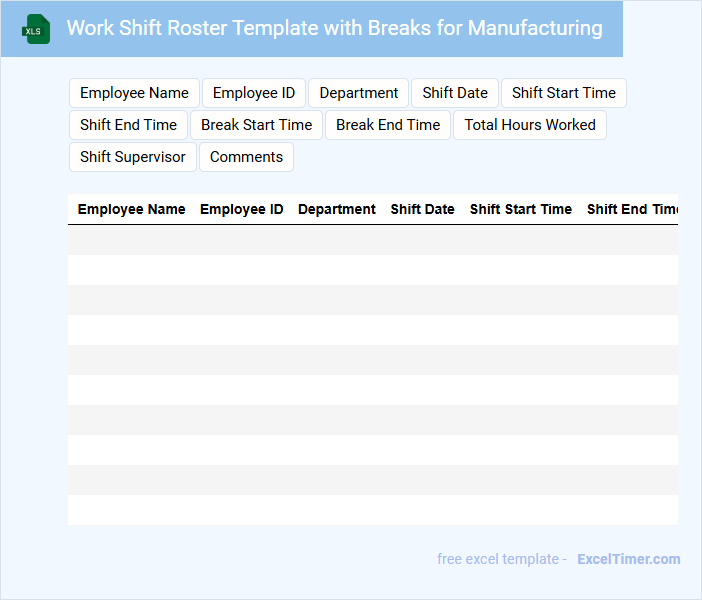

Work Shift Roster Template with Breaks for Manufacturing

A Work Shift Roster Template with breaks for manufacturing is a structured document that outlines employee schedules, including designated work periods and allocated break times. It ensures efficient workforce management by providing clear shifts to optimize productivity and maintain compliance with labor laws. Key components typically include shift start and end times, break durations, and employee assignments.

Manufacturing Staff Shift Log with Overtime Tracking

A Manufacturing Staff Shift Log with Overtime Tracking typically contains detailed records of employee shifts, including hours worked and any overtime accrued to ensure accurate payroll and productivity monitoring.

- Shift Details: Precise start and end times for each employee's shift must be recorded for accountability.

- Overtime Tracking: Overtime hours should be clearly documented to comply with labor regulations and control costs.

- Staff Identification: Employee names and IDs are essential for accurate record-keeping and reporting.

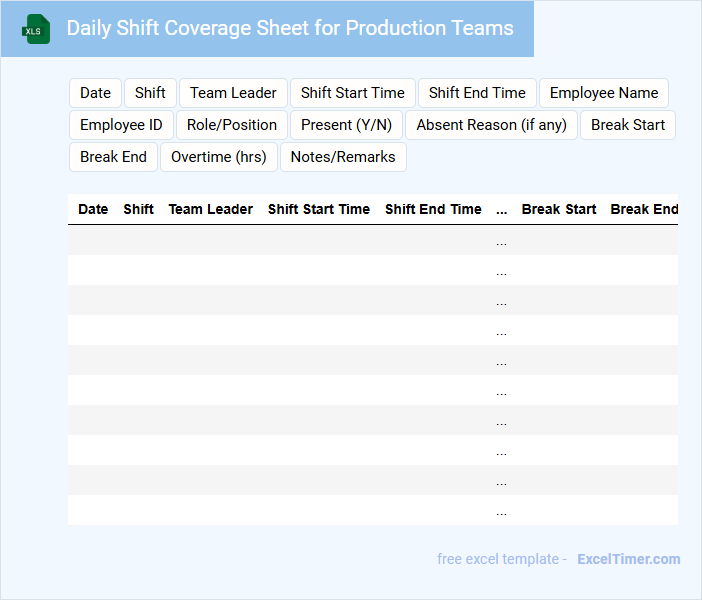

Daily Shift Coverage Sheet for Production Teams

A Daily Shift Coverage Sheet for Production Teams is a document that records shift assignments, personnel attendance, and operational notes to ensure smooth production flow.

- Shift Assignments: Clearly list each team member's role and shift timing to avoid confusion.

- Attendance Tracking: Monitor presence and absences to manage workforce effectively.

- Operational Notes: Include important observations, issues, or instructions to maintain communication.

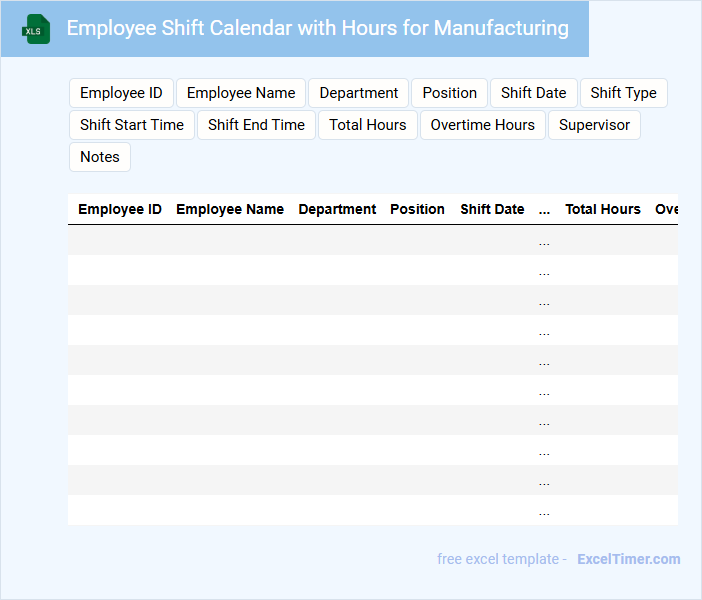

Employee Shift Calendar with Hours for Manufacturing

An Employee Shift Calendar for manufacturing typically contains scheduled work hours, designated shifts, and employee assignments to ensure smooth production flows. It includes detailed information about start and end times, break periods, and any overtime hours to maintain workforce efficiency. This document helps manage labor availability and aligns staffing with production demands. The calendar is crucial for tracking attendance, preventing scheduling conflicts, and maintaining compliance with labor regulations. It often integrates with payroll systems to accurately calculate worked hours and overtime pay. Regular updates and clear communication are important to avoid disruptions and ensure operational continuity.

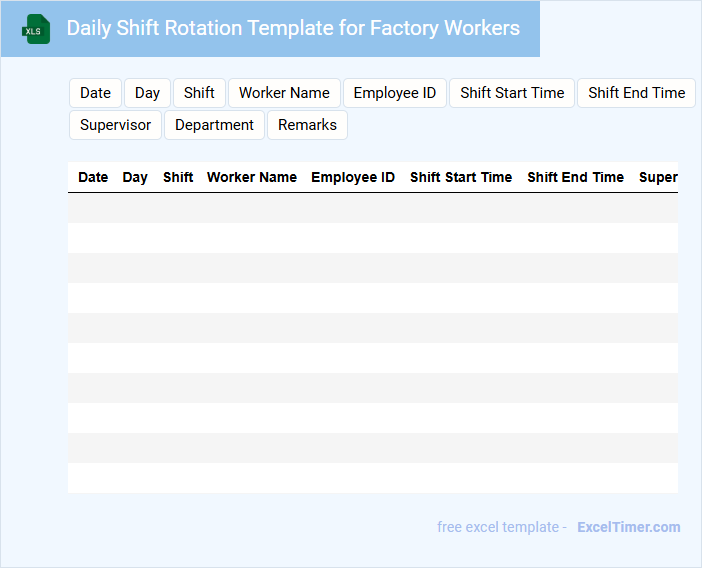

Daily Shift Rotation Template for Factory Workers

What information is typically included in a Daily Shift Rotation Template for Factory Workers? This document usually contains the schedule of workers assigned to specific shifts, including start and end times, along with any breaks or special instructions. It helps ensure smooth transition between shifts, optimize workforce allocation, and maintain production efficiency.

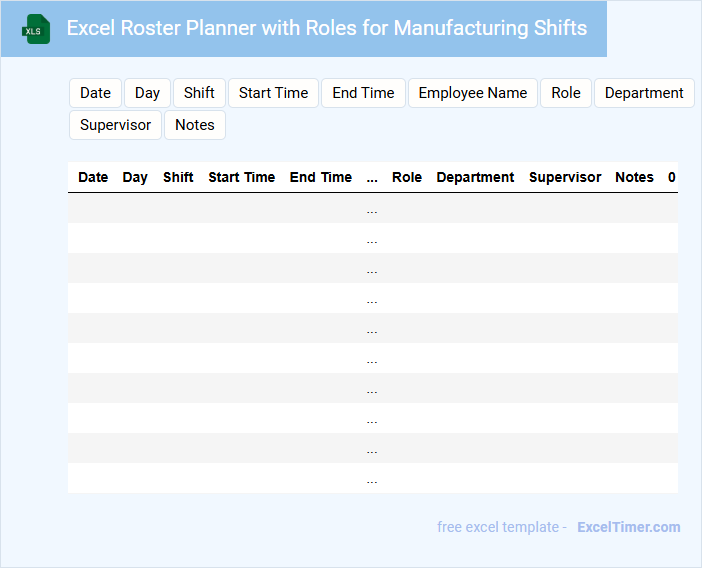

Excel Roster Planner with Roles for Manufacturing Shifts

What information does an Excel Roster Planner with Roles for Manufacturing Shifts typically contain? This document usually includes employee names, assigned roles, shift timings, and days worked to efficiently organize workforce scheduling. It helps ensure adequate coverage of all manufacturing processes while accommodating employee availability and labor regulations.

What important factors should be considered when creating this type of roster? It is essential to balance skill sets across shifts, manage compliance with labor laws regarding work hours and breaks, and allow flexibility to handle unexpected absences or peak production demands. Properly updating and communicating the roster is key to maintaining smooth manufacturing operations.

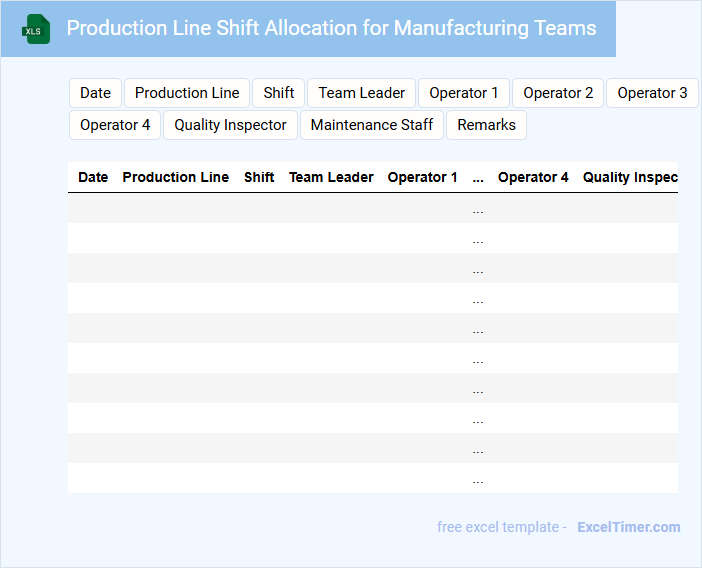

Production Line Shift Allocation for Manufacturing Teams

A Production Line Shift Allocation document outlines the schedule and assignment of manufacturing teams to various shifts on the production floor. It typically includes details such as workforce distribution, shift timings, and team responsibilities to ensure efficient production flow.

Accurate shift allocation helps optimize labor use, minimize downtime, and meet production targets. It should also consider worker skills, labor laws, and team preferences for better morale and productivity.

Ensuring clear communication and flexibility within the document is crucial for smooth shift transitions and handling unexpected changes.

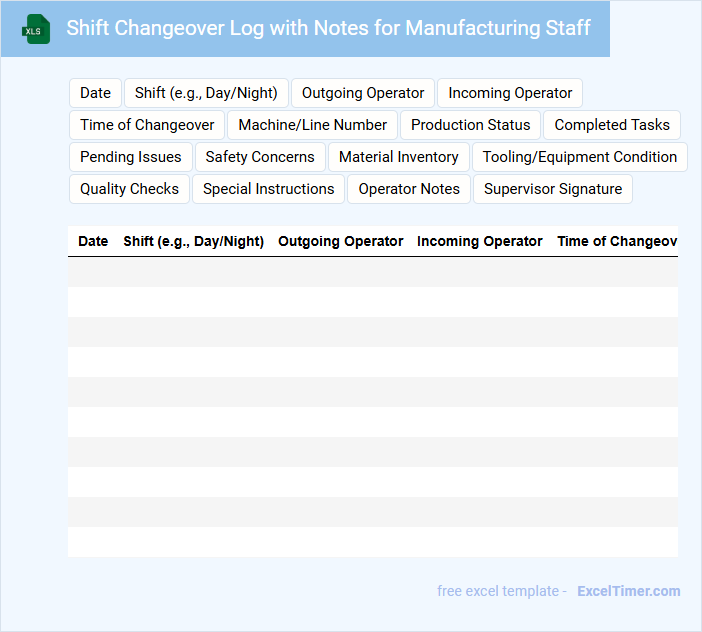

Shift Changeover Log with Notes for Manufacturing Staff

What information is typically recorded in a Shift Changeover Log with Notes for Manufacturing Staff? This document usually contains details such as production status, equipment conditions, incidents, and any anomalies encountered during the shift. It serves as a communication tool ensuring continuity and awareness between outgoing and incoming manufacturing teams.

Why is it important to include detailed notes in the Shift Changeover Log? Detailed notes help prevent misunderstandings and provide critical context for issues or special instructions. This improves operational efficiency, safety, and accountability throughout the manufacturing process.

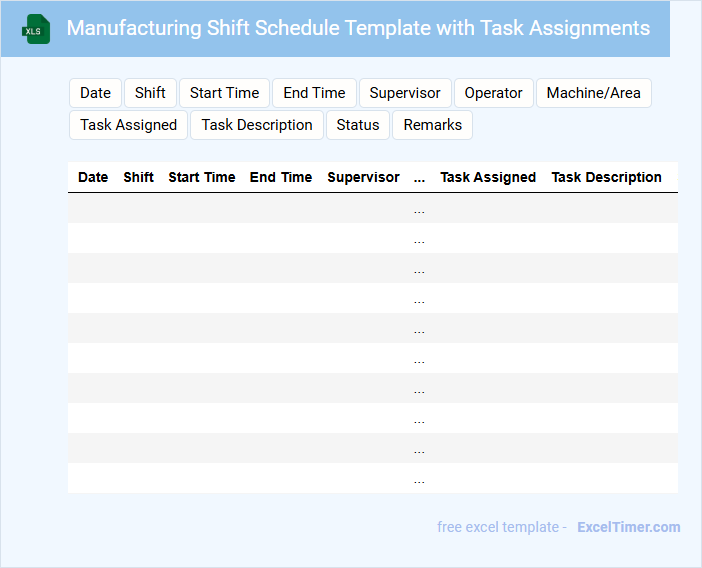

Manufacturing Shift Schedule Template with Task Assignments

A Manufacturing Shift Schedule Template typically contains detailed work shifts, employee assignments, and task responsibilities to ensure smooth production operations. It helps managers allocate resources efficiently and maintain consistent workflow throughout various shifts. Including clear timelines and specific task assignments is crucial to enhance productivity and reduce errors in the manufacturing process.

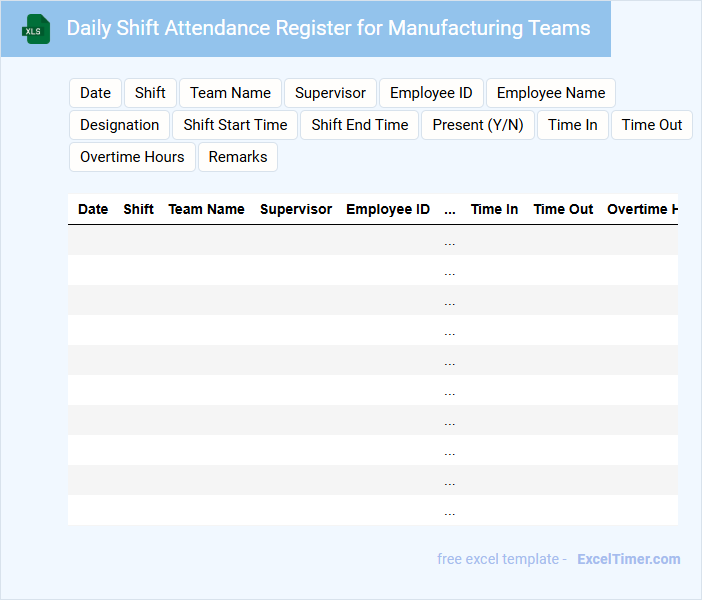

Daily Shift Attendance Register for Manufacturing Teams

The Daily Shift Attendance Register for manufacturing teams is a crucial document used to record the attendance and working hours of employees for each shift. It typically contains details such as employee names, shift timings, check-in and check-out times, and any absences or leaves. Ensuring accurate and timely entries helps maintain workforce accountability and streamline payroll processing.

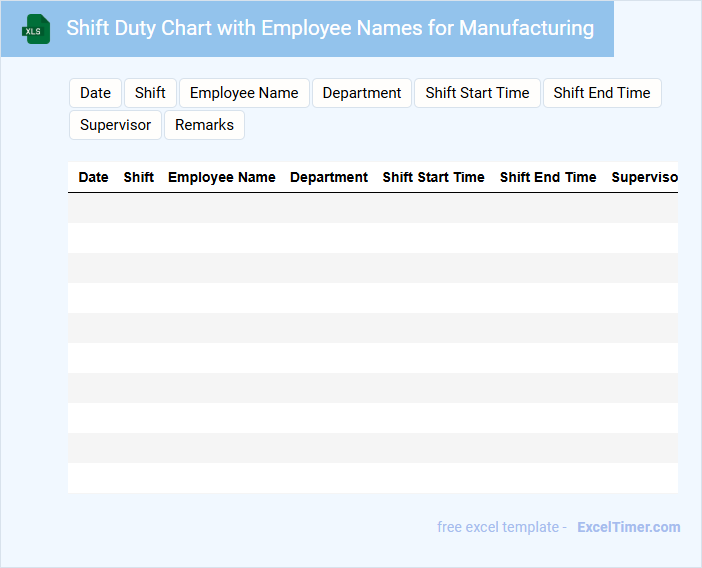

Shift Duty Chart with Employee Names for Manufacturing

What information is typically included in a Shift Duty Chart with Employee Names for Manufacturing? This type of document usually contains a detailed schedule outlining the shifts assigned to each employee, specifying their working hours and responsibilities. It serves as a crucial tool for organizing workforce allocation, ensuring smooth production flow, and avoiding scheduling conflicts in a manufacturing environment.

For optimal use, it is important to include clear employee names, exact shift timings, and designated roles or tasks. Additionally, incorporating a color-coded system or legend can improve readability and quick reference for managers and employees alike.

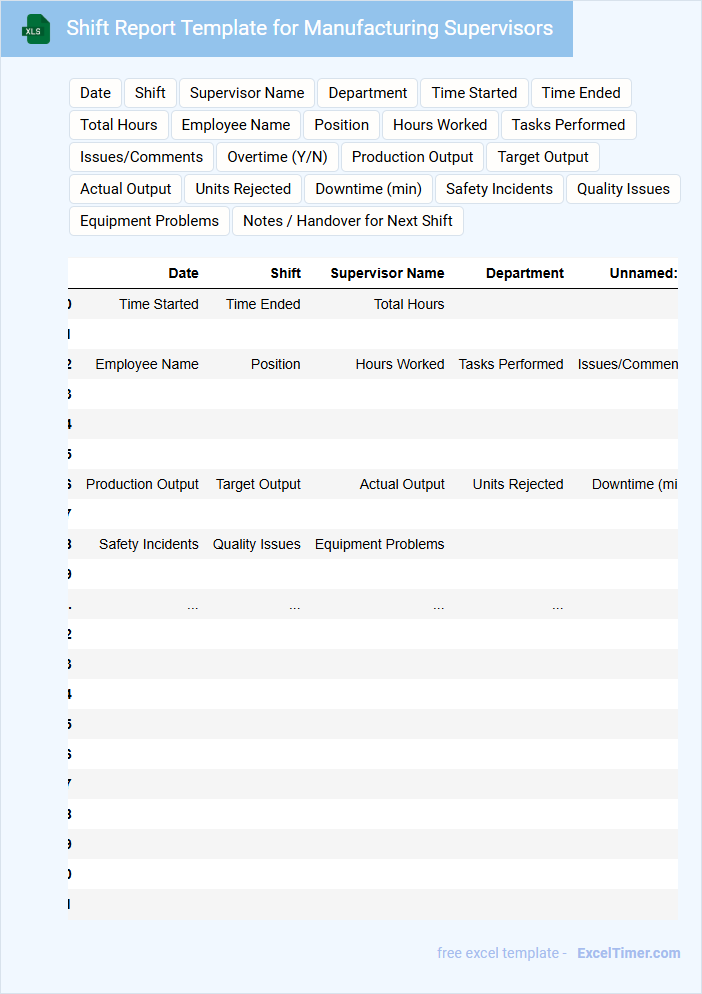

Shift Report Template for Manufacturing Supervisors

What is typically included in a Shift Report Template for Manufacturing Supervisors?

A Shift Report Template for Manufacturing Supervisors generally contains detailed information on production output, equipment status, and any incidents or safety issues that occurred during the shift. It serves as a critical communication tool to ensure continuity and accountability between shifts, helping supervisors track performance and address any operational challenges promptly.

It is important to include key data such as total units produced, downtime reasons, quality control notes, and staff attendance. Additionally, supervisors should document any maintenance needs or unusual events to maintain transparency and improve overall efficiency.

What key columns should be included in a daily shift schedule Excel sheet for manufacturing teams (e.g., Employee Name, Shift Time, Job Role, Station, Supervisor)?

Key columns for a daily shift schedule Excel sheet in manufacturing include Employee Name, Shift Start Time, Shift End Time, Job Role, Work Station, Supervisor Name, and Department. Incorporate Attendance Status and Break Times to track punctuality and compliance with labor regulations. Adding Notes or Special Instructions helps communicate shift-specific requirements and updates effectively.

How can conditional formatting be used to highlight shift overlaps, absences, or understaffed periods in the schedule?

Use conditional formatting in Excel to highlight shift overlaps by applying rules that flag duplicate or conflicting shift times within the same team. Format cells to show absences by identifying blank or marked absence entries in the schedule. Detect understaffed periods by setting rules that highlight timeslots with fewer assigned shifts than the required minimum staff level.

What formula ensures automatic calculation of total work hours for each employee per shift?

Use the formula =SUM(end_time - start_time) formatted as [h]:mm to automatically calculate total work hours for each employee per shift in Excel. This formula accurately computes hours by subtracting start time from end time, accounting for shifts spanning past midnight. Implementing this ensures precise tracking of daily work hours within manufacturing team schedules.

How can the schedule be structured to accommodate different shift patterns (e.g., rotating, fixed, split shifts)?

The Daily Shift Schedule for Manufacturing Teams can be structured using separate columns for shift types such as rotating, fixed, and split shifts, clearly defining start and end times for each. You can incorporate color-coding and conditional formatting in Excel to visually differentiate between shift patterns, enhancing readability. Including employee names alongside shift details ensures efficient tracking and management of varied work schedules.

Which Excel features enable easy updates and sharing of the schedule with the entire manufacturing team?

Excel's Table feature allows you to organize the Daily Shift Schedule efficiently, enabling quick updates and dynamic sorting. The Sharing and Collaboration tools in Excel facilitate real-time co-editing and seamless distribution of the schedule to your entire manufacturing team. Data Validation ensures error-free entries, enhancing accuracy and reliability for every shift update.