The Daily Vehicle Inspection Excel Template for Logistics Companies streamlines the tracking of vehicle conditions, ensuring safety and compliance with industry standards. This template allows for efficient documentation of inspection results, highlighting issues that require immediate attention to prevent costly breakdowns. Utilizing this tool enhances operational efficiency by maintaining a detailed and organized maintenance history for each vehicle in the fleet.

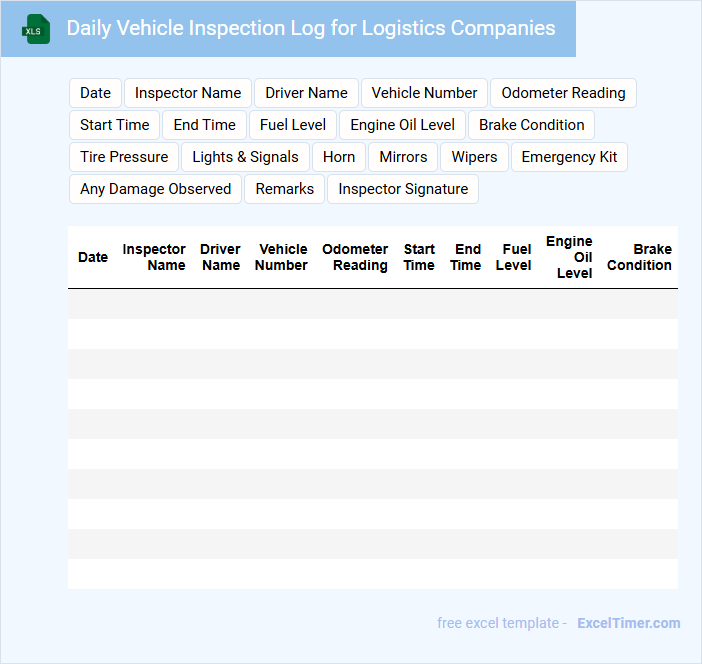

Daily Vehicle Inspection Log for Logistics Companies

A Daily Vehicle Inspection Log for logistics companies is a crucial document that records the condition of vehicles before and after their daily routes. It typically includes details about vehicle maintenance, safety checks, and any defects or issues found.

Ensuring accurate and timely entries helps in maintaining vehicle safety and preventing breakdowns. A key suggestion is to include a section for driver comments and signatures to increase accountability and traceability.

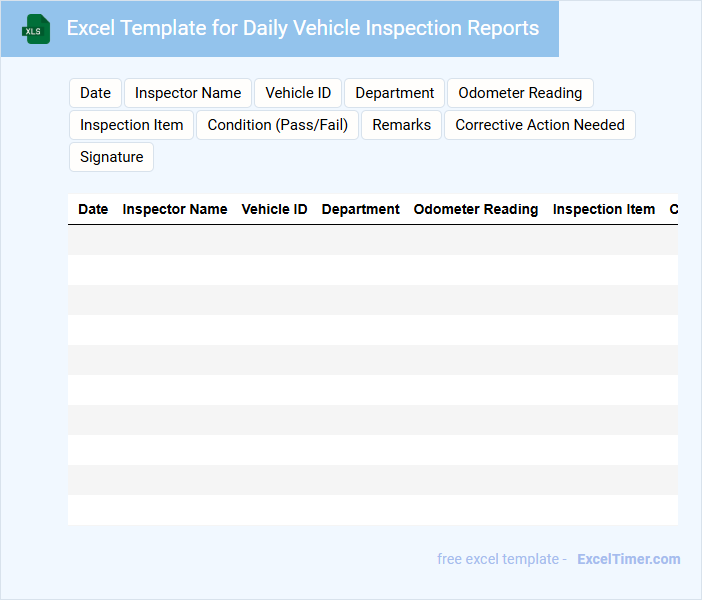

Excel Template for Daily Vehicle Inspection Reports

An Excel Template for Daily Vehicle Inspection Reports typically contains fields for vehicle identification, inspection date, and detailed checklists for various vehicle components such as brakes, tires, lights, and fluid levels. It also includes sections for recording any detected issues and maintenance recommendations to ensure vehicle safety and compliance.

This type of document is essential for fleet management and helps maintain organized records of vehicle conditions to prevent accidents and costly repairs. It is important to include clear instructions and consistent formatting to ensure accurate and efficient data entry by users.

Daily Vehicle Checklist for Fleet Operations

What information is typically included in a Daily Vehicle Checklist for Fleet Operations? This document usually contains details on vehicle inspection points such as tire pressure, fluid levels, brakes, lights, and safety equipment to ensure safe and efficient operation. It serves as a crucial tool for early detection of maintenance needs and helps prevent potential breakdowns during fleet operations.

Why is it important to have a consistent and thorough checklist? Maintaining a standardized daily checklist promotes accountability among drivers and maintenance staff, reducing the risk of accidents and costly repairs. Including space for signatures and remarks ensures that inspections are documented and any issues are promptly addressed.

Vehicle Inspection Record Sheet for Logistics Fleet

Vehicle Inspection Record Sheets for Logistics Fleets typically document the condition and safety status of vehicles to ensure operational reliability and regulatory compliance.

- Inspection Details: Record date, vehicle ID, and inspector information for traceability.

- Condition Checklist: Include key components like brakes, tires, lights, and fluid levels for comprehensive safety review.

- Comments and Signatures: Provide space for notes on defects and approvals to ensure accountability and follow-up.

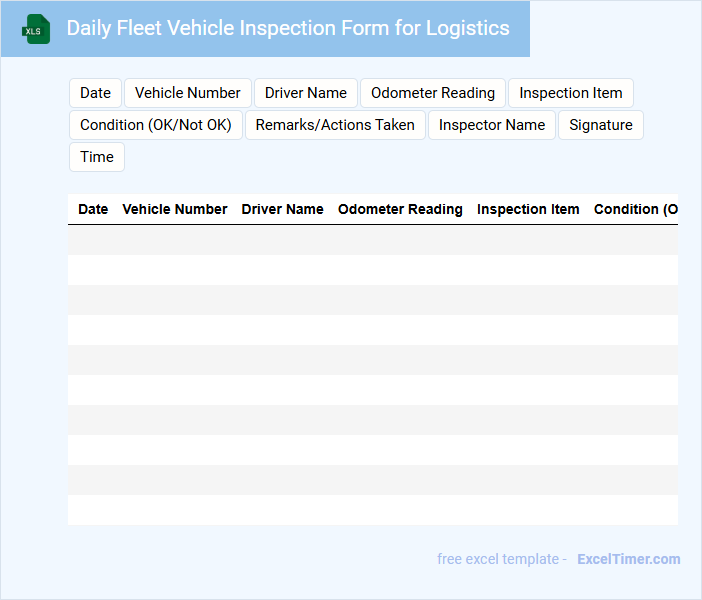

Daily Fleet Vehicle Inspection Form for Logistics

The Daily Fleet Vehicle Inspection Form is a crucial document used to record the condition of logistics vehicles before and after operation. It typically contains details about the vehicle's mechanical status, safety features, and any visible damages.

Ensuring accurate and timely inspections helps maintain vehicle reliability and safety compliance. Important elements to include are tire condition, brake functionality, fluid levels, and any signs of wear or damage.

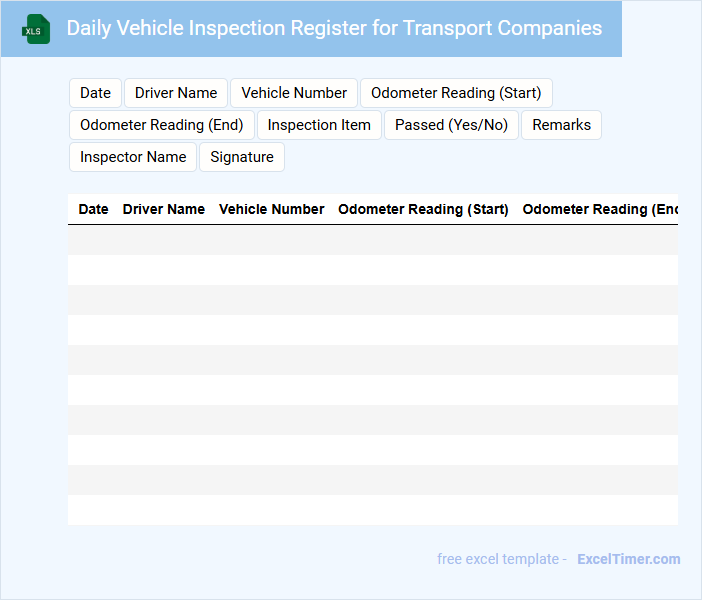

Daily Vehicle Inspection Register for Transport Companies

A Daily Vehicle Inspection Register for Transport Companies typically contains detailed records of vehicle conditions to ensure safety and compliance.

- Inspection Dates and Times: Accurate tracking of when each vehicle is inspected to maintain a consistent schedule.

- Checklist of Vehicle Components: Systematic recording of the status of essential parts like brakes, tires, lights, and fluid levels.

- Driver and Inspector Signatures: Verification by responsible personnel to validate the inspection process and accountability.

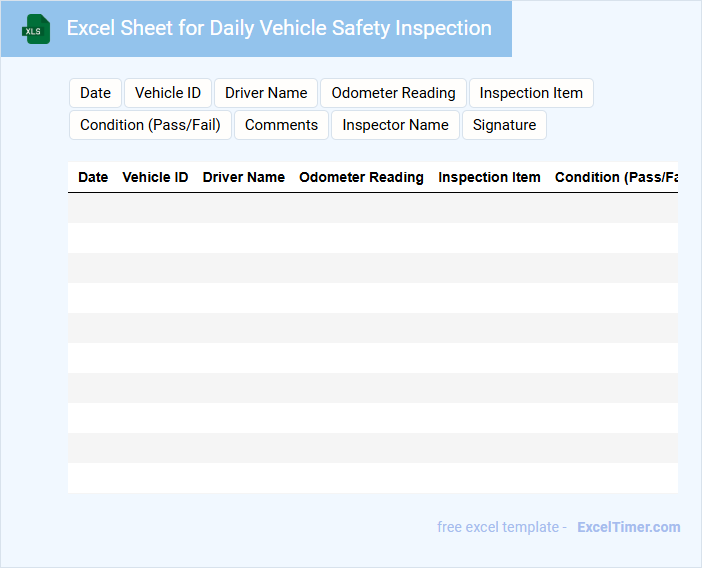

Excel Sheet for Daily Vehicle Safety Inspection

An Excel Sheet for Daily Vehicle Safety Inspection is a structured document used to record the condition and functionality of a vehicle before use each day. It helps ensure the vehicle is safe to operate and compliant with safety regulations.

- Include fields for vehicle identification and inspection date.

- List common safety items to check such as brakes, lights, and tires.

- Provide a section for inspector comments and signature for accountability.

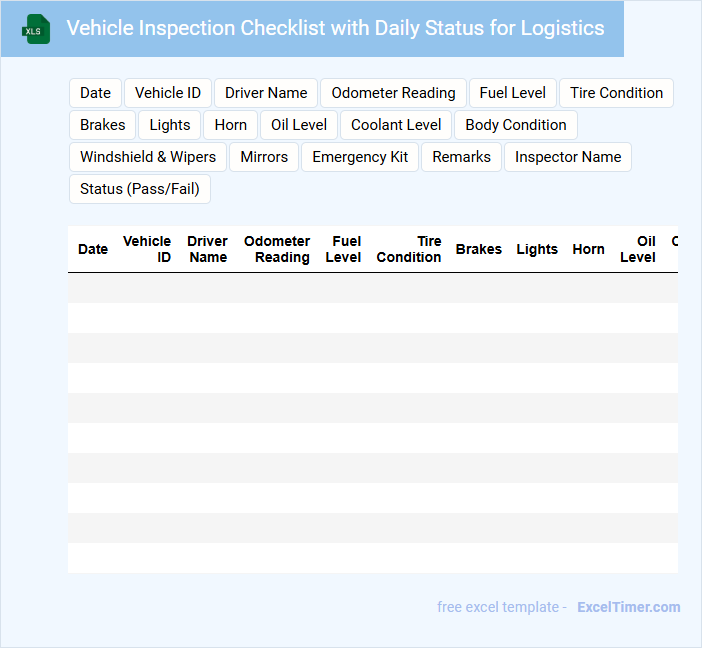

Vehicle Inspection Checklist with Daily Status for Logistics

Vehicle Inspection Checklists with Daily Status for Logistics typically contain detailed records of vehicle condition and operational status to ensure safety and efficiency.

- Maintenance Records: Document routine and urgent repairs to prevent breakdowns.

- Safety Checks: Include daily checks on brakes, tires, lights, and fluid levels for compliance.

- Status Updates: Record daily operational status to track usage and prevent delays.

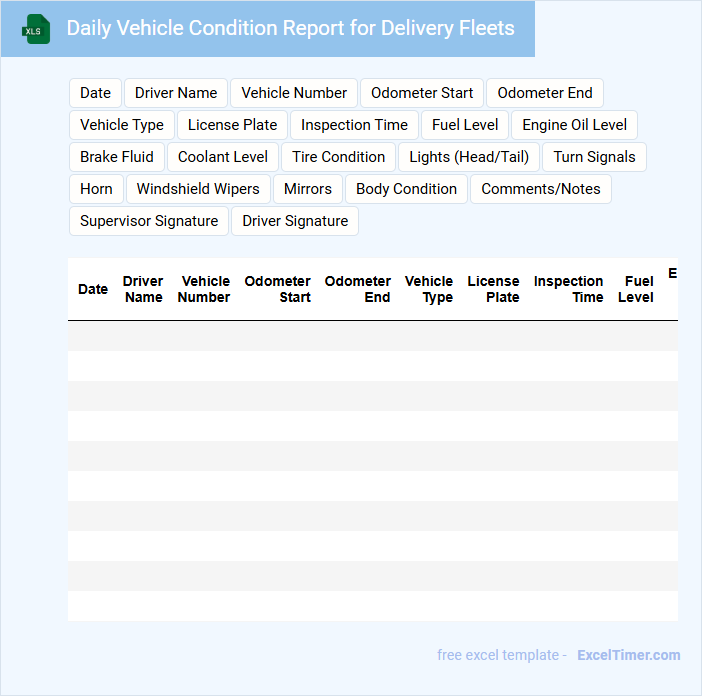

Daily Vehicle Condition Report for Delivery Fleets

The Daily Vehicle Condition Report is a document used to record the status and functionality of each vehicle in the delivery fleet. It typically contains information on key vehicle components such as tires, brakes, lights, and fluid levels to ensure safety and operational efficiency.

Regularly completing this report helps identify potential issues early and prevents breakdowns during delivery routes. It is important to include driver observations and timestamps to maintain accurate and actionable records.

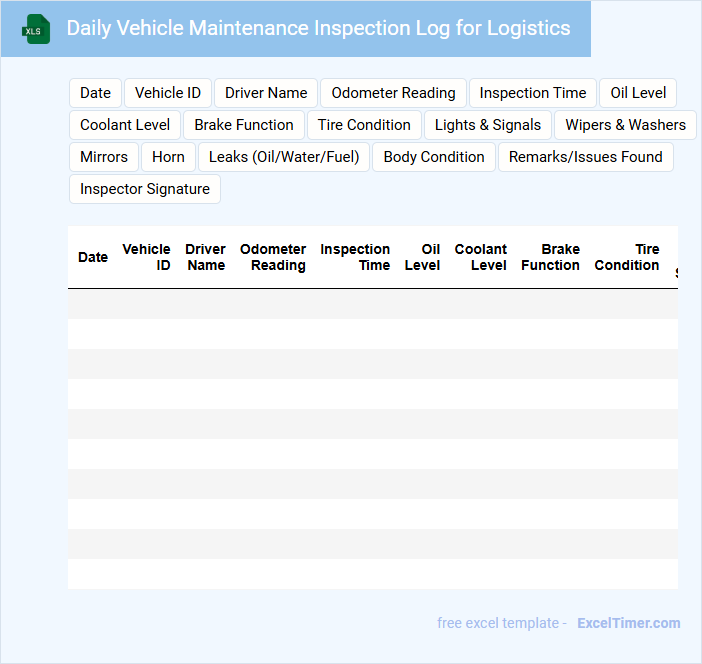

Daily Vehicle Maintenance Inspection Log for Logistics

What is typically included in a Daily Vehicle Maintenance Inspection Log for Logistics? This document usually contains detailed entries about the vehicle's condition such as tire pressure, oil levels, brake functionality, and any noticeable damages. It serves as a daily record to ensure vehicles are safe, operational, and compliant with maintenance standards.

Why is this document important for logistics operations? Maintaining a daily inspection log helps prevent unexpected breakdowns, reduces repair costs, and ensures timely deliveries by promoting vehicle reliability. It also supports regulatory compliance and enhances overall fleet safety management.

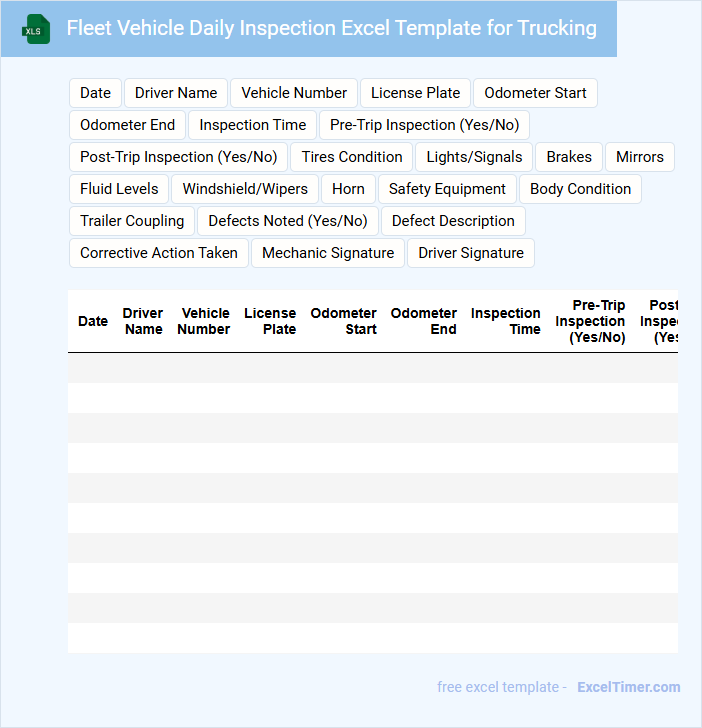

Fleet Vehicle Daily Inspection Excel Template for Trucking

The Fleet Vehicle Daily Inspection Excel Template is designed to streamline the daily check process for trucking companies. It typically contains sections for vehicle condition, safety checks, and maintenance notes. Using this template helps ensure compliance with safety regulations and promotes proactive vehicle upkeep.

Important elements to include are clear inspection criteria, space for driver comments, and a summary for any defects found. Additionally, incorporating date and vehicle ID fields enhances tracking and accountability. This template is essential for improving fleet management efficiency and safety standards.

Daily Vehicle Inspection Tracker for Logistics Managers

The Daily Vehicle Inspection Tracker is a crucial document that logistics managers use to record the condition of each vehicle before operations begin. It typically contains information on vehicle components such as brakes, tires, lights, fluid levels, and overall safety checks. This ensures timely maintenance and reduces the risk of breakdowns during deliveries.

For maximum effectiveness, logistics managers should prioritize accuracy, ensure inspections are completed daily, and maintain easy access to historical records. Including a clear checklist format and a section for noting defects or required repairs is essential. This fosters accountability and promotes safety within the fleet management process.

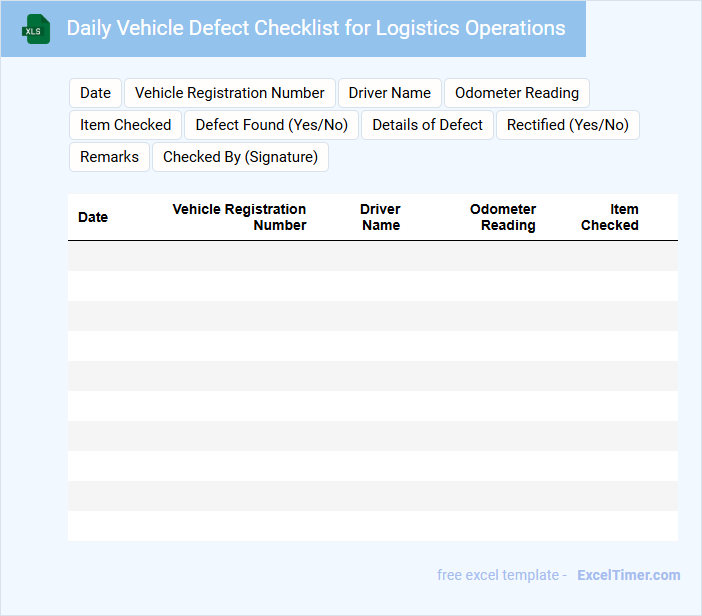

Daily Vehicle Defect Checklist for Logistics Operations

A Daily Vehicle Defect Checklist for Logistics Operations typically contains a list of essential vehicle components and systems to inspect for faults or damages before use. This document ensures safety and operational efficiency by identifying defects early.

- Include checks for brakes, tires, and lights to ensure vehicle safety.

- Document any defects found and actions taken to address them.

- Ensure the checklist is signed by the inspector to verify completion.

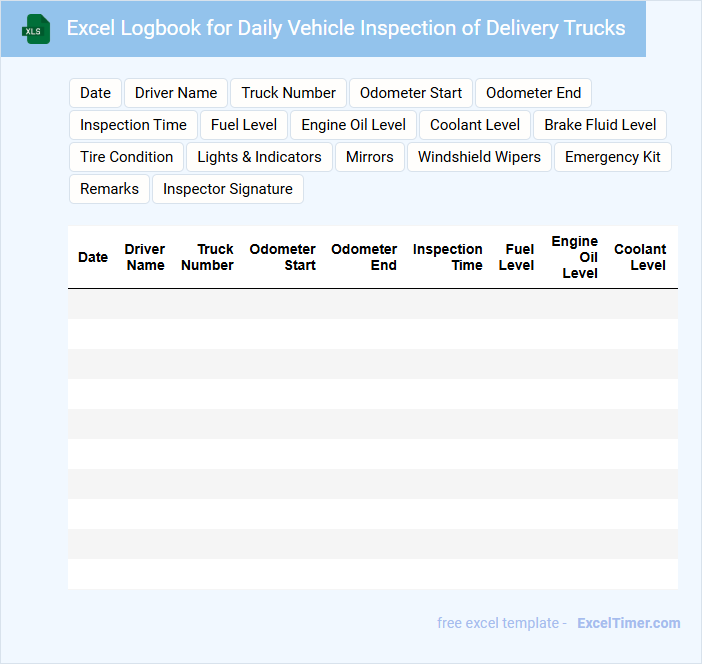

Excel Logbook for Daily Vehicle Inspection of Delivery Trucks

What information is typically included in an Excel Logbook for Daily Vehicle Inspection of Delivery Trucks? This type of document usually contains daily entries regarding the condition of delivery trucks, including checks on brakes, lights, tires, and fluid levels to ensure safety and compliance. It serves as a centralized record to identify potential issues early and maintain fleet reliability.

What are the important considerations when using this logbook? It is crucial to fill out inspections consistently and accurately each day, include clear notes on any detected problems, and ensure the logbook is easily accessible to all responsible personnel. Regular review of the logbook helps in timely maintenance and reducing downtime.

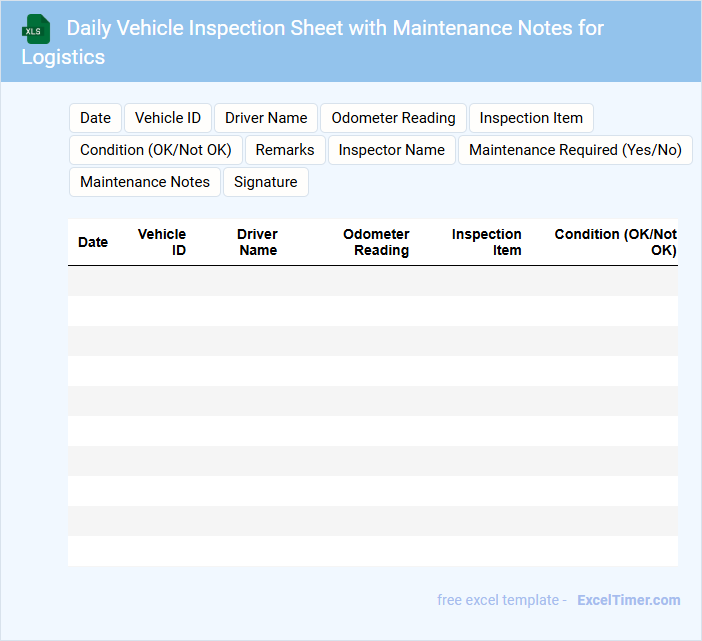

Daily Vehicle Inspection Sheet with Maintenance Notes for Logistics

What information is typically included in a Daily Vehicle Inspection Sheet with Maintenance Notes for Logistics? This document usually contains detailed checklists of vehicle components inspected daily, such as brakes, tires, lights, and fluid levels to ensure safety and operational readiness. It also includes maintenance notes to record any defects, repairs, or servicing needed to maintain vehicle efficiency and compliance.

What key information should be included in a daily vehicle inspection Excel document for logistics companies?

Your daily vehicle inspection Excel document for logistics companies should include key information such as vehicle identification details, inspection date and time, and checklist items covering brakes, tires, lights, fluid levels, and safety equipment. Record inspection results, noted defects, and corrective actions taken to ensure compliance and operational safety. Include fields for inspector name and signature to maintain accountability and traceability.

How can Excel formulas be used to track and flag failed inspection items automatically?

Excel formulas such as IF, COUNTIF, and Conditional Formatting can be used to track and flag failed inspection items by automatically identifying entries that do not meet safety standards. For example, an IF formula can mark cells as "Fail" if inspection criteria like tire pressure or brake functionality fall outside acceptable ranges. Conditional Formatting highlights these failed items in red, enabling logistics companies to quickly identify and address vehicle safety issues.

What are the essential columns needed for effective data recording in a vehicle inspection log?

Essential columns for an effective Daily Vehicle Inspection log include Date, Vehicle ID or License Plate, Inspector Name, Inspection Time, Checklist Items (e.g., brakes, tires, lights), Condition Status (e.g., Pass/Fail), Defects Found, Actions Taken, and Remarks. Including Mileage and Fuel Level columns enhances tracking of vehicle usage. Recording Repair Status and Follow-up Dates helps ensure timely maintenance and compliance.

How can Excel be set up to ensure inspection data is timestamped and logged by employee?

Set up Excel with a macro to automatically insert the current date and time when an employee inputs inspection data, ensuring accurate timestamping. Use drop-down lists for employee names to standardize entries and create filters for easy tracking of daily vehicle inspections. Your logistics company will benefit from organized, time-stamped records that improve accountability and streamline reporting.

What methods can be used in Excel to generate summary reports on vehicle condition trends over time?

Excel offers powerful methods like PivotTables, charts, and conditional formatting to generate summary reports on vehicle condition trends over time. You can use PivotTables to organize inspection data by date, vehicle, or condition, while charts visualize trends in maintenance issues or failures. Applying conditional formatting highlights critical changes in vehicle performance, helping your logistics company track and improve fleet health efficiently.