The Weekly Production Report Excel Template for Manufacturing Units streamlines tracking of daily output, efficiency, and downtime in a single, easy-to-use spreadsheet. It enhances decision-making by providing clear insights into production trends and identifying bottlenecks. Customizable fields allow manufacturers to align the template with specific operational metrics and goals.

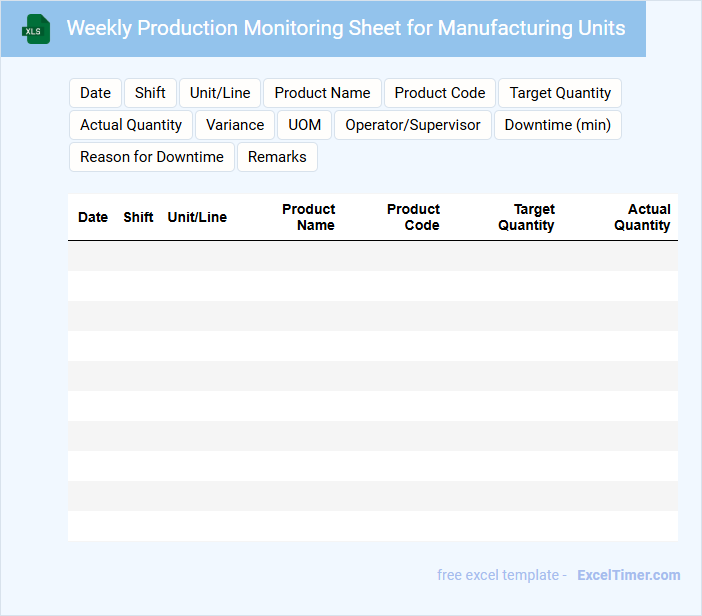

Weekly Production Monitoring Sheet for Manufacturing Units

The Weekly Production Monitoring Sheet is a crucial document used in manufacturing units to track and evaluate the production output on a weekly basis. It typically contains data on units produced, machinery performance, and workforce efficiency. This sheet helps management identify trends, bottlenecks, and areas needing improvement to ensure smooth operations.

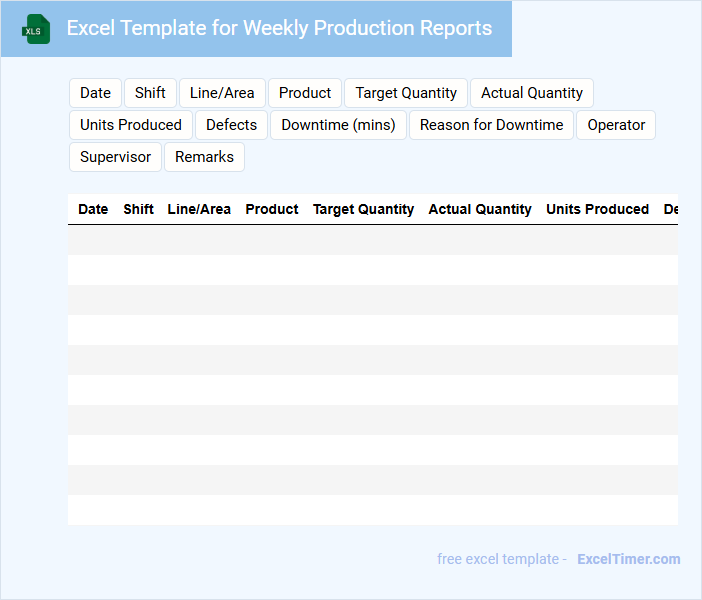

Excel Template for Weekly Production Reports

What information is typically included in an Excel Template for Weekly Production Reports? This type of document usually contains detailed data on production quantities, work hours, and efficiency metrics for a specific week. It helps track performance, identify issues, and ensure accurate reporting for management review.

Important elements to include are clear headers for dates, product names, production targets, actual output, and any discrepancies. Incorporating automated calculations and visual summaries like charts can enhance clarity and usability.

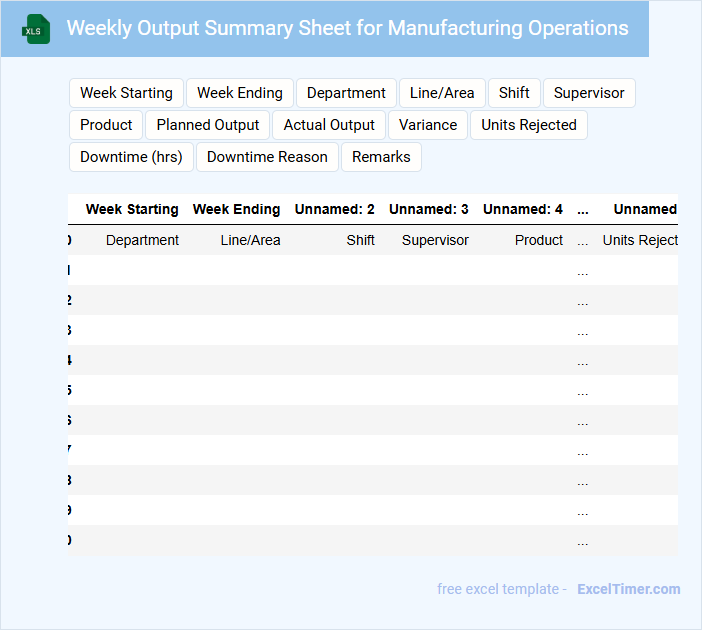

Weekly Output Summary Sheet for Manufacturing Operations

What information is typically included in a Weekly Output Summary Sheet for Manufacturing Operations? This document usually contains detailed records of production quantities, quality control results, and operational issues encountered throughout the week. It serves as a crucial tool to monitor performance trends, identify bottlenecks, and ensure efficient workflow management in manufacturing processes.

What are important considerations when preparing this summary sheet? It is essential to maintain accuracy in data entry and include clear notes on any deviations or downtimes. Additionally, highlighting key performance indicators such as output rates and defect percentages helps in making informed decisions for continuous improvement.

Production Tracking Sheet with Weekly Breakdown

A Production Tracking Sheet with Weekly Breakdown typically contains organized data on production activities, timelines, and output metrics segmented by each week. It helps in monitoring progress, identifying bottlenecks, and ensuring timely delivery of products. Key elements often include task lists, deadlines, status updates, and resource allocation to enhance operational efficiency.

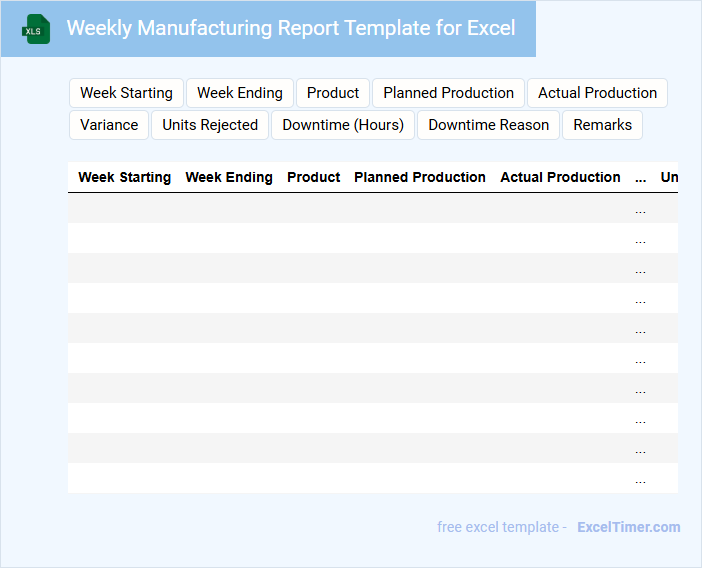

Weekly Manufacturing Report Template for Excel

A Weekly Manufacturing Report Template for Excel typically contains detailed summaries of production metrics, including output quantity, defect rates, and downtime analysis. It provides a structured format for tracking weekly performance and identifying trends over time. This document is essential for ensuring transparency and facilitating data-driven decision-making in manufacturing operations.

For effective use, it is important to include accurate date ranges, clear headers for each metric, and space for supervisor comments. Additionally, incorporating visual elements such as charts can help in better understanding and communication of production data. Consistency in data entry ensures reliable reporting and operational improvements.

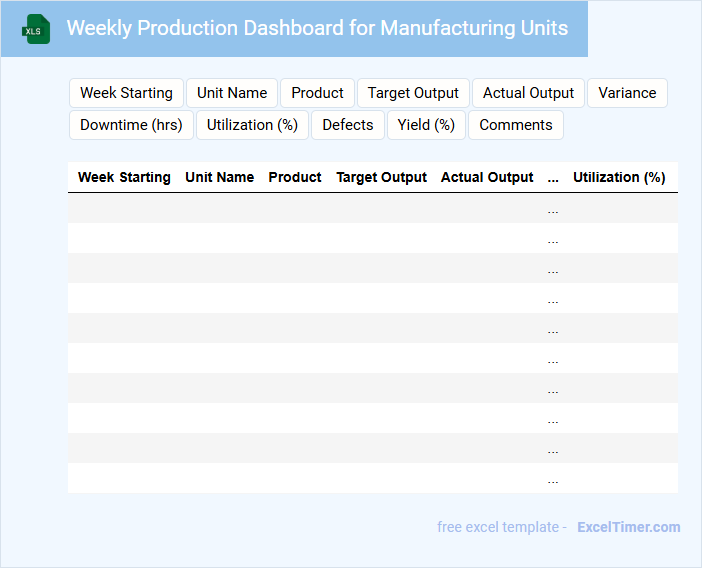

Weekly Production Dashboard for Manufacturing Units

A Weekly Production Dashboard for manufacturing units typically contains key performance indicators such as output volume, machine efficiency, and downtime analysis. It provides real-time insights into production trends, helping management quickly identify bottlenecks and areas for improvement. Regular updates and clear visualizations are important to maintain operational transparency and drive informed decision-making.

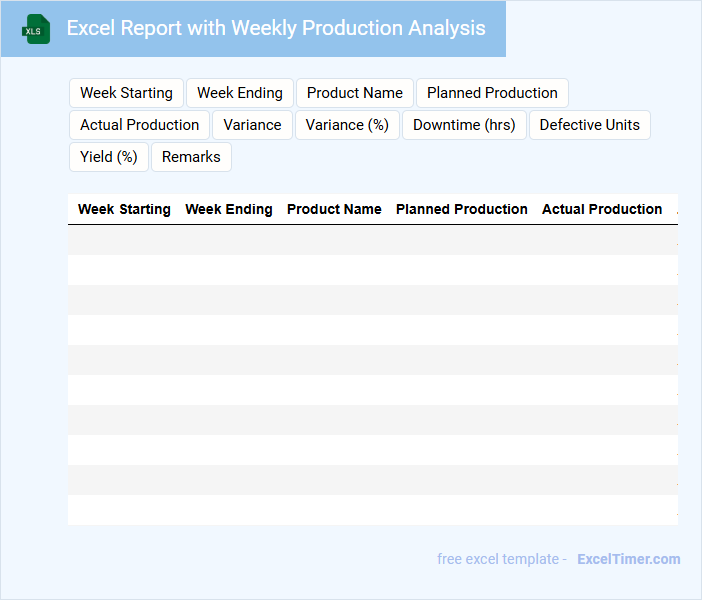

Excel Report with Weekly Production Analysis

An Excel Report with Weekly Production Analysis typically contains data on production volumes, performance metrics, and efficiency trends over a week.

- Data Accuracy: Ensure the input data is precise to maintain the reliability of the analysis.

- Clear Visualization: Use charts and graphs to highlight key production trends effectively.

- Actionable Insights: Focus on deviations and patterns that can help improve production processes.

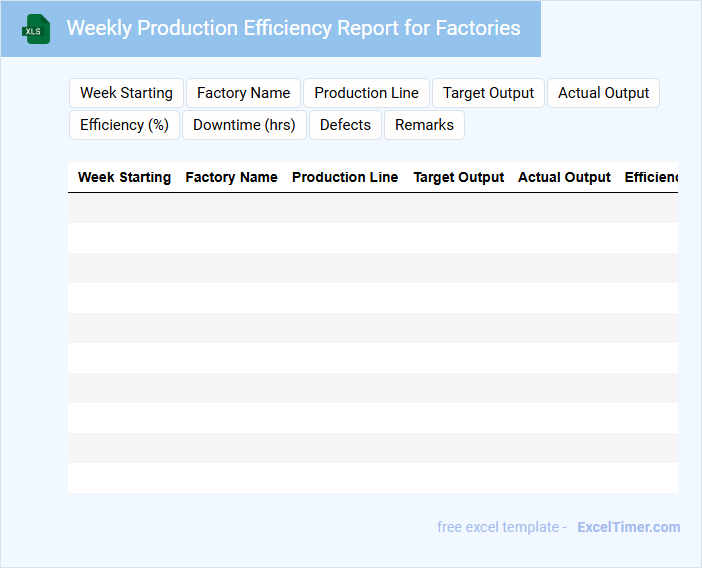

Weekly Production Efficiency Report for Factories

A Weekly Production Efficiency Report for factories typically contains data on output levels, machine performance, and labor productivity. It highlights areas where production processes are performing well and identifies bottlenecks or downtime issues. This report is essential for tracking overall efficiency trends and making informed operational decisions.

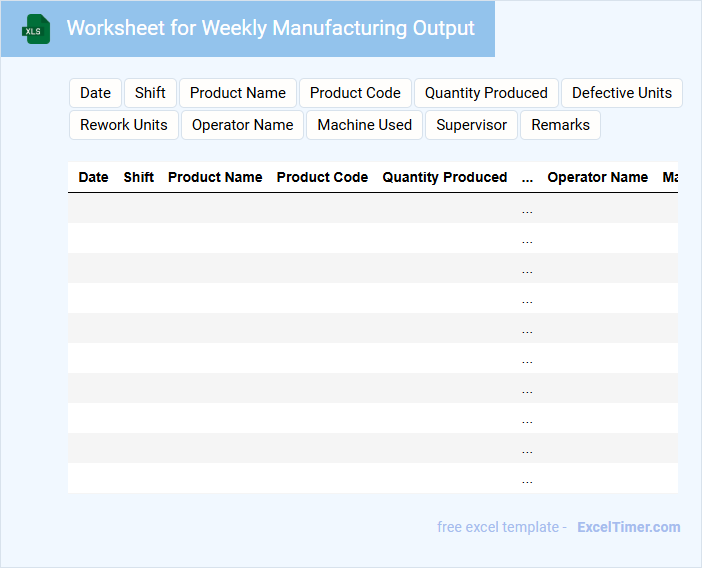

Worksheet for Weekly Manufacturing Output

A Worksheet for Weekly Manufacturing Output typically contains detailed records of production quantities, machine usage, and labor hours for each day of the week. It is essential for tracking efficiency and identifying bottlenecks in the manufacturing process. This document helps ensure accurate data collection for performance analysis. The worksheet also includes sections for quality checks and notes on any issues encountered during production. Maintaining clear and consistent entries in this document is crucial for effective decision-making and continuous improvement. Regularly updating and reviewing this worksheet supports operational transparency and productivity.

Weekly Production Plan and Report for Manufacturing

What does a Weekly Production Plan and Report for Manufacturing typically contain? This document usually includes detailed schedules of production tasks, resource allocation, and output targets for the week. It also records actual production data, deviations, and any issues encountered to ensure efficient workflow and continuous improvement.

What is an important consideration when creating this type of document? It is essential to ensure accurate data collection and clear communication among teams to align objectives and quickly address production bottlenecks. Maintaining real-time updates and actionable insights helps optimize manufacturing processes and meet deadlines effectively.

Weekly Performance Report Template for Manufacturing Units

The Weekly Performance Report for manufacturing units typically contains detailed data on production output, quality control, and equipment efficiency. This document helps track progress against key performance indicators (KPIs) and identify areas for improvement. Important elements to include are downtime reports, safety incidents, and employee productivity metrics.

Excel Template with Weekly Production and Downtime

An Excel Template for Weekly Production and Downtime is a structured document used to track manufacturing output and machine inactivity over a set period. It typically contains sections for recording daily production quantities, downtime causes, and total hours operated. This template facilitates performance analysis and helps identify areas for operational improvement.

Key elements to include are clearly labeled columns for each day of the week, downtime categories, and production targets. Incorporating automated calculations for total production and downtime percentages enhances usability and accuracy. Additionally, visual aids like charts or color-coded indicators can provide immediate insights into performance trends.

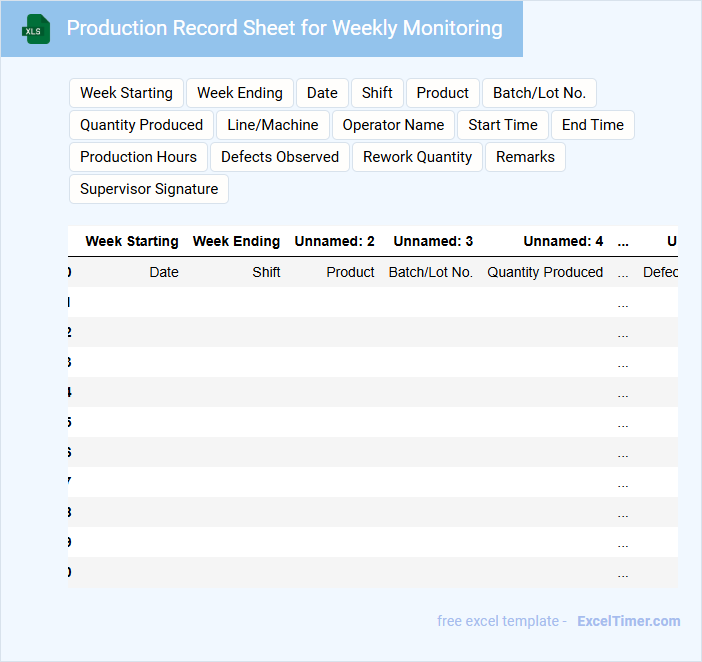

Production Record Sheet for Weekly Monitoring

The Production Record Sheet for weekly monitoring typically contains detailed entries of daily output, machine usage, and labor hours to track manufacturing performance. It includes fields for recording quantities produced, defects, and downtime reasons to ensure accurate production analysis.

Regular updating of this document is crucial for maintaining operational transparency and identifying areas for improvement effectively. Ensuring the records are clear and consistently maintained helps optimize production efficiency and supports informed decision-making.

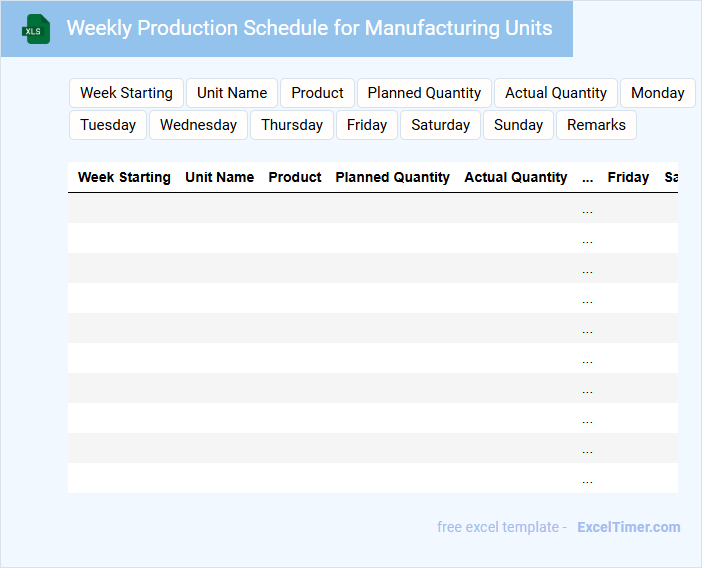

Weekly Production Schedule for Manufacturing Units

The Weekly Production Schedule is a detailed plan that outlines the manufacturing activities for the upcoming week. It helps coordinate resources, labor, and equipment to meet production targets efficiently.

This document typically contains production timelines, assigned tasks, and inventory requirements. For optimal results, it is important to include clear deadlines and flexibility to handle unexpected changes.

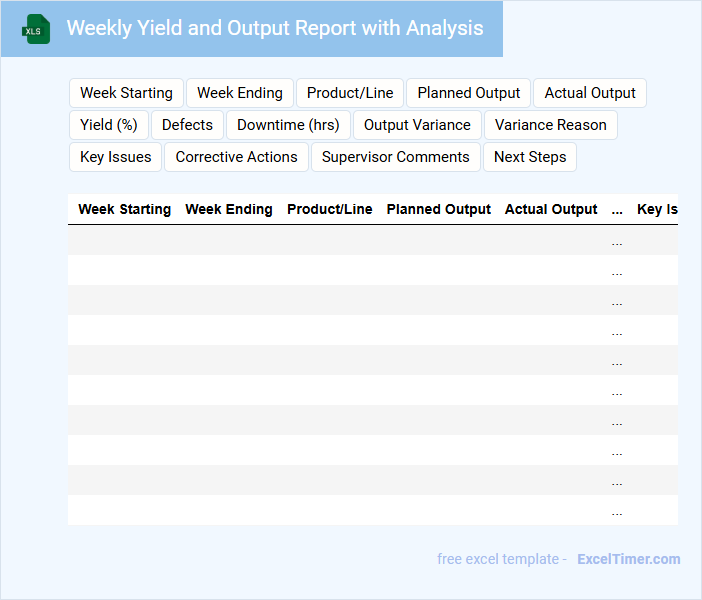

Weekly Yield and Output Report with Analysis

What information is typically included in a Weekly Yield and Output Report with Analysis? This document usually contains data on production volumes, yield percentages, and efficiency metrics collected over the week. It provides a detailed analysis of performance trends, identifies bottlenecks, and highlights areas for improvement to optimize overall productivity.

Why is it important to include detailed analysis in the report? Including analysis helps stakeholders understand the root causes behind fluctuations in output and yield, facilitating informed decision-making. Key suggestions include focusing on trend comparisons, pinpointing deviations from targets, and recommending actionable steps for enhancing production processes.

What key data fields should be included in a weekly production report for manufacturing units?

A weekly production report for manufacturing units should include key data fields such as production volume, machine utilization rates, defect counts, and downtime hours. Your report must also capture labor hours, material consumption, and order fulfillment status to ensure comprehensive tracking. Accurate recording of these metrics enables effective monitoring and optimization of manufacturing performance.

How can you use formulas in Excel to automate calculation of total output and defect rates?

You can use Excel formulas like SUM to automate calculation of total output by summing production data across units and days. To determine defect rates, apply the formula dividing the number of defective items by total output, using cell references for dynamic updates. These automated calculations enhance accuracy and efficiency in analyzing weekly production performance.

What methods can be applied to visually represent weekly production trends and bottlenecks in Excel?

Use line charts and sparklines in Excel to visually represent weekly production trends, highlighting fluctuations over time. Apply conditional formatting with color scales or data bars to identify bottlenecks by emphasizing low production values or delays. Incorporate pivot tables combined with heatmaps to analyze and compare performance across different manufacturing units efficiently.

How can conditional formatting in Excel assist in highlighting anomalies or production shortfalls?

Conditional formatting in Excel helps identify anomalies or production shortfalls by automatically highlighting cells that fall below target thresholds or deviate from normal ranges. It enables visual cues such as color scales, icons, or data bars to quickly pinpoint underperforming units or unusual production values. This feature streamlines monitoring and enhances decision-making efficiency in weekly manufacturing production reports.

What steps are needed to maintain version control and data integrity in weekly Excel production reports?

Implement a structured file naming convention including date and version number to track changes systematically. Use Excel's built-in features like "Track Changes" and "Protect Sheet" to monitor edits and prevent unauthorized modifications. Regularly back up reports on a secure cloud platform to ensure data integrity and enable recovery of previous versions if needed.