The Weekly Production Schedule Excel Template for Manufacturing streamlines tracking and planning of production activities, ensuring efficient resource allocation and timely completion of tasks. It includes customizable columns for listing work orders, machine assignments, shifts, and deadlines, enhancing operational visibility and coordination. Accurate scheduling with this template reduces downtime and helps manufacturers meet delivery targets consistently.

Weekly Production Schedule Excel Template for Manufacturing

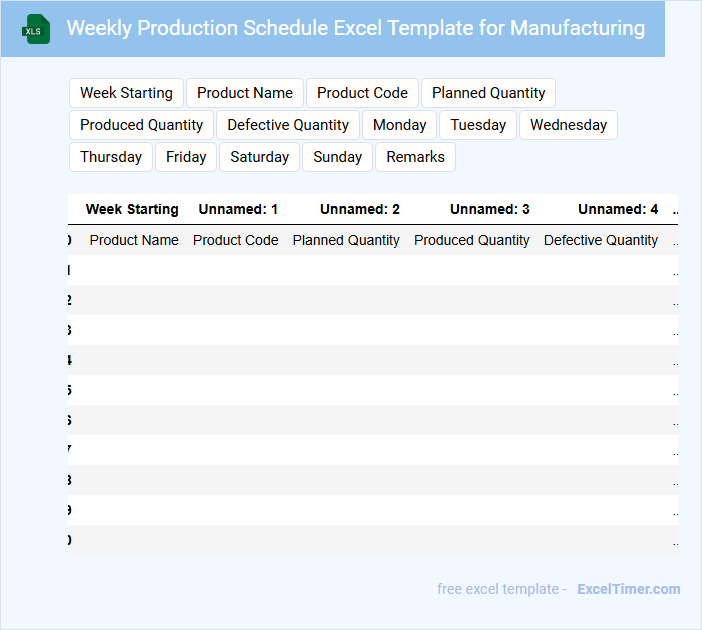

A Weekly Production Schedule Excel Template for Manufacturing typically contains organized data to track and plan manufacturing processes on a weekly basis.

- Production Tasks: Detailed list of tasks to be completed each week for efficient workflow management.

- Resource Allocation: Assignments of machines, materials, and labor to optimize production capacity.

- Timeline Tracking: Schedule milestones and deadlines to ensure timely completion of product batches.

Weekly Work Order Tracker for Manufacturing

A Weekly Work Order Tracker for Manufacturing is a document used to monitor and manage work orders over a specific week. It helps ensure timely production and efficient resource allocation.

- Include clear work order numbers and descriptions for easy identification.

- Track start and completion dates to monitor progress and deadlines.

- Record assigned personnel and equipment to optimize workflow management.

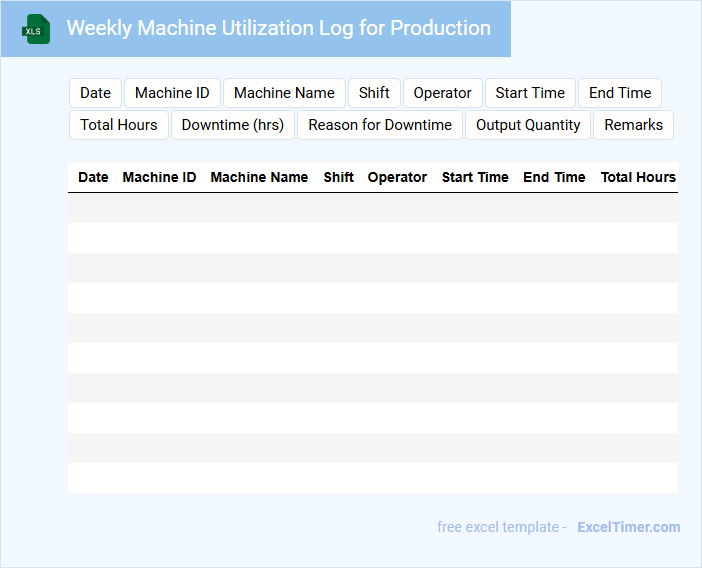

Weekly Machine Utilization Log for Production

What information is typically recorded in a Weekly Machine Utilization Log for Production? This document usually contains detailed entries of the operational hours, downtime, and maintenance activities of machines during the production week. It helps track efficiency, identify bottlenecks, and plan preventive maintenance, ensuring optimal machine performance and minimizing production delays.

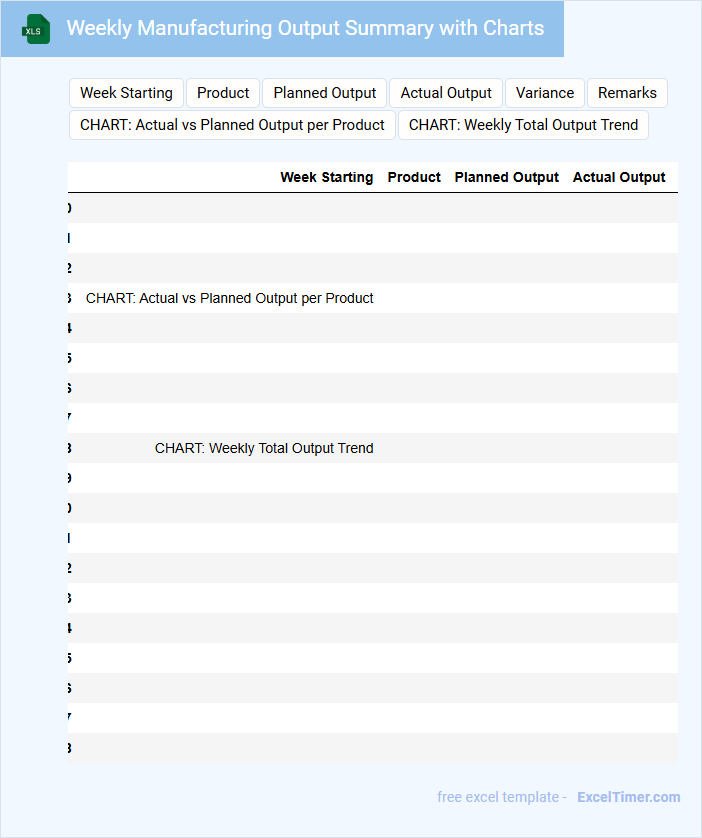

Weekly Manufacturing Output Summary with Charts

A Weekly Manufacturing Output Summary document typically contains detailed data on production volumes, efficiency rates, and quality control metrics. It includes visual charts to illustrate trends, highlight bottlenecks, and compare weekly performance. An important aspect to emphasize is the accuracy and timeliness of the data to support informed decision-making.

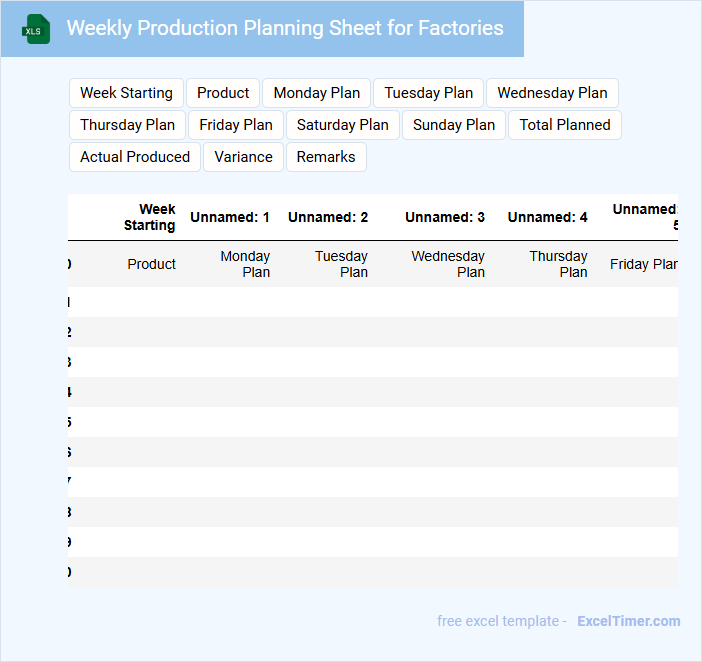

Weekly Production Planning Sheet for Factories

What information is typically included in a Weekly Production Planning Sheet for factories? This document usually contains detailed schedules of production tasks, material requirements, and workforce allocation for the upcoming week. It helps streamline factory operations by coordinating resources and timelines effectively.

Why is it important to update and review this sheet regularly? Consistent updates ensure that production goals align with actual capacity and address any delays or issues promptly. Regular reviews enhance efficiency and help maintain smooth workflow to meet delivery deadlines.

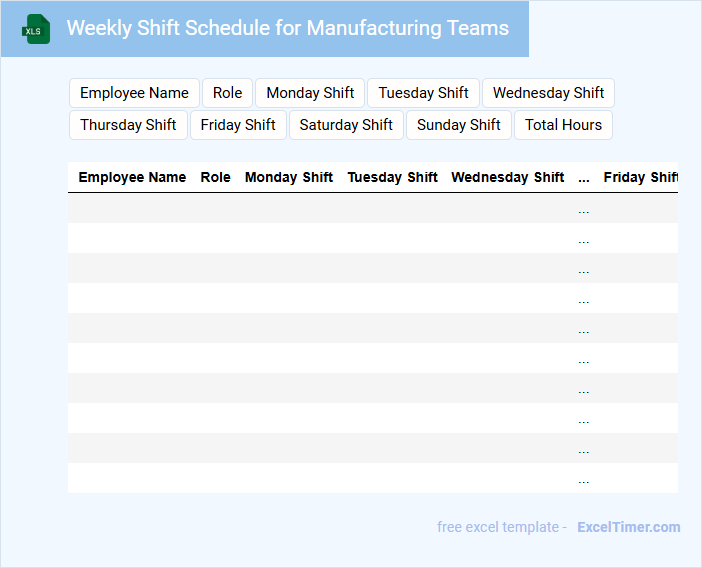

Weekly Shift Schedule for Manufacturing Teams

A Weekly Shift Schedule for Manufacturing Teams outlines the working hours and assigned shifts for production staff over a week. It ensures smooth operations by organizing workforce availability.

- Include clear shift start and end times for each team member.

- Account for breaks and rotation patterns to maintain fairness and compliance.

- Highlight any special instructions or safety considerations specific to shifts.

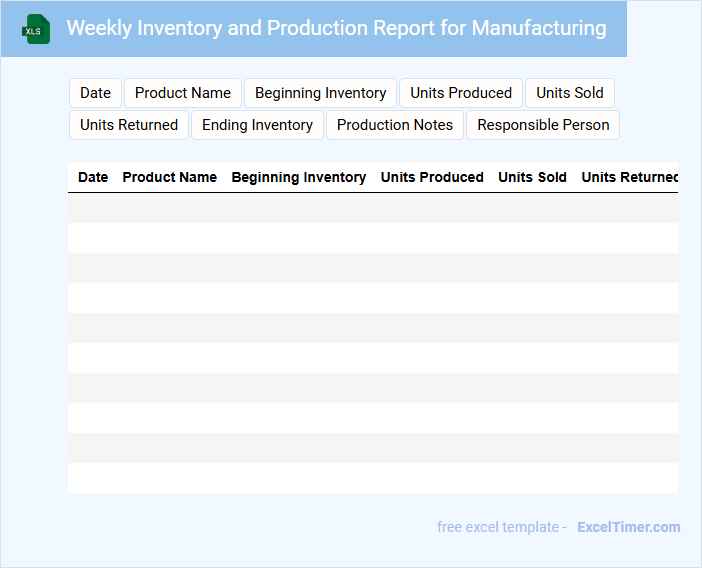

Weekly Inventory and Production Report for Manufacturing

The Weekly Inventory and Production Report typically contains detailed records of the quantities of raw materials, work-in-progress, and finished goods available at the start and end of the week. It also includes the production output, any discrepancies, and adjustments made during the manufacturing process.

This document is crucial for tracking inventory levels and ensuring alignment with production schedules to avoid stockouts or overproduction. Regularly updating and reviewing this report helps optimize resource allocation and maintain efficient manufacturing operations.

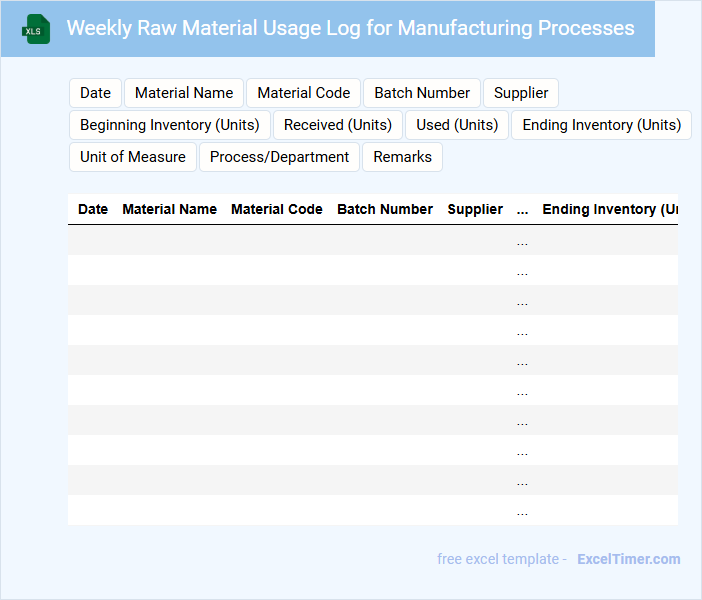

Weekly Raw Material Usage Log for Manufacturing Processes

The Weekly Raw Material Usage Log for manufacturing processes is a critical document used to track the quantity and type of raw materials consumed over a specific week. It helps ensure accurate inventory management and supports cost control in production. Regularly updating this log improves operational efficiency and aids in forecasting future material needs.

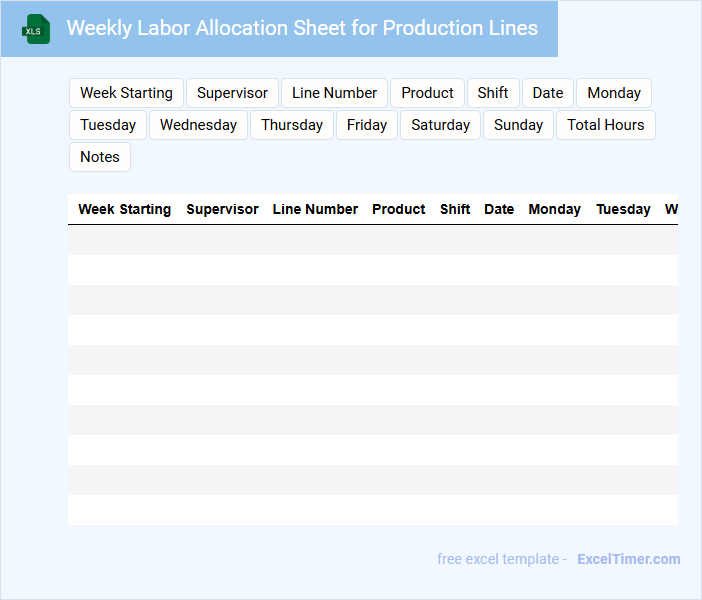

Weekly Labor Allocation Sheet for Production Lines

What information is typically included in a Weekly Labor Allocation Sheet for Production Lines? This document usually contains a detailed schedule of labor hours assigned to various production tasks and shifts throughout the week. It helps ensure optimal workforce distribution and efficient use of human resources in manufacturing processes.

What is an important consideration when preparing this type of sheet? Accuracy in estimating labor requirements for each production line is crucial to avoid overstaffing or understaffing, which can impact productivity and costs. Additionally, regularly updating the sheet to reflect changes in production demand ensures alignment with operational needs.

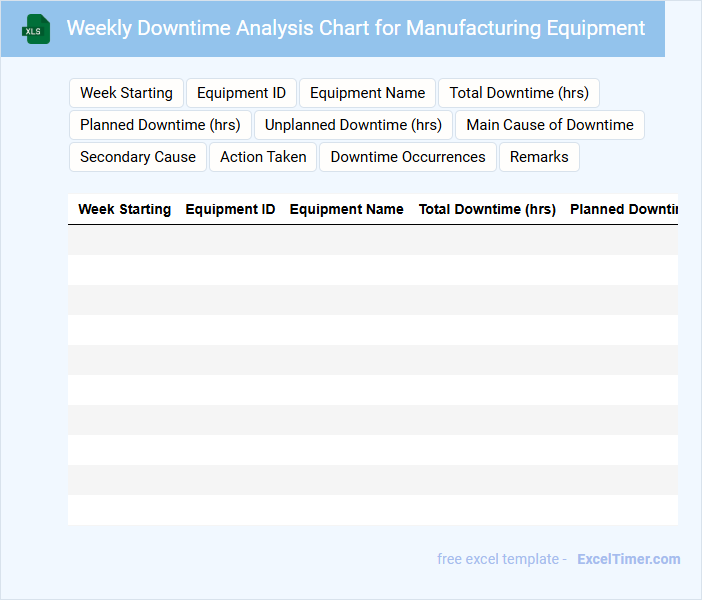

Weekly Downtime Analysis Chart for Manufacturing Equipment

The Weekly Downtime Analysis Chart for manufacturing equipment typically contains detailed records of equipment inactivity, including duration and causes of downtime throughout the week. It helps identify patterns and trends that affect production efficiency. Key data points often include timestamps, reason codes, and the impact on overall output.

For optimal usage, ensure accurate and consistent data entry to maintain reliability. Highlight critical downtime events to prioritize maintenance and prevent recurrence. Incorporating visual elements like bar graphs or pie charts can enhance clarity and decision-making.

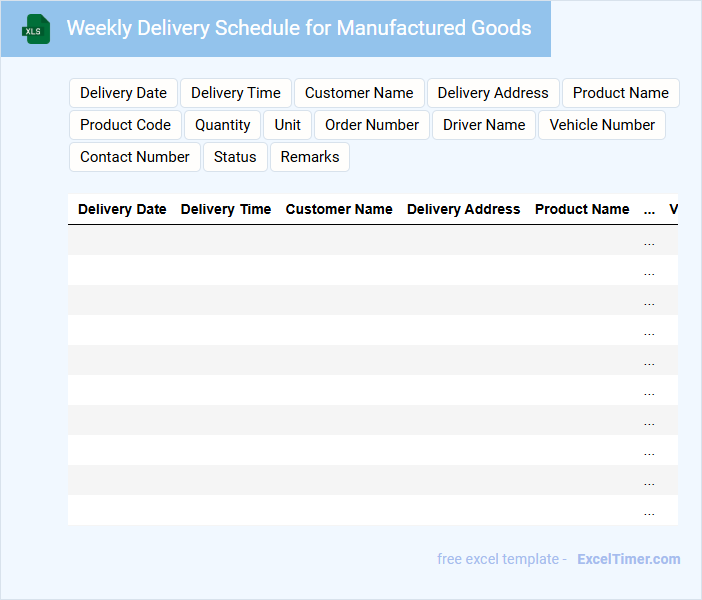

Weekly Delivery Schedule for Manufactured Goods

The Weekly Delivery Schedule for manufactured goods is a critical document used to organize and track the shipment of products within a given week. It typically contains detailed information such as delivery dates, quantities, destination addresses, and transportation methods. Ensuring accuracy in this schedule helps optimize logistics and maintain timely deliveries to customers.

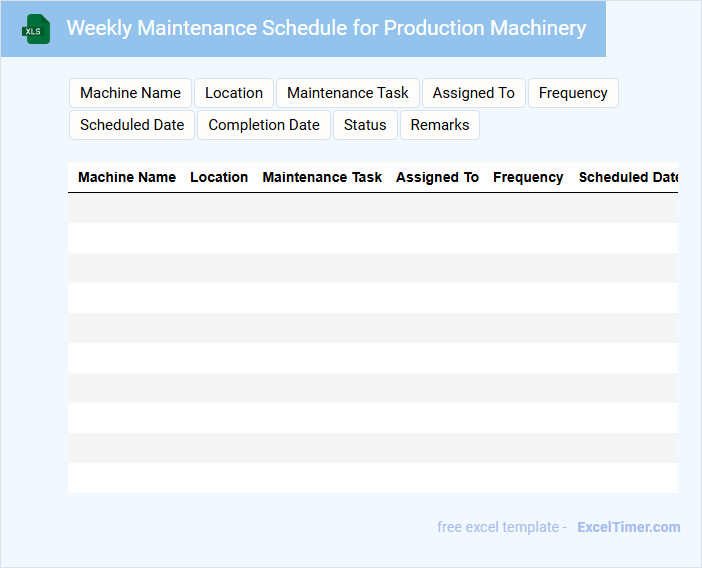

Weekly Maintenance Schedule for Production Machinery

A Weekly Maintenance Schedule for Production Machinery is a document that outlines regular inspection and servicing tasks to ensure machinery operates efficiently and safely.

- Task List: Detailed descriptions of all maintenance activities to be performed during the week.

- Schedule Timing: Specific days and times when each maintenance task should be carried out to minimize downtime.

- Responsible Personnel: Names or roles of staff assigned to perform and oversee the maintenance tasks.

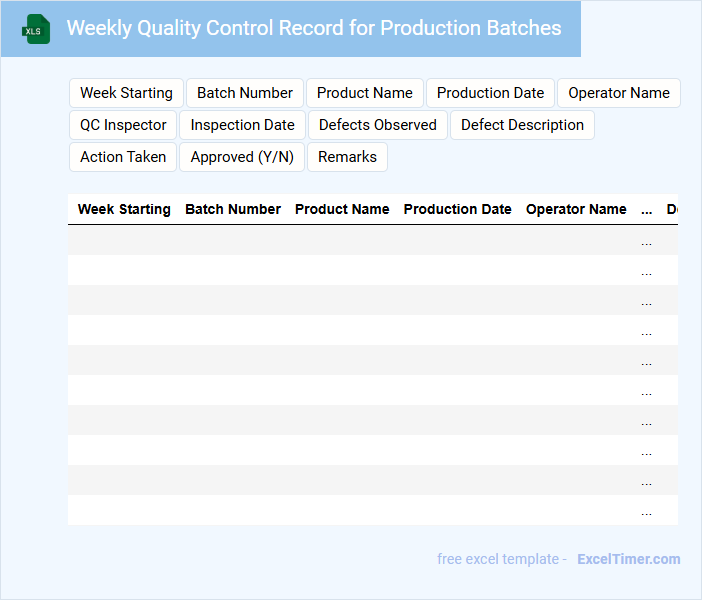

Weekly Quality Control Record for Production Batches

The Weekly Quality Control Record for Production Batches is a vital document used to track and monitor the quality of products manufactured within a specific time frame. This record typically contains batch numbers, test results, and any deviations observed during production. Regular review of this document helps ensure compliance with quality standards and facilitates timely corrective actions.

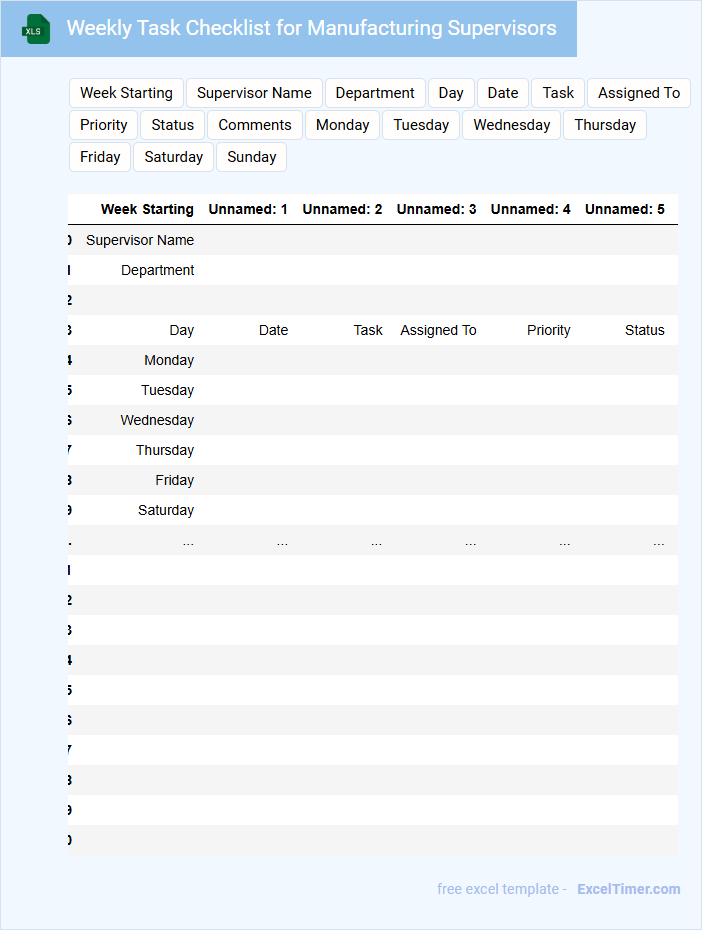

Weekly Task Checklist for Manufacturing Supervisors

What information is typically included in a Weekly Task Checklist for Manufacturing Supervisors? This document usually contains a detailed list of routine tasks and responsibilities that supervisors must complete within the week, ensuring smooth production operations. It serves as a tool to monitor progress, assign accountability, and identify areas needing attention.

What is an important consideration when creating a Weekly Task Checklist for Manufacturing Supervisors? Ensuring the checklist is clear, comprehensive, and prioritized helps supervisors manage time efficiently and maintain high safety and quality standards. Regularly updating the checklist to reflect changing production demands and feedback is essential for ongoing effectiveness.

Weekly Order Fulfillment Tracker for Manufacturing Operations

A Weekly Order Fulfillment Tracker for Manufacturing Operations is a document used to monitor and manage the progress of order processing and delivery within a manufacturing setting.

- Order Status: Track the current stage of each order to ensure timely completion and identify bottlenecks.

- Inventory Levels: Monitor raw materials and finished goods to maintain optimal stock and prevent production delays.

- Delivery Deadlines: Record expected and actual delivery dates to measure performance and improve customer satisfaction.

What key data columns are essential in a Weekly Production Schedule Excel document for manufacturing?

Essential data columns in a Weekly Production Schedule Excel for manufacturing include Production Date, Product Name or SKU, Quantity to Produce, Machine or Line Assigned, Shift Timing, Operator Name, Material Availability Status, and Production Status Updates. Including Planned vs. Actual Output and Quality Control Results enhances schedule tracking and performance analysis. These columns optimize production planning, resource allocation, and operational efficiency.

How is production capacity versus actual output tracked and visualized in the schedule?

The Weekly Production Schedule in Excel tracks production capacity versus actual output using dynamic charts and pivot tables, enabling clear comparison of planned versus achieved units. You can easily monitor performance trends by analyzing color-coded data bars and real-time percentage variances integrated within the schedule. This visualization helps optimize manufacturing efficiency and resource allocation.

What methods are used to indicate product deadlines and prioritize manufacturing orders in the Excel sheet?

The Excel document uses color-coded cells and conditional formatting to clearly mark product deadlines, ensuring timely completion of your manufacturing schedule. Priority levels are indicated through custom tags and sorted columns, streamlining order management. Automated alerts and progress tracking features help monitor critical deadlines and optimize production flow.

How are material inventory levels and usage integrated into the weekly schedule?

Material inventory levels and usage are integrated into the weekly production schedule by tracking real-time stock quantities and forecasting demand based on production targets. Automated updates in the Excel document adjust inventory data to prevent shortages and ensure timely procurement. This synchronization optimizes resource allocation and minimizes production delays.

What formulas or functions are used to automate alerts for delays or resource shortages in the schedule?

Excel uses functions like IF, COUNTIF, and conditional formatting formulas to automate alerts for delays or resource shortages. You can apply these formulas to highlight overdue tasks or flag insufficient materials based on production deadlines and inventory levels. Integrating these functions streamlines monitoring and enhances proactive management in your weekly production schedule.