The Daily Production Log Excel Template for Manufacturing Units is designed to efficiently track daily output, machine performance, and employee productivity in manufacturing settings. It helps managers identify bottlenecks, monitor production targets, and maintain accurate records for quality control. Using this template ensures streamlined data entry and real-time insights into operational efficiency.

Daily Production Log Sheet for Manufacturing Units

A Daily Production Log Sheet for Manufacturing Units typically contains detailed records of production activities to ensure efficient tracking and quality control.

- Date and Shift Details: Records of the specific date and shifts for accurate time tracking.

- Production Output: Quantity of units produced during the shift for performance monitoring.

- Issues and Downtime: Documentation of any problems or stoppages to improve process management.

Excel Template for Daily Production Tracking

An Excel Template for Daily Production Tracking is a structured document used to monitor and record daily manufacturing output efficiently. It helps businesses maintain accurate production records and identify productivity trends.

- Include columns for date, product type, quantity produced, and any defects or downtime.

- Incorporate formulas to automatically calculate totals and averages for better analysis.

- Add visualization tools like charts to quickly assess production performance over time.

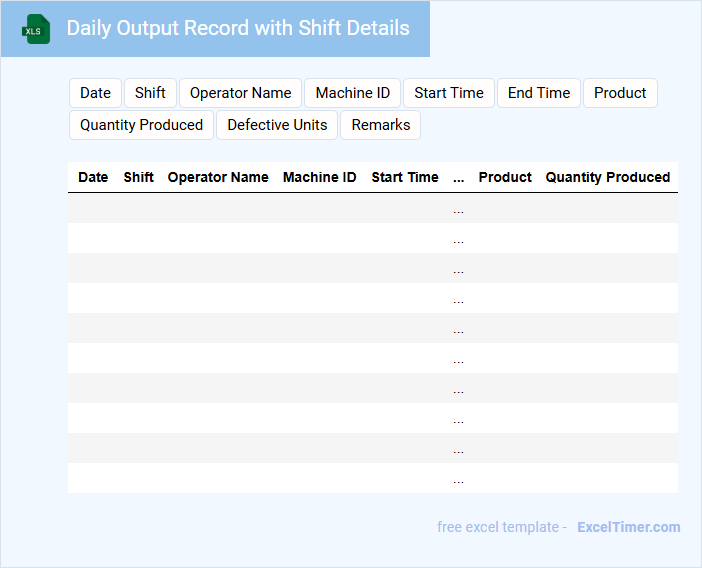

Daily Output Record with Shift Details

What information is typically included in a Daily Output Record with Shift Details? This document usually contains the total production quantity, quality metrics, and machine performance data for each shift. It helps track productivity, identify issues, and ensure accountability throughout the workday.

What important aspects should be carefully recorded in this document? Accurate timestamps, shift identification, operator names, and any downtime or defects should be clearly noted. This ensures comprehensive analysis and facilitates continuous improvement in manufacturing processes.

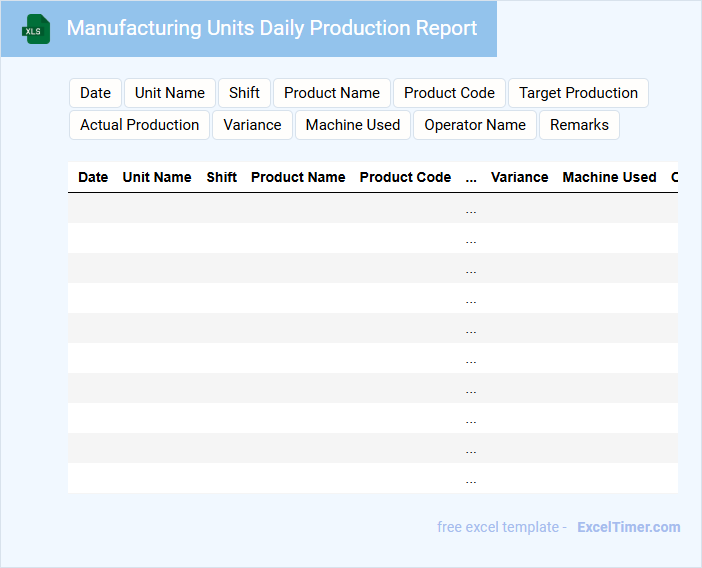

Manufacturing Units Daily Production Report

What information is typically included in a Manufacturing Units Daily Production Report? This type of document usually contains detailed data on the quantity of products produced, the efficiency of the production process, and any issues or delays encountered during the day. It helps management track daily output, identify bottlenecks, and ensure quality control standards are maintained.

What important aspects should be highlighted in these reports? Key elements include accurate production numbers, machine performance metrics, worker attendance, and incident reports. Including clear summaries and action points ensures quick decision-making and continuous improvement in manufacturing operations.

Production Logbook in Excel for Manufacturing

A Production Logbook in Excel for manufacturing typically contains detailed records of daily production activities, machine performance, and operator notes. It helps in tracking production output, identifying bottlenecks, and ensuring quality control. Maintaining accurate entries in this logbook is essential for optimizing manufacturing processes and facilitating audits.

Important aspects to include are timestamps, batch numbers, quantities produced, equipment status, and any incidents or deviations. Use clear, consistent formatting and drop-down menus in Excel to minimize errors and enhance data integrity. Regularly updating and reviewing the logbook ensures reliable data for production analysis and continuous improvement.

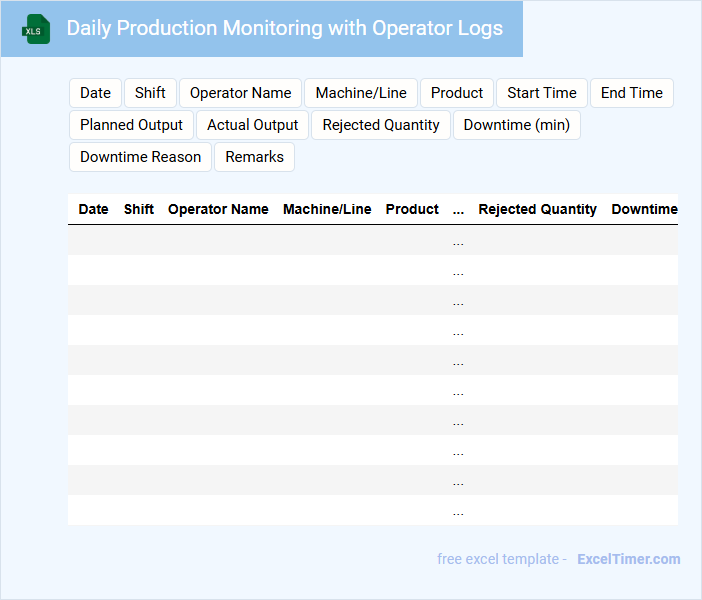

Daily Production Monitoring with Operator Logs

Daily Production Monitoring with Operator Logs is a document used to track and record the daily performance and activities on the production floor. It contains essential data such as machine uptime, output quantities, and any operational issues encountered.

The operator logs provide detailed insights from personnel about shifts, maintenance actions, and unexpected events affecting production. This document helps identify trends, inefficiencies, and areas for improvement.

Ensure accuracy and timely entry of data to maintain effective monitoring and decision-making.

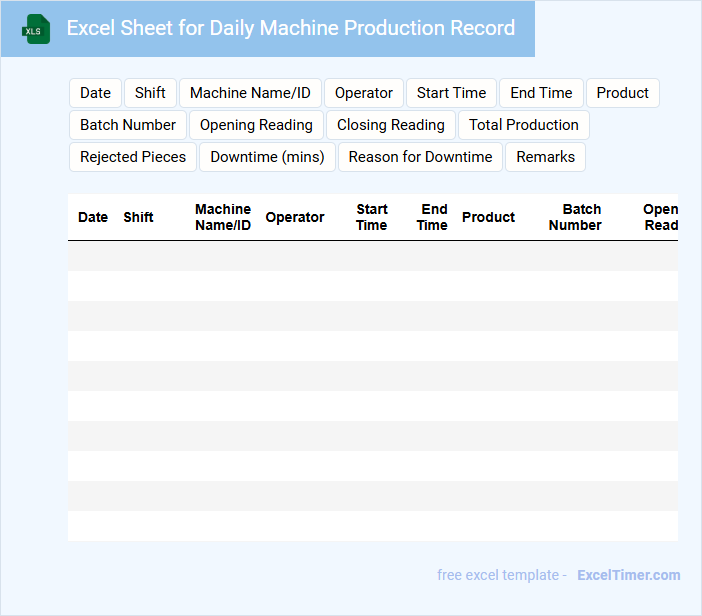

Excel Sheet for Daily Machine Production Record

An Excel Sheet for Daily Machine Production Record typically contains detailed logs of machine output, operational hours, and downtime incidents. It serves as a vital tool for tracking productivity and identifying efficiency patterns. Maintaining accurate data entry and regular updates are crucial for effective analysis and decision making.

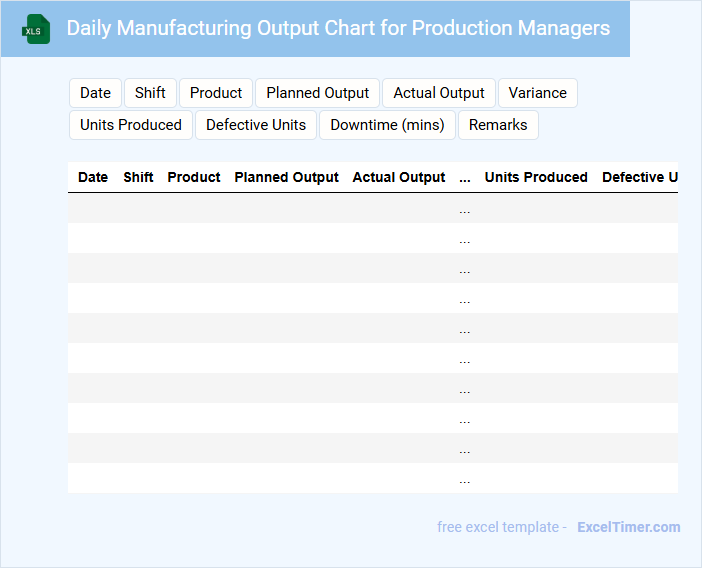

Daily Manufacturing Output Chart for Production Managers

What information is typically included in a Daily Manufacturing Output Chart for Production Managers? This document usually contains detailed records of the quantity of products manufactured each day, along with timestamps and production line identifiers. It helps production managers monitor daily performance, identify bottlenecks, and ensure targets are met efficiently.

What is an important consideration when using a Daily Manufacturing Output Chart? It is crucial to maintain accurate and timely data entry to reflect real-time production status. Additionally, highlighting deviations from targets and reasons for delays can improve decision-making and overall productivity management.

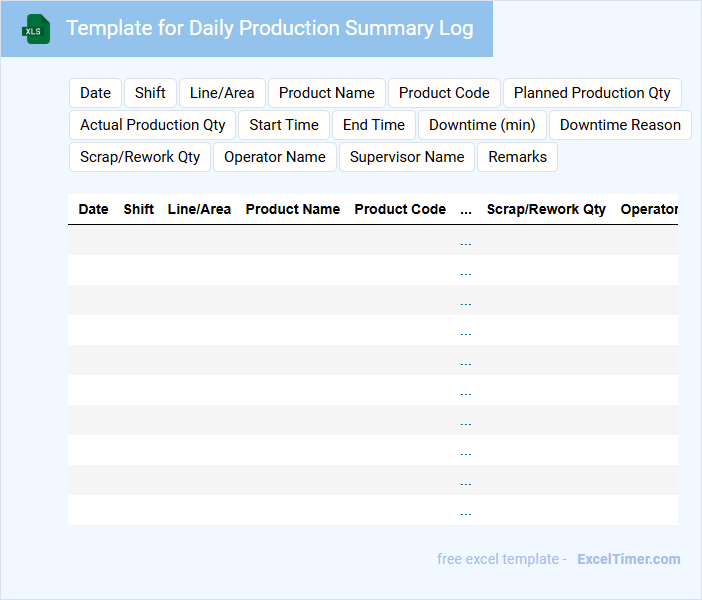

Template for Daily Production Summary Log

A Daily Production Summary Log typically contains detailed records of manufacturing activities conducted within a single day, including output quantities, machine performance, and any production issues encountered. This document helps in tracking efficiency and identifying areas for improvement. Ensuring accuracy and timely updates in this log is crucial for effective production management.

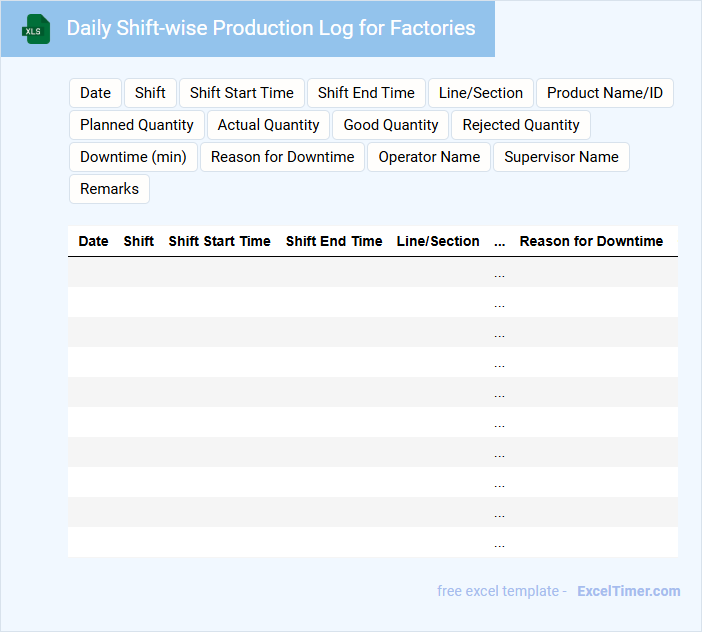

Daily Shift-wise Production Log for Factories

The Daily Shift-wise Production Log is a detailed record maintained in factories to track production activities across different shifts. It typically contains information such as the quantity produced, machine performance, and any interruptions that occurred during each shift.

This document helps in monitoring operational efficiency and identifying improvement areas on a daily basis. Ensuring accurate time-stamping and clear notation of issues is crucial for effective analysis and decision-making.

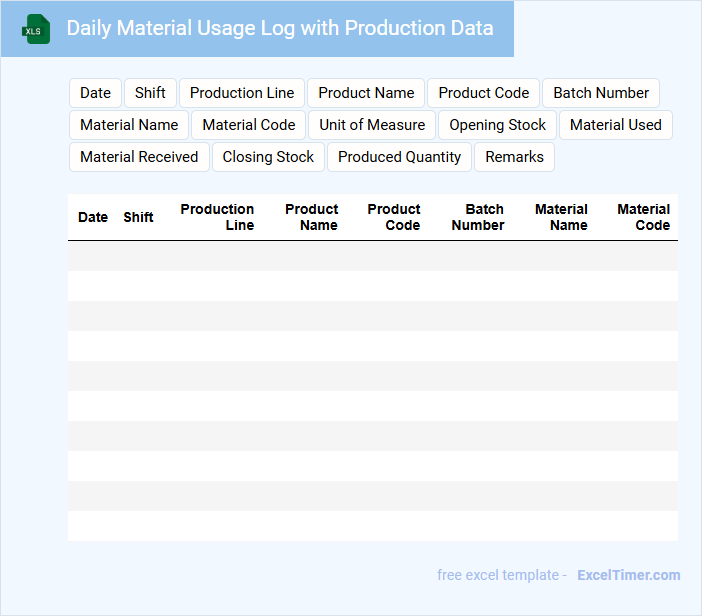

Daily Material Usage Log with Production Data

A Daily Material Usage Log with Production Data is a document that records the materials consumed during production alongside relevant production metrics. It helps in tracking efficiency and managing inventory accurately.

- Include the date, shift, and production batch details for clear identification.

- Record the type and quantity of materials used, correlated with the output produced.

- Note any discrepancies or wastage to improve material utilization and forecasting.

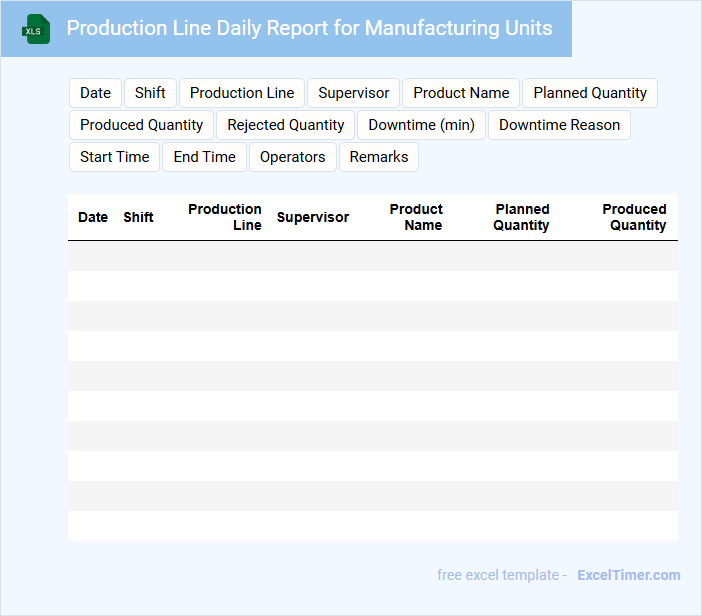

Production Line Daily Report for Manufacturing Units

Production Line Daily Report for Manufacturing Units typically contains detailed information about the daily operations of the production line, including output quantity, equipment performance, and any encountered issues. The report serves as a critical communication tool to monitor efficiency and identify bottlenecks in the manufacturing process. Important elements to include are shift timings, production targets, downtime reasons, and quality control results to ensure comprehensive tracking of daily activities.

Excel Tracker of Daily Manufacturing Performance

An Excel Tracker of Daily Manufacturing Performance typically contains data on production output, machine efficiency, downtime, and quality metrics. It helps in monitoring daily manufacturing activities to identify trends and areas for improvement.

The document often includes fields for date, shifts, units produced, defects, and operational hours. Regularly updating this tracker is essential for maintaining accurate performance records and enabling data-driven decisions.

For optimal use, ensure the tracker has clear labels, automated calculations, and visual charts to quickly highlight key performance indicators.

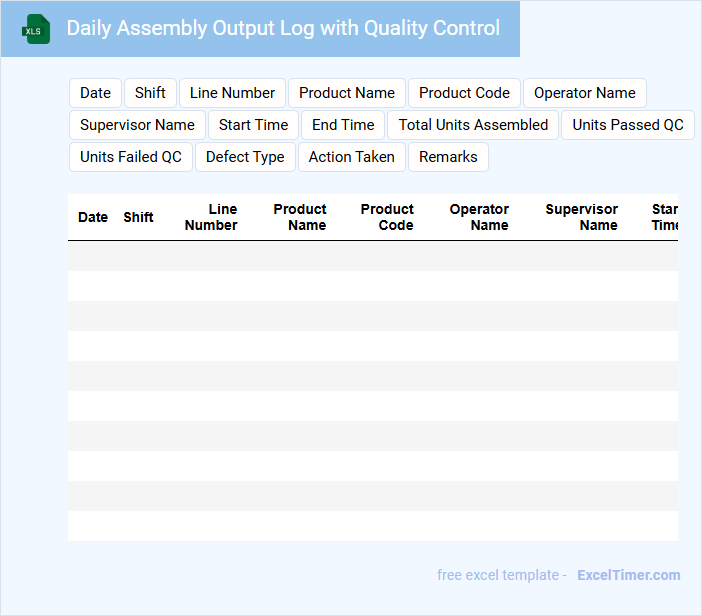

Daily Assembly Output Log with Quality Control

A Daily Assembly Output Log with Quality Control is a document used to record the production details and quality checks of assembled products each day. It ensures traceability and helps maintain manufacturing standards.

- Include the date, shift details, and total units assembled to track productivity accurately.

- Document any defects found during quality control along with corrective actions taken.

- Record operator names and machine identification for accountability and performance analysis.

Factory Daily Production Log Sheet for Teams

A Factory Daily Production Log Sheet is a crucial document used to record the daily manufacturing activities and output of a production team. It typically contains details such as production quantities, machine performance, and any issues encountered during the shift. Keeping this log accurate and up-to-date helps ensure smooth operations and facilitates quick problem-solving.

For teams, it is important to consistently update the log sheet throughout the day to capture real-time data. Including sections for shift changes, quality checks, and downtime reasons enhances the utility of the document. Clear and concise entries improve communication and accountability within the production team.

What are the essential columns required in a Daily Production Log for manufacturing units?

Essential columns in a Daily Production Log for manufacturing units include Date, Shift, Production Unit, Machine ID, Product Code, Batch Number, Quantity Produced, Downtime Duration, Reason for Downtime, Operator Name, Quality Check Status, and Remarks. These columns enable accurate tracking of daily output, machine performance, and quality control. Recording downtime reasons and operator details supports efficient troubleshooting and accountability.

How does the Daily Production Log track and report production targets versus actual output?

The Daily Production Log records daily production targets alongside actual output for each manufacturing unit, enabling real-time performance monitoring. Data entries include product type, quantity produced, and shift details, facilitating precise variance analysis. This log supports management in identifying production bottlenecks and optimizing resource allocation.

How can downtime and reasons for stoppages be effectively documented in the Daily Production Log?

Effectively documenting downtime and reasons for stoppages in your Daily Production Log involves recording precise start and end times for each incident along with detailed descriptions of the causes. Utilize standardized categories for common stoppages such as equipment failure, maintenance, or material shortage to ensure consistency and clarity. This approach helps you analyze trends and improve manufacturing unit efficiency through accurate, organized data.

What methods are used in the log to capture shift-wise production data and operator details?

The Daily Production Log captures shift-wise production data using time-stamped entries and segmented tables for each manufacturing shift. Operator details are recorded through designated fields for name, ID, and signature, ensuring accurate accountability and traceability. Your consistent input enables efficient tracking of production performance across shifts.

How is product quality, including defects and rework, monitored within the Daily Production Log?

The Daily Production Log tracks product quality by recording defect types, quantities, and rework instances for each manufacturing unit. It captures real-time data on defect rates and rework hours, enabling performance analysis and quality improvement. Quality metrics are monitored daily to ensure adherence to production standards and identify recurring issues.