The Daily Production Report Excel Template for Factories streamlines tracking of daily output, machine efficiency, and labor productivity in a user-friendly format. It enables factory managers to monitor production targets, identify bottlenecks, and maintain accurate records for smoother operations. Customizable fields and automated calculations enhance decision-making and improve overall manufacturing performance.

Daily Production Report Excel Template for Factories

The Daily Production Report Excel Template for factories typically contains detailed data on daily manufacturing output, machine performance, and labor efficiency. It helps track production volume, downtime, and quality control metrics to ensure smooth operations.

Using this template, factory managers can quickly identify bottlenecks and optimize workflow by analyzing real-time production figures. A crucial suggestion is to maintain updated and accurate data entry to maximize the report's effectiveness and decision-making capabilities.

Daily Output Tracking Sheet for Production Lines

A Daily Output Tracking Sheet for production lines is a crucial document used to record the quantity of goods produced each day. It typically contains data such as the date, production targets, actual output, and any discrepancies or downtime. This sheet helps in monitoring efficiency, identifying bottlenecks, and improving overall production processes.

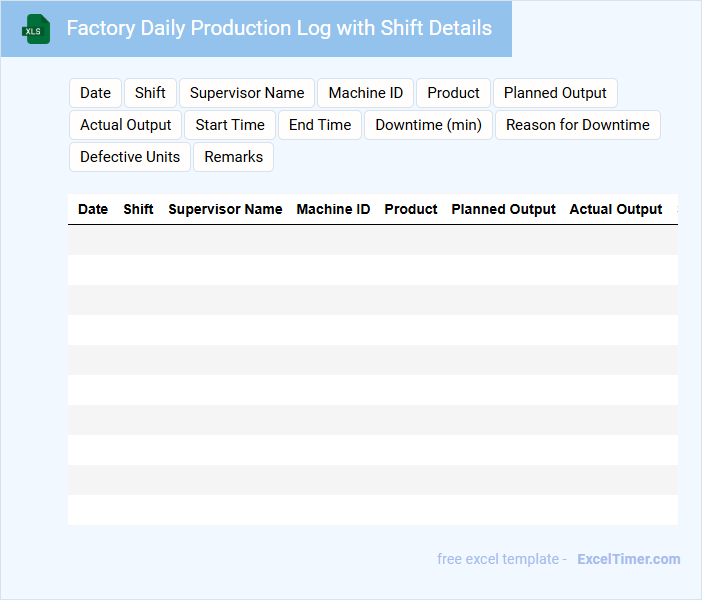

Factory Daily Production Log with Shift Details

What information is typically recorded in a Factory Daily Production Log with Shift Details? This document usually contains detailed records of production activities segmented by different shifts, including output quantities, machine performance, and any issues encountered. It helps ensure accurate tracking of productivity, facilitates communication between shifts, and supports efficient operational management.

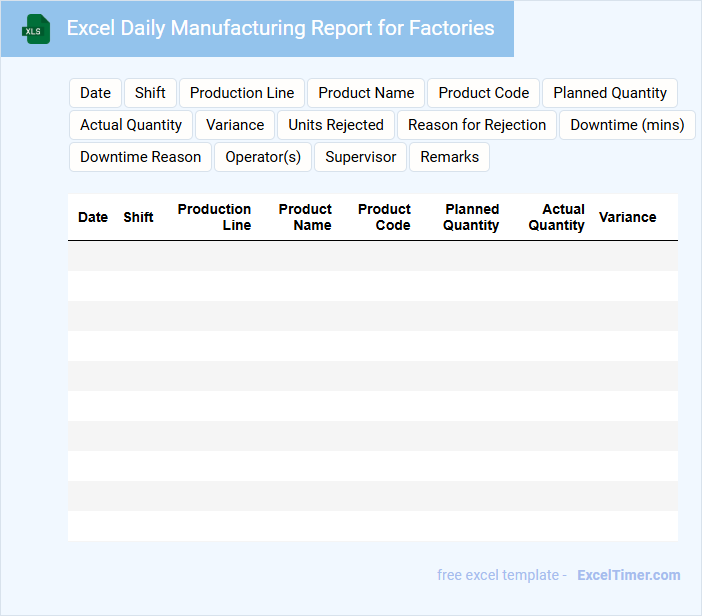

Excel Daily Manufacturing Report for Factories

An Excel Daily Manufacturing Report for factories typically contains detailed records of production activities, including quantities produced, machine performance, and downtime data. It tracks labor hours, raw material consumption, and quality control results to ensure efficient operations.

Such reports play a crucial role in identifying production bottlenecks, monitoring progress against targets, and facilitating decision-making. Including clear headers, accurate timestamps, and standardized data fields is important for consistency and ease of analysis.

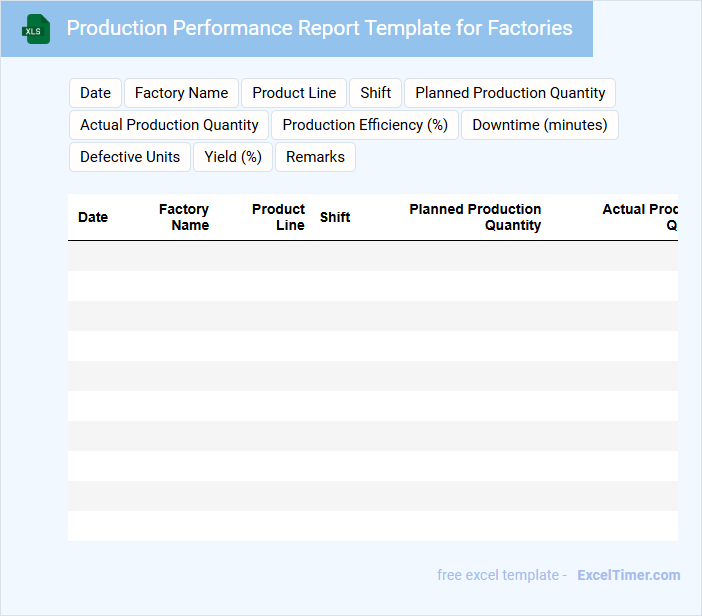

Production Performance Report Template for Factories

A Production Performance Report Template for Factories typically contains key metrics and data reflecting manufacturing efficiency, output quality, and operational status. It helps managers track progress and identify areas for improvement.

- Include detailed production volumes and downtime records for accurate performance assessment.

- Incorporate quality control results to monitor product standards consistently.

- Use clear visual aids like charts and graphs to highlight trends and deviations.

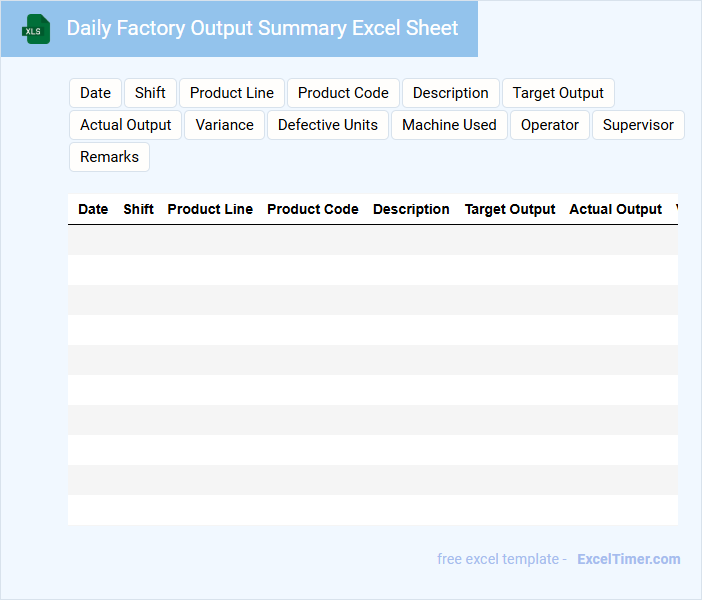

Daily Factory Output Summary Excel Sheet

The Daily Factory Output Summary Excel sheet is typically used to track and record the production data of a factory on a daily basis. It contains key information such as the quantity of goods produced, machine performance, and any production delays or issues. This document helps management monitor productivity and make informed decisions for operational improvements.

Daily Production Monitoring Sheet for Factory Operations

A Daily Production Monitoring Sheet is a crucial document used in factory operations to track and record the output and efficiency of production processes each day. It typically contains data on machine performance, operator details, production quantities, and any issues or delays encountered. This document helps in identifying bottlenecks and ensures timely corrective actions to maintain smooth factory operations.

To optimize its use, it is important to include clear parameters such as shift timings, targets, actual production, downtime reasons, and quality checks. Regular updates and accurate data entry are essential for effective monitoring and decision-making. Additionally, involving supervisors and operators in review meetings can enhance accountability and continuous improvement.

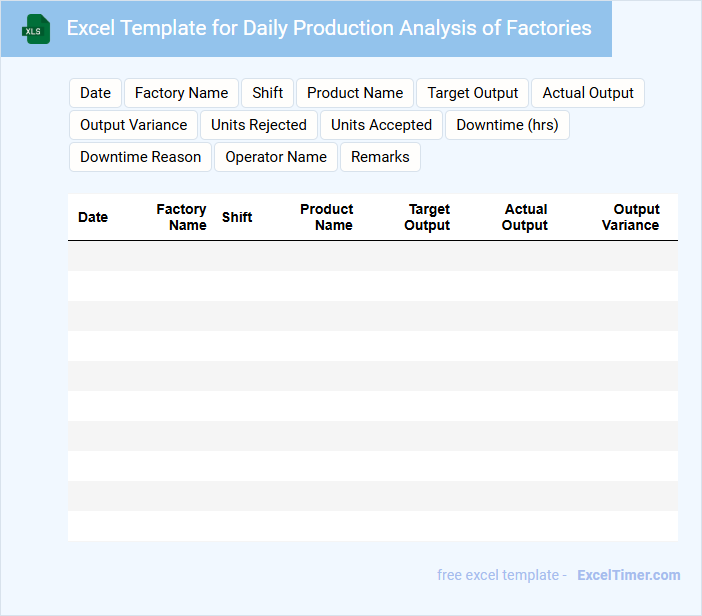

Excel Template for Daily Production Analysis of Factories

Excel Templates for Daily Production Analysis in factories typically contain structured data fields such as production output, machine efficiency, downtime, and quality control metrics. These templates help in tracking daily performance and identifying areas requiring immediate attention.

They often include charts and pivot tables for visualizing trends and making data-driven decisions. Ensuring data accuracy and timely updates is crucial for effective analysis and operational improvements.

Factory Daily Work Report Template with Downtime Tracking

What information is typically included in a Factory Daily Work Report Template with Downtime Tracking? This type of document usually contains detailed records of daily production activities, employee attendance, and equipment performance. It also tracks any instances of downtime, including causes and durations, to help identify patterns and improve factory efficiency.

What is an important aspect to focus on when using this report template? Accurate downtime tracking is essential, as it provides valuable insights into production delays and equipment issues. Ensuring clear and consistent data entry will help management make informed decisions to minimize downtime and enhance overall productivity.

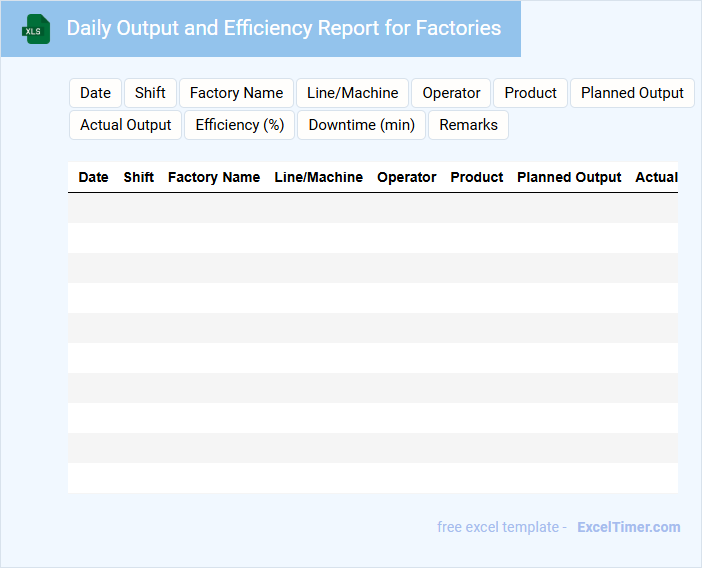

Daily Output and Efficiency Report for Factories

The Daily Output and Efficiency Report for factories typically contains detailed records of production volumes and operational efficiency metrics. It highlights machine performance, labor productivity, and any downtime experienced during the shift.

This document also includes key performance indicators (KPIs) such as output rates, defect counts, and resource utilization percentages. A crucial suggestion is to ensure accuracy in data collection to enable effective decision-making and continuous improvement.

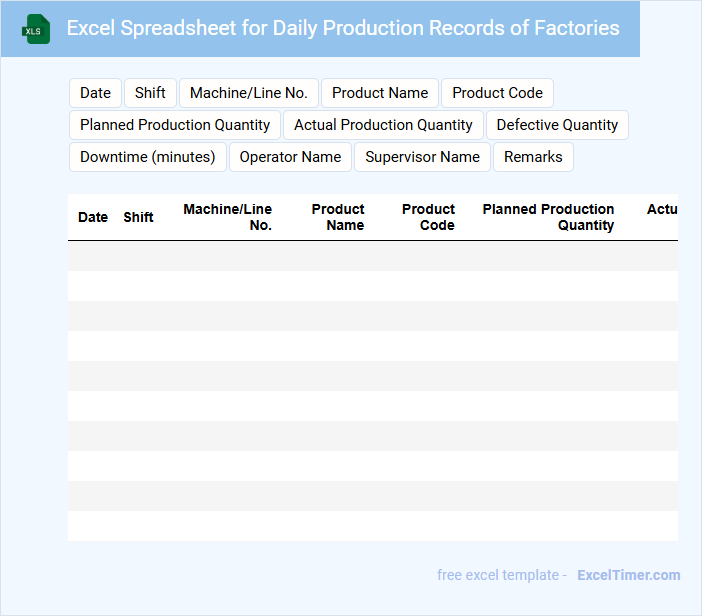

Excel Spreadsheet for Daily Production Records of Factories

What information is typically included in an Excel spreadsheet for daily production records of factories? This type of document usually contains data such as production quantities, machine operation times, employee shifts, and quality control results. It helps track daily factory performance and identify areas for improvement to ensure efficient manufacturing processes.

Why is accuracy important when maintaining daily production records in Excel spreadsheets? Accurate data entry ensures reliable performance analysis and decision-making for factory managers. Consistency in recording production details helps prevent errors and supports better planning and resource allocation.

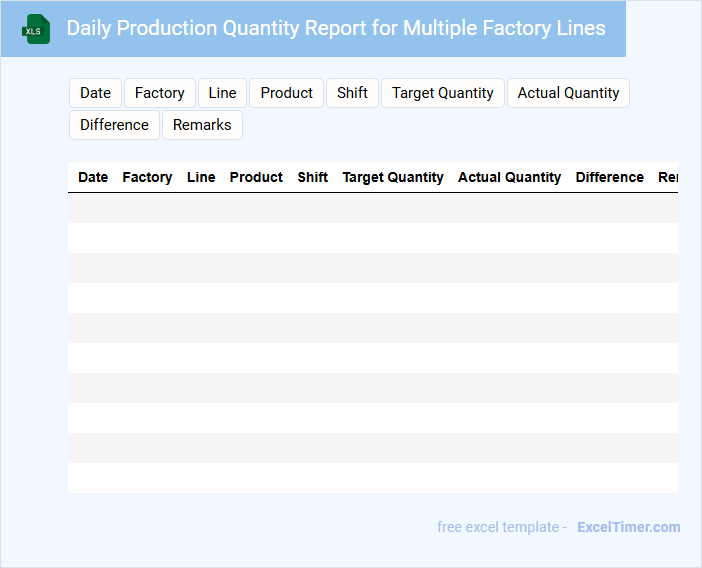

Daily Production Quantity Report for Multiple Factory Lines

A Daily Production Quantity Report typically contains detailed records of the units produced across multiple factory lines within a single day. It includes data such as production volumes, line efficiency, and any discrepancies or downtime observed.

This report is essential for tracking productivity and identifying bottlenecks in the manufacturing process. Regular analysis helps ensure consistent output and supports timely decision-making for process improvements.

It is important to include accurate timestamps, line identification, and clear summaries to facilitate quick review and actionable insights.

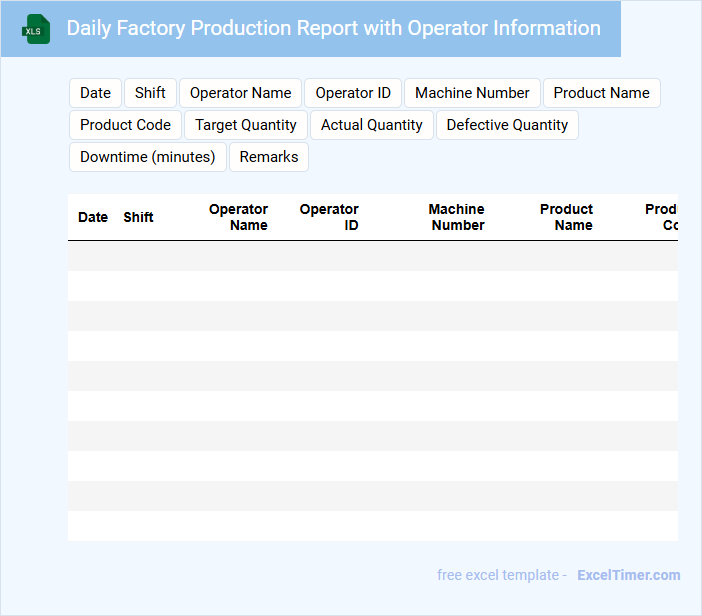

Daily Factory Production Report with Operator Information

The Daily Factory Production Report typically contains detailed data on the daily output, machine performance, and raw material usage. It records specific metrics such as production quantity, downtime, and quality control results.

Including Operator Information in the report helps track individual productivity and accountability. This section often covers operator names, shift timings, and any notes on operational issues encountered during the shift.

Ensuring accuracy and timeliness in this document is crucial for effective production monitoring and continuous improvement.

Manufacturing Daily Report Template for Factory Floor

What key information is typically included in a Manufacturing Daily Report Template for the Factory Floor? This type of document usually contains data on daily production output, machine performance, employee attendance, and any issues encountered during the shift. It serves as a critical tool for tracking operational efficiency, identifying bottlenecks, and ensuring smooth workflow management.

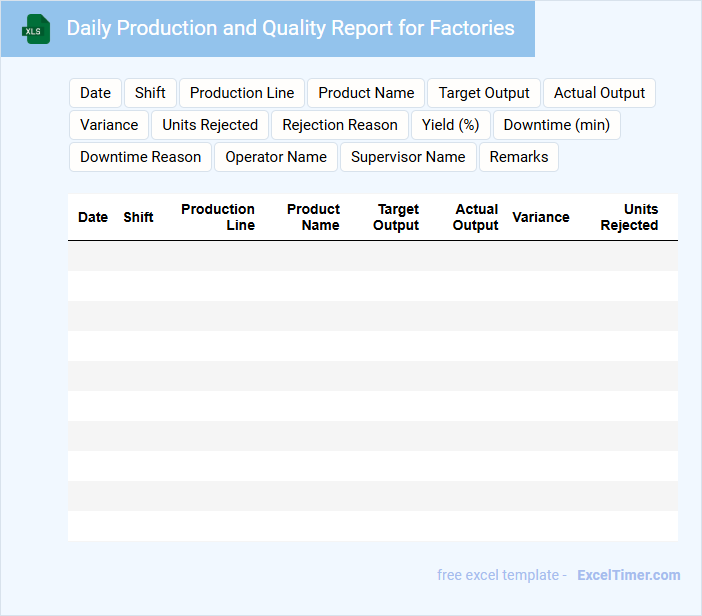

Daily Production and Quality Report for Factories

What information is typically contained in a Daily Production and Quality Report for Factories? This report usually includes detailed data on daily production volumes, quality control results, and any production issues encountered. It serves to monitor factory performance and ensure product standards are consistently met.

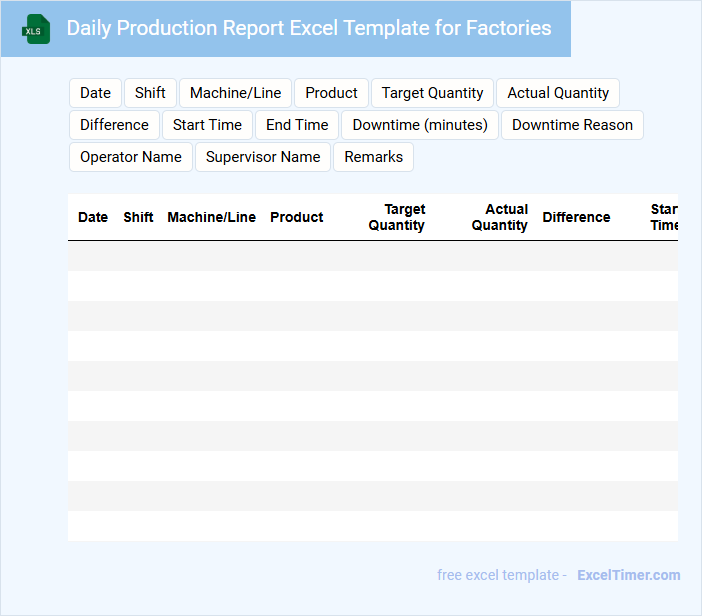

What are the key data fields required in a Daily Production Report for factories?

A Daily Production Report for factories should include key data fields such as production date, factory or production line identifier, product code, quantity produced, machine or equipment used, operator name, shift timing, downtime duration and reasons, raw material consumption, and quality inspection results. These fields provide a comprehensive overview of daily manufacturing performance and operational efficiency. Accurate recording of these metrics supports production tracking, resource management, and quality control.

How can Excel formulas be used to automatically calculate daily output and efficiency?

Excel formulas like SUM and AVERAGE enable you to automatically calculate daily output by totaling production quantities, while efficiency can be computed using division formulas that compare actual output against target goals. Incorporating functions such as IF and conditional formatting highlights production variances and flags inefficiencies in real-time. This automation streamlines your Daily Production Report, ensuring accurate, up-to-date insights for factory performance analysis.

What methods ensure accurate data entry and validation in a Daily Production Report spreadsheet?

Accurate data entry in a Daily Production Report spreadsheet is ensured through dropdown lists, data validation rules, and conditional formatting to prevent errors. You can implement Excel formulas and macros to automatically cross-check and flag inconsistencies in production figures. Regular audits and protected cells also maintain data integrity throughout the reporting process.

How can conditional formatting highlight production deviations or errors in the report?

Conditional formatting in an Excel Daily Production Report can highlight production deviations by applying color scales or flags to cells that fall outside predefined thresholds, such as low output or high defect rates. This visual differentiation enables quick identification of factories with abnormal production levels or errors. Using rules based on target production values or defect limits ensures immediate attention to areas requiring corrective action.

What summary charts or pivot tables best visualize daily and cumulative production metrics in Excel?

To effectively visualize daily and cumulative production metrics in your Daily Production Report, use pivot tables summarizing daily output by factory and product type. Incorporate line charts to display trends over time, highlighting total accumulated production alongside daily figures. Bar charts comparing production targets versus actual output provide clear performance insights.