The Daily Production Report Excel Template for Manufacturing Plants streamlines tracking of daily output, machine usage, and labor efficiency in one organized spreadsheet. It enables manufacturing managers to quickly identify bottlenecks, monitor production targets, and ensure timely decision-making. Using this template enhances accuracy and saves time compared to manual reporting methods.

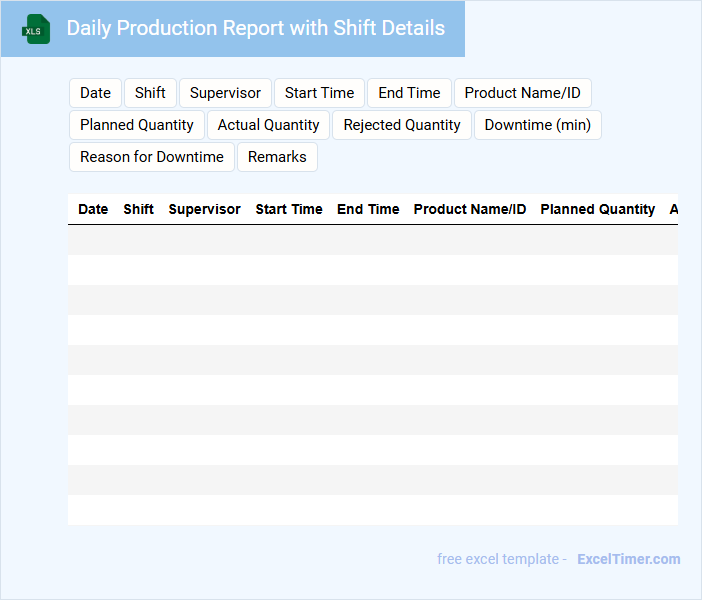

Daily Production Report with Shift Details

A Daily Production Report with shift details typically contains data on the total output, machine performance, and manpower utilization for each shift. It includes information on any incidents, downtime, and quality issues encountered during the production process. This document is crucial for monitoring productivity and ensuring smooth operations across different shifts.

Daily Production Report for Manufacturing Units

A Daily Production Report for Manufacturing Units is a document that records the daily output and performance metrics of a production line. It helps in tracking productivity, identifying issues, and improving operational efficiency.

- Include key production data such as quantity produced, downtime, and scrap rates.

- Ensure accurate recording of shift timings and operator details.

- Highlight any production challenges or deviations from the planned schedule.

Daily Output Tracking Template for Factories

A Daily Output Tracking Template for factories typically contains essential data such as production quantities, machine performance, and workforce efficiency. It helps management monitor daily progress and identify bottlenecks promptly. Ensuring accuracy in data entry and including clear headers are important for maximizing its effectiveness.

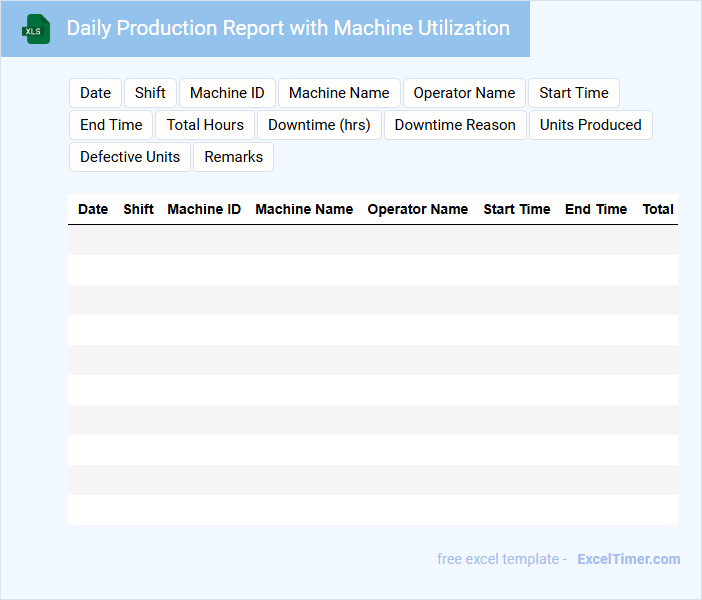

Daily Production Report with Machine Utilization

A Daily Production Report with Machine Utilization typically contains data on the total units produced, operational hours of machines, and any downtime experienced. It helps track production efficiency and identify bottlenecks in the manufacturing process. Key metrics such as machine run time, idle time, and output quantity are essential for accurate monitoring.

Suggested important inclusions are clear timestamps, machine identification, and reasons for any downtime. Adding operator notes and quality checks can improve the report's usefulness for continuous improvement. Consistent formatting and digital accessibility enhance data analysis and decision-making.

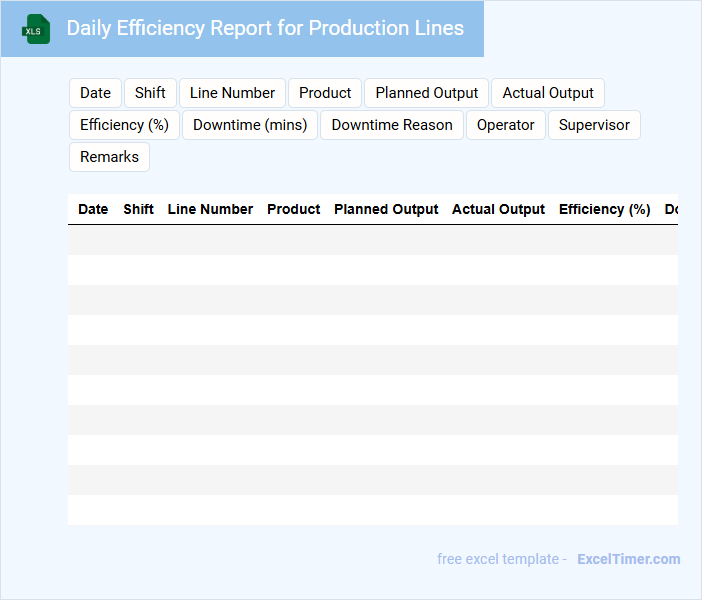

Daily Efficiency Report for Production Lines

A Daily Efficiency Report for Production Lines typically contains key performance indicators such as output rates, downtime, and quality metrics. It provides a concise overview of the production line's efficiency and identifies areas needing improvement.

Important elements include accurate time tracking and detailed incident reporting to ensure reliable data analysis. Consistent updates and clear visuals like charts enhance the report's usability for management decisions.

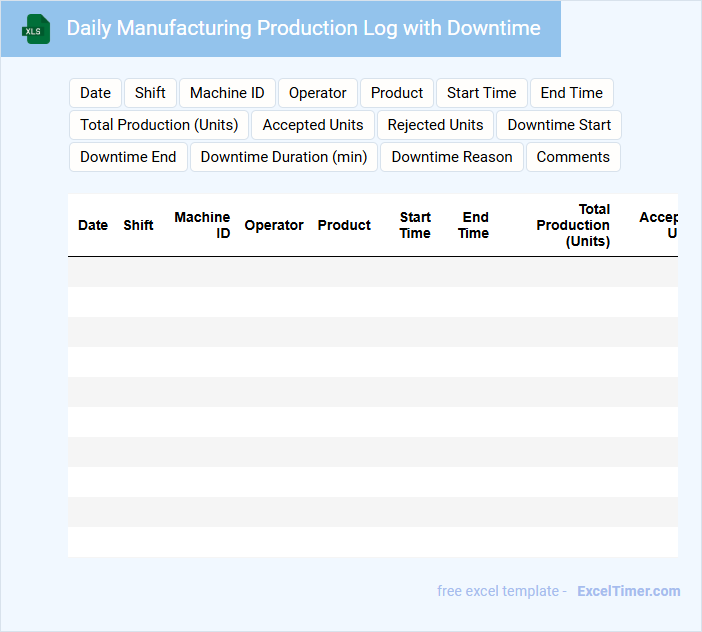

Daily Manufacturing Production Log with Downtime

What information does a Daily Manufacturing Production Log with Downtime usually contain? This document typically records the amount of production completed, machine performance, and any periods of downtime that occurred during the shift. It helps track productivity and identify issues causing delays to improve overall manufacturing efficiency.

What key elements should be included in this log for effectiveness? Important details include timestamps for start and end of production, quantity produced, reasons for downtime, and corrective actions taken. Ensuring accurate and timely entries supports better analysis and decision-making for production optimization.

Daily Production Tracking Sheet for Plant Supervisors

The Daily Production Tracking Sheet is a crucial document used by plant supervisors to monitor the daily output of manufacturing processes. It typically contains details such as production quantities, machine performance, and any downtime incidents. This sheet helps in identifying bottlenecks, ensuring quality control, and maintaining overall operational efficiency.

To optimize its effectiveness, the sheet should include clear timestamps, operator names, and shift details for accurate accountability. Incorporating sections for unexpected issues and corrective actions can facilitate quicker resolutions and continuous improvement. Finally, using easy-to-read formats and digital integration enhances real-time data tracking and decision-making.

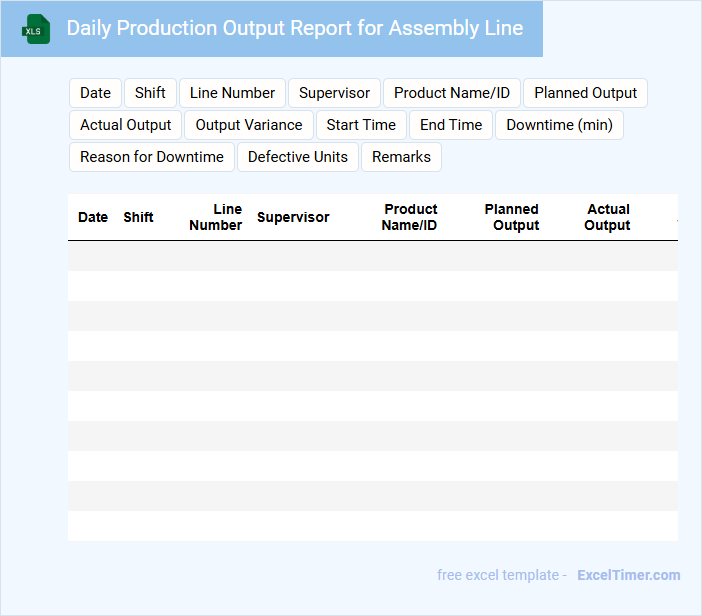

Daily Production Output Report for Assembly Line

The Daily Production Output Report for an assembly line typically contains detailed information about the quantity of products manufactured within a specific day. It includes metrics such as total units produced, defective units, and operational hours. This document helps monitor efficiency and identify areas for improvement in the production process.

Important aspects to include are accurate time stamps, clear identification of production shifts, and notes on any equipment downtime or issues encountered. Consistent formatting ensures ease of comparison across days. Additionally, incorporating visual aids like charts can enhance quick understanding of trends and performance.

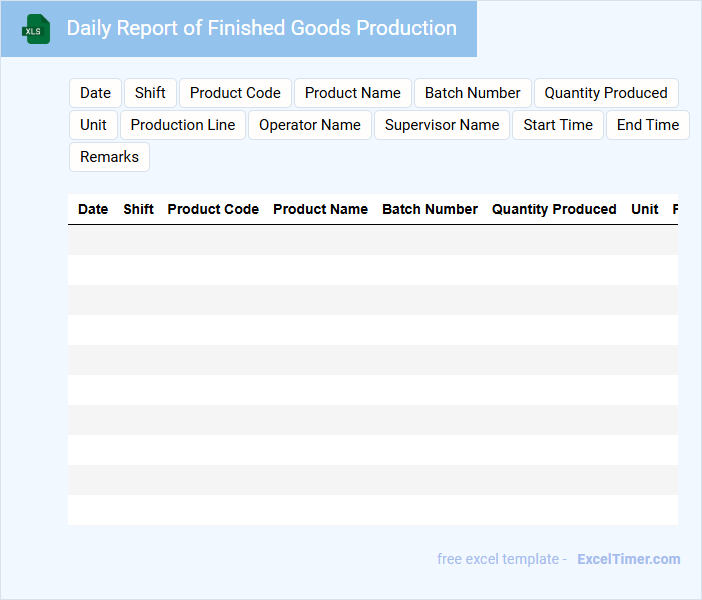

Daily Report of Finished Goods Production

What information is typically included in a Daily Report of Finished Goods Production? This report usually contains details such as the quantity of finished goods produced, the production date, and any issues encountered during the production process. It helps track daily output and ensures quality control by documenting any deviations or delays.

Why is it important to include accurate timestamps and batch numbers in this report? Including precise timestamps and batch numbers ensures traceability and accountability for each production batch. This information is crucial for quality assurance, inventory management, and addressing any product recalls efficiently.

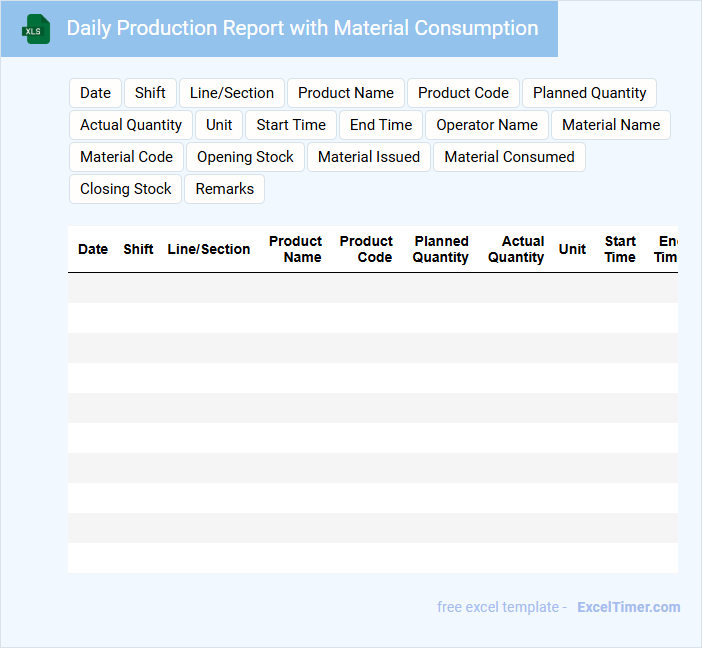

Daily Production Report with Material Consumption

A Daily Production Report with Material Consumption documents the amount of products manufactured and the materials used each day. It helps in tracking production efficiency and resource utilization.

- Include accurate quantities of materials consumed to monitor inventory levels.

- Record production output to evaluate daily performance against targets.

- Note any discrepancies or issues to identify areas for process improvement.

Daily Production QC Report for Factories

A Daily Production QC Report for Factories typically contains crucial information about the quality control measures and production status for the day.

- Production Metrics: Details on the quantity produced, inspected, and passed quality standards.

- Defect Analysis: Summary of any defects found, including their nature and possible causes.

- Corrective Actions: Recommendations or actions taken to address quality issues and prevent recurrence.

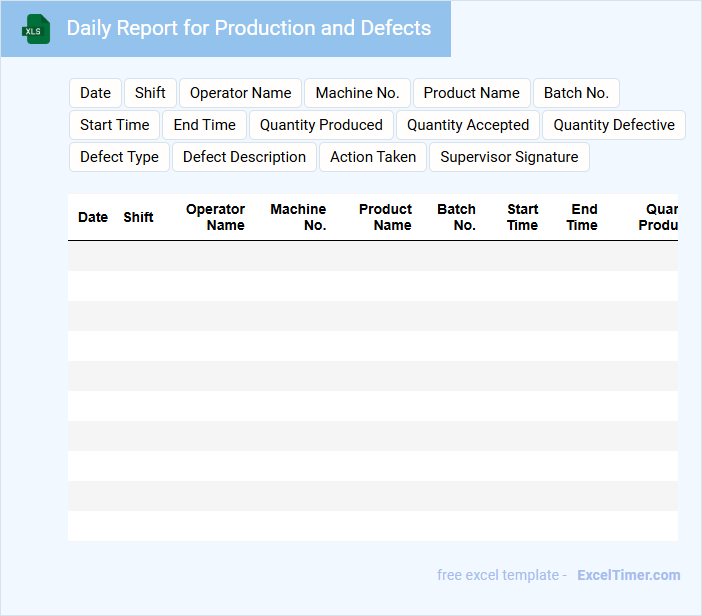

Daily Report for Production and Defects

A Daily Report for Production and Defects typically contains detailed information about the quantity of items produced and any defects identified during the production process. It serves as a vital tool for tracking manufacturing efficiency and quality control on a daily basis. Such reports help managers quickly identify issues and ensure timely corrective actions are taken to maintain production standards.

Daily Labor Productivity Report for Manufacturing

A Daily Labor Productivity Report for Manufacturing typically contains detailed records of workforce efficiency, production output, and time management.

- Workforce Efficiency: Tracks the performance and output of individual workers or teams throughout the day.

- Production Output: Measures the quantity and quality of goods produced within a specific time frame.

- Time Management: Records the hours worked and identifies any downtime or delays affecting productivity.

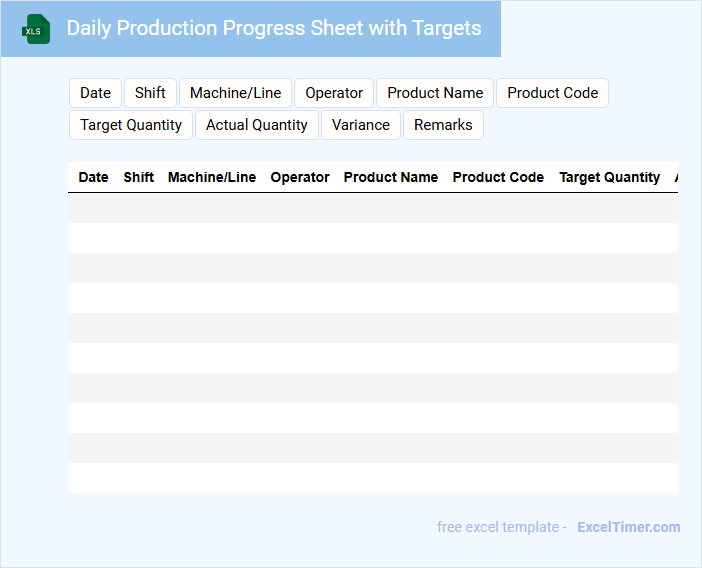

Daily Production Progress Sheet with Targets

The Daily Production Progress Sheet typically contains detailed records of the day's manufacturing or production activities, including the quantity produced, quality checks, and any deviations from planned targets. It helps in tracking performance against set objectives, providing real-time data for timely decision-making. To maximize its effectiveness, ensure that targets are clearly defined and updated regularly, with space for notes on issues encountered and corrective actions taken.

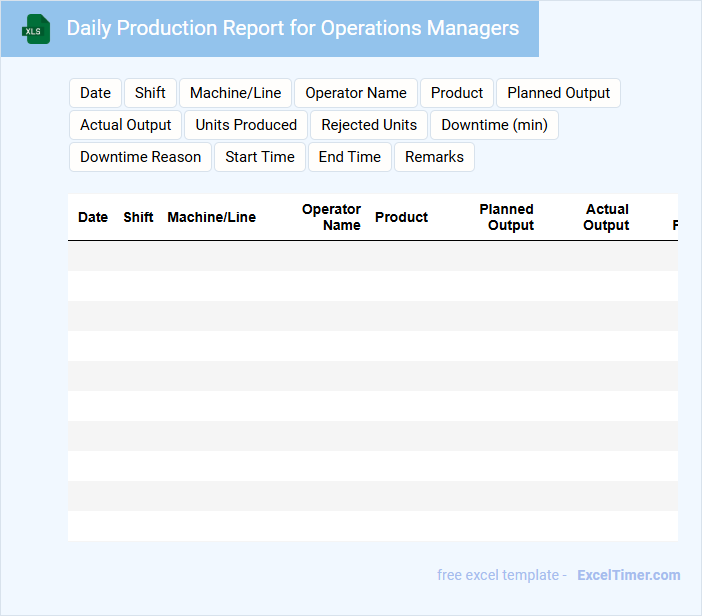

Daily Production Report for Operations Managers

What information is typically included in a Daily Production Report for Operations Managers? This document usually contains data on production output, machine performance, labor efficiency, and any issues encountered during the shift. It serves as a critical tool for monitoring daily operations and making informed decisions to improve productivity and address problems promptly.

What key metrics should be included in a daily production report for manufacturing plants?

A daily production report for manufacturing plants should include key metrics such as total units produced, machine utilization rates, defect or scrap rates, and downtime duration. Tracking labor hours, production efficiency, and order fulfillment status provides valuable insights into operational performance. Your report ensures real-time visibility into production health, enabling informed decision-making.

How can Excel formulas automate calculation of production efficiency and downtime?

Excel formulas automate calculation of production efficiency by dividing total output by standard output targets, providing real-time efficiency percentages. Downtime is tracked by summing the duration of non-operational periods using time functions, quantifying total lost production minutes. You can customize these formulas to instantly analyze performance metrics and optimize manufacturing processes.

What are effective ways to visualize daily output trends in an Excel report?

To effectively visualize daily output trends in your Excel Daily Production Report, use line charts to track production volume over time, which highlight patterns and fluctuations clearly. Incorporate conditional formatting with color scales to quickly identify high and low production days. Pivot tables combined with slicers offer dynamic filtering to analyze output by shifts, machines, or product lines for deeper insights.

How should shift-wise production data be structured for easy comparison in Excel?

Structure shift-wise production data in Excel with clearly labeled columns for each shift and rows representing daily production metrics such as output volume, downtime, and defect rates. Use consistent formatting and color-coding to highlight key differences and trends across shifts. Your report will enable quick comparison and data-driven decision-making for manufacturing plants.

Which essential data validation techniques ensure report accuracy in daily production tracking?

Key data validation techniques for daily production reports in manufacturing include setting data type restrictions to enforce numeric entries for production counts, implementing drop-down lists for predefined categories like shift or product type, and using conditional formatting to highlight anomalies such as negative values or unexpected production spikes. Cross-referencing reported output with inventory or machine runtime logs enhances accuracy by detecting discrepancies early. Employing date and time validations ensures production entries correspond to the correct shifts and operational periods.