The Daily Production Report Excel Template for Manufacturing Units streamlines tracking of daily output, machine efficiency, and labor productivity. It helps managers quickly identify bottlenecks and maintain accurate records for performance analysis. Utilizing this template improves operational transparency and supports data-driven decision-making.

Daily Production Report Excel Template for Manufacturing Units

The Daily Production Report Excel template is a vital document used in manufacturing units to record and track daily production activities. It typically contains sections for input materials, output quantities, machine hours, and any downtime or delays experienced. This structured format helps in monitoring performance, identifying bottlenecks, and ensuring efficient resource utilization.

Important aspects to include are accurate timestamps, clear categorization of production stages, and fields for operator remarks or issues encountered during the shift. Incorporating automated calculations for efficiency and defect rates enhances productivity analysis. Ensuring data validation and easy-to-read layouts can greatly improve usability and reporting accuracy.

Daily Output Tracking Sheet for Manufacturing Production

A Daily Output Tracking Sheet for manufacturing production typically contains detailed records of the number of units produced, production shifts, and machine performance metrics. It helps in monitoring daily progress and identifying any bottlenecks in the production process.

This document also includes data on workforce attendance, material usage, and downtime reasons to ensure comprehensive tracking. Maintaining accuracy and timely updates are crucial for effective production management.

For better efficiency, ensure consistent data entry and regularly review the sheet to quickly address any discrepancies or delays.

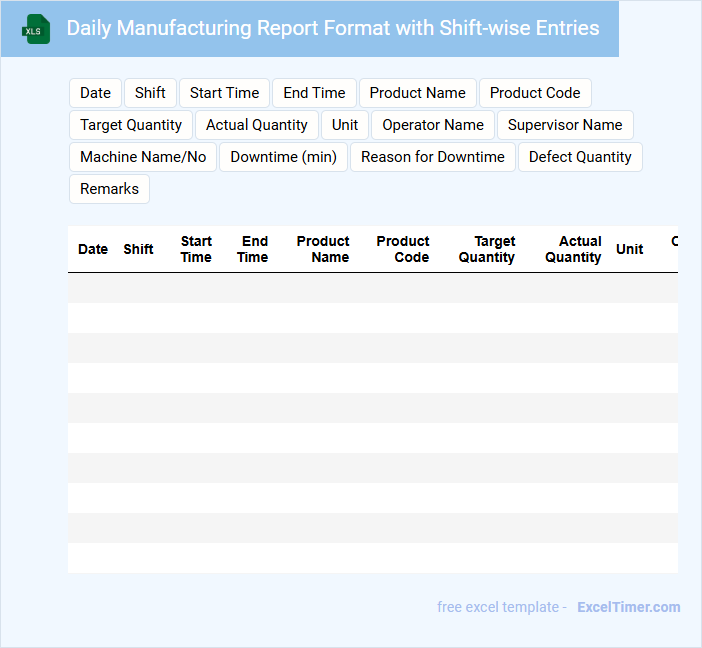

Daily Manufacturing Report Format with Shift-wise Entries

What information is typically included in a Daily Manufacturing Report Format with Shift-wise Entries? This type of document usually contains detailed production data segmented by shifts, including output quantities, downtimes, quality issues, and operator performance. It provides a clear, organized view of manufacturing activities to help identify trends and areas needing improvement across different shifts.

What are some important considerations when creating a Daily Manufacturing Report Format with Shift-wise Entries? It is essential to ensure accuracy in data collection for each shift and to include key metrics such as production targets, actual output, equipment status, and any incidents. Additionally, the format should be easy to understand and accessible for all shift supervisors to promote timely reporting and effective decision-making.

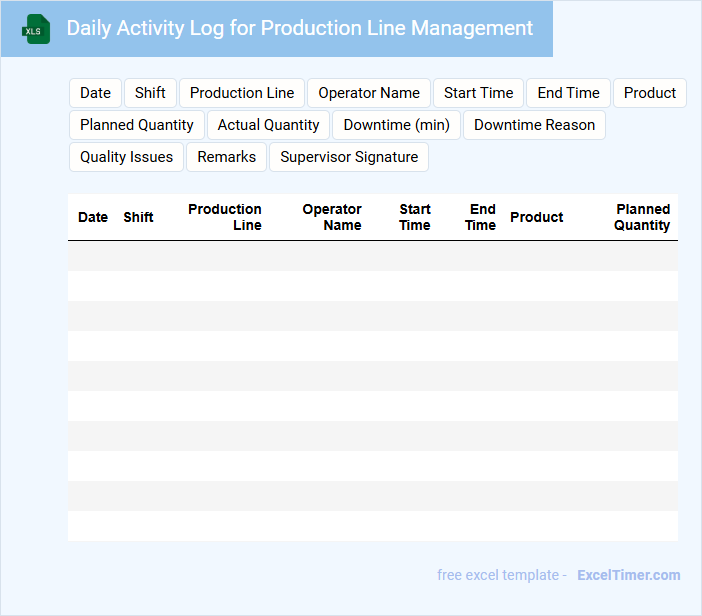

Daily Activity Log for Production Line Management

A Daily Activity Log for Production Line Management typically contains detailed records of operational activities, equipment status, and workforce performance to ensure efficient production tracking.

- Operational Activities: Document start and end times, tasks performed, and any deviations from the production schedule.

- Equipment Status: Record machine performance, maintenance needs, and any malfunctions during the shift.

- Workforce Performance: Track employee attendance, shift changes, and any safety incidents.

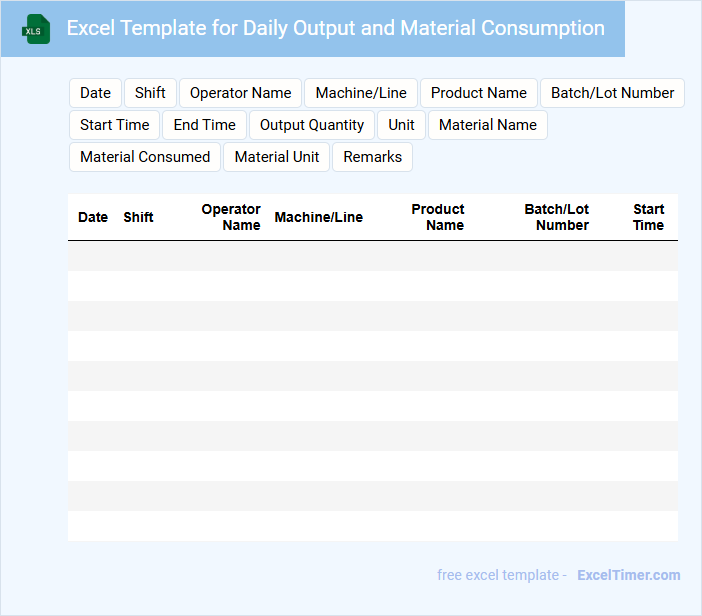

Excel Template for Daily Output and Material Consumption

An Excel Template for Daily Output and Material Consumption typically includes detailed records of production quantities, raw material usage, and operational efficiency. It helps track daily performance metrics to ensure accurate monitoring and reporting.

This document usually contains fields for date, product type, output volume, material input, and waste calculation. Regular updating and validation of data entries are crucial to maintain accuracy and facilitate analysis.

It is important to integrate automated formulas and conditional formatting to highlight discrepancies and support decision-making.

Daily Production Sheet with Operator Performance Tracking

The Daily Production Sheet is a crucial document used to record and monitor daily output in manufacturing or production environments. It captures quantitative data, including units produced, defects, and machine utilization rates.

Operator Performance Tracking focuses on individual employee metrics such as efficiency, accuracy, and downtime. This aids in identifying skill gaps and optimizing workforce allocation.

For effective use, ensure data accuracy and timely updates to facilitate real-time decision-making and continuous improvement.

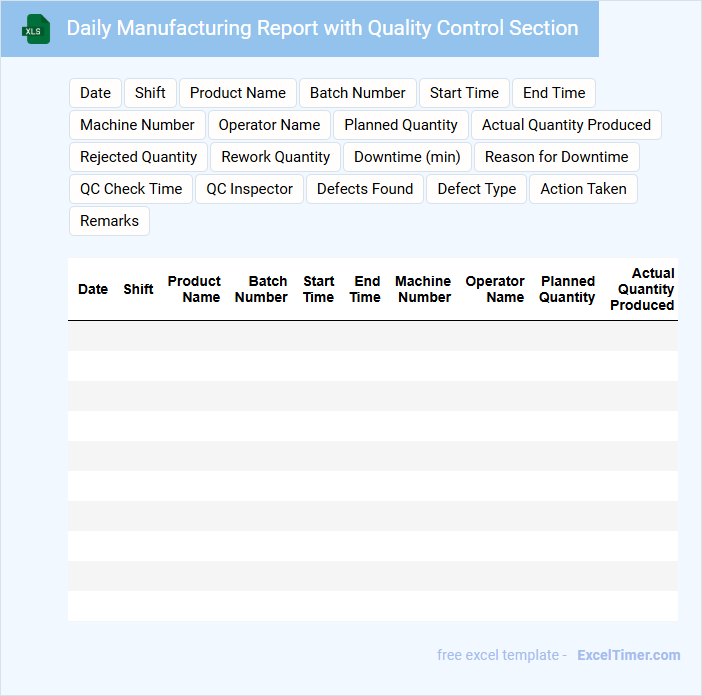

Daily Manufacturing Report with Quality Control Section

A Daily Manufacturing Report typically contains detailed information about the production output, machine performance, and labor utilization for the day. It helps track efficiency and identify any production issues promptly.

The Quality Control Section includes data on product inspections, defect rates, and compliance with quality standards. This section ensures that manufacturing processes meet the required specifications and helps prevent defective products from reaching customers.

Including timestamps, operator details, and corrective actions taken in the report enhances traceability and continuous improvement efforts.

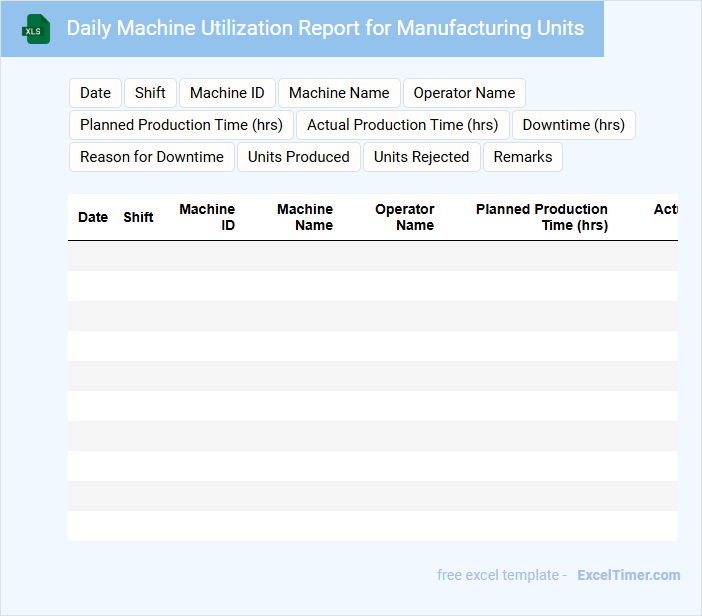

Daily Machine Utilization Report for Manufacturing Units

A Daily Machine Utilization Report for Manufacturing Units typically contains data on machine operating hours, idle time, and efficiency metrics to monitor production performance.

- Accurate Time Tracking: Record precise start and stop times for each machine to ensure reliable utilization data.

- Downtime Reasons: Include detailed causes for any idle periods to identify and address operational inefficiencies.

- Performance Metrics: Summarize key indicators such as utilization rate and output quantity for effective decision-making.

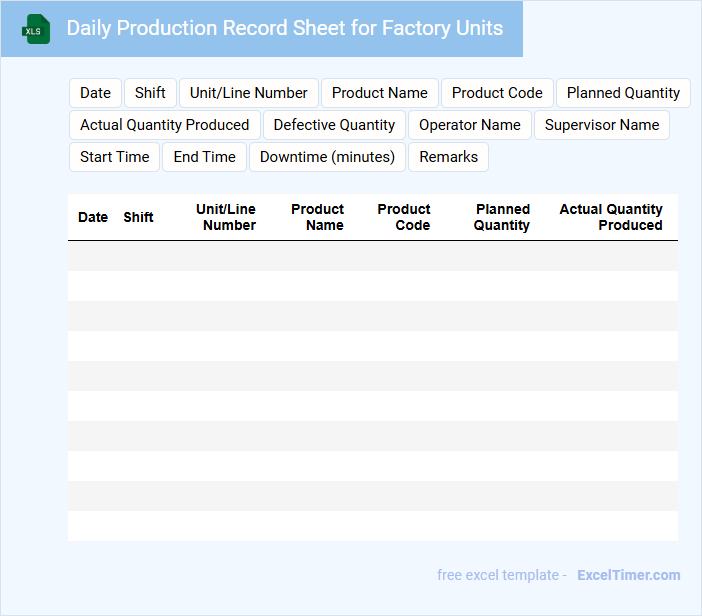

Daily Production Record Sheet for Factory Units

The Daily Production Record Sheet is a vital document used in factory units to track the daily output and operational efficiency. It typically contains details such as the quantity produced, machine performance, and any downtime or issues encountered. This record helps in analyzing productivity trends and identifying areas for improvement.

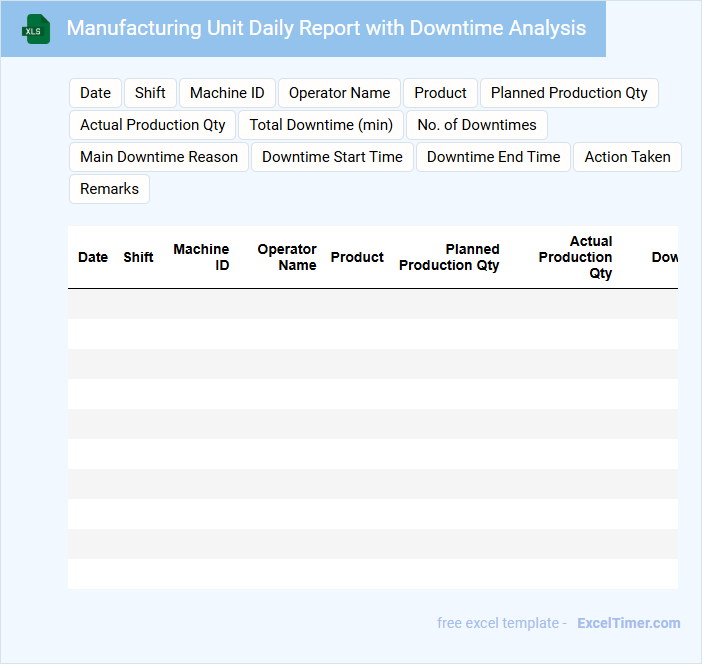

Manufacturing Unit Daily Report with Downtime Analysis

A Manufacturing Unit Daily Report with Downtime Analysis typically contains detailed production data, downtime incidents, and efficiency metrics to monitor and improve manufacturing processes.

- Production Output: Records the total units produced and quality checks performed during the shift.

- Downtime Events: Documents the causes, duration, and impact of any production stoppages.

- Efficiency Metrics: Analyzes machine utilization and operator performance to identify improvement areas.

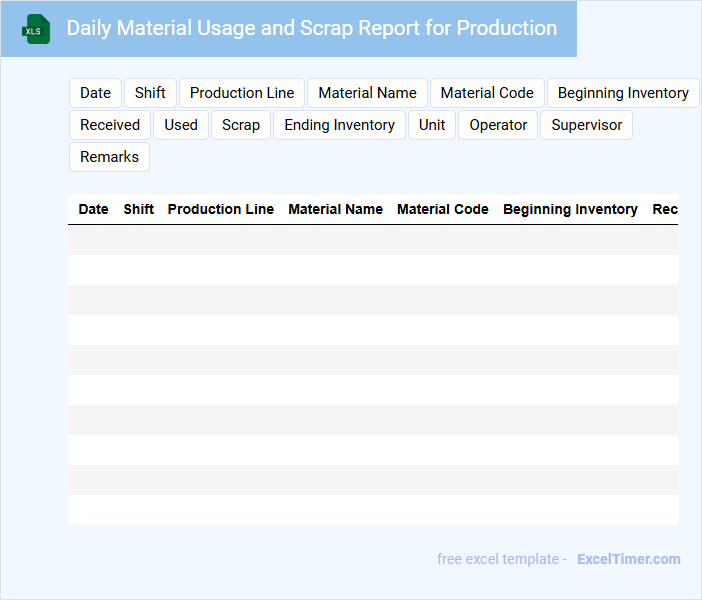

Daily Material Usage and Scrap Report for Production

The Daily Material Usage and Scrap Report is a critical document that tracks the quantity and type of materials consumed and the amount of scrap generated during production. It helps monitor efficiency and identify areas of waste in the manufacturing process.

Typically, this report includes details such as material quantities issued, scrap reasons, and production timelines. Ensuring accuracy and timely entry of data is important for effective cost control and process improvement.

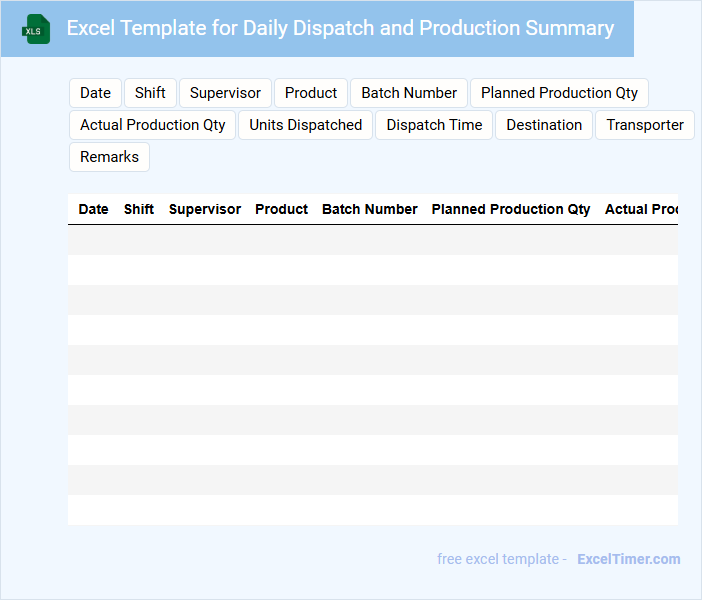

Excel Template for Daily Dispatch and Production Summary

An Excel Template for Daily Dispatch and Production Summary typically contains detailed records of daily shipments and manufacturing output. It is designed to track quantities, times, and personnel involved in dispatch and production activities.

This document is essential for monitoring operational efficiency and ensuring timely delivery. Including accurate date stamps and standardized data entry fields is important for consistency and easy analysis.

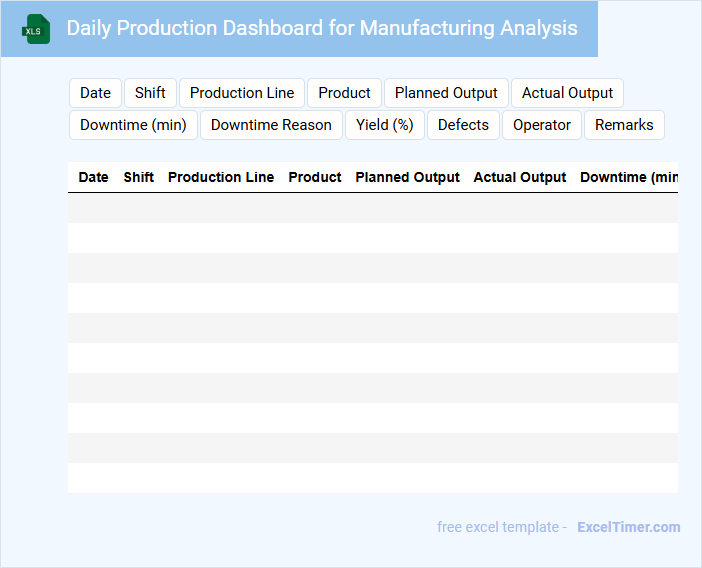

Daily Production Dashboard for Manufacturing Analysis

A Daily Production Dashboard for Manufacturing Analysis typically contains real-time data, key performance indicators, and visual summaries to monitor and optimize production processes.

- Real-time data updates provide immediate insights into production status and machine performance.

- Key performance indicators (KPIs) highlight efficiency, output rates, and quality metrics.

- Visual charts and graphs facilitate quick identification of bottlenecks and trends.

Daily Defect Tracking Sheet for Manufacturing Floor

The Daily Defect Tracking Sheet is a critical document used on the manufacturing floor to record and monitor defects found during production. It provides real-time data that helps in identifying patterns and areas requiring immediate attention. Maintaining accuracy in this sheet ensures effective quality control and continuous improvement.

This sheet typically contains details such as defect types, quantities, time of occurrence, and responsible shifts or teams. Including root cause analysis and corrective actions taken is essential for preventing recurring issues. Regular review meetings based on this document drive proactive problem-solving and operational efficiency.

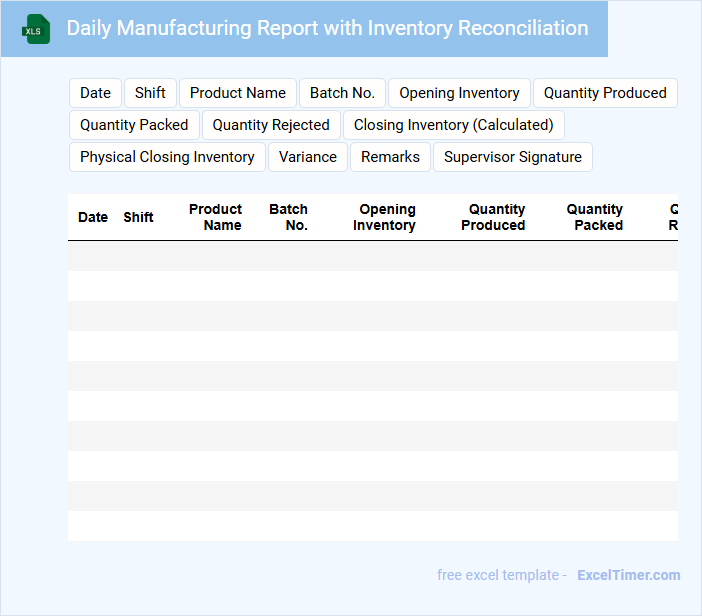

Daily Manufacturing Report with Inventory Reconciliation

The Daily Manufacturing Report with Inventory Reconciliation typically contains production data, inventory levels, and discrepancies between actual and recorded stock. It serves as a critical document for tracking manufacturing performance and ensuring inventory accuracy. Regular review of this report helps in identifying process inefficiencies and potential stock issues early.

What are the key data fields required in a Daily Production Report for manufacturing units?

A Daily Production Report for manufacturing units must include key data fields such as production date, shift details, machine or production line ID, product codes, quantities produced, raw material usage, and labor hours. Your report should also track downtime reasons, quality control results, and scrap or rework volumes to ensure comprehensive production analysis. Capturing these critical metrics helps optimize operational efficiency and maintain accurate production records.

How is actual production quantity tracked and compared against planned targets in the report?

The Daily Production Report in your Excel document tracks actual production quantity by recording real-time output data from manufacturing units. It compares these figures against planned targets using embedded formulas and charts, highlighting variances for performance analysis. This approach ensures accurate monitoring and timely adjustments to meet production goals.

What formulas or functions are essential for calculating efficiency and downtime?

Your Daily Production Report in Excel should use the formula = (Actual Output / Standard Output) * 100 to calculate efficiency percentage. To track downtime, apply =SUMIFS(Downtime_Range, Date_Range, Today()) to aggregate downtime hours per day. Utilizing these functions ensures accurate monitoring of manufacturing unit performance and productivity.

How is raw material consumption recorded and reconciled in the Daily Production Report?

Raw material consumption in the Daily Production Report is recorded by tracking the quantities issued from inventory against the production output for each manufacturing unit. The report reconciles consumption by comparing raw material usage with production data and inventory records to identify discrepancies. This ensures accurate monitoring of material efficiency and cost control.

How can the report be structured in Excel to show shifts, operators, and production lines distinctly?

Organize your Daily Production Report in Excel by creating separate sheets or tables for each production line, with columns dedicated to shifts, operators, and output metrics. Use filters and conditional formatting to clearly distinguish shifts and highlight operator performance. Incorporate pivot tables to summarize production data for efficient analysis and reporting.