The Daily Production Report Excel Template for Manufacturing Workers streamlines tracking of daily output, labor hours, and machinery usage, enhancing operational efficiency. It allows managers to monitor productivity, identify bottlenecks, and ensure quality control with easy-to-analyze data. Customizable fields provide flexibility to match specific manufacturing processes and reporting needs.

Daily Production Report Excel Template for Manufacturing Workers

The Daily Production Report Excel Template for manufacturing workers typically contains essential data such as production quantities, machine usage, and worker shifts to track daily output effectively. It helps in identifying bottlenecks and ensuring quality control by providing a structured format for recording and analyzing manufacturing metrics. Regularly updating this document enhances operational efficiency and supports timely decision-making in the production process.

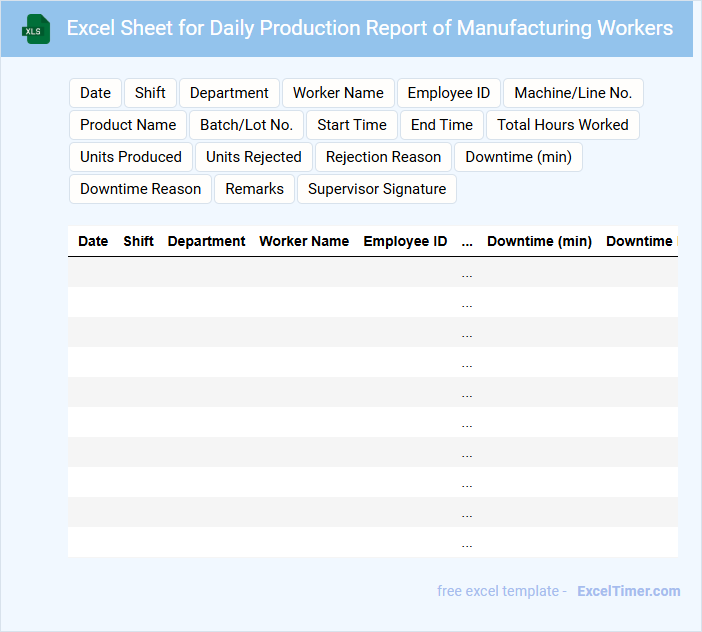

Excel Sheet for Daily Production Report of Manufacturing Workers

An Excel Sheet for Daily Production Report is a structured document designed to track the daily output of manufacturing workers. It typically contains details such as worker names, production targets, actual output, and any discrepancies. This report helps in monitoring productivity and identifying areas for operational improvement.

Important elements to include are clear headers for each data category, date fields to filter reports easily, and automated formulas to calculate totals or averages. Ensuring data accuracy and real-time updates will enhance decision-making and workforce management. Additionally, incorporating charts or graphs can provide quick visual insights into production trends.

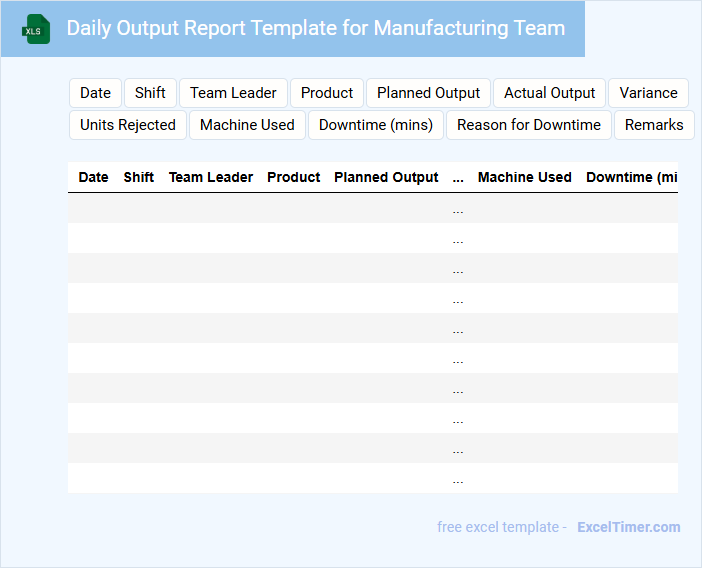

Daily Output Report Template for Manufacturing Team

A Daily Output Report Template for Manufacturing Team typically contains detailed records of the daily production activities, including quantities produced, machine performance, and any issues faced during the shift. It helps track productivity and ensures smooth workflow management.

- Include the date, shift details, and team members involved for clear accountability.

- Record quantity produced, equipment status, and downtime to monitor efficiency.

- Note any quality issues or safety incidents to address before the next shift.

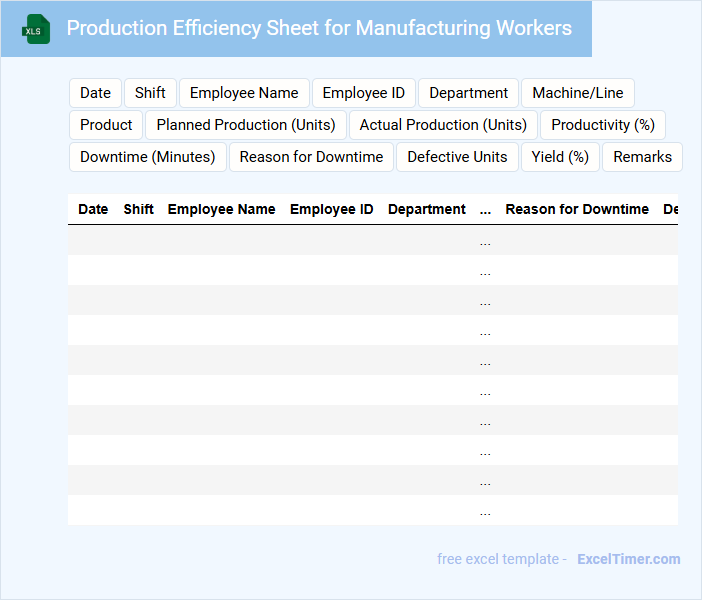

Production Efficiency Sheet for Manufacturing Workers

What information is typically included in a Production Efficiency Sheet for Manufacturing Workers? This document usually contains data on the number of units produced, the time taken for production, and the efficiency rate of each worker. It serves as a key tool to monitor performance, identify bottlenecks, and improve overall productivity on the manufacturing floor.

What important factors should be considered when creating a Production Efficiency Sheet? Accuracy in recording production data and time metrics is crucial to ensure reliable analysis. Additionally, including space for notes on operational issues or suggestions can help in addressing challenges and enhancing worker performance effectively.

Daily Production Log for Manufacturing Operations

The Daily Production Log is a critical document in manufacturing operations, recording all activities and events that occur during a production day. It typically contains data on production quantities, machine performance, and any issues encountered.

This log helps maintain transparency and provides a historical record for troubleshooting and improving efficiency. Ensuring accuracy and timeliness in entries is an important aspect to maximize its effectiveness.

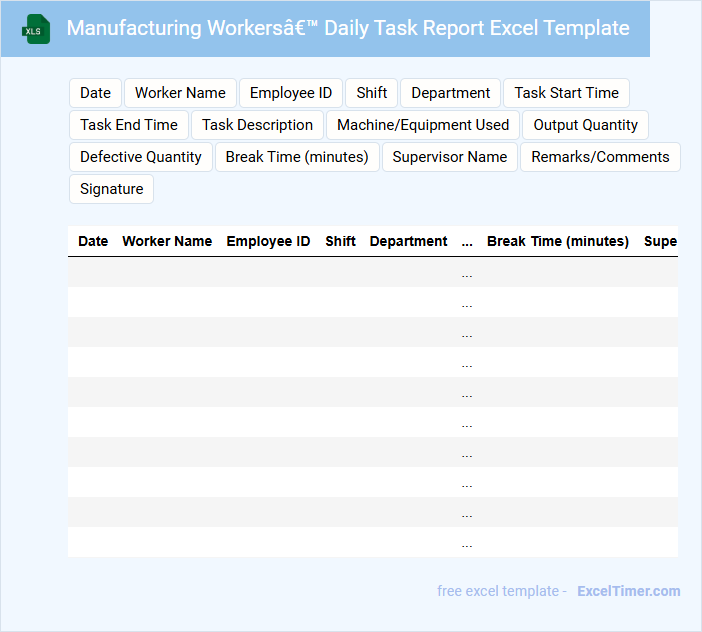

Manufacturing Workers’ Daily Task Report Excel Template

The Manufacturing Workers' Daily Task Report Excel Template is typically used to document daily assignments, progress, and output of workers on the manufacturing floor. It often includes detailed sections for task descriptions, hours worked, and any issues encountered during shifts. This template helps streamline workflow tracking and improve overall productivity tracking.

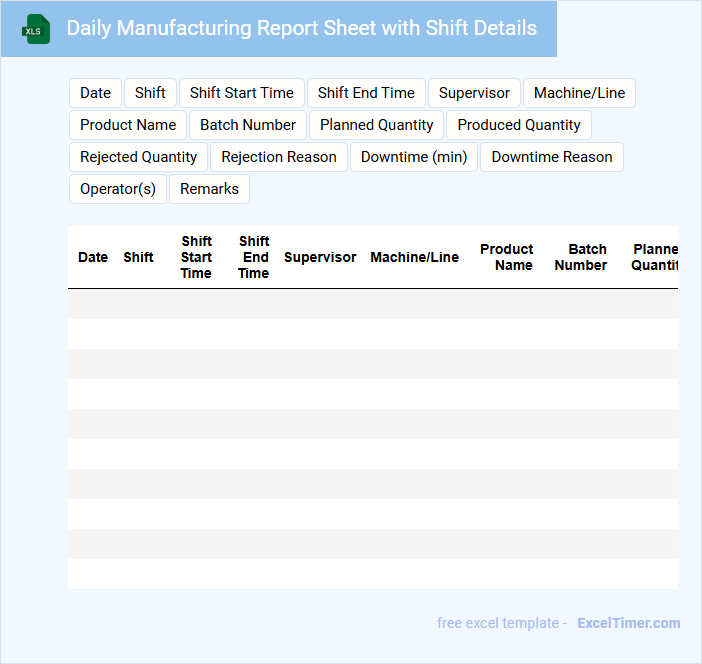

Daily Manufacturing Report Sheet with Shift Details

A Daily Manufacturing Report Sheet with Shift Details is a vital document used to track production activities on a day-to-day basis across different shifts. It typically contains information such as production quantities, machine utilization, downtime, and quality metrics. Including detailed shift information helps in analyzing performance variations and identifying areas for improvement.

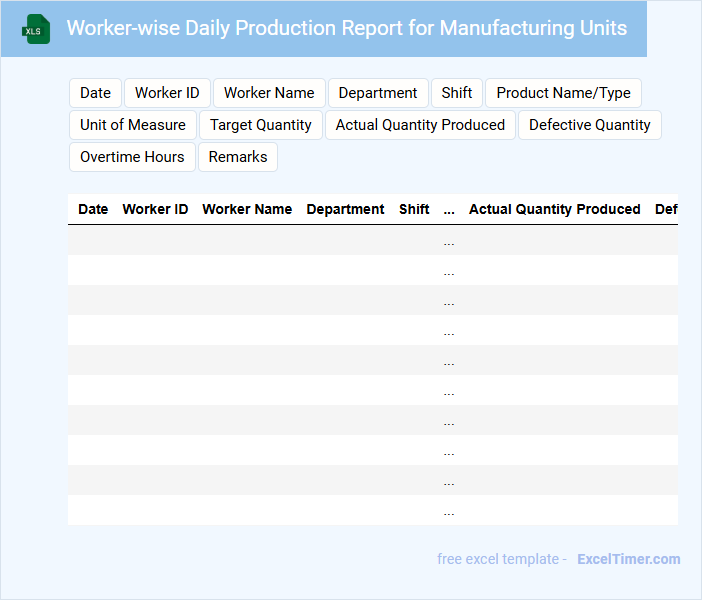

Worker-wise Daily Production Report for Manufacturing Units

A Worker-wise Daily Production Report typically contains detailed information about the daily output of each worker within a manufacturing unit. It tracks individual performance, production quantity, and quality metrics to identify productivity trends. This document is essential for monitoring efficiency and addressing any operational issues promptly.

Excel Template for Daily Output Tracking of Manufacturing Workers

An Excel Template for daily output tracking is designed to record and monitor the productivity of manufacturing workers efficiently. It typically contains fields for worker names, tasks, output quantities, and timestamps.

Such a document emphasizes accuracy and ease of data entry to maintain reliable records over time. Important elements include clear input validation, automated calculations, and summaries for quick performance reviews.

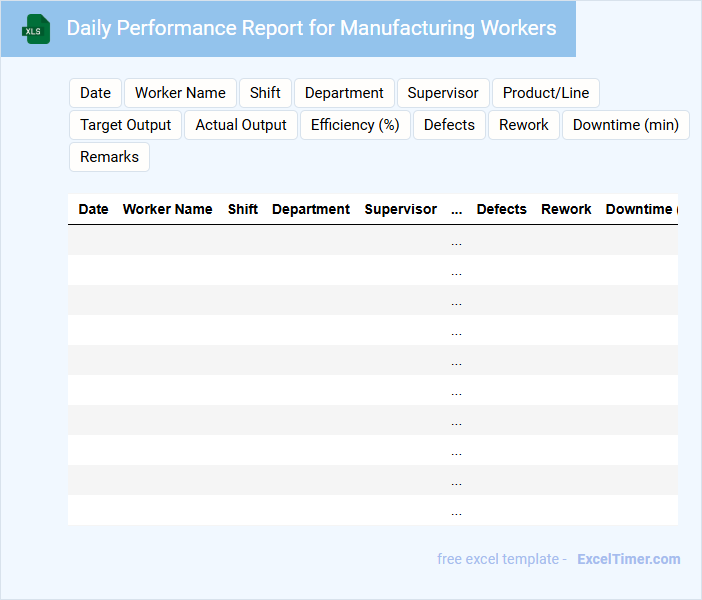

Daily Performance Report for Manufacturing Workers

The Daily Performance Report for manufacturing workers typically contains essential data on individual productivity, machine operation efficiency, and quality control outcomes. This document helps supervisors track daily outputs, identify bottlenecks, and ensure production targets are met. Including clear metrics and timely updates is crucial for maintaining workflow and improving overall factory performance.

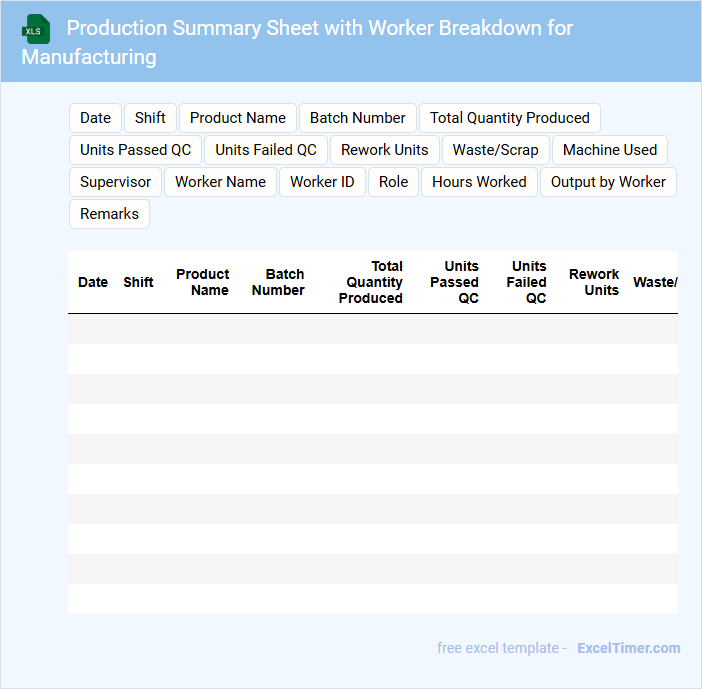

Production Summary Sheet with Worker Breakdown for Manufacturing

The Production Summary Sheet typically contains detailed records of manufacturing output, including quantities produced, timeframes, and machinery used. It also provides a comprehensive worker breakdown, outlining individual contributions and labor hours. This document serves as a vital tool for tracking productivity and identifying areas for process optimization.

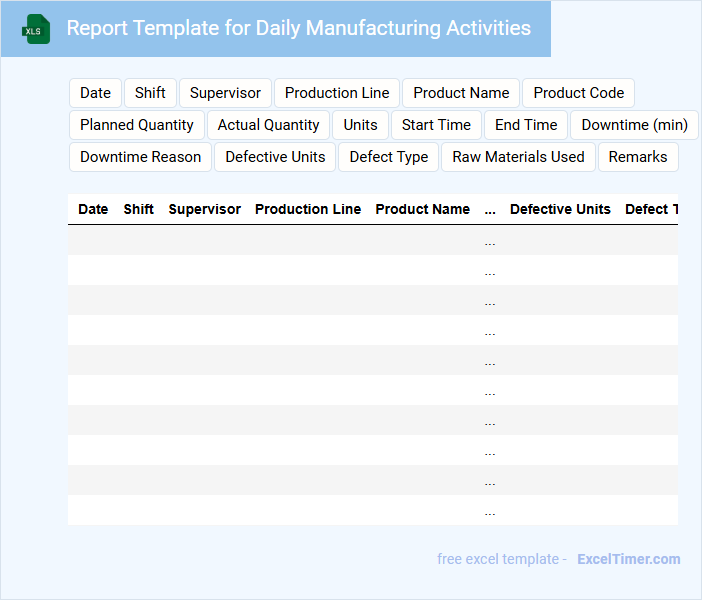

Report Template for Daily Manufacturing Activities

A Report Template for Daily Manufacturing Activities typically contains detailed records of production output, equipment status, and workforce performance. It helps in tracking daily progress and identifying bottlenecks in the manufacturing process. Ensuring accuracy and consistency in data entry is crucial for effective decision-making.

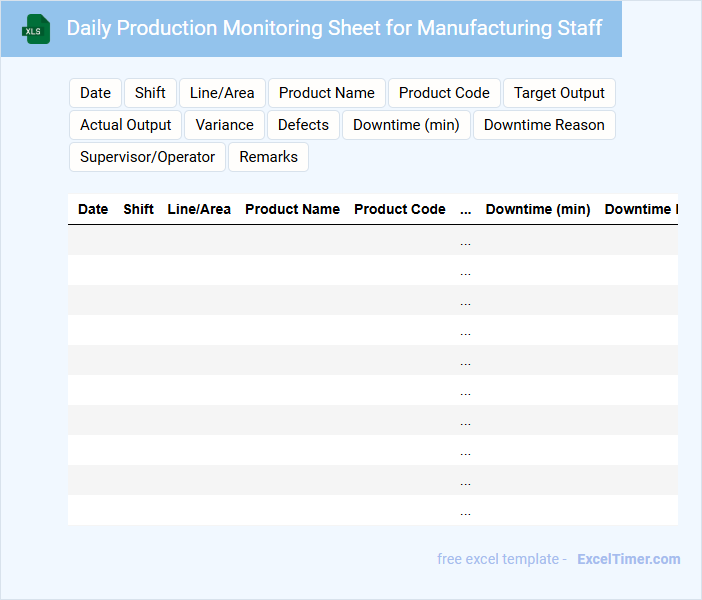

Daily Production Monitoring Sheet for Manufacturing Staff

A Daily Production Monitoring Sheet for Manufacturing Staff typically contains essential data to track daily output and operational efficiency.

- Output Records: Document the quantity produced per shift to monitor productivity trends.

- Quality Checks: Include inspection results to ensure product standards are consistently met.

- Downtime Tracking: Record any machine or process stoppages to identify and address production bottlenecks.

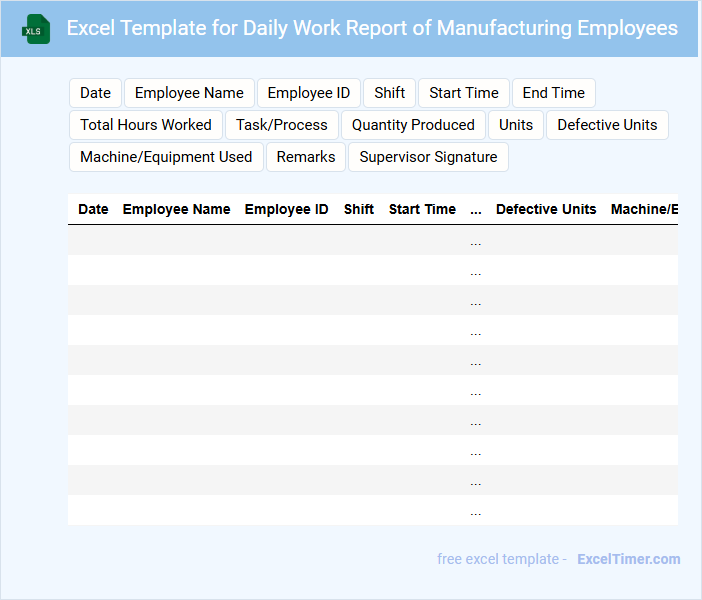

Excel Template for Daily Work Report of Manufacturing Employees

This document is an Excel template designed to streamline the daily work reporting process for manufacturing employees. It typically contains fields for recording tasks completed, hours worked, and any issues encountered during the shift. The template helps ensure consistent and accurate data collection for performance tracking and operational efficiency.

Important elements to include are clear headers for date, employee name, department, task description, start and end times, and comments for additional notes. Incorporating drop-down lists for task types can improve data uniformity. Additionally, formulas to calculate total hours and highlight incomplete entries ensure data integrity and ease of use.

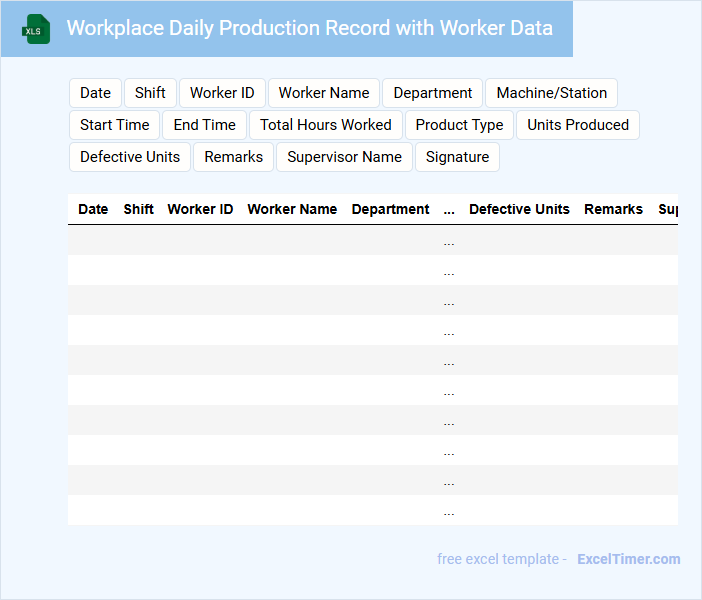

Workplace Daily Production Record with Worker Data

Workplace Daily Production Record with Worker Data is a crucial document used to track the daily output and performance of workers in a production environment. This record typically contains detailed information such as worker names, hours worked, tasks completed, and production quantities. Maintaining accurate production records helps in monitoring efficiency, identifying bottlenecks, and ensuring accountability on the shop floor.

What key data fields should be included in a Daily Production Report for manufacturing workers?

A Daily Production Report for manufacturing workers should include key data fields such as production date, worker ID, shift details, total units produced, units rejected or defective, machine or workstation used, and total hours worked. Recording downtime incidents and reasons enhances accuracy in tracking productivity and identifying bottlenecks. Quality metrics and operator comments provide valuable insights for continuous improvement in manufacturing processes.

How do you track and record the number of units produced versus the production target in Excel?

You can track and record the number of units produced versus the production target in Excel by creating columns for daily production output and target goals, then using formulas like SUM or COUNT to calculate totals. Conditional formatting highlights when production meets or exceeds targets, providing visual cues for performance assessment. PivotTables and charts summarize and analyze production data for manufacturing workers efficiently.

Which Excel formulas or functions help calculate efficiency or productivity rates from daily production data?

Excel formulas like =SUM to total units produced and =AVERAGE to find average output per worker enable basic productivity analysis. The =IF function combined with =DIVIDE calculates efficiency rates by comparing actual output against target production. Advanced users apply =VLOOKUP or =INDEX-MATCH to integrate worker-specific data, enhancing daily production performance insights.

How can you monitor and highlight machine downtime or worker absences in the report?

Monitor machine downtime and worker absences in the Daily Production Report by integrating time-stamped logs and attendance records into Excel. Use conditional formatting to highlight cells with zero production, unplanned downtime, or missing worker hours for quick identification. Implement pivot tables and charts to analyze trends and correlate downtime causes with specific shifts or machines.

What method would you use in Excel to visualize production trends or performance over multiple days?

You can use Excel's line charts to effectively visualize production trends or performance over multiple days in your Daily Production Report. By plotting daily output on the y-axis and dates on the x-axis, these charts highlight fluctuations and patterns clearly. This method helps manufacturing workers quickly assess productivity changes and optimize processes.