The Daily Quality Control Excel Template for Food Processing is designed to streamline monitoring of critical quality parameters, ensuring consistent product safety and compliance with industry standards. This template enables efficient tracking of variables such as temperature, pH levels, and contamination risks, facilitating early detection of potential issues. Accurate data entry and analysis through this tool support continuous improvement and regulatory adherence in food production processes.

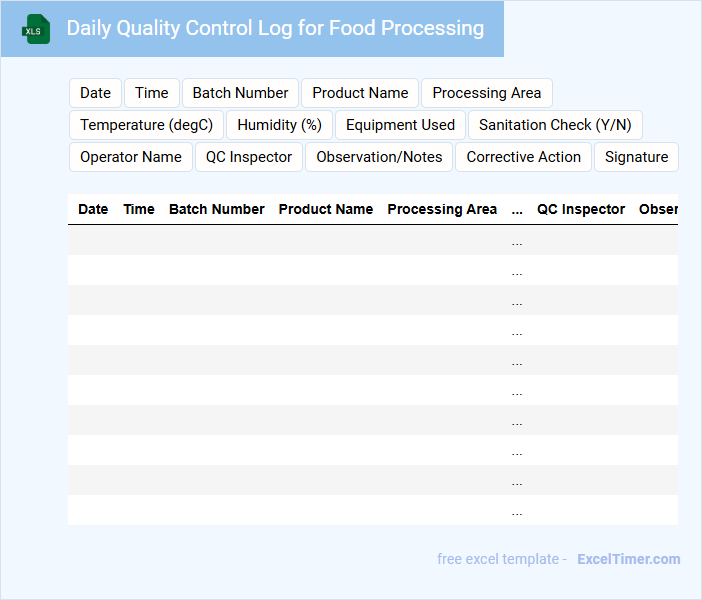

Daily Quality Control Log for Food Processing

What information is typically documented in a Daily Quality Control Log for Food Processing? This document usually contains records of daily inspections, temperature checks, equipment maintenance, and microbial test results to ensure food safety and quality standards are met. It serves as a critical tool for tracking compliance and identifying any deviations in the production process promptly.

What important elements should be included to optimize effectiveness? Key details such as date and time of each check, specific parameters measured, responsible personnel initials, and corrective actions taken should be clearly recorded. Maintaining accuracy and consistency in entries enhances traceability and supports audits or safety investigations.

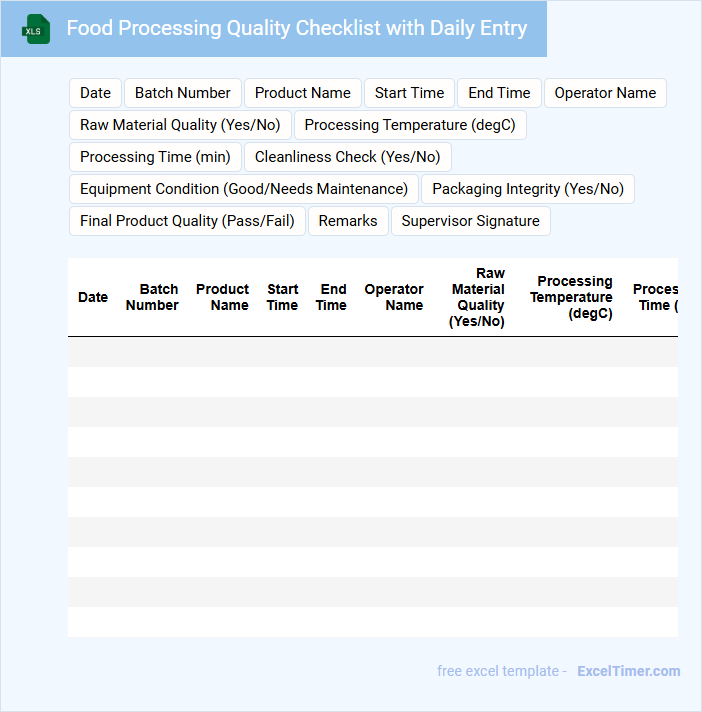

Food Processing Quality Checklist with Daily Entry

A Food Processing Quality Checklist with Daily Entry is a critical document used to ensure consistent product standards and safety in food production. It typically contains detailed checkpoints on hygiene, equipment sanitation, temperature control, and ingredient quality. Regular daily entries help track compliance and identify areas for immediate corrective action.

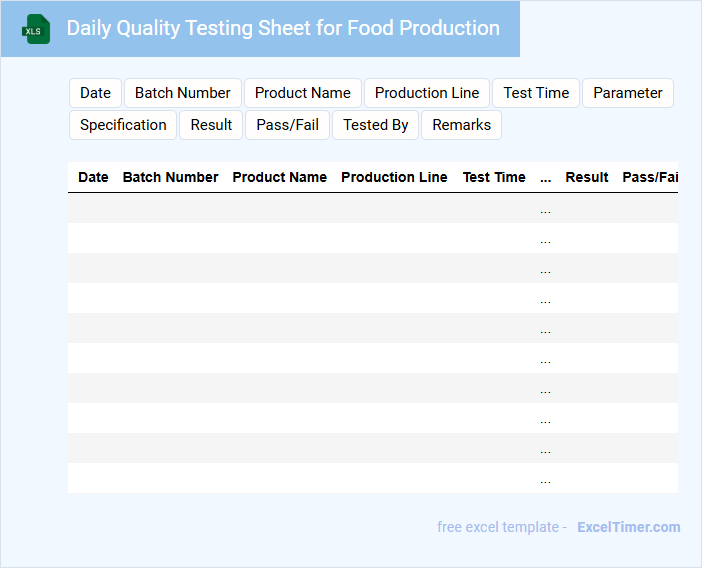

Daily Quality Testing Sheet for Food Production

What information is typically included in a Daily Quality Testing Sheet for Food Production? This document usually contains detailed records of various quality parameters such as temperature, texture, taste, and contamination levels for products tested throughout the production day. It helps ensure that all food items meet safety and quality standards consistently.

Why is it important to include traceability and corrective actions in the Daily Quality Testing Sheet? Including batch numbers, testing times, and responsible personnel ensures accountability and facilitates quick identification of issues. Documenting corrective measures is crucial for continuous improvement and compliance with food safety regulations.

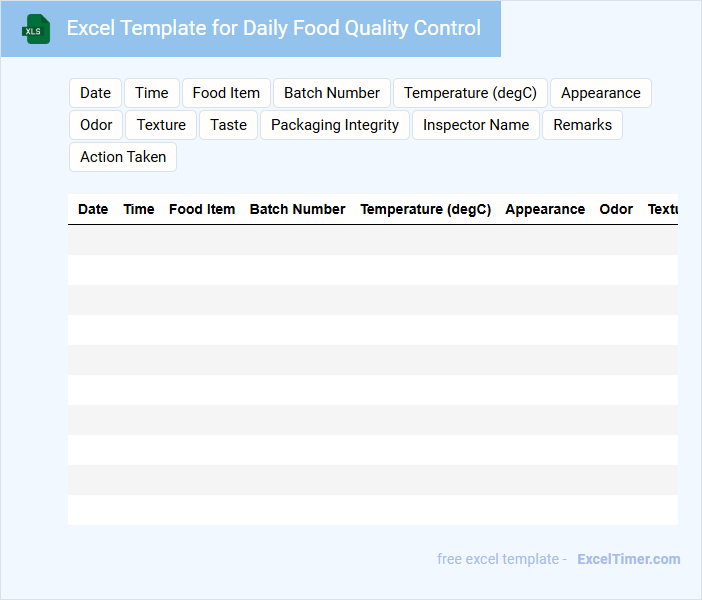

Excel Template for Daily Food Quality Control

An Excel Template for Daily Food Quality Control typically includes sections for recording inspection data, tracking food safety parameters, and noting corrective actions. It helps ensure consistent monitoring of food quality by capturing temperature readings, hygiene checks, and expiry dates. Utilizing this template supports regulatory compliance and enhances overall food safety management.

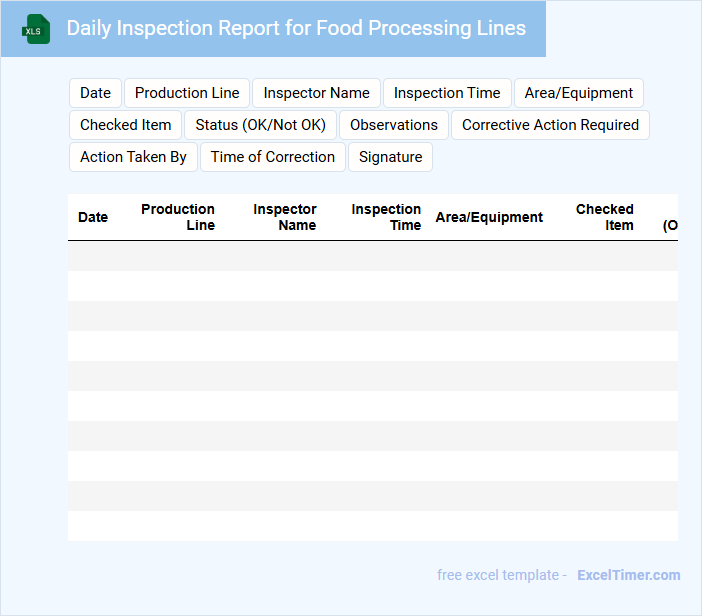

Daily Inspection Report for Food Processing Lines

A Daily Inspection Report for Food Processing Lines typically contains detailed observations about equipment functionality, hygiene standards, and safety compliance to ensure smooth operation. It helps in maintaining quality control and identifying potential issues early.

- Check and record the condition of all machinery and processing equipment.

- Verify cleanliness and sanitation levels throughout the processing line.

- Document any deviations or malfunctions and actions taken for correction.

Quality Control Register with Daily Tracking for Food Plants

What information is usually recorded in a Quality Control Register with Daily Tracking for Food Plants? This document typically contains detailed entries of daily quality inspections, test results, and any deviations observed in the production process. It helps ensure that all food safety and quality standards are consistently met throughout manufacturing.

Why is maintaining such a register important? Maintaining an accurate Quality Control Register enables timely identification of issues, supports regulatory compliance, and facilitates continuous improvement by providing a reliable record of plant performance and corrective actions.

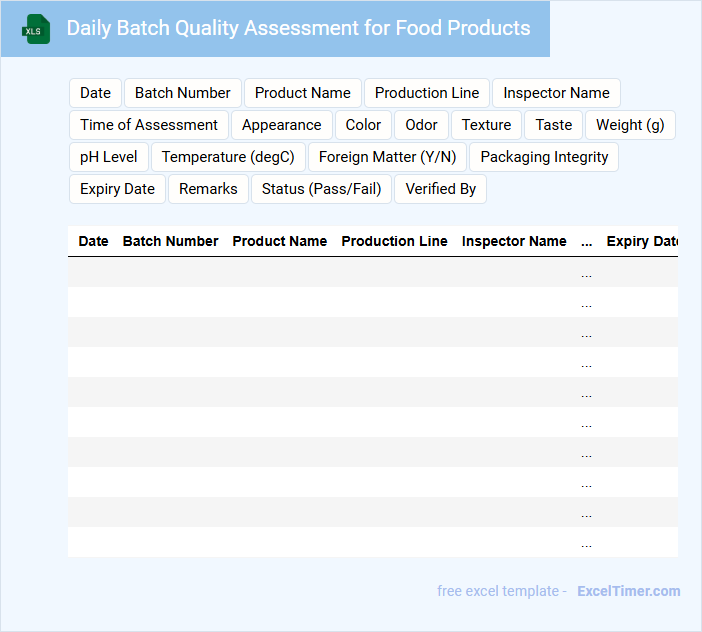

Daily Batch Quality Assessment for Food Products

What information is typically included in a Daily Batch Quality Assessment for Food Products? This document usually contains detailed records of the quality parameters, sensory evaluations, and compliance checks conducted on each batch produced daily. It helps ensure that food products meet safety standards and consistency requirements before distribution.

Why is maintaining a Daily Batch Quality Assessment important for food manufacturers? Regular assessments enable early detection of potential quality issues, reducing the risk of contamination or defects. It is essential to include critical control points, ingredient traceability, and corrective actions to maintain product integrity and consumer safety.

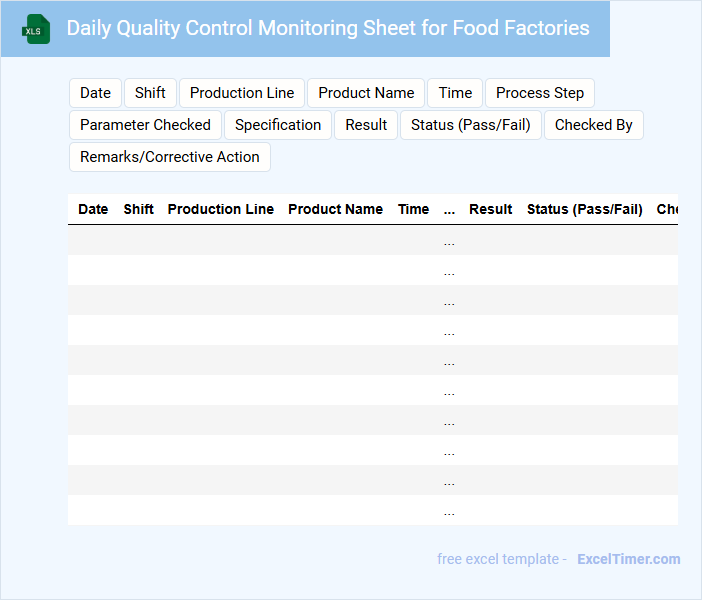

Daily Quality Control Monitoring Sheet for Food Factories

What information is typically included in a Daily Quality Control Monitoring Sheet for Food Factories? This document usually contains data on critical control points such as temperature readings, hygiene checks, and equipment calibration results. It helps ensure that the food production process consistently meets safety and quality standards to prevent contamination and maintain product integrity.

What important elements should be included for effective monitoring? Key details like date, shift time, operator name, specific parameters being checked, acceptable limits, and corrective actions taken must be recorded. This structured information allows quick identification of issues and supports regulatory compliance and continuous improvement in food quality.

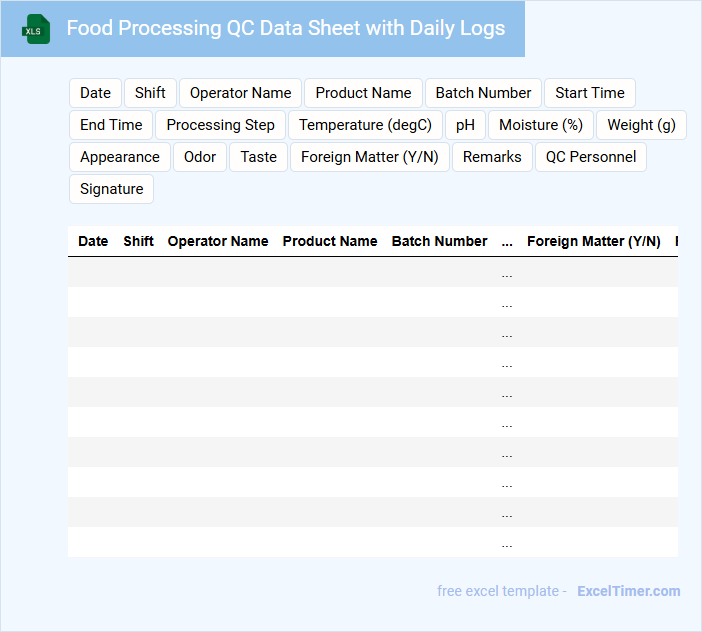

Food Processing QC Data Sheet with Daily Logs

A Food Processing QC Data Sheet with Daily Logs is a document used to record and monitor quality control parameters throughout food production. It typically contains detailed entries such as temperature checks, equipment calibration, and hygiene standards verified daily. This record ensures compliance with safety regulations and helps identify any deviations early in the process.

Excel Daily Record for Quality Control of Food Processing

An Excel Daily Record for Quality Control in food processing typically contains detailed logs of production parameters, temperature checks, and hygiene inspections to ensure compliance with safety standards. It also tracks raw material usage and output quality to monitor consistency and detect any deviations.

Maintaining accurate and up-to-date records helps identify trends and potential issues early, facilitating timely corrective actions. Regular audits and staff training on data entry accuracy are important to sustain the reliability of these records.

Daily Food Quality Checklist for Processing Plants

What does a Daily Food Quality Checklist for Processing Plants usually contain? This type of document typically includes detailed criteria for monitoring the quality and safety of food products throughout the processing stages. It outlines daily inspections, sanitation checks, and compliance with regulatory standards to ensure product consistency and safety.

What important aspects should be included in the checklist? Key elements should cover equipment cleanliness, employee hygiene, ingredient verification, temperature control, and proper labeling. Regularly updating and training staff on this checklist ensures ongoing adherence to food safety protocols and reduces the risk of contamination.

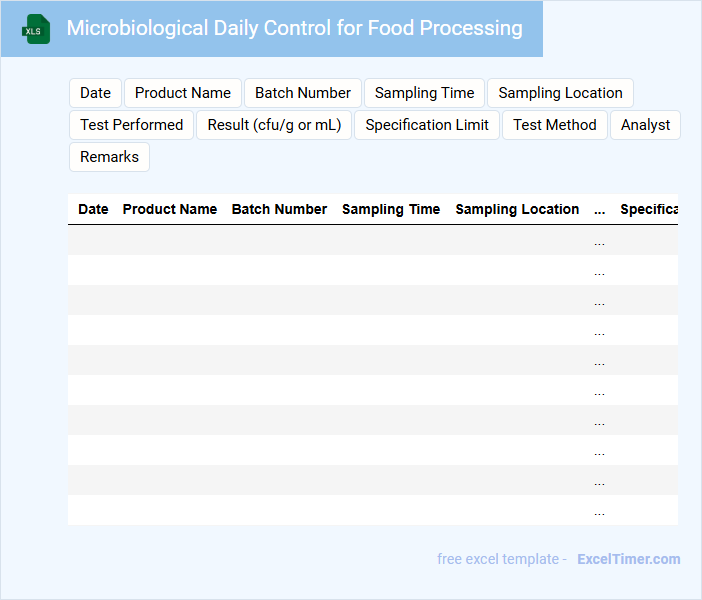

Microbiological Daily Control for Food Processing

The Microbiological Daily Control document for food processing typically contains records of microbial counts to ensure food safety and hygiene standards are continuously met. It includes data on the types and levels of microorganisms detected in raw materials, processing environments, and finished products. Maintaining accurate and timely entries in this document is crucial for identifying contamination risks and implementing corrective actions promptly.

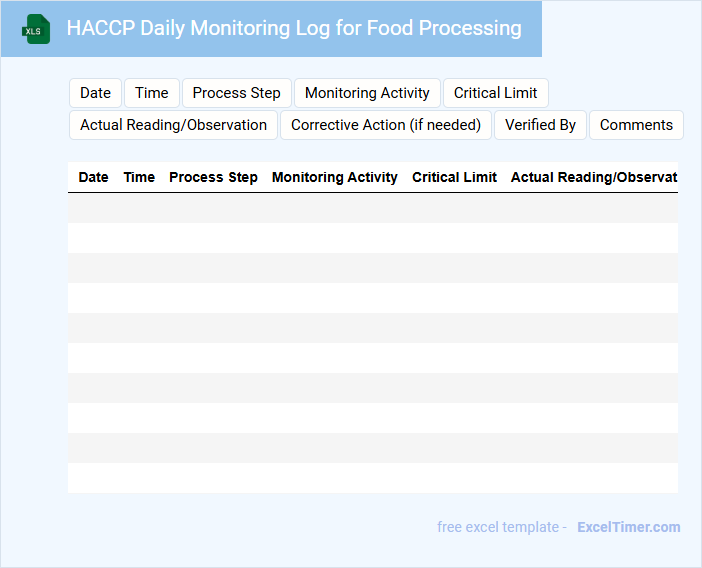

HACCP Daily Monitoring Log for Food Processing

The HACCP Daily Monitoring Log is a critical document used in food processing to record daily observations of critical control points. It typically contains data on temperature readings, equipment checks, and sanitation verification to ensure food safety standards are consistently met. Maintaining accurate logs helps in early detection of potential hazards and compliance with regulatory requirements.

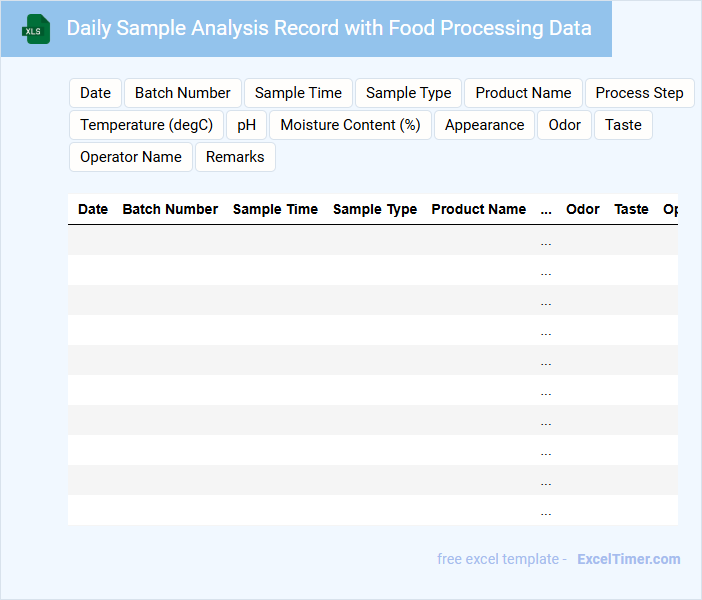

Daily Sample Analysis Record with Food Processing Data

What information is typically included in a Daily Sample Analysis Record with Food Processing Data? This document usually contains detailed records of the samples analyzed on a daily basis, including parameters such as quality, composition, and safety indicators relevant to food processing. It serves as a critical tool to ensure consistent product standards and compliance with regulatory requirements.

Why is it important to maintain accurate and thorough records in this document? Accurate documentation helps trace any deviations in the production process and supports quality control efforts to prevent contamination or product failures. Consistent record-keeping also facilitates timely decision-making and continuous improvement in food processing operations.

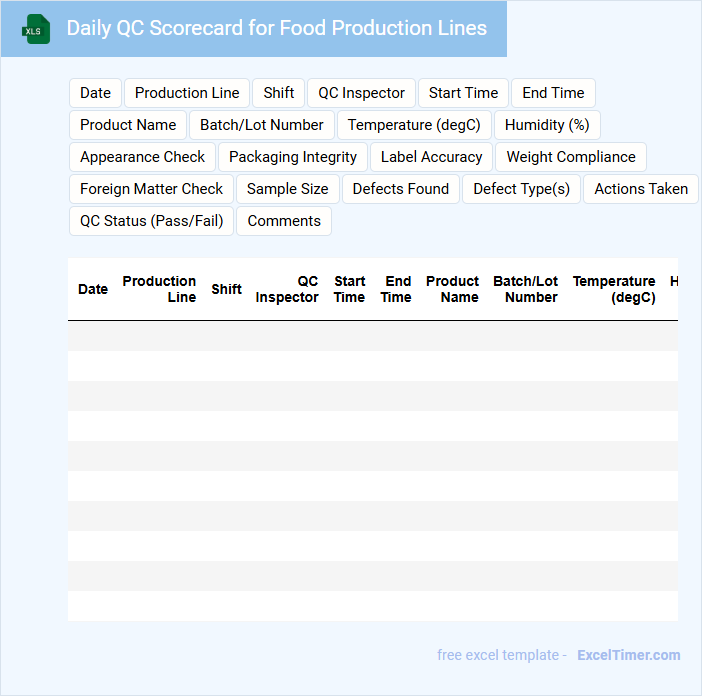

Daily QC Scorecard for Food Production Lines

A Daily QC Scorecard for Food Production Lines typically contains key quality control metrics and performance indicators to ensure consistent product standards.

- Inspection Results: Includes detailed records of visual and physical inspections conducted on the production line.

- Defect Tracking: Highlights any defects or deviations found during production with corresponding corrective actions.

- Performance Metrics: Summarizes line efficiency, downtime, and adherence to safety protocols for the day.

What key parameters should be recorded daily in a food processing quality control Excel document?

Your daily quality control Excel document for food processing should record key parameters including temperature readings, microbial test results, pH levels, and sensory evaluation scores. Tracking critical control points such as cooking times and equipment sanitation status ensures compliance with food safety standards. Accurate documentation helps identify trends and prevent contamination, maintaining high product quality.

How can trend analysis be implemented in Excel to monitor daily product quality?

Trend analysis for daily product quality in Excel can be implemented by organizing data in a structured table with date and quality metrics columns. Use Excel chart features like line graphs or sparklines to visualize changes over time and identify patterns or deviations. Apply conditional formatting and formulas such as moving averages or TREND function to highlight trends and forecast future quality performance.

Which columns are essential for tracing non-conformance incidents in daily records?

Essential columns for tracing non-conformance incidents in daily quality control records include Date, Product Batch Number, Inspection Type, Non-Conformance Description, Corrective Action Taken, Responsible Personnel, and Verification Status. These fields enable you to accurately track and address issues in the food processing workflow. Ensuring these columns are consistently filled enhances traceability and compliance.

How can conditional formatting in Excel help highlight out-of-spec measurements?

Conditional formatting in Excel automatically highlights out-of-spec measurements in your Daily Quality Control for Food Processing, making it easy to identify deviations quickly. By setting specific rules based on acceptable value ranges, you can visually flag data points that fall outside quality standards. This feature helps you maintain consistent monitoring and ensures rapid response to potential quality issues.

What formulas are most effective for automatic calculation of daily defect rates?

To automatically calculate daily defect rates in your food processing quality control Excel document, use formulas like =SUM(defect_range)/SUM(total_produced_range) to determine defect percentages. Implementing =IFERROR() around these formulas helps manage division errors on zero production days. Conditional formatting linked to these formulas highlights critical defect thresholds, ensuring real-time quality monitoring.