The Monthly Production Planner Excel Template for Manufacturing helps streamline production schedules by organizing tasks, resources, and timelines efficiently. It enables manufacturers to monitor daily outputs, manage inventory levels, and optimize workforce allocation in one easy-to-use spreadsheet. Accurate planning with this template reduces downtime and improves overall manufacturing productivity.

Monthly Production Planner with Capacity Analysis Excel Template

The Monthly Production Planner with Capacity Analysis Excel Template typically contains detailed schedules of production activities, capacity utilization data, and resource allocation metrics. It is designed to help manufacturers optimize their production flow and ensure efficient use of machinery and labor.

Key components often include projected output volumes, shift planning, and bottleneck identification to improve operational efficiency. Regular updates and accurate forecasting are important to maintain alignment with demand and avoid production delays.

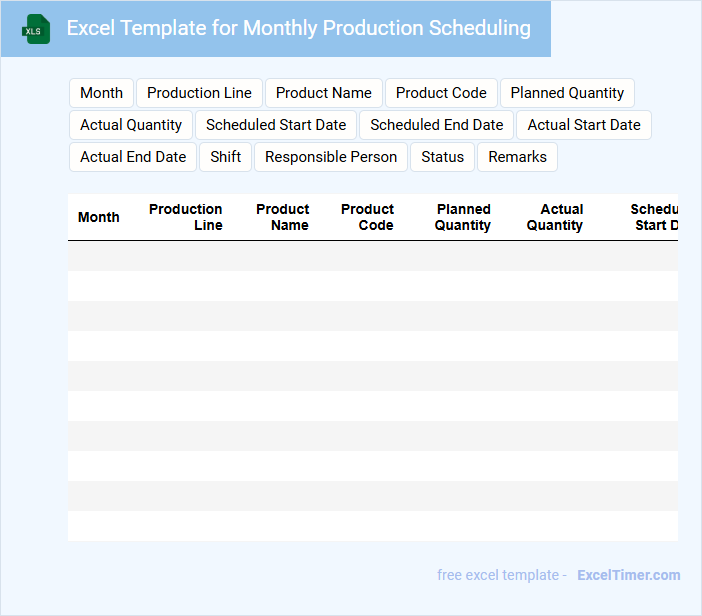

Excel Template for Monthly Production Scheduling

An Excel Template for Monthly Production Scheduling is a structured document used to plan and manage manufacturing activities throughout the month. It helps ensure efficient resource allocation and timely delivery of products.

- Include clear timelines and deadlines for each production phase.

- Incorporate resource availability, such as labor and machinery capacity.

- Provide sections for tracking progress and any deviations from the plan.

Monthly Production Planner with Inventory Tracking

A Monthly Production Planner with Inventory Tracking is a document designed to organize production schedules and monitor inventory levels to optimize manufacturing efficiency.

- Production Schedule: Detailed timelines outlining daily and weekly production targets.

- Inventory Status: Real-time tracking of raw materials and finished goods quantities.

- Resource Allocation: Identification of required labor and machinery for meeting production goals.

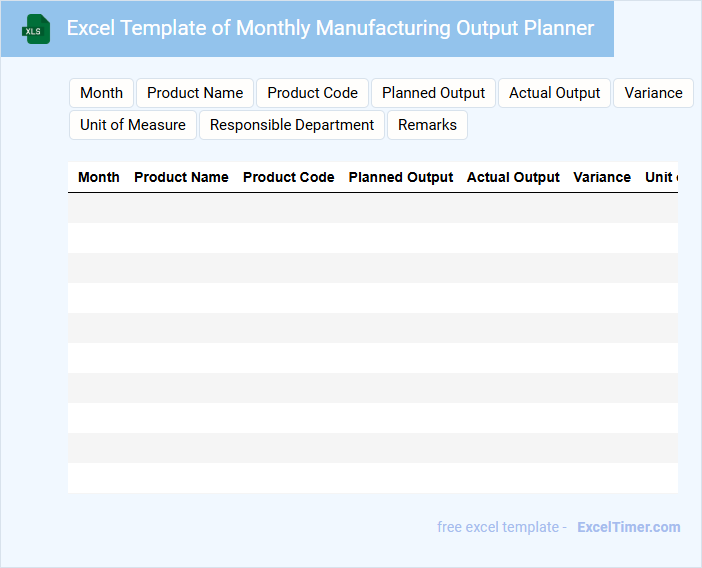

Excel Template of Monthly Manufacturing Output Planner

This Excel Template of Monthly Manufacturing Output Planner is designed to help track and manage production schedules efficiently. It typically contains sections for inputting daily outputs, planned targets, and variance analysis. For best results, ensure to include clear columns for production dates, product categories, and performance metrics for accuracy and ease of use.

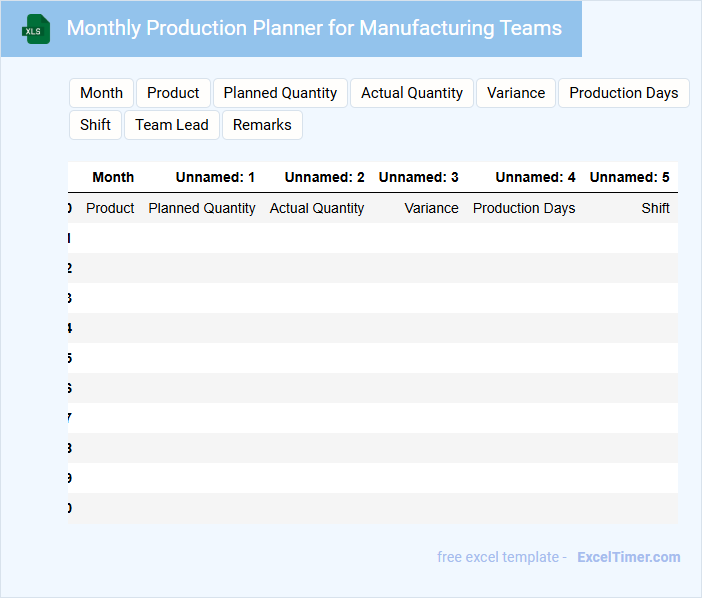

Monthly Production Planner for Manufacturing Teams

The Monthly Production Planner is a critical document outlining the scheduled manufacturing activities for the upcoming month. It typically includes production targets, resource allocation, and timelines to ensure efficient workflow.

This planner helps manufacturing teams coordinate tasks, manage inventory, and anticipate potential bottlenecks. Including contingency plans and clear communication channels is essential for smooth operations.

Excel Template for Production Goals Tracking per Month

An Excel Template for Production Goals Tracking per Month is designed to help businesses monitor and manage their monthly production targets efficiently. It typically includes structured data entry fields and visual tools for performance analysis.

- Include separate columns for planned goals, actual production, and variance to measure performance accurately.

- Incorporate charts or graphs for quick visual comparison of monthly production trends.

- Ensure the template is flexible to adjust for changes in production goals or timeframes.

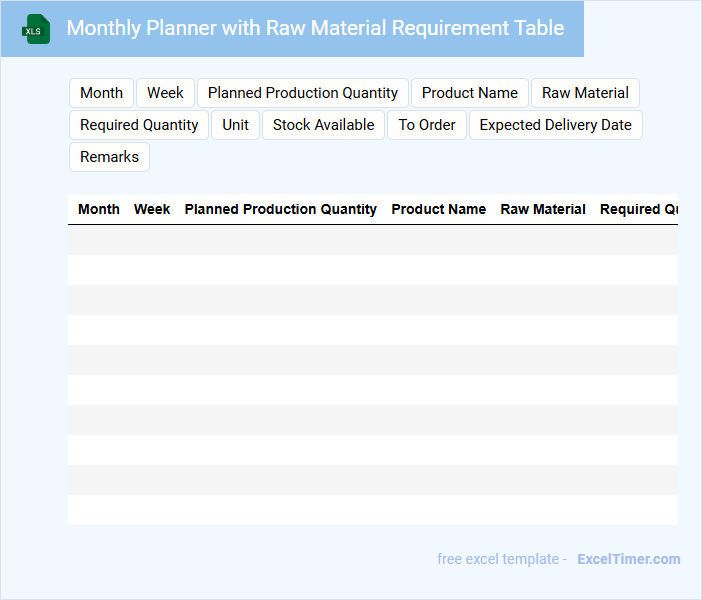

Monthly Planner with Raw Material Requirement Table

A Monthly Planner with Raw Material Requirement Table typically includes a detailed schedule of production activities alongside a comprehensive list of raw materials needed for the period. This document helps organizations track inventory levels, plan procurement, and ensure timely availability of essential materials to avoid production delays. It is crucial for synchronizing supply chain operations and optimizing resource allocation efficiently.

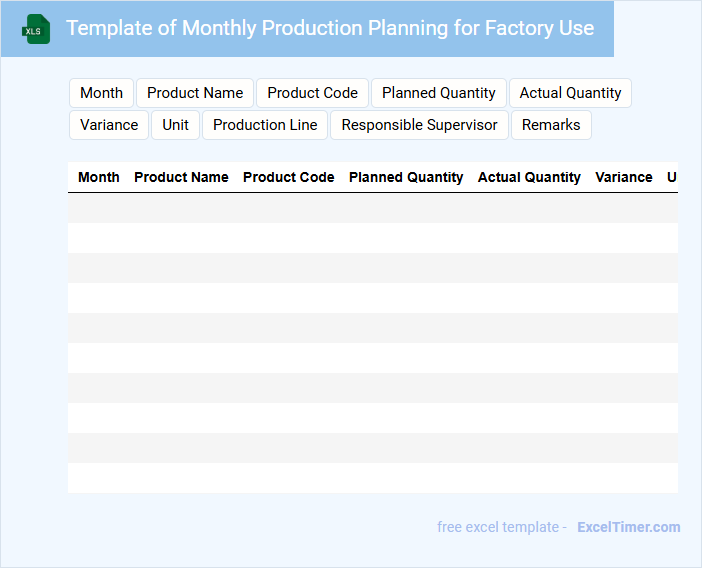

Template of Monthly Production Planning for Factory Use

The Monthly Production Planning template is a structured document used to outline the production schedule for a factory within a specific month. It details the quantities, timelines, and resources required to meet production goals efficiently.

Typically, it includes sections for raw material needs, labor allocation, machine usage, and inventory management to ensure smooth operations. Regular updates and clear communication are crucial to adapting plans to any changes in demand or supply.

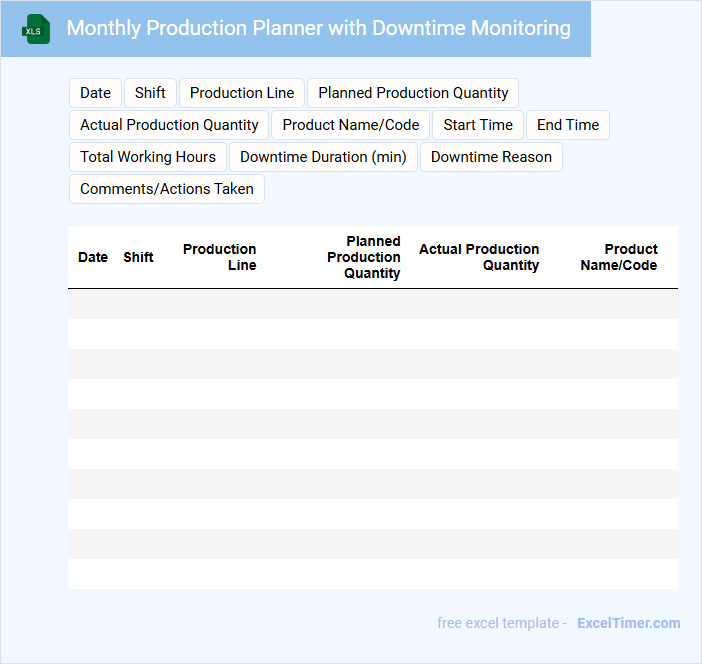

Monthly Production Planner with Downtime Monitoring

A Monthly Production Planner with Downtime Monitoring is a document that outlines scheduled production activities alongside tracking equipment or process downtimes. It typically contains machine usage plans, production targets, and recorded downtime incidents to identify bottlenecks. This enables effective resource allocation and improves overall operational efficiency.

Important aspects to include are clear downtime categories, root cause analysis, and contingency plans to minimize interruptions. Detailed production targets aligned with capacity and realistic timelines ensure achievable goals. Consistent updates and real-time monitoring data are crucial for proactive decision-making and continuous improvement.

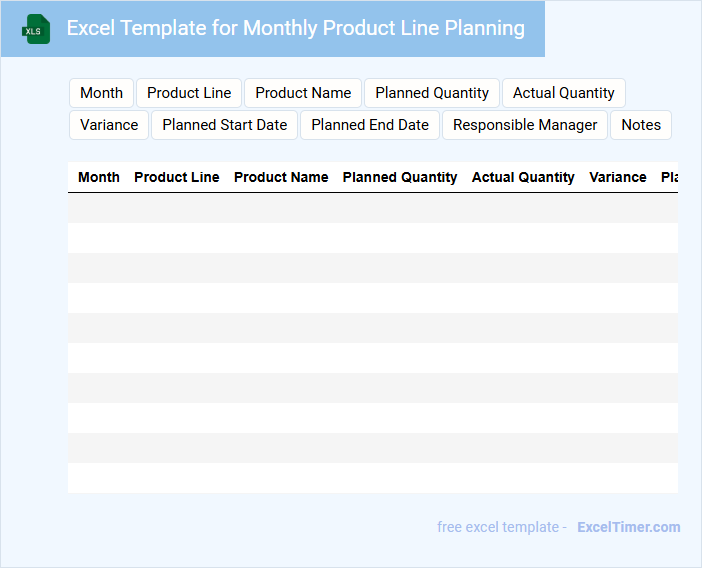

Excel Template for Monthly Product Line Planning

An Excel Template for Monthly Product Line Planning is designed to streamline the organization and tracking of product statuses, sales forecasts, and inventory levels. It typically contains sections for monthly targets, budget allocations, and performance metrics. Using this template helps ensure efficient resource management and strategic decision-making for product development and marketing.

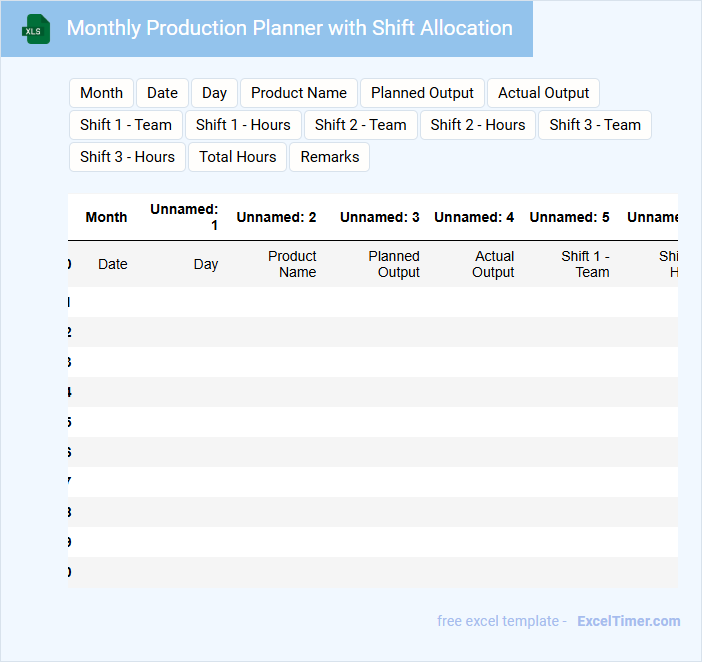

Monthly Production Planner with Shift Allocation

The Monthly Production Planner is a crucial document that outlines the production schedule for the entire month, ensuring that manufacturing targets are met efficiently. It typically contains detailed information on planned output, resource allocation, and timelines.

The Shift Allocation component assigns specific shifts to workers or teams, optimizing labor distribution to maintain continuous production flow. This section helps manage workforce availability and maximize productivity.

For effective use, ensure accurate demand forecasting and clear communication of shift schedules to all relevant departments.

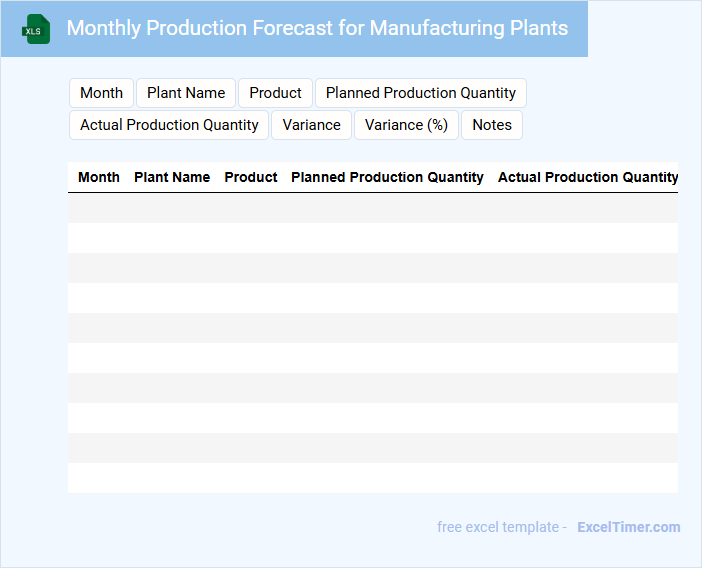

Monthly Production Forecast for Manufacturing Plants

The Monthly Production Forecast is a crucial document that outlines the expected manufacturing output for a specific period. It typically contains detailed projections of product quantities, resource allocation, and potential bottlenecks. This forecast helps in aligning production schedules with demand and optimizing plant efficiency.

To ensure accuracy, it is important to incorporate historical production data, current inventory levels, and market demand trends. Including clear updates on machinery maintenance and workforce availability enhances the reliability of the forecast. Additionally, collaboration between production, sales, and supply chain teams is essential for comprehensive planning.

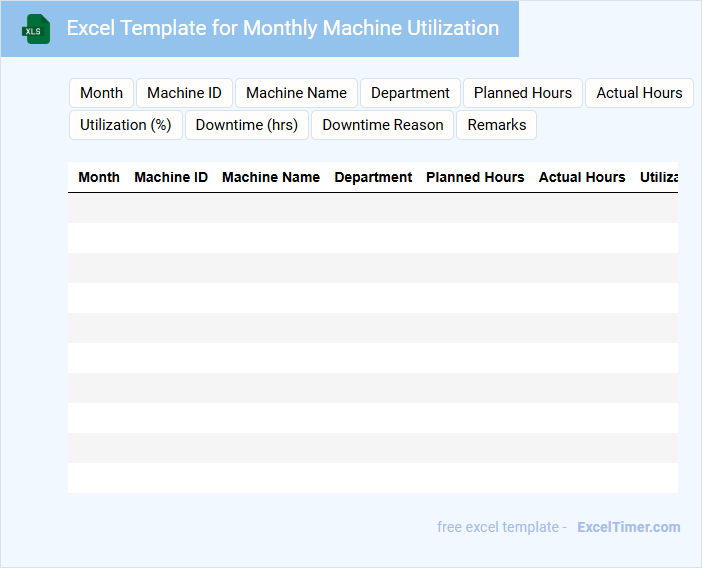

Excel Template for Monthly Machine Utilization

What information is typically included in an Excel Template for Monthly Machine Utilization? This type of document usually contains data such as machine names, operating hours, downtime, and efficiency percentages to track performance over the month. It helps businesses monitor equipment usage, identify maintenance needs, and optimize production schedules for improved productivity.

What are the important considerations when creating or using this template? Ensure accurate input of machine operating times and downtime to get reliable utilization rates, and include visual elements like charts or graphs for quick analysis. Additionally, regularly updating the template and standardizing data entry formats promote consistency and actionable insights.

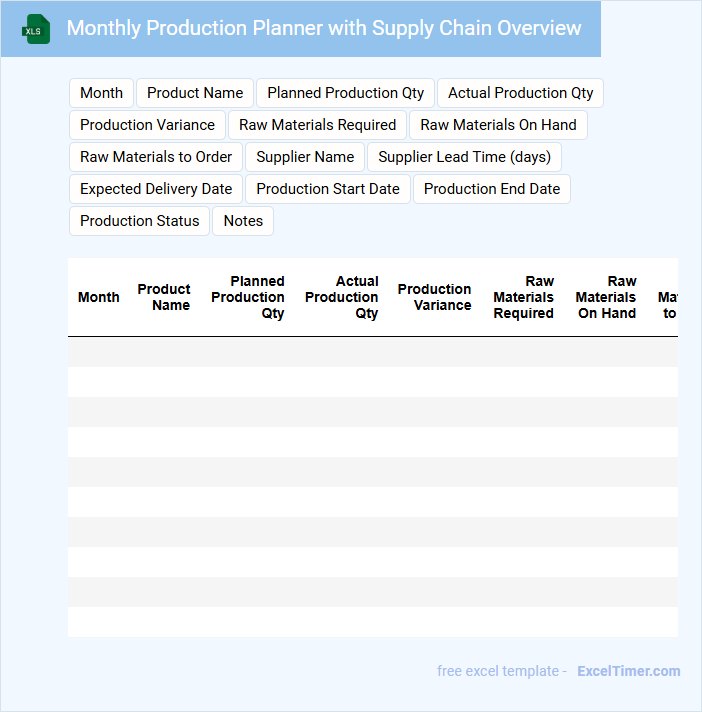

Monthly Production Planner with Supply Chain Overview

A Monthly Production Planner with Supply Chain Overview typically contains detailed schedules of production activities aligned with supply chain logistics. It includes forecasts, inventory levels, and delivery timelines to ensure smooth operations. This document aids in coordinating manufacturing output with supplier capabilities and customer demand.

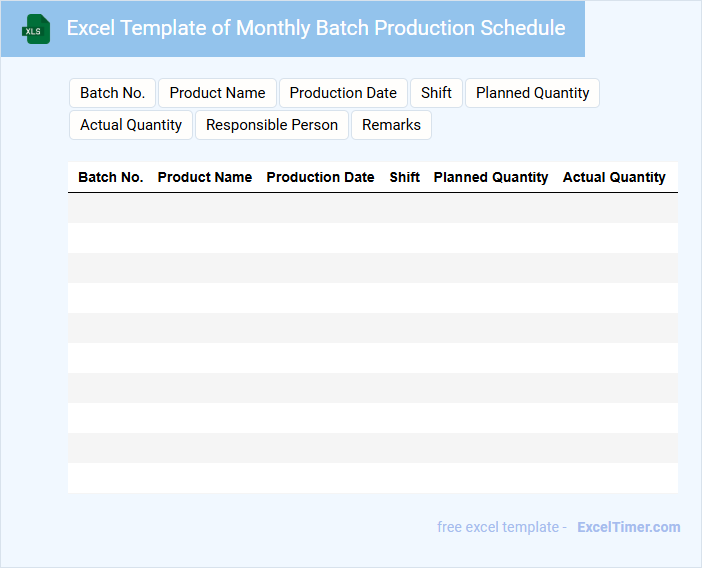

Excel Template of Monthly Batch Production Schedule

An Excel Template for a Monthly Batch Production Schedule typically includes fields for product names, batch numbers, start and end dates, and assigned resources. It organizes production activities chronologically to ensure smooth workflow and timely completion.

This document is essential for tracking multiple batches within a month, monitoring capacity, and managing inventory levels. Including clear milestones and quality checkpoints is highly recommended to enhance efficiency and reduce errors.

What key columns are necessary for tracking daily versus monthly production targets in a Monthly Production Planner?

Key columns for tracking daily versus monthly production targets in a Monthly Production Planner include Date, Product Name, Daily Target, Actual Daily Output, Monthly Target, and Cumulative Monthly Output. You should also include columns for Shift, Machine ID, and Status to monitor real-time production efficiency. These columns enable precise comparison between planned and actual production for effective manufacturing management.

How do you use formulas in Excel to automatically calculate production variances between planned and actual output?

Use Excel formulas like =B2-C2 to subtract Actual Output from Planned Output, showing production variance in corresponding cells. Apply conditional formatting to highlight significant positive or negative variances for quick analysis. Summarize variances using SUM or AVERAGE functions to monitor overall production accuracy monthly.

What methods can be applied to visualize production trends and bottlenecks using Excel charts or graphs?

Excel's Line Charts effectively display monthly production trends by showing output variations over time. Stacked Bar Charts highlight bottlenecks by categorizing production stages and revealing capacity constraints. Conditional Formatting heatmaps visually pinpoint delays and underperforming areas within the production schedule.

Which Excel functions are most effective for summarizing raw material usage and forecasting future needs?

Your Monthly Production Planner can leverage the SUMIFS function to accurately summarize raw material usage by various categories such as date and product type. The FORECAST.ETS function effectively predicts future material needs based on historical consumption trends. Utilizing these functions enhances inventory management and ensures smoother production scheduling.

How can conditional formatting highlight overdue tasks or under-performing production lines in the planner?

Conditional formatting in your Monthly Production Planner can highlight overdue tasks by applying red fill or font color to dates past the current day. Under-performing production lines can be flagged using color scales or icons based on key performance indicators like output rates below target thresholds. This visual differentiation enables you to quickly identify and address critical issues in the manufacturing schedule.