The Monthly Production Schedule Excel Template for Manufacturing is designed to streamline production planning by organizing tasks, timelines, and resource allocation in a clear format. It allows manufacturers to track output, monitor deadlines, and adjust schedules efficiently to meet demand and reduce downtime. Maintaining an updated schedule helps optimize workflow, improve communication among teams, and enhance overall productivity.

Monthly Production Schedule Template for Manufacturing

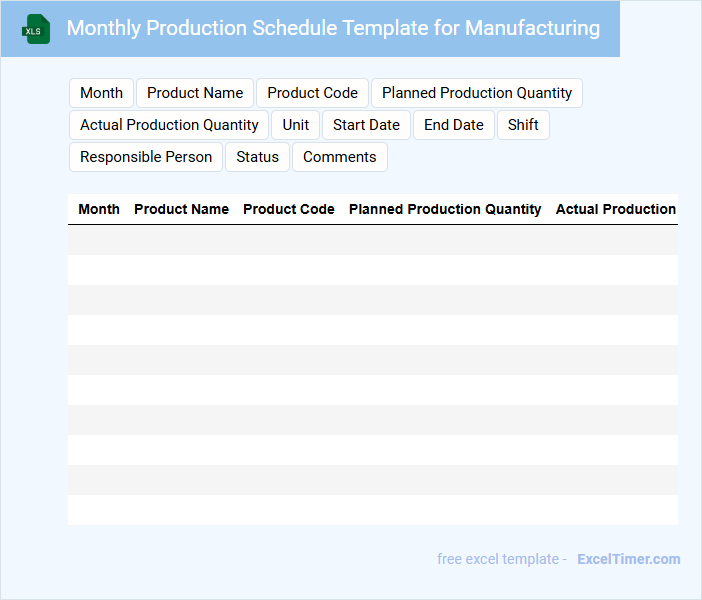

What information does a Monthly Production Schedule Template for Manufacturing typically contain?

This document usually includes detailed timelines, production quantities, and resource allocation for each manufacturing phase within the month. It helps streamline operations by providing a clear overview of tasks, deadlines, and responsible teams.

Important elements to consider are accurate forecast data, equipment maintenance schedules, and contingency plans to handle potential disruptions efficiently. Including these ensures smooth production flow and minimizes delays.

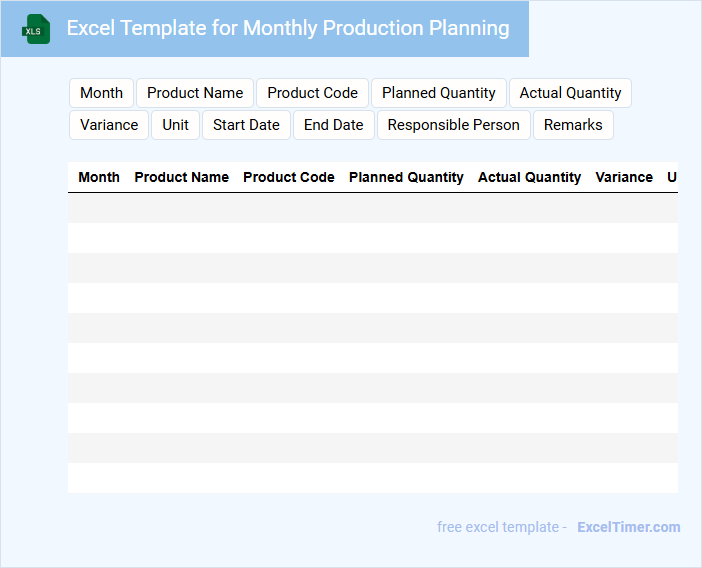

Excel Template for Monthly Production Planning

What information is typically included in an Excel Template for Monthly Production Planning? This document usually contains detailed schedules of production activities, resource allocation, and output targets for each day or week of the month. It helps to optimize workflow, track progress, and ensure timely completion of manufacturing goals.

What is an important feature to include in this template? Including dynamic formulas and clear visual charts is essential for real-time updates and easy interpretation of production data, which supports effective decision-making and adjustments.

Monthly Production Timeline Tracker for Manufacturing

A Monthly Production Timeline Tracker for manufacturing is a document used to monitor and manage production schedules within a factory. It typically contains timelines, key milestones, and deadlines for different manufacturing phases. Ensuring timely updates and accuracy in tracking helps maintain efficient workflow and prevents delays.

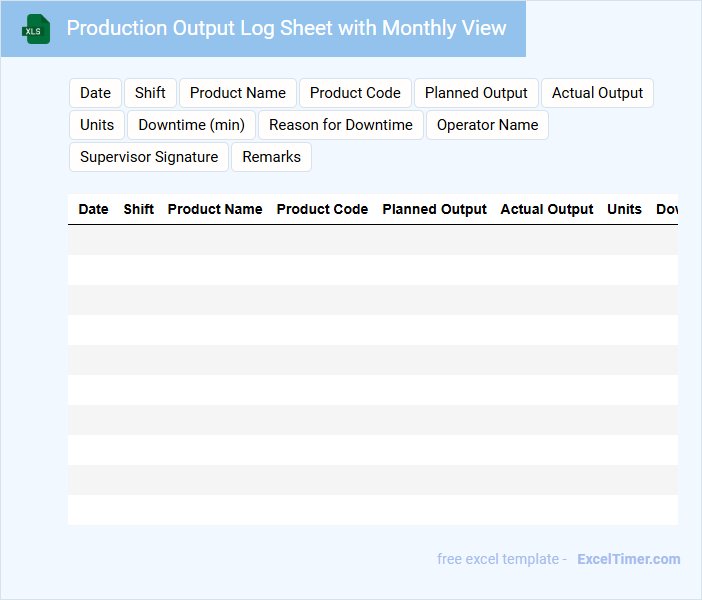

Production Output Log Sheet with Monthly View

A Production Output Log Sheet with Monthly View typically contains detailed records of daily production data consolidated into a monthly overview. It includes entries such as quantities produced, machine performance, and operator details. This document is essential for monitoring productivity trends and identifying areas for improvement.

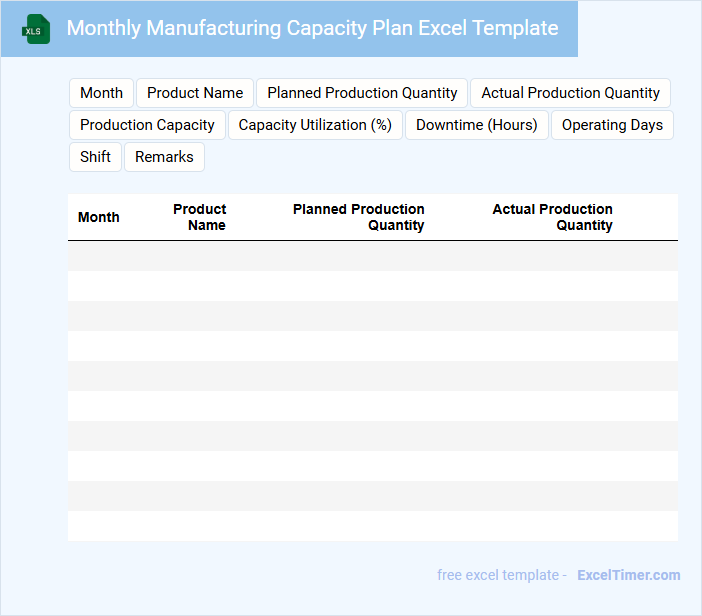

Monthly Manufacturing Capacity Plan Excel Template

The Monthly Manufacturing Capacity Plan is a document used to outline production capabilities for a specific month, helping manufacturers align resources with demand. It typically contains detailed data on machine hours, labor availability, and scheduled downtime. This template is essential for optimizing production efficiency and avoiding bottlenecks.

Important elements to include are clear capacity limits, accurate demand forecasts, and contingency plans for unexpected disruptions. Additionally, incorporating real-time updates allows for better responsiveness to changes in manufacturing schedules. Regular review and adjustment of the plan can significantly improve operational performance.

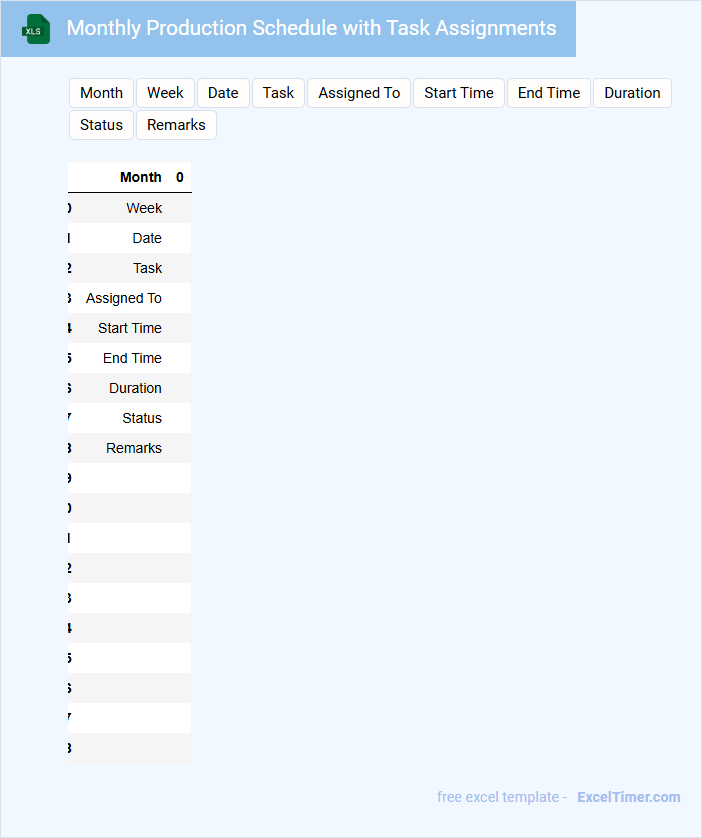

Monthly Production Schedule with Task Assignments

A Monthly Production Schedule with Task Assignments typically contains detailed timelines, assigned responsibilities, and production goals to ensure efficient workflow within a manufacturing or project environment.

- Clear timelines: Outline specific start and end dates for each production task to maintain schedule adherence.

- Task assignments: Assign responsibilities to team members to ensure accountability and resource optimization.

- Progress tracking: Include mechanisms to monitor task completion and address delays promptly.

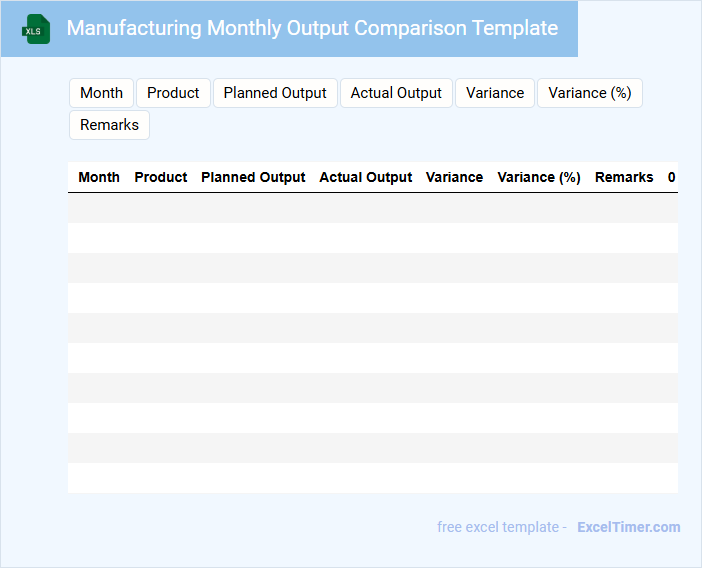

Manufacturing Monthly Output Comparison Template

What information is typically included in a Manufacturing Monthly Output Comparison Template? This type of document usually contains data on production volumes, efficiency rates, and output comparisons across different months. It is designed to help manufacturers track productivity trends and identify areas for improvement.

What is an important consideration when using this template? Ensuring accurate and consistent data entry is crucial for meaningful analysis, alongside setting clear benchmarks to compare monthly performance effectively.

Manufacturing Order Tracking Sheet for Monthly Scheduling

What information is typically included in a Manufacturing Order Tracking Sheet for Monthly Scheduling? This document usually contains details such as order numbers, product descriptions, scheduled start and end dates, quantities, and status updates. It is designed to help production managers monitor progress and ensure timely completion of manufacturing orders within the monthly schedule.

What key elements should be emphasized in this tracking sheet? It is important to include real-time status indicators, priority levels, and resource allocation details to optimize workflow. Additionally, incorporating clear deadlines and responsible personnel improves accountability and efficiency in production management.

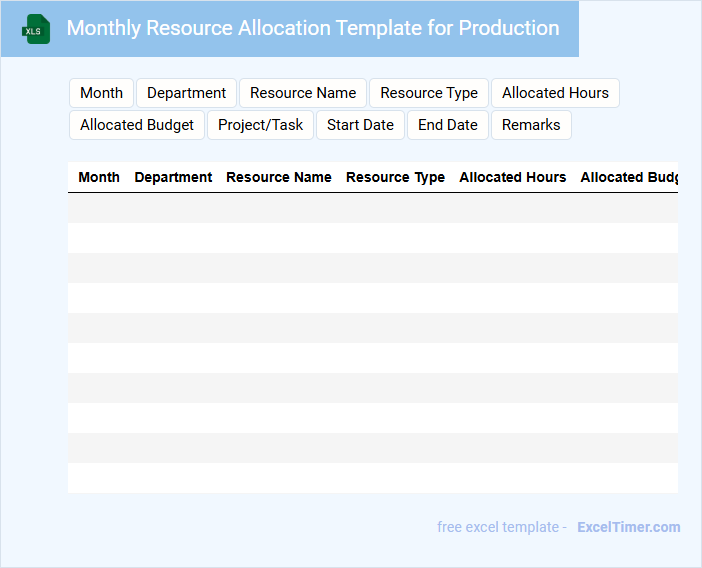

Monthly Resource Allocation Template for Production

What does a Monthly Resource Allocation Template for Production typically contain? This document usually includes a detailed schedule of resources such as labor, machinery, and materials allocated across different production tasks for the month. It helps in tracking availability and utilization to optimize workflow and prevent bottlenecks.

Why is it important to include clear timelines and resource capacities in this template? Including specific timeframes and capacity limits ensures realistic planning and efficient resource management. This reduces downtime and maximizes productivity by aligning resources with production demands.

Excel Template with Monthly Production Targets

What information does an Excel template with monthly production targets typically contain? This type of document usually includes detailed production goals broken down by month, allowing teams to plan and track their output effectively. It often features fields for inputting target quantities, actual production numbers, and variance analysis to monitor performance.

What is an important consideration when designing or using this template? Ensuring clarity and simplicity is crucial, so users can easily update and understand the data, while incorporating automated calculations helps minimize errors and improve accuracy in tracking progress against targets.

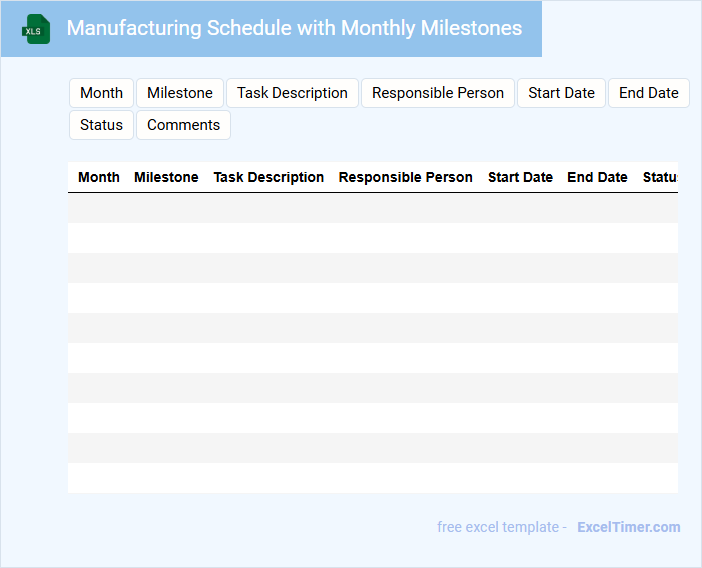

Manufacturing Schedule with Monthly Milestones

A Manufacturing Schedule with Monthly Milestones typically contains detailed timelines outlining production phases, resource allocation, and critical deadlines. It helps coordinate team efforts and ensures timely completion of manufacturing processes.

Important elements include clear milestone markers, contingency plans, and progress tracking mechanisms. Consistently updating the schedule is crucial to adapt to unforeseen delays and maintain efficiency.

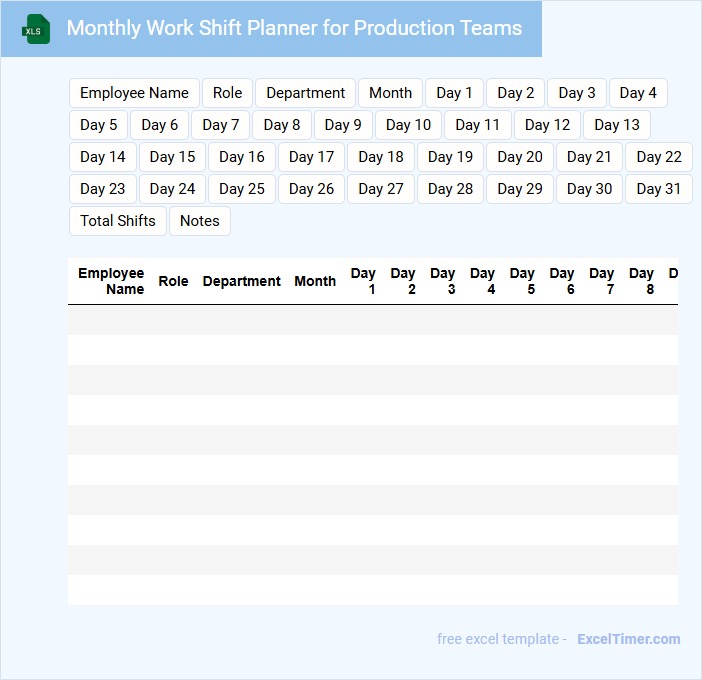

Monthly Work Shift Planner for Production Teams

A Monthly Work Shift Planner for production teams is a structured document designed to organize and allocate shifts effectively over a month. It typically contains detailed schedules, employee names, shift timings, and role assignments to ensure seamless operations. An important consideration is to maintain flexibility while ensuring adequate coverage to accommodate production demands and employee availability.

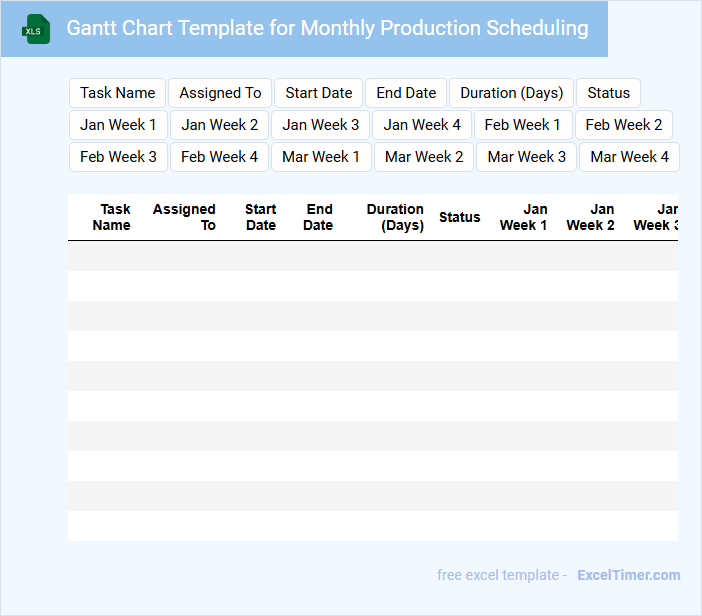

Gantt Chart Template for Monthly Production Scheduling

A Gantt Chart Template for monthly production scheduling typically contains a detailed timeline of production tasks, their durations, and dependencies. It helps visualize the entire production process over the month, highlighting start and end dates for each task. Crucial elements include task names, timelines, milestones, and assigned responsibilities to ensure smooth operations. Important suggestions for an effective template include clear task prioritization, real-time progress tracking, and flexibility to adjust schedules as needed. This helps optimize resource allocation and meet production deadlines efficiently.

Monthly Production Inventory Tracking with Excel

Monthly Production Inventory Tracking with Excel is a document used to monitor and manage inventory levels, production output, and material usage on a monthly basis. It helps businesses maintain accuracy in stock control and production planning.

- Include clear columns for dates, item descriptions, quantities produced, and inventory balances.

- Use formulas to automatically calculate totals and track discrepancies in inventory levels.

- Incorporate charts or graphs for visual analysis of production trends and inventory changes.

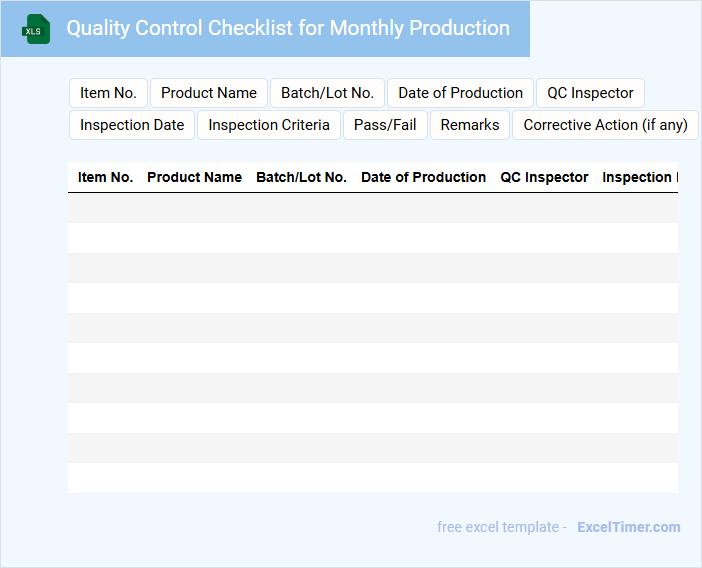

Quality Control Checklist for Monthly Production

A Quality Control Checklist for Monthly Production is a document that ensures consistent adherence to production standards by systematically verifying key quality parameters.

- Inspection Criteria: Clearly define specific quality attributes to be checked during each production phase.

- Frequency and Schedule: Set regular intervals for checklist completion to maintain steady oversight.

- Documentation and Feedback: Record results accurately and implement corrective actions based on findings.

How do you track and update daily production targets in the Monthly Production Schedule Excel document?

You can track and update daily production targets in the Monthly Production Schedule Excel document by entering actual output numbers in designated cells and using formulas to compare them against planned targets. Conditional formatting highlights variances, making it easy to monitor production efficiency in real time. Integrating data validation and pivot tables streamlines updates and analysis for accurate manufacturing management.

What is the method for allocating resources and raw materials across different production lines each month?

Your Monthly Production Schedule uses a resource allocation method based on priority demand forecasting and capacity planning for each manufacturing line. Raw materials and equipment are distributed according to production volume targets and lead times to optimize workflow efficiency. This systematic approach ensures balanced resource utilization and timely order fulfillment.

How does the schedule account for machine maintenance and downtime within the monthly plan?

Your Monthly Production Schedule integrates machine maintenance and downtime by allocating specific time slots for scheduled upkeep, ensuring minimal disruption to overall output. It uses real-time data to dynamically adjust production timelines, maintaining efficiency and meeting manufacturing targets. This proactive approach helps avoid unexpected delays and optimizes resource utilization throughout the month.

Which columns or sections monitor production progress versus planned output in the Excel schedule?

The columns labeled "Planned Output" and "Actual Output" monitor production progress versus planned targets in the Monthly Production Schedule. The "Variance" or "Deviation" section calculates differences between planned and actual figures to highlight discrepancies. A "Completion Percentage" column may also track the progress rate relative to the schedule.

How is inventory managed and reflected in relation to the production schedule throughout the month?

Your monthly production schedule integrates real-time inventory levels to align manufacturing output with demand fluctuations. Inventory data is updated daily, ensuring accurate reflection of stock on hand and materials required for upcoming production runs. This seamless synchronization helps optimize resource allocation and minimize delays.