The Monthly Production Schedule Excel Template for Manufacturing Units streamlines production planning by organizing tasks, timelines, and resource allocation efficiently. It helps manufacturers track daily output, manage work shifts, and ensure timely completion of production targets. Using this template enhances workflow visibility and improves overall operational efficiency.

Monthly Production Schedule with Shift Planning

A Monthly Production Schedule with Shift Planning is a document that outlines the planned manufacturing activities and workforce allocation across different shifts for a given month to ensure efficient production flow.

- Detailed Task Breakdown: Clearly specifies daily production goals and assigned tasks for each shift to maintain clarity and accountability.

- Shift Timings and Workforce Allocation: Defines exact work hours and assigns appropriate personnel to each shift to optimize labor usage.

- Contingency Provisions: Includes strategies for handling unexpected delays or workforce shortages to minimize production disruptions.

Excel Template for Monthly Manufacturing Output Tracking

An Excel Template for Monthly Manufacturing Output Tracking typically contains structured data fields to record production quantities, dates, and product types. It facilitates the monitoring of manufacturing efficiency and helps identify trends or discrepancies over time. Key elements often include input sections for daily output, summary tables, and visual charts for performance analysis.

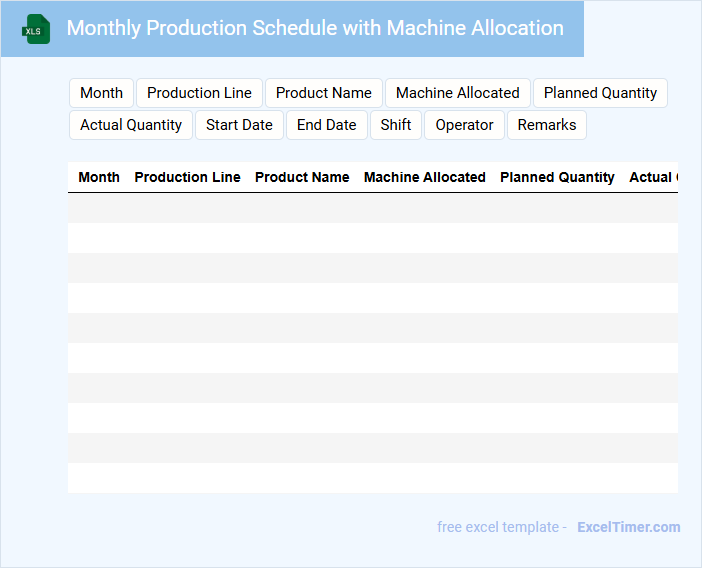

Monthly Production Schedule with Machine Allocation

The Monthly Production Schedule is a detailed plan outlining the manufacturing activities to be completed within a month. It typically contains information about production targets, timelines, and required resources.

Machine allocation is a crucial component, specifying which machines are assigned to particular tasks to optimize efficiency and reduce downtime. This document helps in coordinating workflow, managing capacity, and ensuring deadlines are met.

For effective use, it's important to regularly update the schedule based on real-time production data and machine availability to adapt to any changes or disruptions.

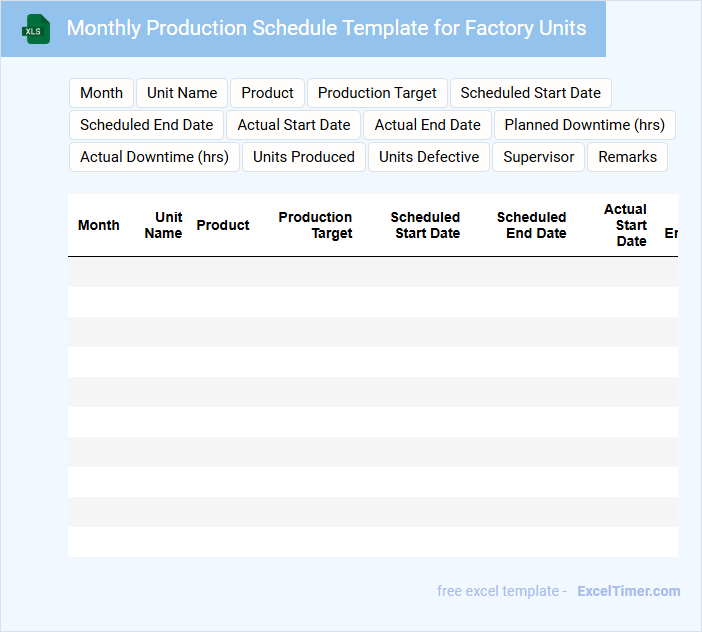

Monthly Production Schedule Template for Factory Units

What information is typically contained in a Monthly Production Schedule Template for Factory Units? This type of document usually includes detailed timelines for production tasks, allocation of resources, and deadlines for each manufacturing stage. It helps ensure efficient workflow, minimizes downtime, and facilitates coordination between departments.

What is an important consideration when creating a Monthly Production Schedule Template? It is crucial to accurately estimate production capacity and account for potential delays or maintenance to maintain realistic deadlines. Regular updates and clear communication with all teams involved help keep the schedule practical and achievable.

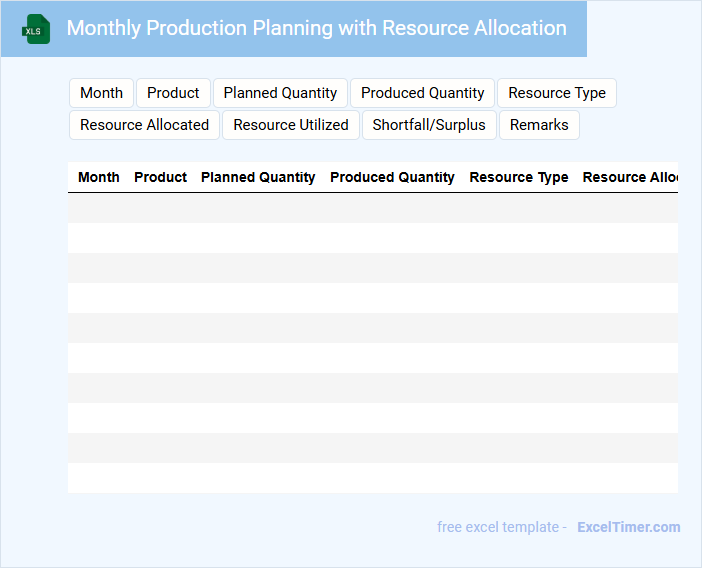

Monthly Production Planning with Resource Allocation

Monthly Production Planning with Resource Allocation is a crucial document that outlines the scheduled manufacturing activities and assigns the necessary resources to ensure efficient production. It typically contains detailed production targets, timelines, and a comprehensive allocation of labor, machinery, and materials. This planning helps in optimizing resource utilization and minimizing downtime.

To enhance its effectiveness, it is important to include clear capacity assessments, prioritize critical production tasks, and maintain flexibility to adjust for unforeseen changes or delays.

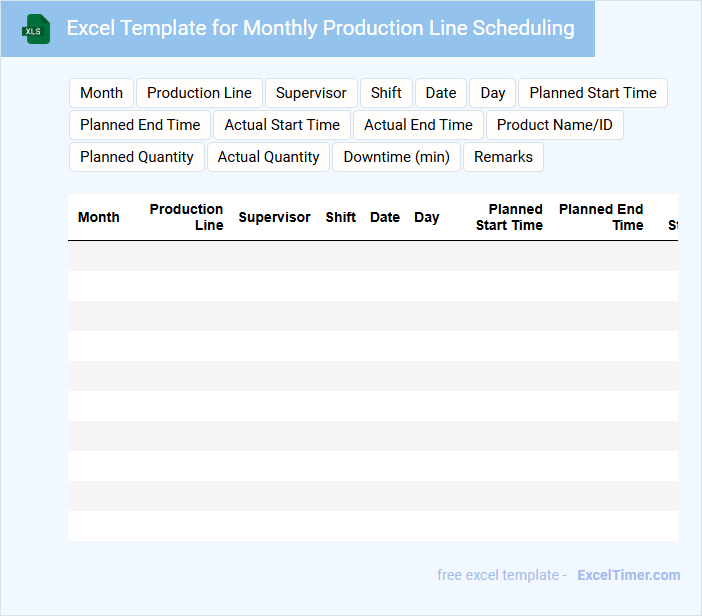

Excel Template for Monthly Production Line Scheduling

An Excel Template for Monthly Production Line Scheduling typically contains detailed timelines, task assignments, and resource allocation to streamline manufacturing processes. It helps in tracking productivity and identifying bottlenecks to optimize workflow efficiency.

Key features often include capacity planning, shift scheduling, and inventory monitoring to ensure smooth operations. For best results, ensure the template incorporates real-time updates and clear visual indicators of production milestones.

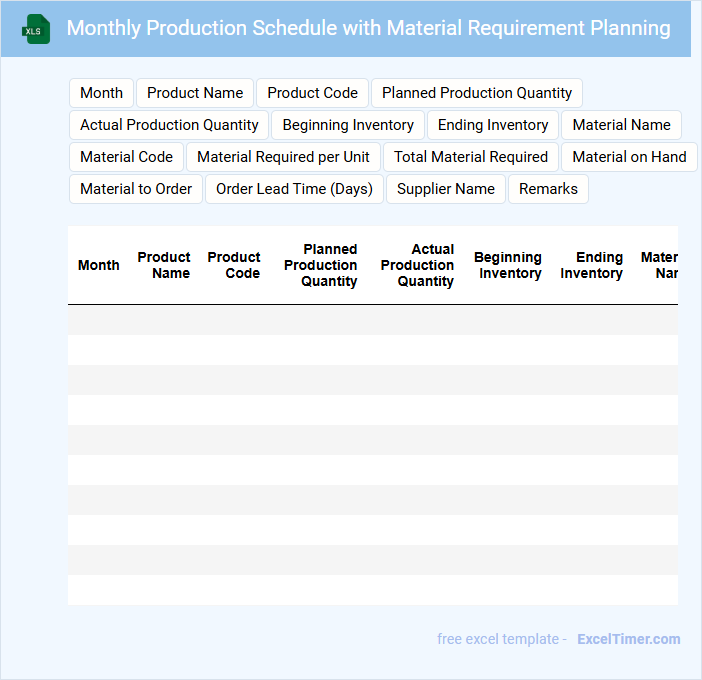

Monthly Production Schedule with Material Requirement Planning

What information is typically included in a Monthly Production Schedule with Material Requirement Planning? This document usually contains a detailed timeline of production activities and the corresponding material requirements needed to meet production targets. It helps coordinate manufacturing processes with inventory management to ensure timely availability of materials and efficient workflow.

Why is it important to integrate material requirement planning into the monthly production schedule? Integrating MRP ensures that raw materials and components are ordered and available just in time, minimizing downtime and reducing excess inventory costs. This alignment enhances production efficiency and supports meeting delivery deadlines consistently.

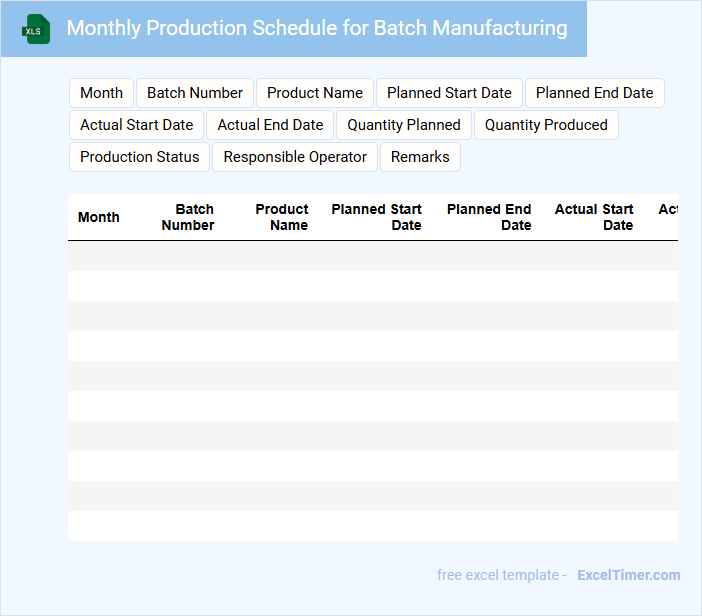

Monthly Production Schedule for Batch Manufacturing

The Monthly Production Schedule for batch manufacturing is a critical document that outlines the planned production quantities and timelines for each product batch within a given month. It typically contains detailed information about batch sizes, production dates, resource allocation, and sequencing of manufacturing processes to ensure efficiency. An important aspect to include is the flexibility to accommodate changes in demand or unexpected delays.

Monthly Output Schedule with Downtime Tracking

A Monthly Output Schedule with Downtime Tracking document typically contains detailed records of production volumes and the corresponding periods of machinery or process downtime within a month. It helps organizations monitor efficiency and identify patterns that cause delays or stoppages. This document is essential for optimizing operational performance by providing clear visibility into production output alongside downtime data.

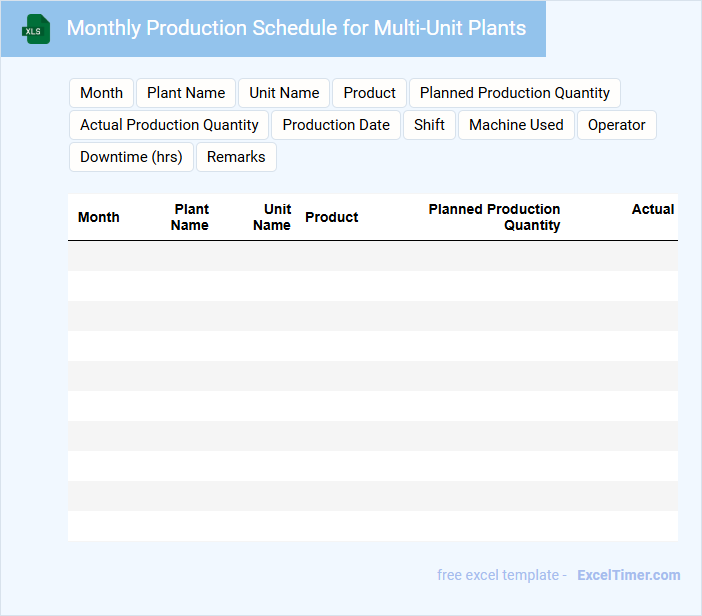

Monthly Production Schedule for Multi-Unit Plants

The Monthly Production Schedule for multi-unit plants details the planned production activities across various units over a month. It helps in coordinating resources, managing workforce, and ensuring timely output.

This document typically contains unit-specific production targets, timelines, resource allocation, and critical milestones. An important aspect to include is a clear overview of potential bottlenecks to optimize efficiency and minimize downtime.

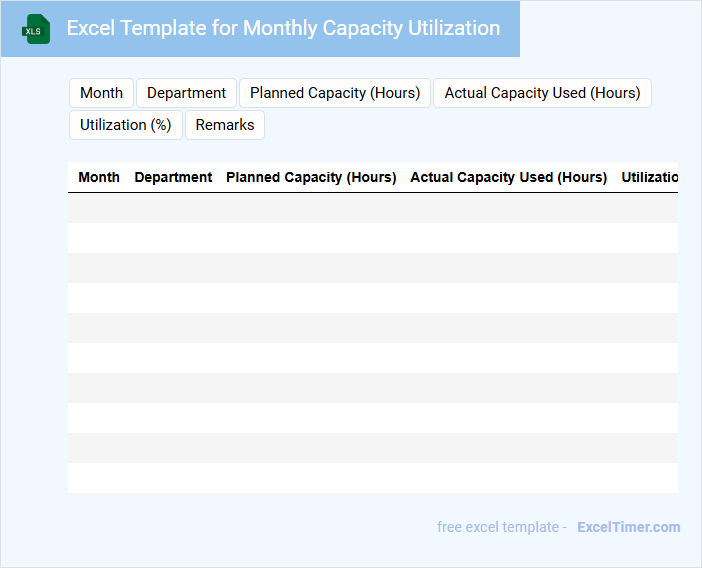

Excel Template for Monthly Capacity Utilization

An Excel Template for Monthly Capacity Utilization typically contains data fields for tracking production capacity, actual output, and utilization percentages over a monthly period. It often includes charts or tables that visually represent performance trends and help identify bottlenecks. The template serves as a practical tool for monitoring operational efficiency and making informed decisions.

It is important to ensure the template includes clear labels for each data point, automated calculations to reduce manual errors, and customizable fields to adapt to different industries. Incorporating visual aids like graphs enhances data interpretation. Regularly updating the template helps maintain accuracy and relevance.

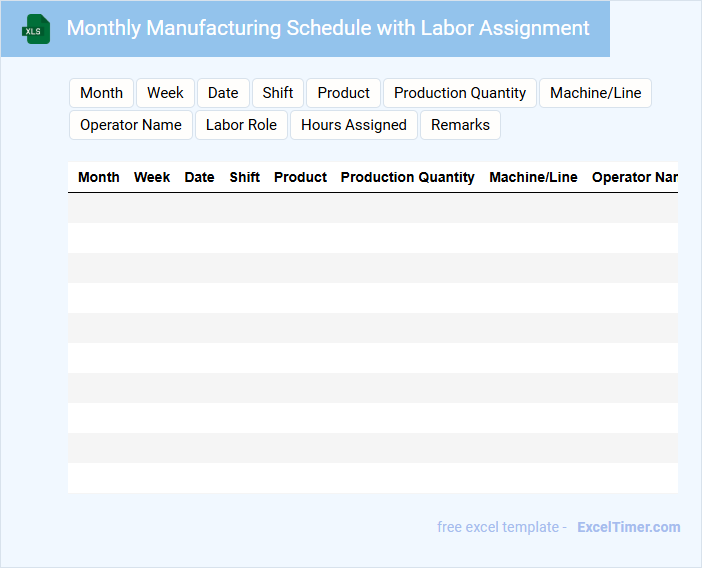

Monthly Manufacturing Schedule with Labor Assignment

What information is typically included in a Monthly Manufacturing Schedule with Labor Assignment? This document usually contains detailed timelines for production activities and specific labor tasks assigned to each team member for the month. It ensures efficient resource allocation and helps track progress toward manufacturing goals.

Why is it important to include labor assignment details in the schedule? Including labor assignments clarifies responsibilities, reduces downtime, and optimizes workforce utilization. This enables better coordination and improves overall productivity in the manufacturing process.

Monthly Production Timeline for Manufacturing Units

The Monthly Production Timeline for manufacturing units outlines the scheduled production activities and deadlines within a given month. It typically includes key milestones, resource allocation, and expected output quantities. Ensuring accuracy and timely updates in this document is essential for optimizing manufacturing efficiency and meeting delivery commitments.

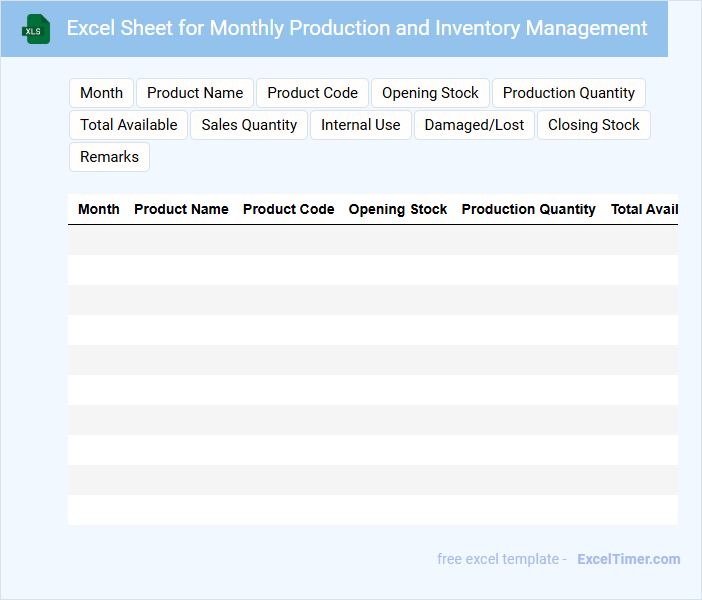

Excel Sheet for Monthly Production and Inventory Management

What information is typically included in an Excel sheet for Monthly Production and Inventory Management? This document usually contains detailed records of production quantities, inventory levels, raw material usage, and finished goods stock updated monthly. It helps businesses track supply chain efficiency, manage resources, and plan future production needs accurately.

What important features should be incorporated for optimal use? Including clear date stamps, categorization by product type, real-time formulas for automatic calculations, and summary dashboards for quick visualization will enhance its functionality and decision-making capabilities.

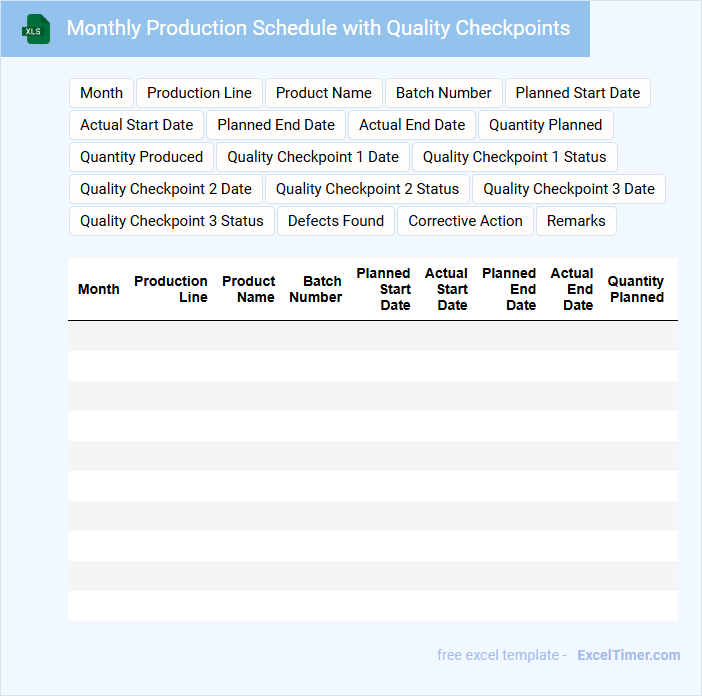

Monthly Production Schedule with Quality Checkpoints

What information is typically included in a Monthly Production Schedule with Quality Checkpoints?

This document usually contains a detailed timeline of production activities mapped out for the month, including start and end dates for each task. It also highlights specific quality checkpoints designed to ensure products meet required standards throughout the production process.

An important aspect to include is clear deadlines for each quality inspection and responsible personnel to maintain accountability and product consistency.

What key data fields should be included in a Monthly Production Schedule for manufacturing units?

A Monthly Production Schedule for manufacturing units should include key data fields such as Product Name, Production Quantity, Start Date, End Date, Production Unit or Line, Machine or Equipment ID, Shift Details, and Responsible Supervisor. Additional fields like Material Requirements, Quality Checks, and Status Updates ensure comprehensive tracking and resource allocation. These elements optimize planning, enhance workflow management, and facilitate timely delivery.

How does the schedule track planned versus actual production outputs throughout the month?

Your Monthly Production Schedule for Manufacturing Units uses real-time data entry to compare planned production targets with actual output daily. It incorporates automated variance calculations and visual charts to highlight discrepancies and trends across different production lines. This system enables proactive adjustments, ensuring alignment with monthly manufacturing goals.

Which Excel functions or tools are best for visualizing production trends and capacity utilization?

Excel functions like SPARKLINE and conditional formatting effectively visualize monthly production trends by highlighting performance variations. PivotTables summarize capacity utilization across manufacturing units, enabling dynamic data analysis. Chart tools such as line charts and stacked bar charts provide clear graphical representations of production schedules and resource allocation.

How is raw material availability integrated and updated in the Monthly Production Schedule?

Raw material availability is integrated in the Monthly Production Schedule through real-time inventory data linked within the Excel document, ensuring accurate production planning. Your schedule updates automatically as procurement inputs and stock levels change, optimizing resource allocation. This dynamic integration minimizes delays and aligns manufacturing output with material readiness.

What are the essential steps to automate alerts for production delays or bottlenecks in the Excel document?

Set up conditional formatting rules in the Excel Monthly Production Schedule to highlight tasks exceeding their deadlines or showing reduced output. Use Excel formulas like IF and VLOOKUP combined with date comparisons to detect delays or bottlenecks. Implement VBA macros or Power Automate flows to send automated email alerts or notifications when these conditions are met.