The Quarterly Service Maintenance Excel Template for Facility Managers streamlines tracking and scheduling of routine maintenance tasks, ensuring facilities operate smoothly and reduce downtime. It features customizable columns for task details, dates, responsible personnel, and status updates, promoting organized and timely service delivery. Using this template enhances facility management efficiency by centralizing maintenance records and facilitating proactive issue resolution.

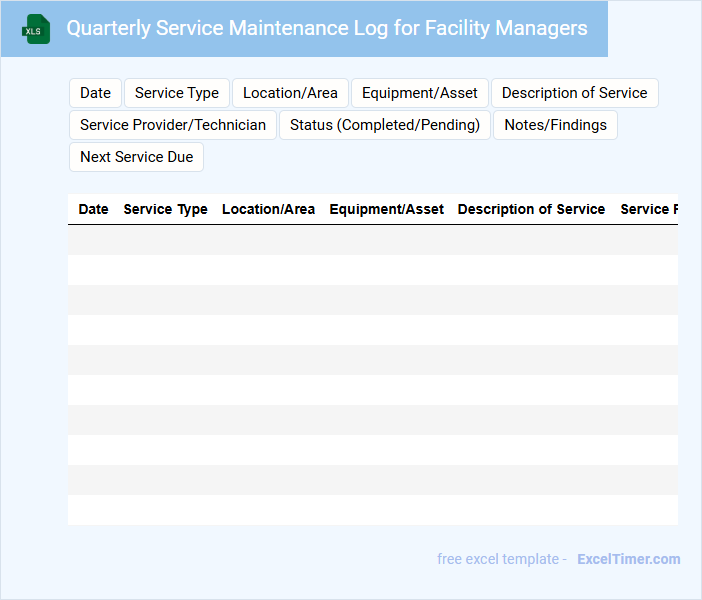

Quarterly Service Maintenance Log for Facility Managers

The Quarterly Service Maintenance Log is a crucial document that records all maintenance activities performed within a facility every three months. It typically contains detailed entries of equipment inspections, repairs, and routine servicing schedules.

For Facility Managers, this log helps track maintenance trends, ensure compliance with safety standards, and plan future upkeep. Maintaining accurate records can prevent costly breakdowns and extend asset lifespan effectively.

Facility Maintenance Schedule with Quarterly Tracking

The Facility Maintenance Schedule is a document that outlines all planned maintenance activities for a facility, organized by date and priority to ensure operational efficiency. It typically includes details such as equipment inspections, servicing tasks, and assigned personnel.

Quarterly tracking is essential to monitor progress, identify recurring issues, and adjust future maintenance plans accordingly. Regular updates and clear communication enhance reliability and extend the life of facility assets.

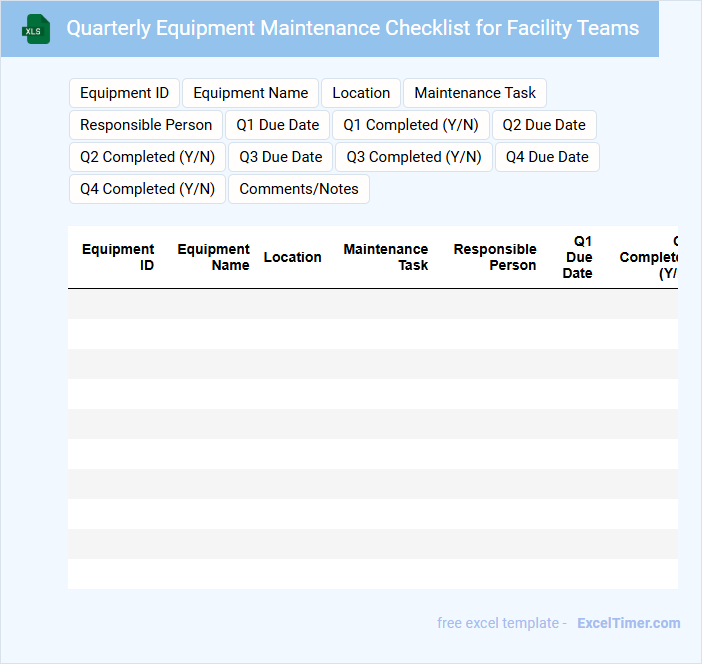

Quarterly Equipment Maintenance Checklist for Facility Teams

A Quarterly Equipment Maintenance Checklist is a crucial document designed to ensure the proper functioning and longevity of facility equipment. It typically contains detailed tasks, inspection schedules, and safety checks that need to be performed every quarter. This document helps facility teams stay organized, avoid unexpected breakdowns, and maintain compliance with safety standards.

Important suggestions for this checklist include clearly listing all equipment to be inspected, including specific maintenance actions and deadlines. Additionally, incorporating sections for recording observations, repairs, and responsible personnel enhances accountability. Finally, regularly updating the checklist based on equipment performance and manufacturer recommendations ensures ongoing effectiveness.

Maintenance Task Tracker with Quarterly Intervals

A Maintenance Task Tracker with quarterly intervals is a document designed to monitor and schedule routine maintenance activities every three months. It typically contains detailed task descriptions, assigned personnel, deadlines, and progress status. This tracker is essential for ensuring that equipment and systems operate efficiently and downtime is minimized.

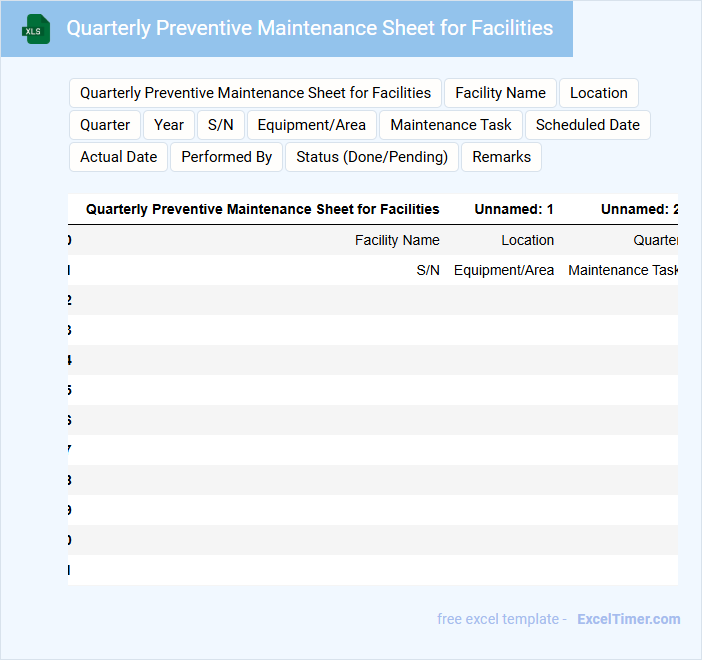

Quarterly Preventive Maintenance Sheet for Facilities

A Quarterly Preventive Maintenance Sheet for Facilities is a document used to schedule and track routine maintenance tasks to ensure equipment and infrastructure remain in optimal condition. It helps prevent unexpected breakdowns and extends the lifespan of facility assets.

- List all equipment and systems requiring maintenance with detailed descriptions.

- Include specific tasks, frequencies, and responsible personnel for accountability.

- Record dates, observations, and any corrective actions taken during inspections.

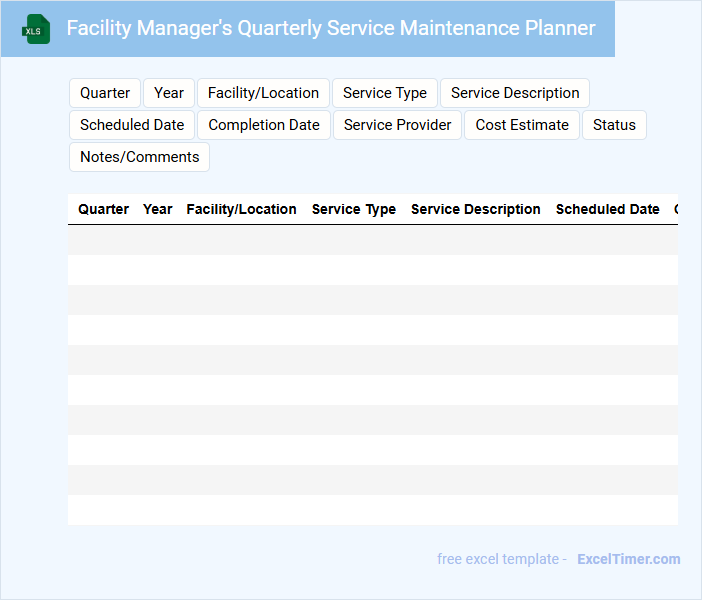

Facility Manager's Quarterly Service Maintenance Planner

The Facility Manager's Quarterly Service Maintenance Planner is a crucial document that outlines scheduled maintenance activities for facility systems and equipment. It helps ensure that all operations run smoothly and prevents unexpected breakdowns.

This planner typically contains detailed timelines, assigned responsibilities, and checklists for inspections and repairs. Including clear documentation of previous maintenance actions is an important practice for tracking asset performance and planning future tasks.

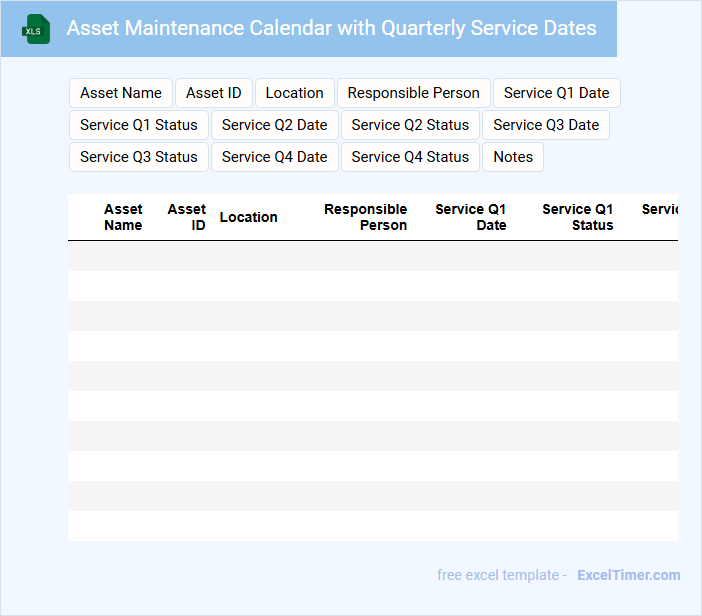

Asset Maintenance Calendar with Quarterly Service Dates

An Asset Maintenance Calendar typically contains scheduled dates for regular maintenance tasks to ensure the longevity and performance of assets. It includes quarterly service dates, details of required maintenance activities, and responsible personnel. This document is essential for planning, tracking, and preventing unexpected equipment failures.

To optimize its use, ensure clear identification of assets, specify exact service intervals, and incorporate reminders for upcoming maintenance. Including space for notes on completed work or issues observed can improve record accuracy. Consistent updates and accessibility for the maintenance team are crucial for operational efficiency.

Quarterly Building Maintenance Tracker for Facilities

A Quarterly Building Maintenance Tracker for Facilities is a document used to systematically record, monitor, and manage maintenance activities every three months to ensure building safety and efficiency.

- Comprehensive Logs: It should include detailed records of all maintenance tasks performed, dates, and responsible personnel.

- Priority Scheduling: Highlight urgent repairs or inspections to prioritize resource allocation effectively.

- Compliance Checklist: Ensure that all maintenance actions meet regulatory standards and safety requirements.

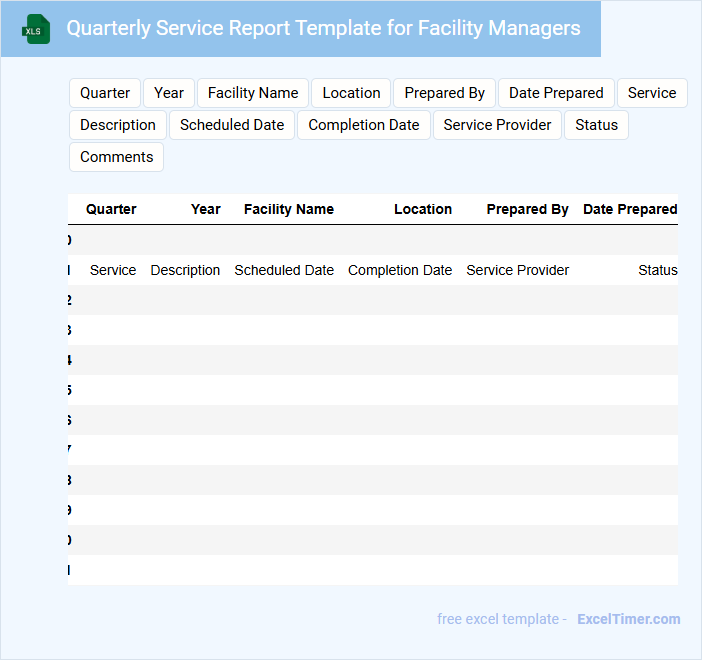

Quarterly Service Report Template for Facility Managers

The Quarterly Service Report is a vital document for facility managers, summarizing maintenance activities, service requests, and operational status over the past three months. It provides a clear overview of the facility's condition and any issues that require attention.

This report typically contains performance metrics, completed tasks, upcoming maintenance schedules, and recommendations to enhance efficiency and safety. Including detailed data and visual aids ensures effective communication with stakeholders.

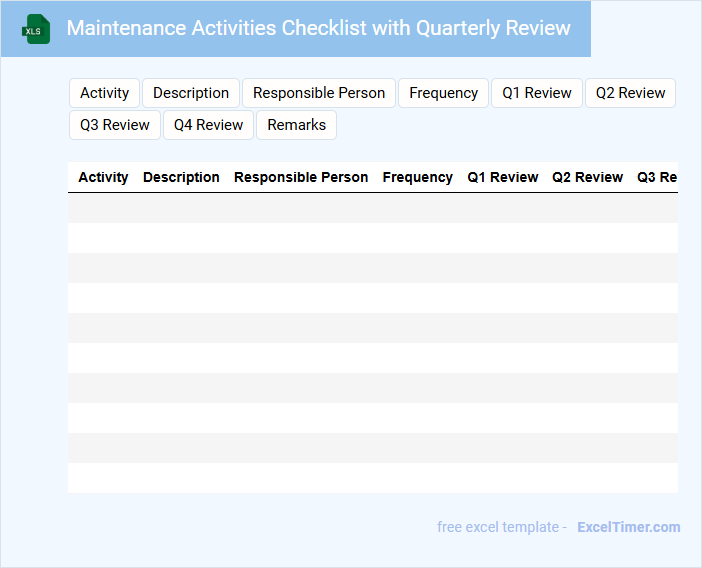

Maintenance Activities Checklist with Quarterly Review

A Maintenance Activities Checklist with Quarterly Review is a crucial document used to systematically track and manage routine maintenance tasks within a specified period. It typically contains detailed to-do items, frequency schedules, and responsible personnel to ensure equipment reliability and compliance with safety standards. For optimal use, including a clear review section to evaluate completed tasks and update maintenance plans is highly recommended.

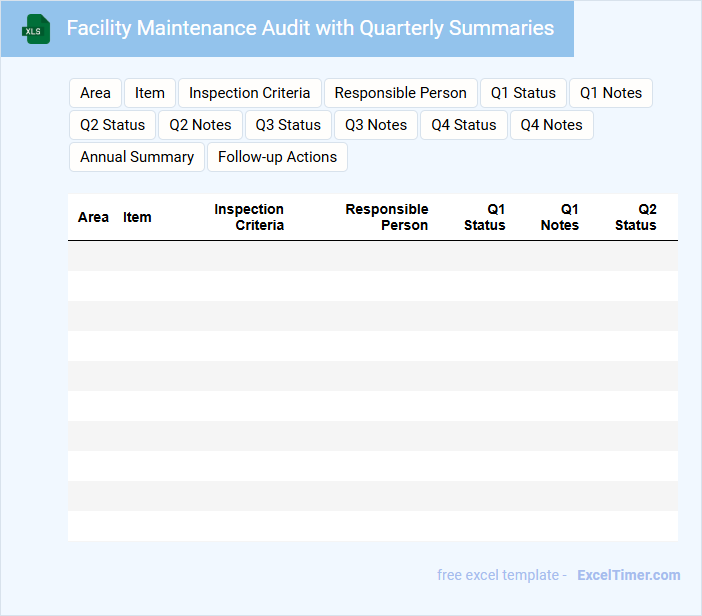

Facility Maintenance Audit with Quarterly Summaries

The Facility Maintenance Audit document typically contains detailed assessments of building systems, equipment conditions, and compliance with safety standards. It also includes identification of maintenance issues and recommendations for corrective actions to ensure operational efficiency.

Quarterly summaries provide a concise overview of maintenance activities, completed tasks, and progress on addressing previous audit findings. This helps track performance trends and prioritize future maintenance efforts effectively.

It is important to ensure accurate data collection and regular updates to support informed decision-making and maintain facility reliability.

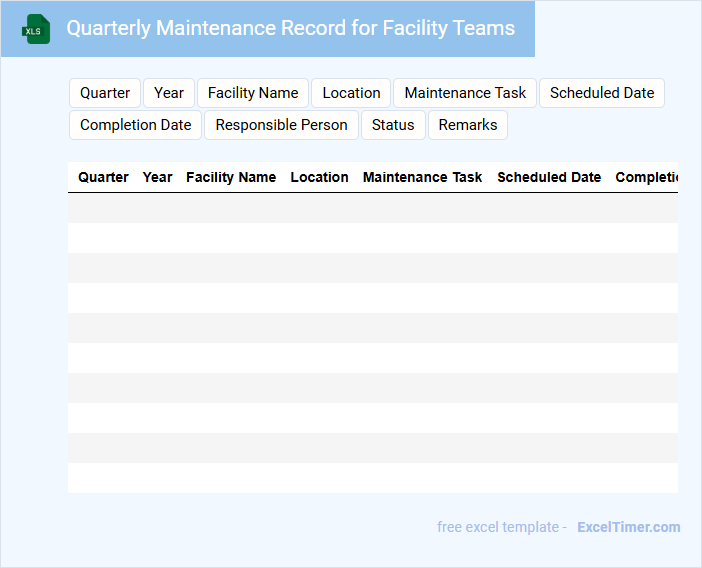

Quarterly Maintenance Record for Facility Teams

The Quarterly Maintenance Record is a document that tracks all maintenance activities performed within a facility over a three-month period. It ensures that equipment and systems are regularly checked and serviced to prevent breakdowns.

This record typically contains details such as the date of maintenance, description of work done, personnel involved, and any issues identified. Important elements include accurate time stamps and clear documentation of corrective actions taken to maintain operational efficiency.

Service Request Tracker with Quarterly Maintenance Section

A Service Request Tracker document typically contains detailed records of service requests, tracking their status from initiation to resolution. It helps in organizing and prioritizing maintenance tasks efficiently. Including a clear summary of each request ensures better communication among teams. The Quarterly Maintenance Section focuses on scheduled maintenance activities performed every three months to prevent equipment failures. It outlines planned tasks, responsible personnel, and timelines for completion. Consistent updates to this section are crucial for maintaining operational reliability.

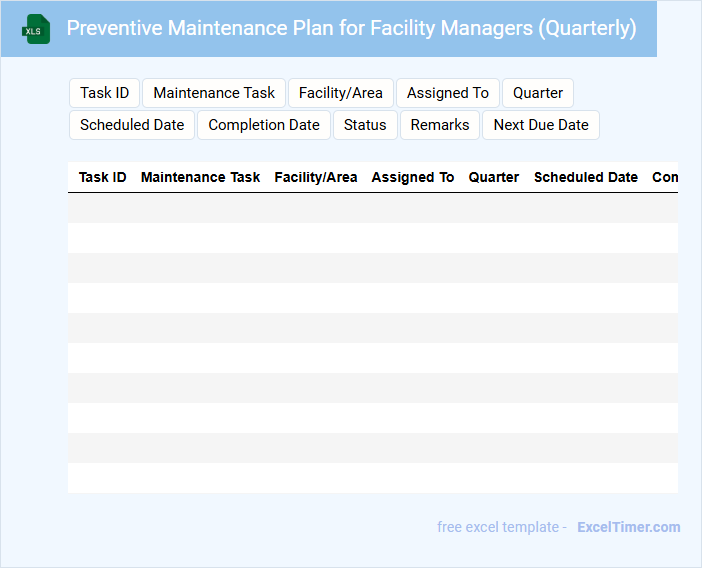

Preventive Maintenance Plan for Facility Managers (Quarterly)

A Preventive Maintenance Plan for Facility Managers is a detailed document outlining scheduled inspections and routine upkeep activities to ensure the longevity and efficiency of equipment and infrastructure. It typically contains timelines, checklists, and responsibilities for quarterly maintenance tasks. An important aspect is setting clear deadlines to avoid unexpected breakdowns and costly repairs.

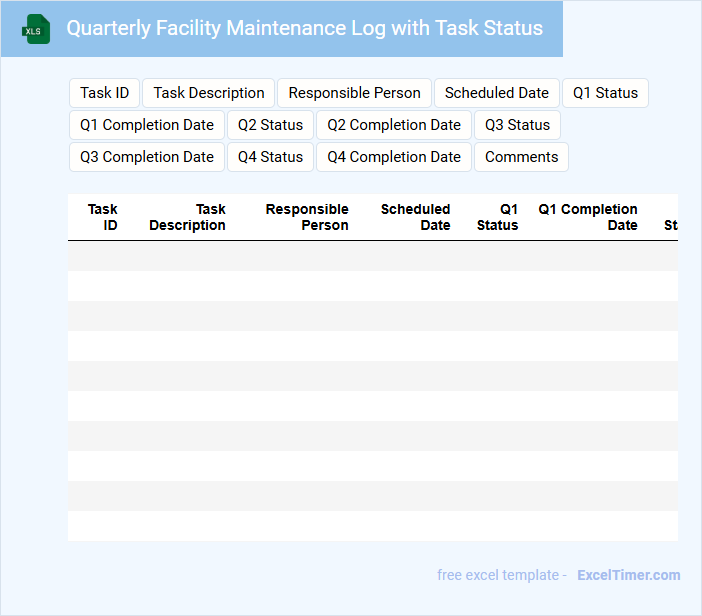

Quarterly Facility Maintenance Log with Task Status

A Quarterly Facility Maintenance Log with Task Status typically contains detailed records of all maintenance activities conducted within a facility over a three-month period, including task descriptions, dates, personnel involved, and current statuses.

- Accurate Task Tracking: Ensure every maintenance task is logged with clear completion status to monitor progress effectively.

- Regular Updates: Update the log promptly to reflect any changes or delays in task execution.

- Comprehensive Details: Include relevant notes on materials used and any issues encountered during maintenance.

What are the key components of a Quarterly Service Maintenance schedule for facility equipment?

A Quarterly Service Maintenance schedule for facility equipment includes inspection, cleaning, lubrication, and testing of critical systems such as HVAC, electrical panels, and fire safety devices. Your schedule should also track performed maintenance tasks, identify potential issues, and ensure compliance with safety regulations. Regular updates help maximize equipment lifespan and minimize unexpected downtime.

How does tracking quarterly maintenance activities in Excel improve compliance and equipment longevity?

Tracking quarterly maintenance activities in Excel ensures accurate documentation of service dates, tasks completed, and upcoming schedules, enhancing regulatory compliance. Your facility benefits from timely maintenance alerts that prevent equipment breakdowns and extend operational life. This organized approach supports proactive facility management and reduces costly repairs.

What essential data fields should facility managers include in an Excel quarterly service maintenance log?

Your quarterly service maintenance log should include essential data fields such as Service Date, Equipment ID, Service Description, Technician Name, Status, Next Scheduled Service, and Cost. Tracking these details ensures efficient maintenance scheduling and timely equipment upkeep. Accurate records help you minimize downtime and extend asset lifespan.

How can conditional formatting in Excel help facility managers quickly identify overdue maintenance tasks?

Conditional formatting in Excel highlights overdue maintenance tasks by automatically changing the cell color based on due dates, allowing facility managers to quickly spot urgent issues. Your ability to visually prioritize these tasks improves response times and reduces the risk of equipment failure. This feature streamlines quarterly service maintenance tracking for efficient facility management.

What are the benefits of utilizing Excel charts and pivot tables for analyzing quarterly service maintenance trends?

Excel charts and pivot tables provide Facility Managers with clear visual representations of quarterly service maintenance trends, enabling quick identification of recurring issues and peak service periods. These tools facilitate efficient data summarization and comparison across different facilities or time frames, improving decision-making and resource allocation. Leveraging Excel's analytical capabilities enhances tracking of maintenance performance and supports proactive facility management strategies.