The Quarterly Energy Consumption Excel Template for Manufacturing Plants provides a streamlined way to track and analyze energy usage over three-month periods, enabling efficient monitoring of power costs and identifying areas for potential savings. This template is essential for manufacturing plants aiming to optimize energy consumption and reduce operational expenses through data-driven insights and trend analysis. Accurate quarterly records help in compliance with environmental regulations and support sustainability initiatives.

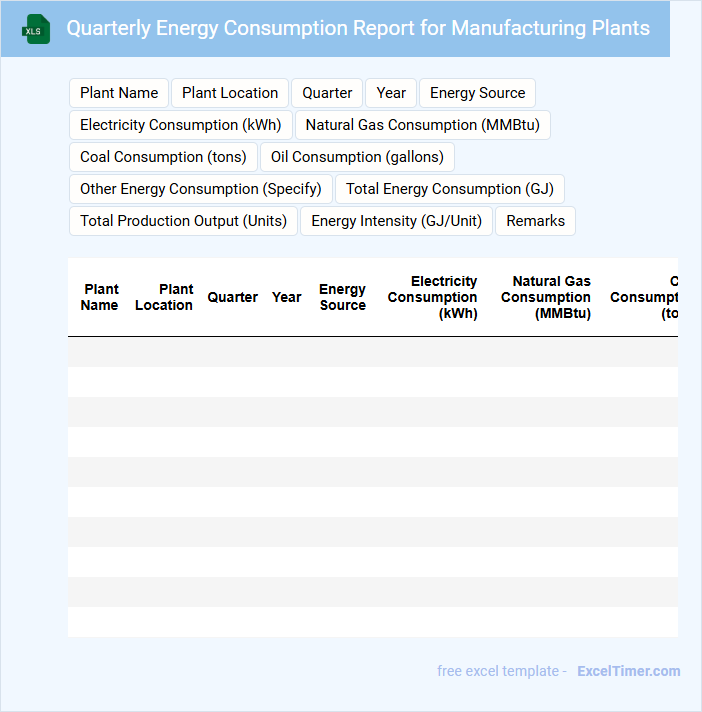

Quarterly Energy Consumption Report for Manufacturing Plants

A Quarterly Energy Consumption Report for Manufacturing Plants typically details the energy usage patterns and efficiency metrics over a three-month period to optimize operational costs and sustainability.

- Energy Usage Data: A detailed overview of the total energy consumed by each plant, broken down by type and source.

- Comparison Metrics: Analysis of current quarter consumption compared to previous quarters to identify trends and anomalies.

- Recommendations: Suggested actions for reducing energy consumption and improving energy efficiency based on the report's findings.

Excel Tracker for Quarterly Energy Use in Manufacturing

An Excel Tracker for Quarterly Energy Use in Manufacturing is a crucial tool for monitoring and analyzing energy consumption across different production phases. This document typically contains detailed records of energy usage, comparative quarterly data, and visual charts to highlight trends and inefficiencies. Ensuring accurate data entry and consistent updating is essential for effective energy management and cost reduction.

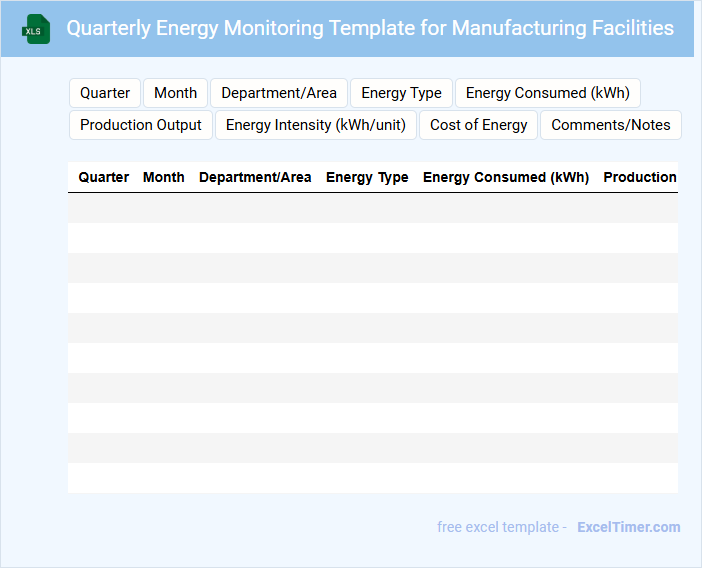

Quarterly Energy Monitoring Template for Manufacturing Facilities

This Quarterly Energy Monitoring Template for Manufacturing Facilities is designed to systematically track and analyze energy consumption to improve efficiency and reduce costs.

- Energy Usage Data: Collect detailed energy consumption figures for different departments or machinery within the facility.

- Performance Metrics: Include key indicators such as energy intensity, cost per unit of production, and comparative benchmarks.

- Improvement Actions: Document strategies and initiatives undertaken to optimize energy use and track their progress.

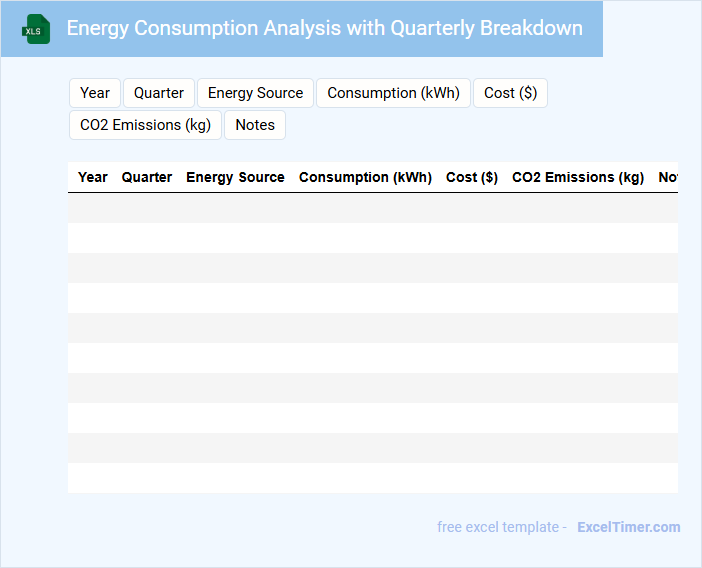

Energy Consumption Analysis with Quarterly Breakdown

An Energy Consumption Analysis document typically includes detailed data on energy usage over a specific period, breaking down consumption by quarters for clearer insights. It helps identify trends, peak usage times, and potential areas for energy savings. A well-structured report also provides recommendations based on the analyzed data.

Important elements to include are accurate quantitative data, graphical representations like charts or tables for quarterly comparisons, and a summary highlighting key findings. Including both historical data and projections can enhance the report's usefulness. Lastly, clear labeling and consistent units of measurement ensure better understanding and usability.

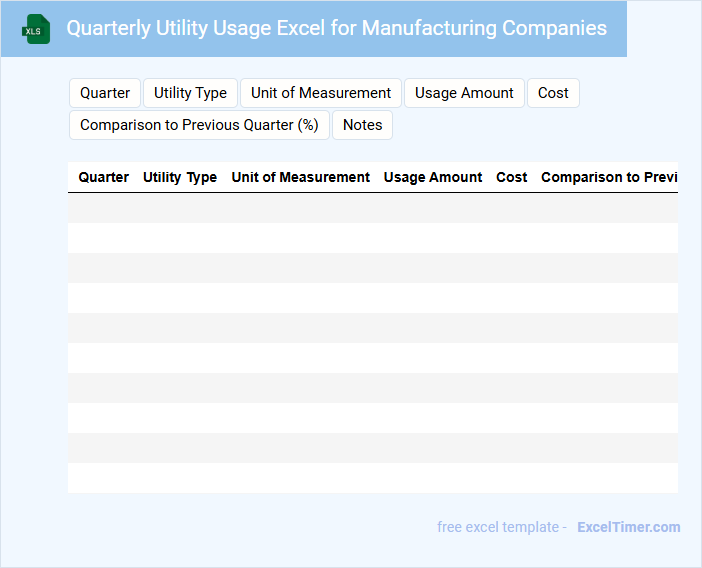

Quarterly Utility Usage Excel for Manufacturing Companies

This document typically contains detailed records of utility consumption over a quarter to help manufacturing companies monitor and optimize their resource usage.

- Consumption Data: Accurate logs of electricity, water, and gas usage segmented by time and production area.

- Cost Analysis: Breakdown of utility expenses to identify potential savings and budget adjustments.

- Trend Monitoring: Comparative charts and graphs illustrating usage patterns to support efficiency improvements.

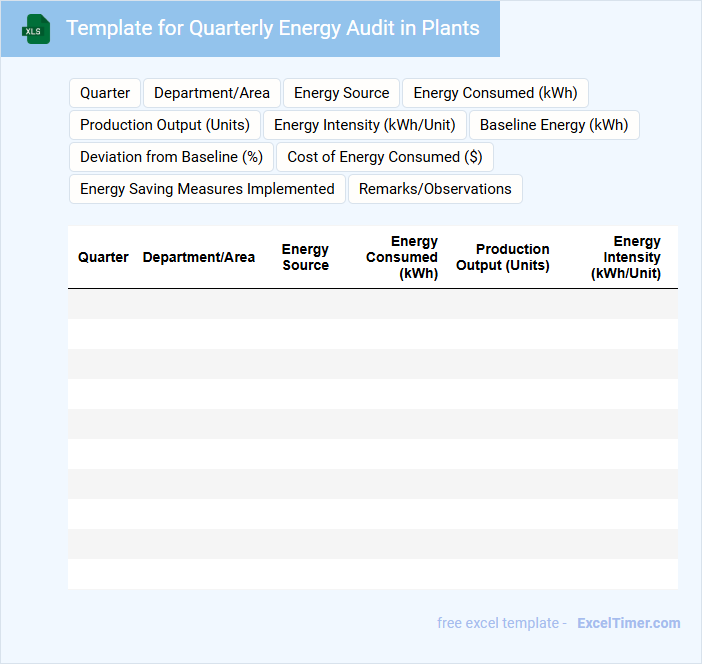

Template for Quarterly Energy Audit in Plants

What information is typically included in a Template for Quarterly Energy Audit in Plants? This document usually contains detailed records of energy consumption data, analysis of energy efficiency, and identification of potential areas for energy savings. It serves as a systematic tool to monitor, evaluate, and optimize energy usage in industrial plants on a quarterly basis.

What key elements should be considered when creating this template? Important aspects include clear sections for data collection, energy performance indicators, summary of findings, and actionable recommendations. Ensuring the template is user-friendly and adaptable for different plant types helps maintain consistency and improves the accuracy of energy audits.

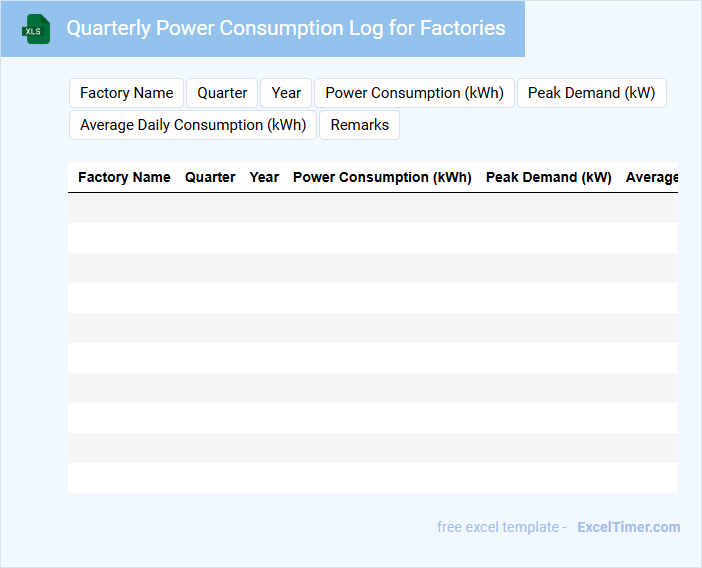

Quarterly Power Consumption Log for Factories

A Quarterly Power Consumption Log for factories typically contains detailed records of energy usage data collected over a three-month period. This document helps in analyzing consumption patterns and identifying opportunities for energy efficiency improvements. Factories rely on accurate logging to manage operational costs and comply with regulatory requirements.

It is crucial to include consistent measurements from all power sources and clearly note any anomalies or unusual spikes in consumption. Including a summary of energy-saving initiatives and their impact can enhance the document's usefulness. Regularly reviewing the log supports informed decision-making for sustainable factory management.

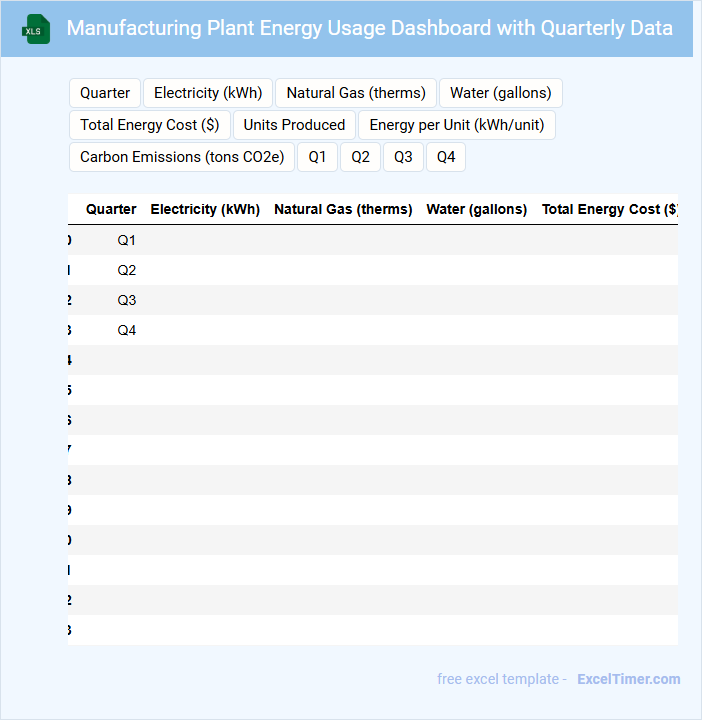

Manufacturing Plant Energy Usage Dashboard with Quarterly Data

What information is typically included in a Manufacturing Plant Energy Usage Dashboard with Quarterly Data? This type of document usually contains detailed energy consumption metrics, categorized by different departments or processes within the plant over quarterly intervals. It helps in identifying trends, anomalies, and opportunities for energy savings to optimize operational efficiency and reduce costs.

What are some important considerations when designing this dashboard? It is crucial to ensure clear visualization of data with graphs and charts for easy interpretation, and to include key performance indicators (KPIs) such as total energy usage, peak demand times, and comparisons to previous quarters. Additionally, incorporating actionable insights and recommendations supports informed decision-making for energy management strategies.

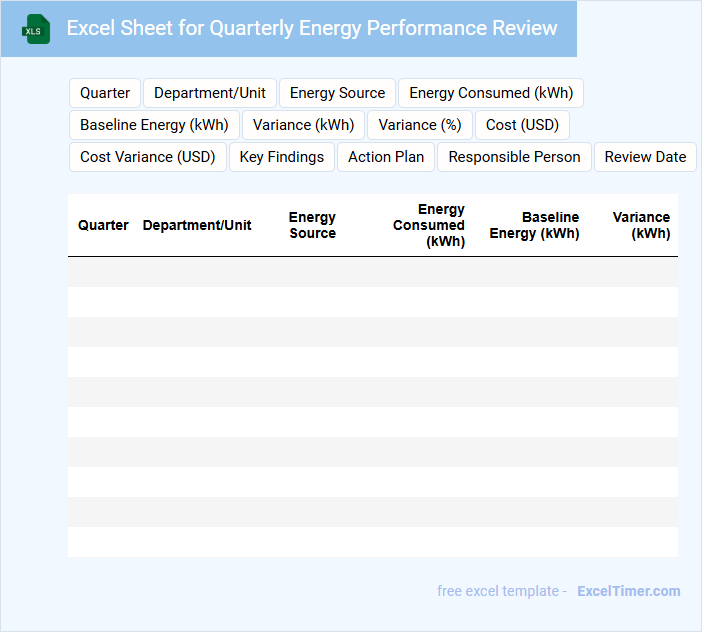

Excel Sheet for Quarterly Energy Performance Review

An Excel Sheet for Quarterly Energy Performance Review typically contains data on energy consumption, cost analysis, and efficiency metrics segmented by each quarter. It often includes charts and tables that highlight trends, peak usage periods, and areas of waste or savings. The document is essential for tracking progress towards energy goals and identifying actionable improvements.

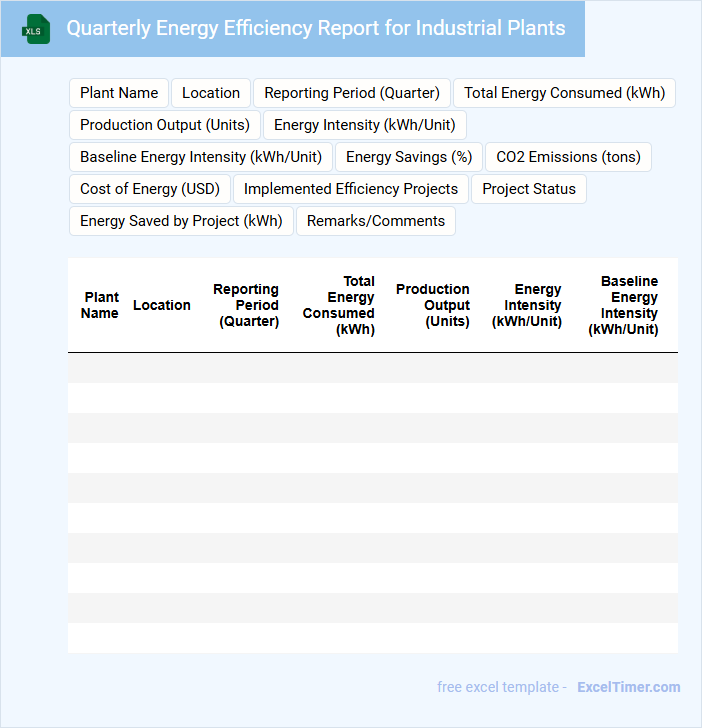

Quarterly Energy Efficiency Report for Industrial Plants

The Quarterly Energy Efficiency Report for Industrial Plants typically summarizes energy consumption trends, identifies inefficiencies, and recommends improvements.

- Energy Consumption Data: Detailed metrics on energy usage to track performance over the quarter.

- Efficiency Analysis: Comparative assessment of energy use against benchmarks and goals.

- Improvement Recommendations: Actionable steps to enhance energy efficiency and reduce costs.

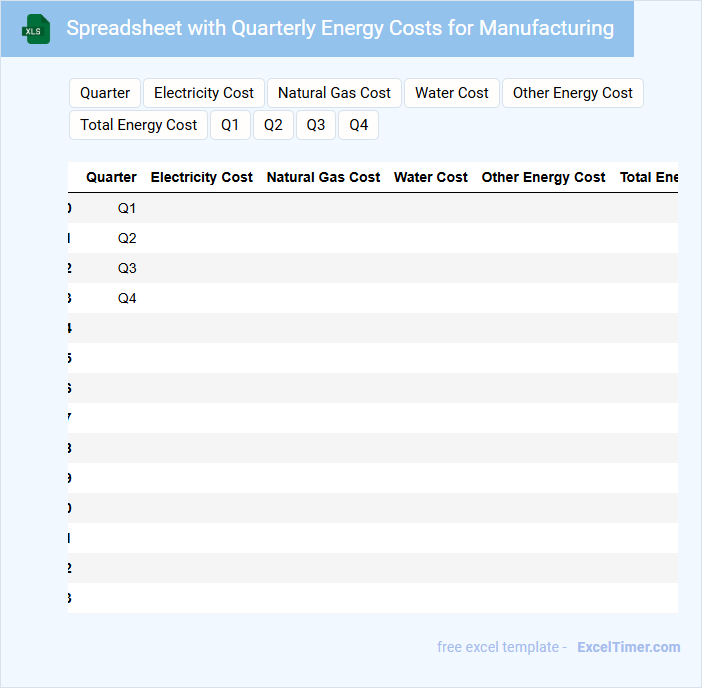

Spreadsheet with Quarterly Energy Costs for Manufacturing

What information is typically contained in a spreadsheet with quarterly energy costs for manufacturing? This type of document usually includes detailed records of energy consumption and associated expenses divided by each quarter. It is used to monitor, analyze, and optimize energy usage for cost savings and efficiency improvements within manufacturing operations.

What important factors should be considered when preparing this spreadsheet? Accurate data entry, clear labeling of time periods and cost categories, and inclusion of relevant units of measurement are essential for effective tracking. Additionally, incorporating charts or graphs can help visualize trends and support decision-making.

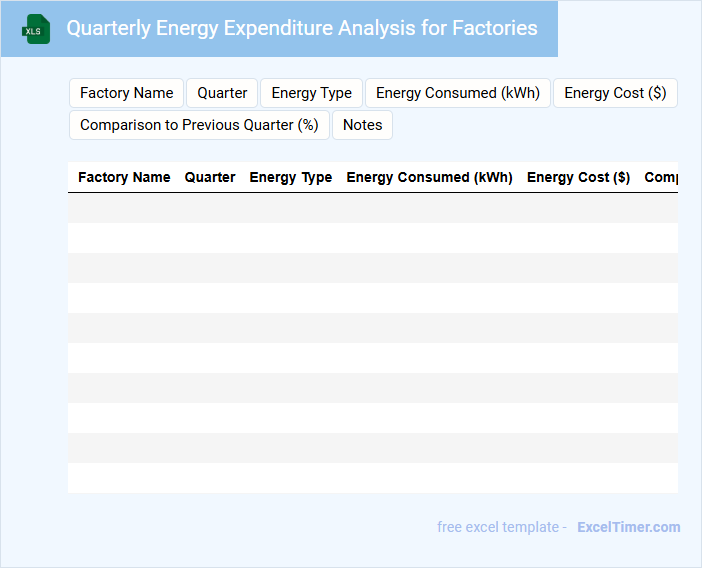

Quarterly Energy Expenditure Analysis for Factories

The Quarterly Energy Expenditure Analysis for factories typically contains detailed insights into energy consumption patterns, cost breakdowns, and efficiency metrics over a three-month period. It helps identify areas where energy usage can be optimized to reduce expenses and environmental impact. This document is essential for making informed decisions about energy management and sustainability initiatives.

Manufacturing Facility Energy Tracking with Quarterly Sheets

Manufacturing Facility Energy Tracking documents typically contain detailed records of energy consumption across various processes and equipment. The main purpose is to monitor usage patterns and identify opportunities for efficiency improvements. Energy tracking helps facilities reduce costs and minimize environmental impact through informed decision-making.

Important elements to include are monthly energy data segmented by source, comparisons against previous quarters, and notes on operational changes affecting consumption. Visual aids like charts or graphs are useful for quickly spotting trends and anomalies. It is also recommended to document any energy-saving initiatives and their respective impact on usage statistics.

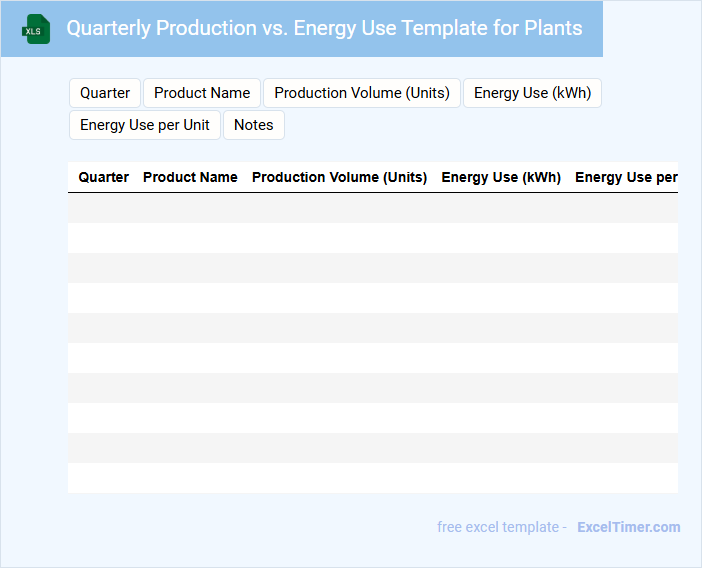

Quarterly Production vs. Energy Use Template for Plants

What information is typically included in a Quarterly Production vs. Energy Use Template for Plants? This document usually contains data comparing the amount of production output with the corresponding energy consumption over a specific quarter. It helps identify trends, efficiency levels, and areas where energy use can be optimized relative to production.

What important factors should be considered when using this template? Accurate and consistent data collection is crucial to ensure meaningful analysis. Additionally, including key performance indicators (KPIs) like energy per unit of production and setting realistic targets can drive better decision-making and energy management improvements.

Template for Tracking Quarterly Energy KPIs of Manufacturing Units

This template is designed to systematically monitor the energy consumption and efficiency of manufacturing units on a quarterly basis. It typically includes fields for tracking key performance indicators such as energy usage, cost, and reduction targets.

Using this document helps organizations identify trends, pinpoint inefficiencies, and support sustainability goals. Ensure to regularly update data and compare results against benchmarks for effective energy management.

What are the key factors influencing quarterly energy consumption trends in manufacturing plants?

Key factors influencing quarterly energy consumption trends in manufacturing plants include production volume, equipment efficiency, and seasonal temperature variations. Energy management practices and technology upgrades also play a significant role in optimizing usage. Your ability to monitor these variables closely ensures accurate analysis and sustainable energy strategies.

How is quarterly energy consumption measured and tracked within Excel documents for manufacturing operations?

Quarterly energy consumption in manufacturing plants is measured by recording usage data from meters or energy management systems and inputting it into Excel spreadsheets. Data is organized by plant, month, and energy source, enabling calculation of total consumption per quarter using formulas like SUM or PivotTables. Visualization tools within Excel, such as charts and conditional formatting, help track trends and identify anomalies for operational efficiency.

What are the most critical data columns to include for analyzing quarterly energy consumption in manufacturing plants?

Key data columns for analyzing quarterly energy consumption in manufacturing plants include Plant Name, Quarter, Energy Source, Total Energy Consumed (kWh), and Production Output. Tracking Energy Cost ($) and Energy Intensity (kWh per unit of production) helps identify cost efficiency and operational performance. Your analysis benefits from including these critical metrics to optimize energy usage and reduce expenses effectively.

How can Excel formulas or pivot tables be used to identify inefficiencies in quarterly energy usage?

Excel formulas and pivot tables analyze Quarterly Energy Consumption data by summarizing and comparing usage across different manufacturing plants and time periods. You can use formulas like SUMIFS to calculate energy totals for specific quarters and pivot tables to quickly visualize trends and highlight plants with unusually high energy consumption. This enables identification of inefficiencies and targeted energy-saving strategies.

What role does equipment type or production volume play in interpreting quarterly energy consumption data within Excel reports?

Equipment type influences energy consumption patterns by determining specific power requirements and operational efficiency, while production volume directly affects total energy usage due to output scale. Analyzing these variables in Excel reports enables accurate identification of energy-intensive processes and supports targeted efficiency improvements. Incorporating equipment and production data enhances the precision of energy performance assessments for manufacturing plants.