The Semi-annually Excel Template for Maintenance Scheduling simplifies tracking and planning maintenance tasks every six months, ensuring consistent upkeep of equipment and facilities. This template enhances organization by providing clear timelines, reminders, and checklists, reducing the risk of overlooked maintenance activities. Utilizing this tool improves asset longevity and minimizes unexpected downtime through proactive scheduling.

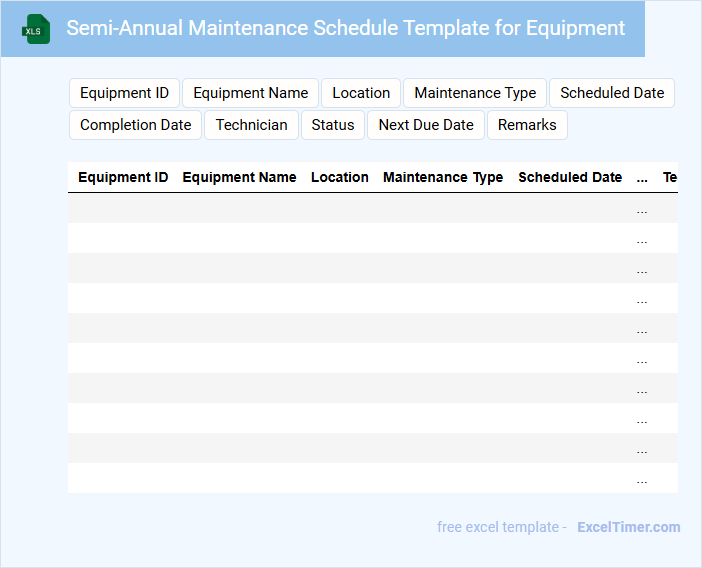

Semi-Annual Maintenance Schedule Template for Equipment

This type of document typically contains a planned timetable outlining routine maintenance activities for equipment every six months to ensure optimal performance and longevity.

- Equipment Details: Specific information about each piece of equipment to be maintained, including model numbers and serial numbers.

- Maintenance Tasks: Detailed descriptions of required maintenance activities, such as inspections, cleaning, lubrication, and part replacements.

- Scheduling and Responsibilities: Clear dates for each maintenance activity along with assigned personnel responsible for completing the tasks.

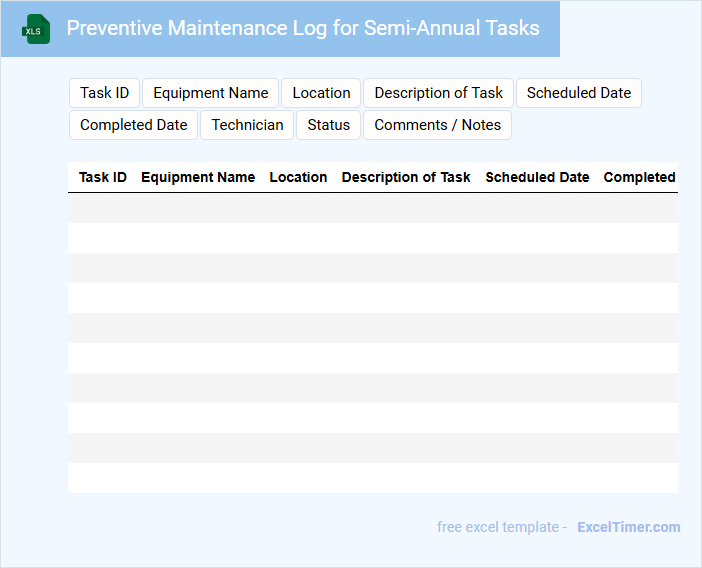

Preventive Maintenance Log for Semi-Annual Tasks

This document typically contains detailed records of scheduled semi-annual maintenance activities aimed at preventing equipment failure and ensuring operational efficiency.

- Consistency: Maintain regular and accurate entries to track all performed tasks comprehensively.

- Detail: Include specific information about the equipment, tasks performed, dates, and responsible personnel.

- Review: Periodically analyze the log to identify recurring issues and improve maintenance strategies.

Semi-Annual Inspection Checklist with Task Tracker

The Semi-Annual Inspection Checklist is a structured document used to systematically assess equipment, facilities, or processes every six months. It ensures that all critical components are reviewed to maintain operational efficiency and safety.

Including a Task Tracker within this document allows for effective monitoring and completion of identified actions. This helps in prioritizing maintenance tasks and improving accountability.

Ensure the checklist covers all relevant areas and that the task tracker is kept up-to-date to maximize its effectiveness.

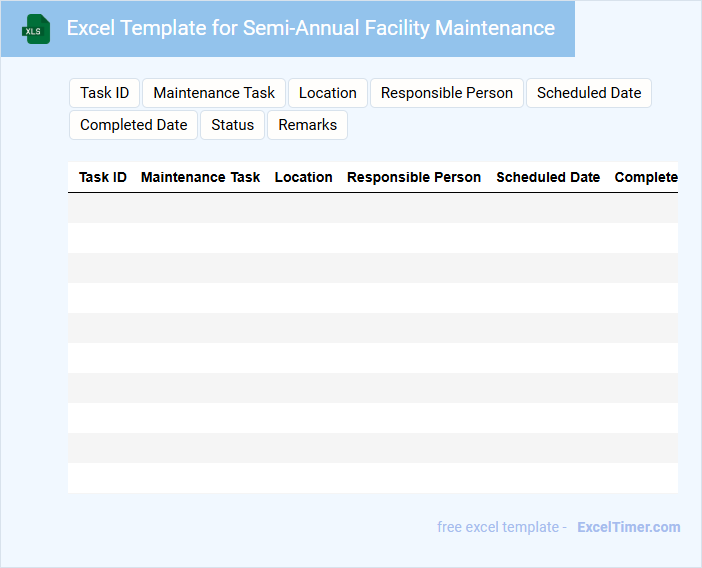

Excel Template for Semi-Annual Facility Maintenance

An Excel template for semi-annual facility maintenance typically contains detailed schedules and checklists for routine inspections, repairs, and cleaning tasks. It helps streamline the tracking of maintenance activities over the six-month period to ensure operational efficiency and safety compliance.

Key components include asset details, maintenance tasks, assigned personnel, and status updates for each activity. Including automated reminders and a summary dashboard is important to enhance tracking and accountability.

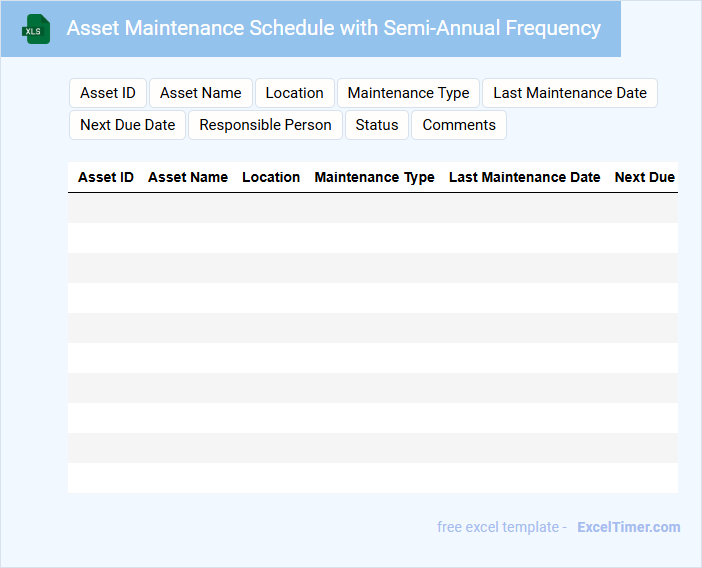

Asset Maintenance Schedule with Semi-Annual Frequency

An Asset Maintenance Schedule with a semi-annual frequency is a document that outlines planned inspections and servicing activities for equipment every six months. This type of schedule ensures timely upkeep, which helps in minimizing downtime and extending asset lifespan. Important elements to include are detailed task descriptions, assigned personnel, and deadlines to maintain systematic and efficient maintenance operations.

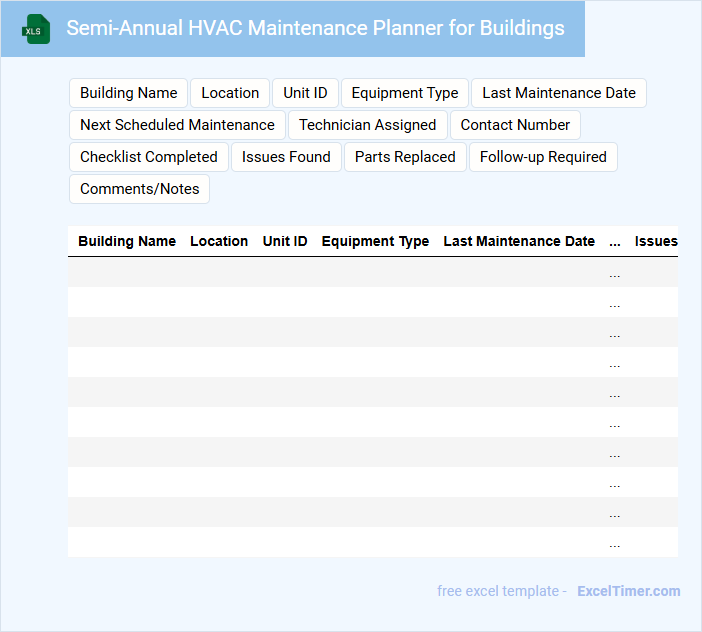

Semi-Annual HVAC Maintenance Planner for Buildings

The Semi-Annual HVAC Maintenance Planner is a document designed to schedule and track regular maintenance tasks for heating, ventilation, and air conditioning systems in buildings. It usually contains lists of essential checks, cleaning schedules, and recommended service intervals to ensure system efficiency and longevity. This planner helps facility managers prevent unexpected breakdowns and optimize energy consumption.

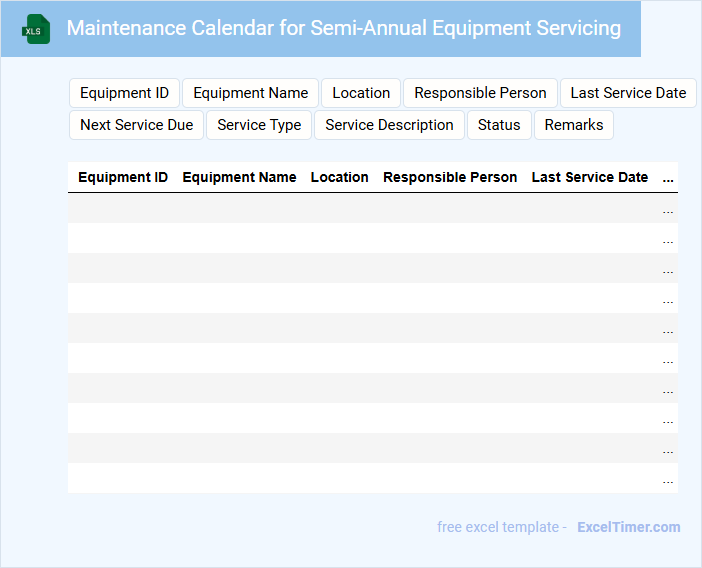

Maintenance Calendar for Semi-Annual Equipment Servicing

A Maintenance Calendar for Semi-Annual Equipment Servicing is a structured timetable outlining the scheduled upkeep activities for machinery biannually. It ensures timely maintenance to prevent breakdowns and prolong equipment life.

- Include specific dates and detailed descriptions of required maintenance tasks.

- Highlight critical equipment that needs prioritized attention during servicing.

- Incorporate reminders and responsible personnel for each maintenance activity.

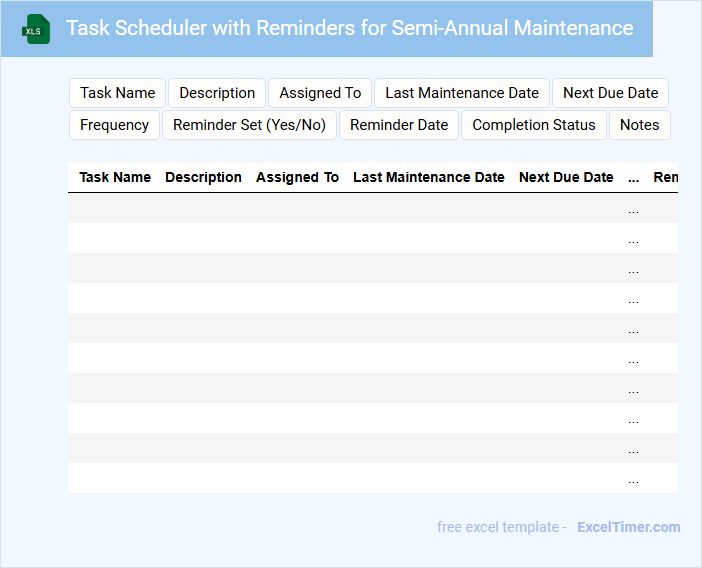

Task Scheduler with Reminders for Semi-Annual Maintenance

A Task Scheduler with reminders is a crucial tool designed to organize and automate maintenance activities efficiently. This type of document typically contains a detailed list of tasks, scheduled dates, and timely reminders to ensure no maintenance is overlooked. It's especially important for semi-annual maintenance to track recurring duties and deadlines systematically.

Key elements to include are task descriptions, assigned personnel or teams, deadlines, priority levels, and notification settings for upcoming tasks. Incorporating a review section for completed work and updates can enhance accountability and continuous improvement. Ensuring reminders are clear and actionable will help maintain consistent compliance and operational reliability.

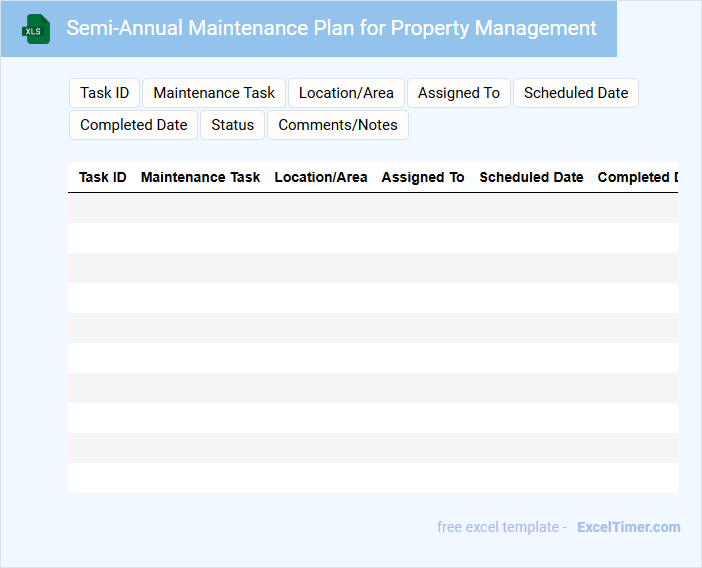

Semi-Annual Maintenance Plan for Property Management

What does a Semi-Annual Maintenance Plan for Property Management typically include? This document usually contains detailed schedules of inspection, cleaning, and repair tasks to be conducted every six months to ensure proper upkeep of the property. It outlines responsibilities, timelines, and key maintenance activities to prevent deterioration and extend the property's lifespan.

What important considerations should be included when creating this plan? It is crucial to prioritize safety checks for electrical, plumbing, and structural systems while incorporating budget estimates and emergency procedures. Additionally, clear communication with maintenance staff and tenants is essential to ensure timely and effective execution of the plan.

Work Order Tracker with Semi-Annual Service Intervals

Work Order Trackers with Semi-Annual Service Intervals typically contain detailed schedules for tasks that must be completed every six months to ensure proper maintenance and operational efficiency. These documents include fields such as work order numbers, descriptions of services, assigned personnel, deadlines, and status updates to monitor progress. An important suggestion is to consistently update and review the tracker to prevent missed services and reduce equipment downtime.

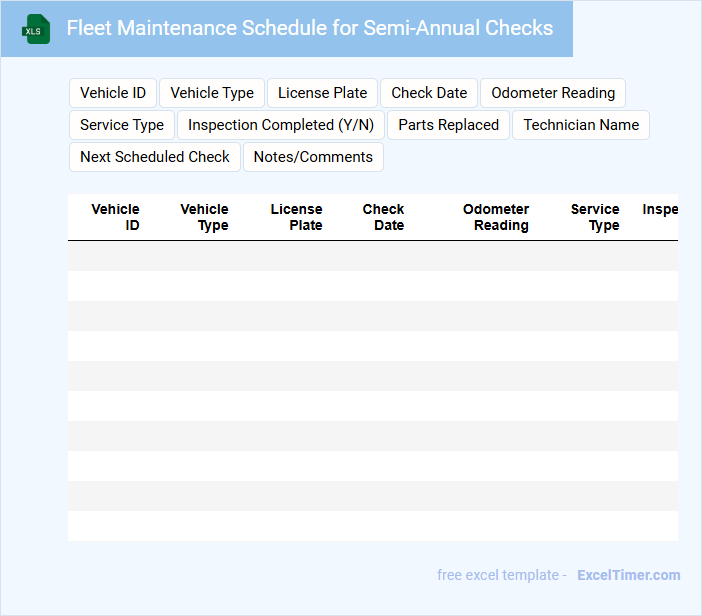

Fleet Maintenance Schedule for Semi-Annual Checks

What information is typically included in a Fleet Maintenance Schedule for Semi-Annual Checks? This document usually contains detailed timelines and checklists for inspecting and servicing vehicles every six months to ensure operational safety and efficiency. It outlines key maintenance tasks such as engine inspections, tire rotations, brake checks, and fluid replacements, helping fleet managers plan routine upkeep and prevent unexpected breakdowns.

What is an important aspect to consider when creating a Fleet Maintenance Schedule for Semi-Annual Checks? Prioritizing critical components prone to wear and documenting compliance with industry safety standards is essential. Additionally, incorporating a clear record-keeping system for completed tasks enhances accountability and aids in long-term vehicle performance monitoring.

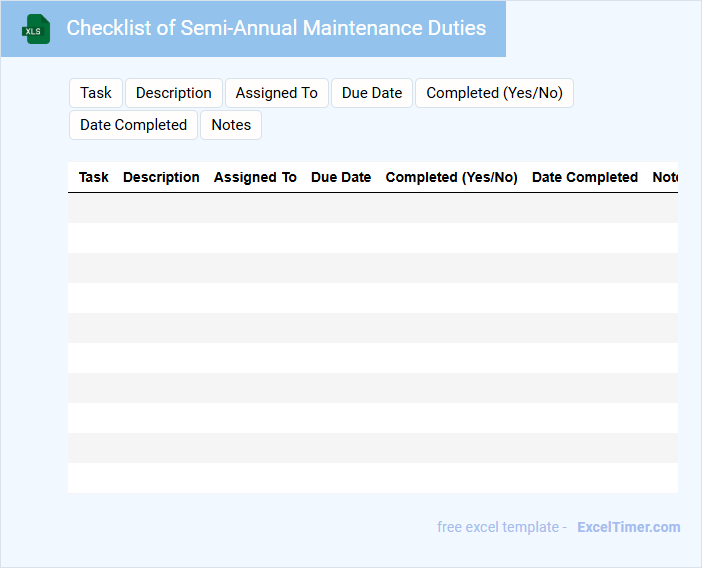

Checklist of Semi-Annual Maintenance Duties

What is typically included in a Checklist of Semi-Annual Maintenance Duties? This document generally contains a detailed list of tasks and inspections that are required to be performed every six months to ensure equipment or facility functionality and safety. It serves as a guide for maintenance personnel to systematically verify that all critical components are checked and serviced on time.

What important considerations should be made for this checklist? It is essential to prioritize tasks based on safety and operational impact, ensuring that high-risk areas receive prompt attention. Additionally, the checklist should be regularly updated to reflect changes in equipment, regulations, or best practices for optimal maintenance performance.

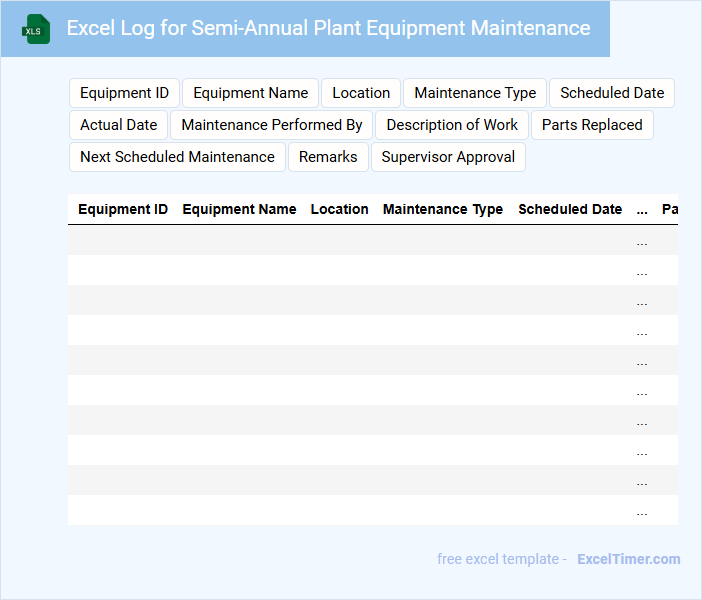

Excel Log for Semi-Annual Plant Equipment Maintenance

An Excel Log for Semi-Annual Plant Equipment Maintenance is a structured document used to track and schedule regular upkeep of machinery to ensure optimal performance. It typically contains detailed records of maintenance activities, dates, responsible personnel, and any observed issues or repairs. Maintaining accurate logs helps in predicting equipment lifespan and preventing unexpected failures, making it essential for operational efficiency.

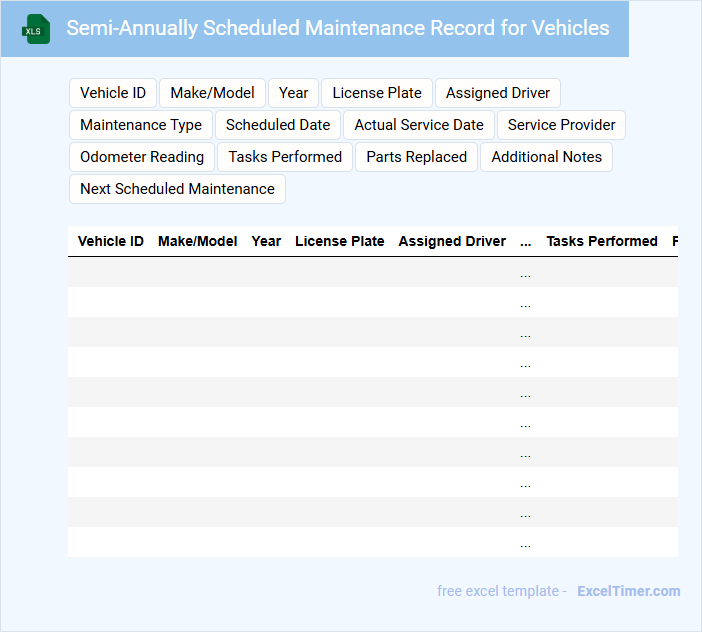

Semi-Annually Scheduled Maintenance Record for Vehicles

The Semi-Annually Scheduled Maintenance Record for vehicles documents routine checks and servicing conducted every six months. It includes inspection details, parts replaced, and performance evaluations to ensure optimal vehicle operation.

This document helps track maintenance history and plan future service dates effectively. Important elements include accurate date entries, mileage, and technician notes to guarantee comprehensive vehicle care.

Maintenance Tracking Sheet with Semi-Annual Intervals

What information is typically included in a Maintenance Tracking Sheet with Semi-Annual Intervals? This document usually contains records of equipment or facility maintenance tasks scheduled every six months, including dates, descriptions, responsible personnel, and status updates. It helps ensure timely inspections and upkeep to prevent breakdowns and extend asset life.

What key elements should be emphasized for effective use of this sheet? Clear identification of equipment, detailed task descriptions, consistent date entries, and a space for notes on issues or follow-up actions are important. Additionally, including reminders or alerts for upcoming maintenance ensures accountability and optimized scheduling.

What is the correct way to set a semi-annual recurrence for maintenance tasks in an Excel schedule?

Set a semi-annual recurrence in Excel by entering the initial maintenance date and using the formula =EDATE(start_date,6) to add six months for each subsequent task. Drag the formula down to fill the schedule with dates spaced exactly six months apart. This method ensures consistent semi-annual intervals for maintenance scheduling.

How can you use formulas to highlight upcoming semi-annual maintenance dates automatically?

You can use Excel formulas like =TODAY() combined with conditional formatting rules to automatically highlight upcoming semi-annual maintenance dates. By calculating the next maintenance due date using the DATE or EDATE functions based on the last service date, your spreadsheet updates dynamically. This approach ensures timely reminders and efficient scheduling for all semi-annual maintenance tasks.

Which Excel functions help in calculating the next semi-annual maintenance period from a given start date?

Excel functions like EDATE and DATE help calculate the next semi-annual maintenance period from a given start date by adding six months increments. Using EDATE(start_date, 6) returns the date exactly six months after the start date, ideal for scheduling maintenance every half year. Combining these functions with IF or TODAY can automate future maintenance tracking efficiently within the spreadsheet.

What best practices ensure data validity and accuracy for semi-annual schedules in Excel documents?

To ensure data validity and accuracy for semi-annual maintenance schedules in Excel, use data validation rules to restrict input types and range limits. Implement conditional formatting to highlight overdue or upcoming maintenance tasks based on the current date. Utilize structured tables and dynamic named ranges to maintain organized, easily updatable schedules.

How can you track and report completion status for semi-annual maintenance using Excel filters or tables?

Use Excel tables to list maintenance tasks with columns for scheduled dates, completion dates, and status. Apply filters to display tasks due within the current semi-annual period and those marked as completed or pending. Utilize conditional formatting to highlight overdue maintenance for efficient tracking and reporting.