The Weekly Production Report Excel Template for Manufacturing Teams streamlines tracking of output, efficiency, and downtime, providing clear insights into weekly performance. It enables quick identification of bottlenecks and helps optimize resource allocation to boost productivity. Customizable features ensure the report fits diverse manufacturing environments and reporting needs.

Weekly Production Report Template for Manufacturing Teams

A Weekly Production Report template for manufacturing teams typically contains detailed records of production output, equipment performance, and any issues encountered during the week. It serves as a critical tool for tracking progress against targets and identifying areas for improvement. Ensuring accurate data entry and timely updates is essential for maximizing efficiency and decision-making.

Production Output Tracker with Weekly Summary

A Production Output Tracker is a document used to monitor and record the quantity of goods produced over a specified period. It typically contains daily or weekly production figures, machine or worker efficiency data, and notes on any production issues. For a weekly summary, it's important to highlight trends, identify bottlenecks, and compare performance against targets to improve overall productivity.

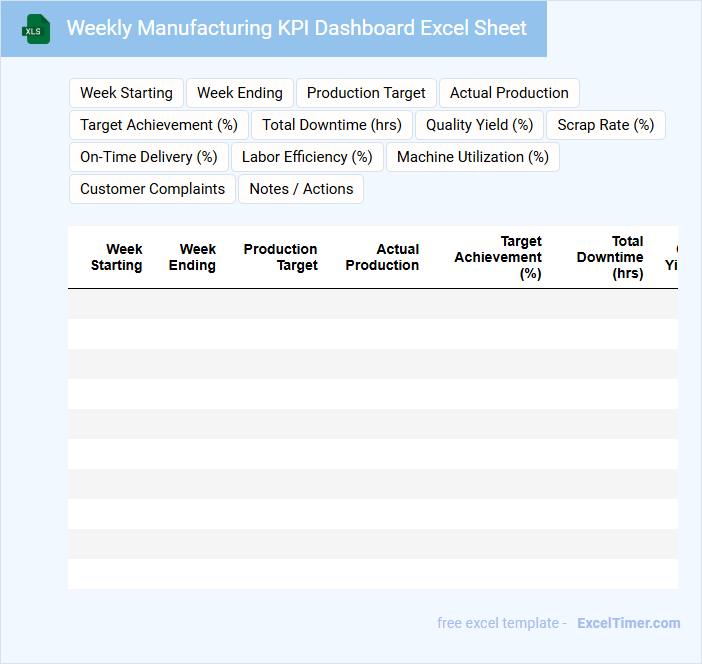

Weekly Manufacturing KPI Dashboard Excel Sheet

A Weekly Manufacturing KPI Dashboard Excel sheet typically contains key performance indicators such as production volume, defect rates, and equipment efficiency. It tracks these metrics on a weekly basis to provide insights into the manufacturing process effectiveness.

These dashboards often include visual elements like charts and graphs to help quickly identify trends and issues. Regular updates and accuracy are critical for making informed operational decisions.

Important considerations for this document include ensuring data accuracy, timely updates, and clear visualization to support management in optimizing production performance.

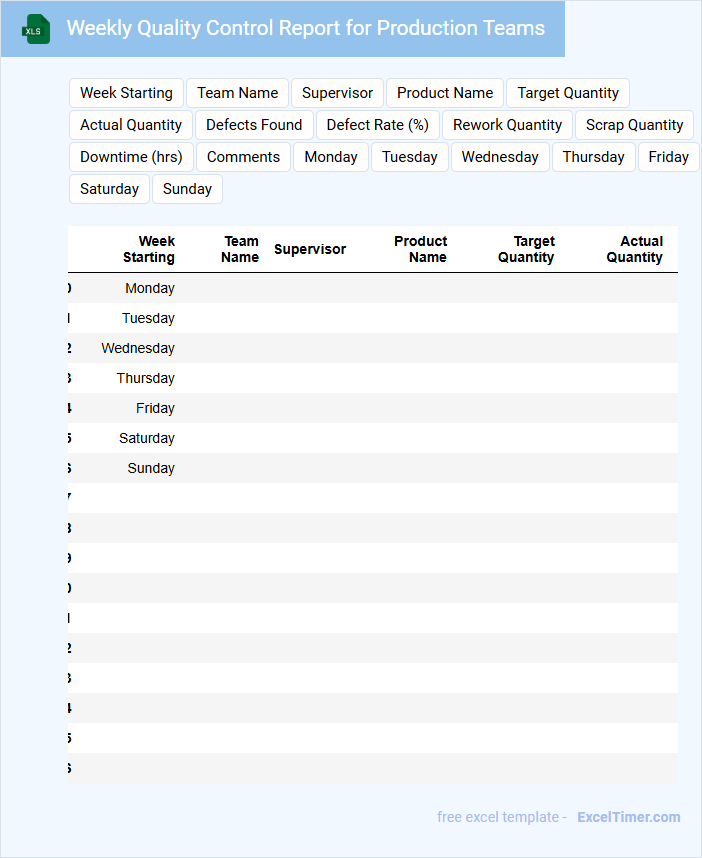

Weekly Quality Control Report for Production Teams

A Weekly Quality Control Report for Production Teams typically contains summarized data and analysis of product quality, highlighting any defects or deviations encountered during the production week.

- Inspection Results: Detailed records of quality checks performed on products and materials.

- Defect Analysis: Identification and categorization of common defects and their root causes.

- Corrective Actions: Suggested or implemented measures to improve quality and prevent recurrence.

Weekly Production Schedule Template with Task Tracking

A Weekly Production Schedule Template typically contains a detailed outline of production tasks, timelines, and responsible personnel for each day of the week. It helps in organizing workflow and managing resources efficiently to meet production targets. Clear task tracking columns ensure accountability and progress monitoring throughout the week. Important elements in this template include task priorities, deadlines, and status updates to maintain transparency and optimize productivity. Incorporating a section for notes or issues encountered during production can improve communication between team members and facilitate problem-solving. Consistent updating of the schedule is essential for accurate tracking and timely completion of tasks.

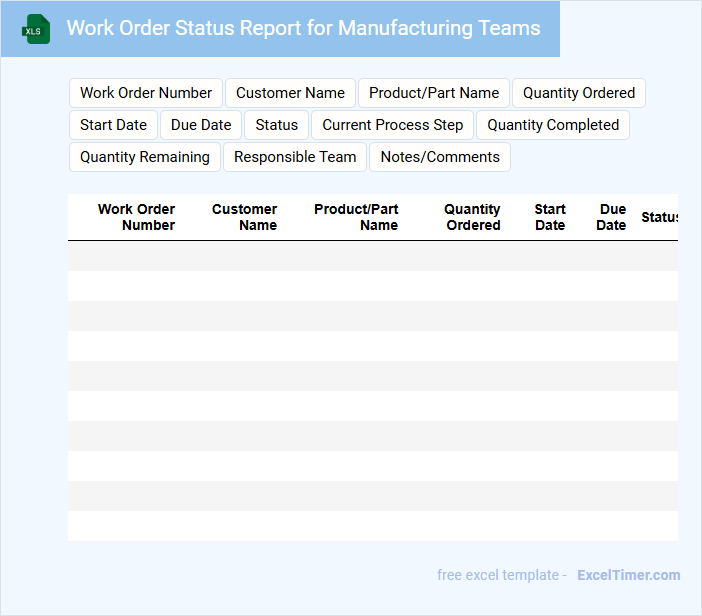

Work Order Status Report for Manufacturing Teams

A Work Order Status Report for manufacturing teams typically contains detailed information on the progress of various work orders currently in production. It includes key data such as order numbers, assigned personnel, start and completion dates, and current status to ensure transparency and efficiency. This report helps in identifying bottlenecks and optimizing workflow within the manufacturing process.

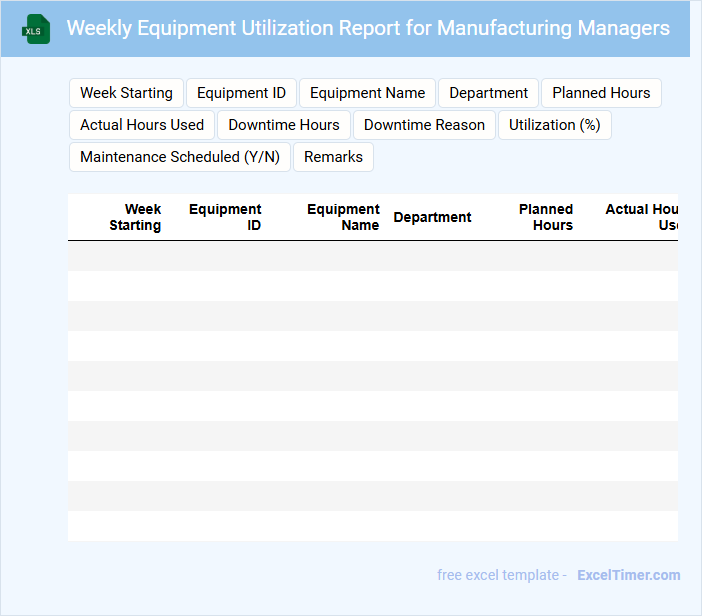

Weekly Equipment Utilization Report for Manufacturing Managers

What does a Weekly Equipment Utilization Report for Manufacturing Managers typically contain? This report usually includes data on the operational status, usage hours, downtime, and efficiency rates of manufacturing equipment over the week. By analyzing this information, managers can identify performance bottlenecks and optimize maintenance schedules to ensure smooth production flow.

Shift Production Summary with Weekly Metrics

A Shift Production Summary with Weekly Metrics document typically contains detailed records of production output, efficiency, and downtime for each shift across the week. It provides insights into the performance trends and helps identify areas for improvement.

- Include key performance indicators such as units produced, defect rates, and machine uptime.

- Highlight any production bottlenecks or delays encountered during shifts.

- Summarize shift-to-shift and week-to-week performance variations for trend analysis.

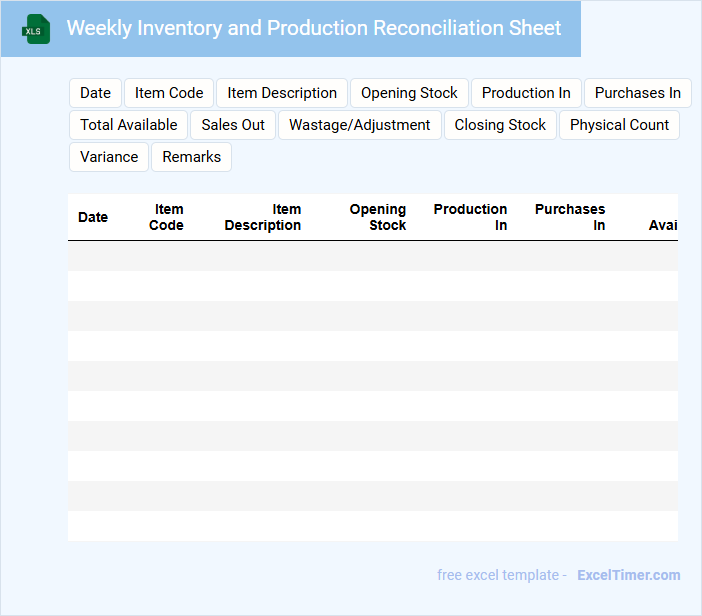

Weekly Inventory and Production Reconciliation Sheet

A Weekly Inventory and Production Reconciliation Sheet typically contains detailed records of inventory levels and production outputs over a week to ensure accuracy and identify discrepancies. It is essential for maintaining balanced stock and production management.

- Accurately record beginning and ending inventory quantities for the week.

- Track production volumes and compare them against inventory usage.

- Identify and investigate any variances or discrepancies promptly.

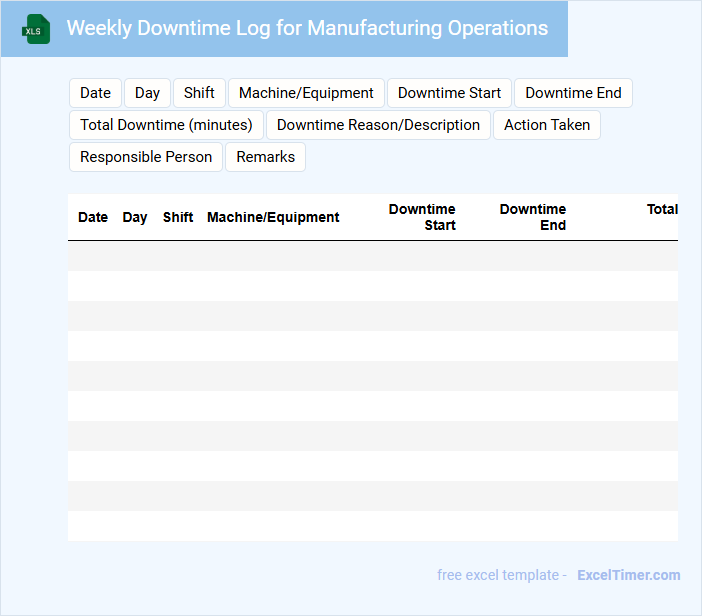

Weekly Downtime Log for Manufacturing Operations

A Weekly Downtime Log for manufacturing operations typically records all instances of equipment or process stoppages during the week. This document captures details such as the duration, cause, and impact of each downtime event to help identify patterns. Maintaining accurate entries ensures effective tracking and analysis of operational inefficiencies.

It is essential to include clear categorization of downtime reasons and assign responsibility for resolution in the log. Regular review meetings based on this document help prioritize maintenance and process improvements. Consistency and accuracy in this log support minimizing unplanned production losses.

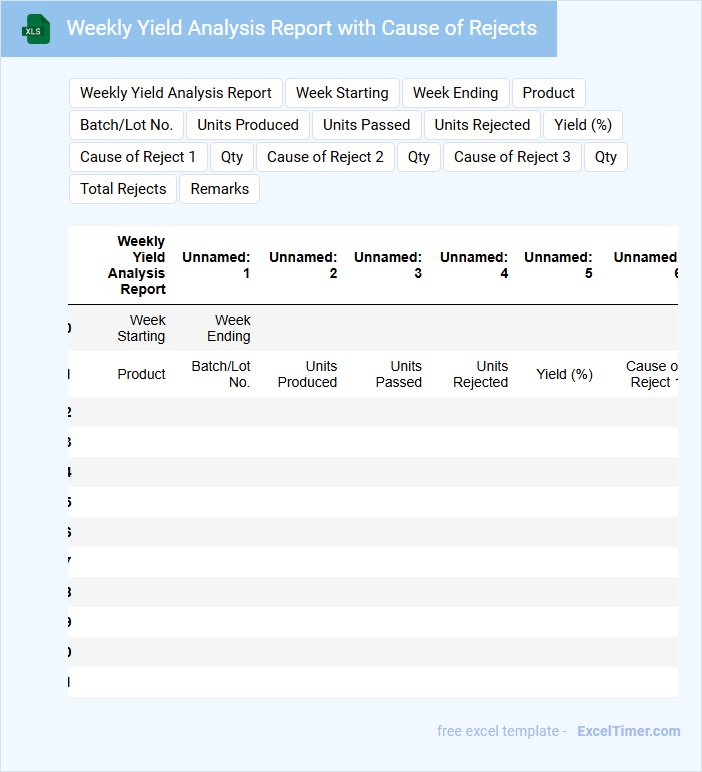

Weekly Yield Analysis Report with Cause of Rejects

The Weekly Yield Analysis Report usually contains detailed data on production output and the efficiency of manufacturing processes over a week. It highlights the percentage of yield achieved and compares it against targets or previous periods. Additionally, it identifies and categorizes causes of rejects to help pinpoint problem areas in production.

Important considerations for this document include ensuring accurate data collection, thorough analysis of reject causes, and clear visualization of trends for quick decision-making. Including root cause analysis and proposed corrective actions can significantly enhance its usefulness. Consistent formatting and timely reporting are crucial for effective communication across teams.

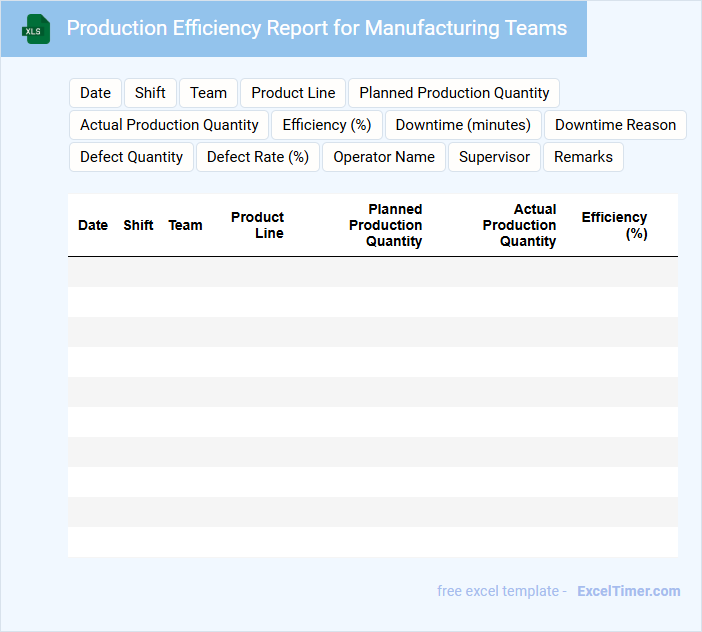

Production Efficiency Report for Manufacturing Teams

A Production Efficiency Report for manufacturing teams typically contains data on output rates, machinery performance, and labor productivity. It highlights areas of success and identifies bottlenecks that affect overall efficiency. This report is crucial for continuous improvement and informed decision-making on the factory floor.

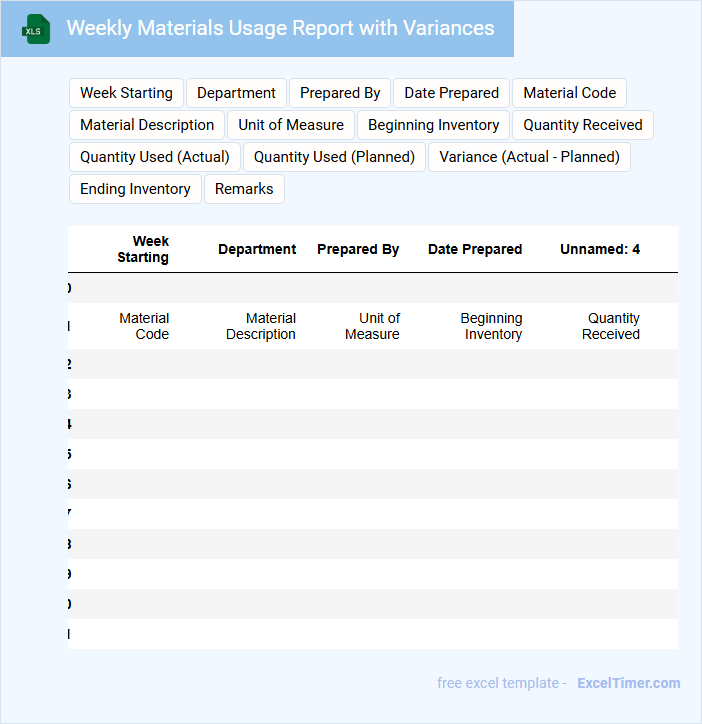

Weekly Materials Usage Report with Variances

The Weekly Materials Usage Report typically contains detailed records of materials used in production over a week, including quantities and costs. It highlights variances between planned and actual usage to identify discrepancies.

Monitoring these variances helps in controlling expenses and optimizing inventory management. Consistent tracking of such reports ensures better decision-making and resource allocation.

Important elements to include are accurate data entries, clear variance explanations, and actionable recommendations for process improvements.

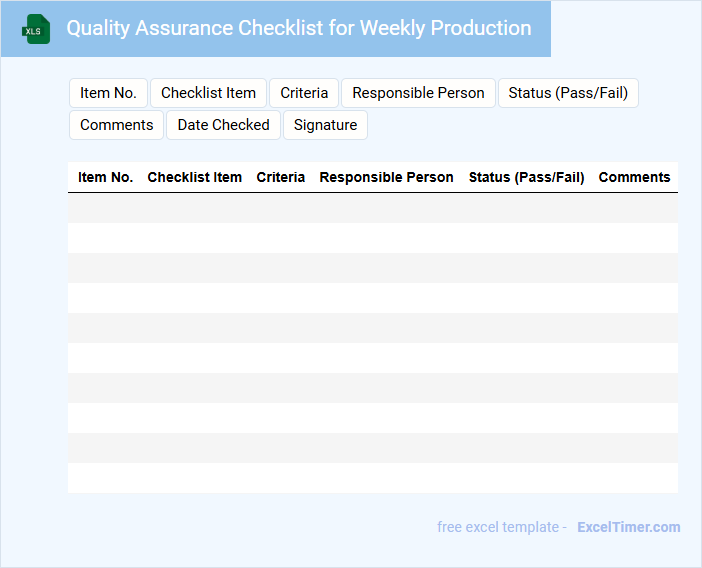

Quality Assurance Checklist for Weekly Production

The Quality Assurance Checklist for Weekly Production typically contains a comprehensive list of tasks aimed at ensuring product consistency and meeting standards. It includes verification points for raw materials, machinery calibration, and final product inspection. Additionally, it serves as a crucial tool for identifying potential issues early and maintaining regulatory compliance.

Weekly Packing and Shipment Record for Manufacturing

A Weekly Packing and Shipment Record for Manufacturing typically contains detailed information about the products packed and shipped within the week to ensure accurate tracking and inventory management.

- Product Details: Includes descriptions, quantities, and batch numbers of items packed and shipped.

- Shipment Dates: Records the exact dates when shipments are dispatched to maintain timely delivery schedules.

- Carrier Information: Documents the shipping companies and tracking numbers used for each shipment to enable tracking and accountability.

What key metrics should be included in a Weekly Production Report for effective manufacturing team analysis?

A Weekly Production Report for manufacturing teams should include key metrics such as total units produced, production efficiency rate, machine downtime hours, and defect rates. Tracking these data points enables accurate assessment of your team's performance and identification of bottlenecks. Monitoring raw material usage and labor hours also supports optimized resource allocation and cost control.

How can Excel formulas be used to automatically calculate production totals, variances, and efficiency rates?

Excel formulas such as SUM can calculate total production by aggregating daily output data across the week. Variances are computed using formulas like =Actual Production - Target Production, highlighting discrepancies for each team. Efficiency rates are derived by dividing actual output by the planned capacity using formulas like =(Actual Production / Planned Capacity) * 100%, enabling precise performance analysis.

What essential sections or tables should be structured in the Excel document for clear data segmentation?

An effective Weekly Production Report for Manufacturing Teams should include sections such as Production Summary, detailing units produced, target vs. actual output, and efficiency rates. A Defects and Quality Issues table capturing defect types, counts, and resolution status ensures quality tracking. Labor and Machine Utilization data highlighting hours worked, downtime, and machine availability provide insight into operational performance.

How should downtime and production delays be tracked and visually represented in the report?

Downtime and production delays should be tracked using precise timestamps and categorized by cause in the Weekly Production Report. Visual representation can include color-coded bar charts or Gantt charts highlighting periods of inactivity alongside active production times. Incorporating key metrics such as total downtime hours, delay frequency, and impact on output ensures clear insight for manufacturing team performance analysis.

Which data validation or protection features in Excel help maintain report accuracy and restrict unauthorized edits?

Excel's Data Validation feature restricts inputs to predefined criteria, ensuring accuracy in Weekly Production Reports. Protect Sheet and Workbook options limit unauthorized edits by allowing only designated users to modify the report. Combining these tools enhances data integrity for manufacturing team reports.