The Annually Compliance Checklist Excel Template for Food Industry helps businesses maintain strict adherence to food safety regulations and industry standards. It systematically tracks inspections, audits, and corrective actions, ensuring timely compliance with health codes and certifications. Utilizing this template enhances operational efficiency and reduces the risk of regulatory penalties.

Annual Compliance Checklist Excel Template for Food Industry

This document typically contains a structured list of regulatory and operational requirements for food industry compliance on an annual basis.

- Regulatory Standards: Detailed sections covering relevant food safety and quality regulations.

- Inspection Schedules: Timelines and checkpoints for routine and special inspections throughout the year.

- Corrective Actions: Clear documentation fields for identifying and addressing compliance deficiencies.

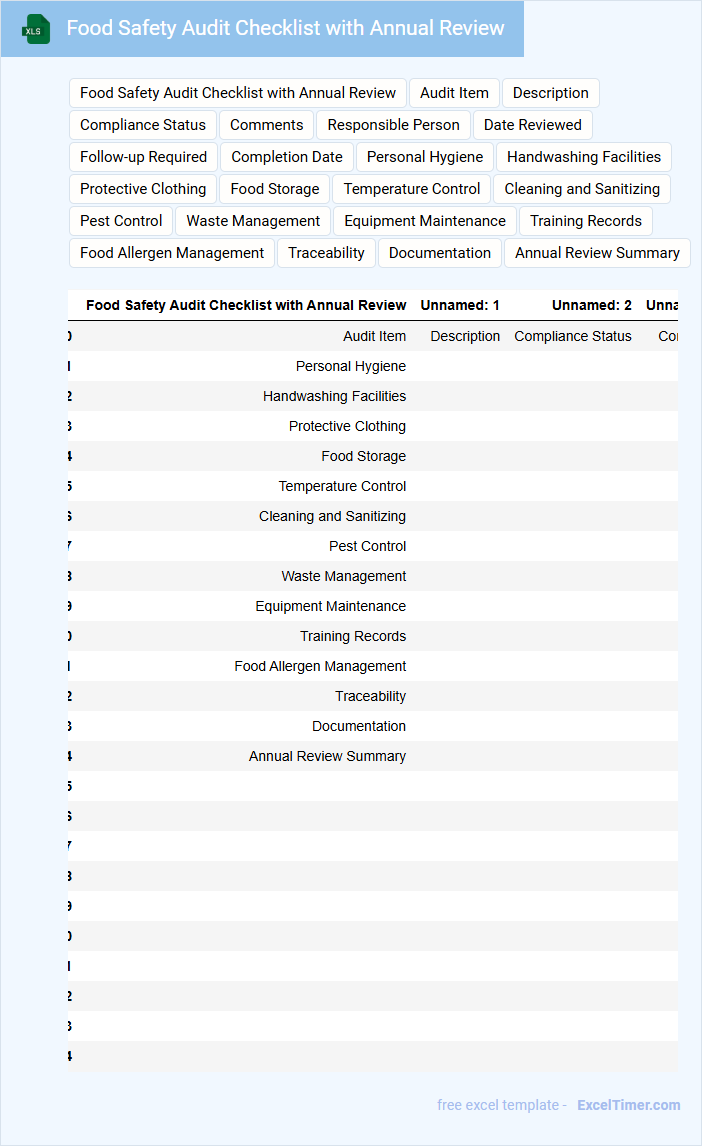

Food Safety Audit Checklist with Annual Review

A Food Safety Audit Checklist is a structured document used to evaluate compliance with food safety standards and regulations. It ensures that all critical control points in food handling and processing are regularly monitored and documented.

The Annual Review of this checklist updates criteria based on the latest food safety practices and regulatory changes. This review helps maintain continual improvement and risk mitigation strategies.

Important elements to include are hazard identification, sanitation procedures, employee training records, and corrective action documentation.

Yearly Compliance Tracking Sheet for Food Manufacturers

A Yearly Compliance Tracking Sheet for food manufacturers is a document that monitors adherence to regulatory standards and safety requirements throughout the year. It typically contains records of inspections, certifications, and corrective actions taken to ensure ongoing compliance.

Maintaining accurate and up-to-date entries in the tracking sheet helps prevent legal issues and supports food safety management systems. Regular review and timely updates are crucial to address new regulations and maintain industry standards.

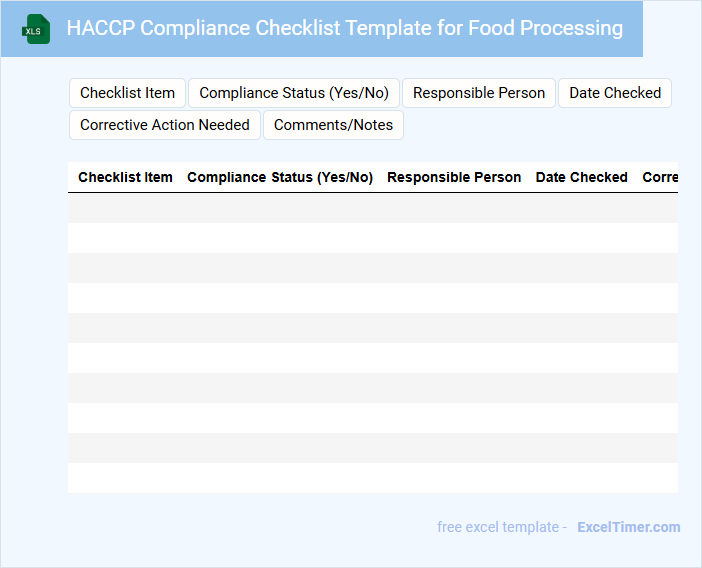

HACCP Compliance Checklist Template for Food Processing

What information is typically included in a HACCP Compliance Checklist Template for Food Processing? This document usually contains detailed criteria and checkpoints related to hazard analysis and critical control points within food production processes. It serves as a guide to ensure all necessary safety measures are identified, monitored, and documented to maintain food safety standards.

Why is it important to carefully review and update the HACCP Compliance Checklist Template regularly? Regular updates ensure the checklist reflects the latest regulatory requirements and industry best practices, helping avoid contamination risks and ensuring effective control measures. Keeping the document current supports continuous improvement and compliance with food safety legislation.

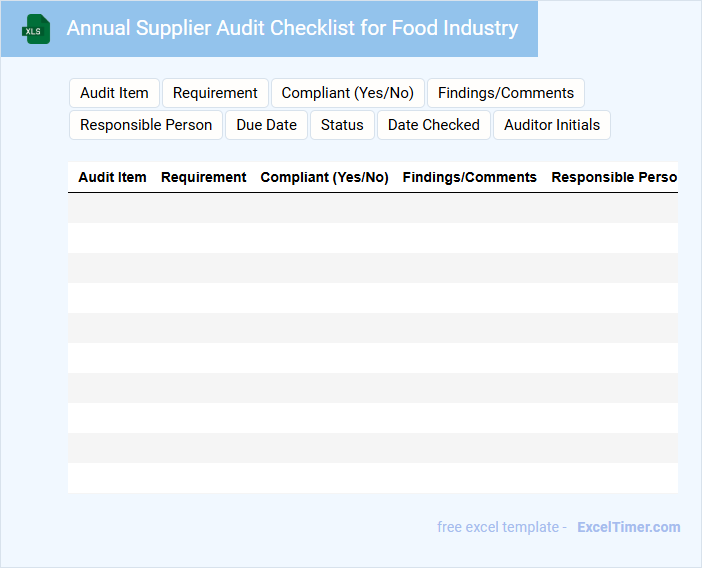

Annual Supplier Audit Checklist for Food Industry

Annual Supplier Audit Checklist is a critical document used in the food industry to systematically evaluate supplier compliance with food safety and quality standards. It typically contains detailed criteria covering hygiene, documentation, and product traceability to ensure supplier reliability and regulatory adherence.

The checklist emphasizes key areas such as sanitation procedures, ingredient sourcing, and record-keeping to identify potential risks early. Including corrective action plans and verification steps is essential for continuous improvement and maintaining a robust supply chain.

Annual GMP Compliance Tracker for Food Production

The Annual GMP Compliance Tracker for food production is a document that records adherence to Good Manufacturing Practices throughout the year. It ensures that all food safety protocols and regulatory standards are consistently met.

This tracker typically includes inspection dates, corrective actions, and verification results. Maintaining accurate records helps identify trends and areas needing improvement to uphold product quality.

Important considerations are regular updates, thorough documentation, and clear accountability to drive continuous compliance and food safety excellence.

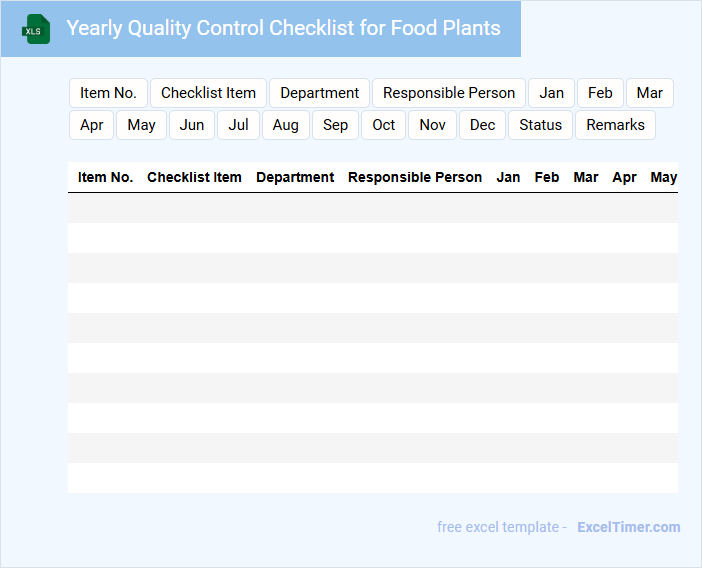

Yearly Quality Control Checklist for Food Plants

The Yearly Quality Control Checklist for food plants is a comprehensive document designed to ensure all quality standards are met throughout the year. It typically contains detailed inspections of equipment, hygiene practices, and compliance with food safety regulations. The checklist helps identify areas for improvement to maintain consistent product quality and safety.

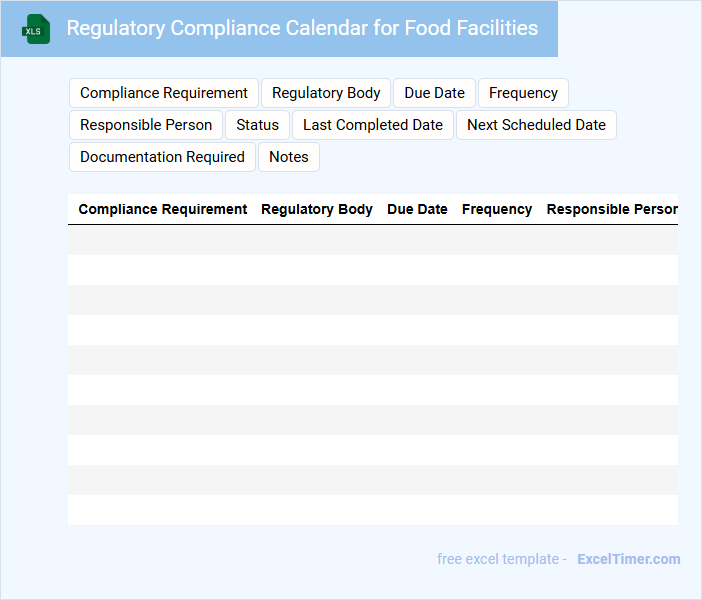

Regulatory Compliance Calendar for Food Facilities

A Regulatory Compliance Calendar for food facilities is a crucial document that outlines important dates and deadlines related to safety inspections, certification renewals, and reporting requirements. It helps ensure that food facilities stay compliant with local, state, and federal food safety regulations. Maintaining this calendar prevents costly fines and safeguards public health by promoting timely adherence to legal obligations.

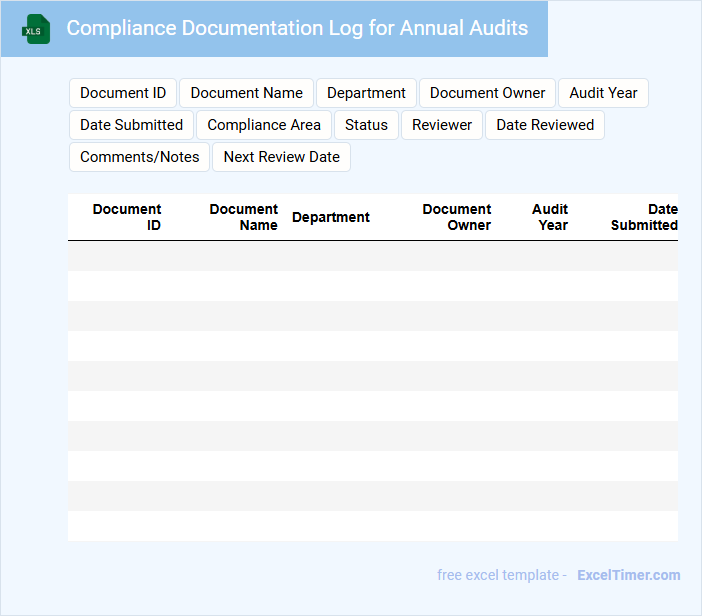

Compliance Documentation Log for Annual Audits

Compliance Documentation Log for Annual Audits is a structured record that tracks all necessary documents to ensure regulatory adherence during yearly audit processes.

- Identification: Clearly label each document with dates, authors, and category for easy reference.

- Completeness: Ensure all compliance-related files are included and updated regularly.

- Accessibility: Maintain secure but easy access for auditors and authorized personnel.

Annual Sanitation Checklist for Food Industry Operations

What does an Annual Sanitation Checklist for Food Industry Operations typically contain? This type of document usually includes detailed criteria for cleanliness, hygiene practices, and sanitation protocols specific to food processing environments. It serves to ensure compliance with health regulations and maintain safe food handling standards throughout the year.

What important aspects should be included in this checklist? Key elements to include are equipment sanitation procedures, employee hygiene requirements, pest control measures, and verification of cleaning schedules. Incorporating these factors helps prevent contamination and supports consistent food safety management.

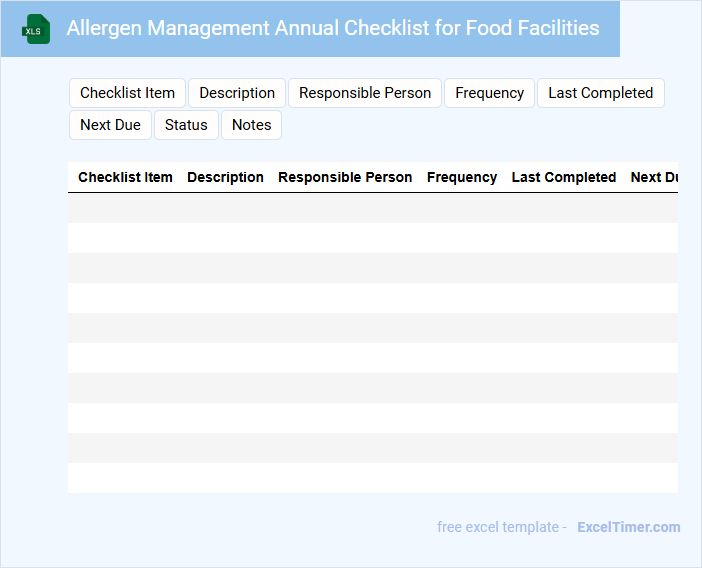

Allergen Management Annual Checklist for Food Facilities

The Allergen Management Annual Checklist for food facilities is a critical document ensuring the safe handling and identification of allergens within food production environments. It typically contains comprehensive protocols, verification steps, and corrective actions aimed at minimizing allergen cross-contact risks. Facilities use this checklist to maintain compliance with food safety regulations and uphold consumer trust.

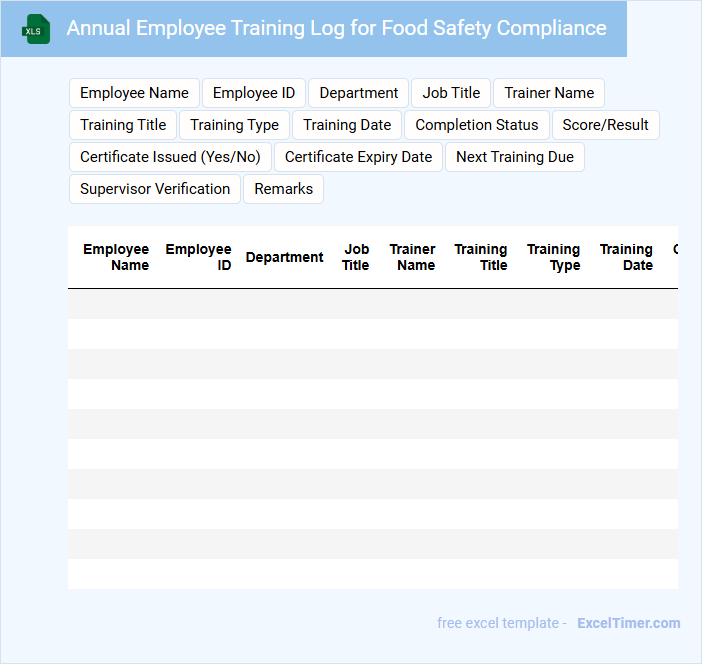

Annual Employee Training Log for Food Safety Compliance

Annual Employee Training Log for Food Safety Compliance typically contains detailed records of employee training sessions aimed at ensuring food safety standards are met.

- Training Dates and Topics: Documenting when and what specific food safety subjects were covered in each training session.

- Employee Attendance and Certification: Tracking which employees attended the training and any certifications they obtained.

- Trainer Information and Assessment Results: Recording the credentials of trainers and evaluating employee understanding through assessments or quizzes.

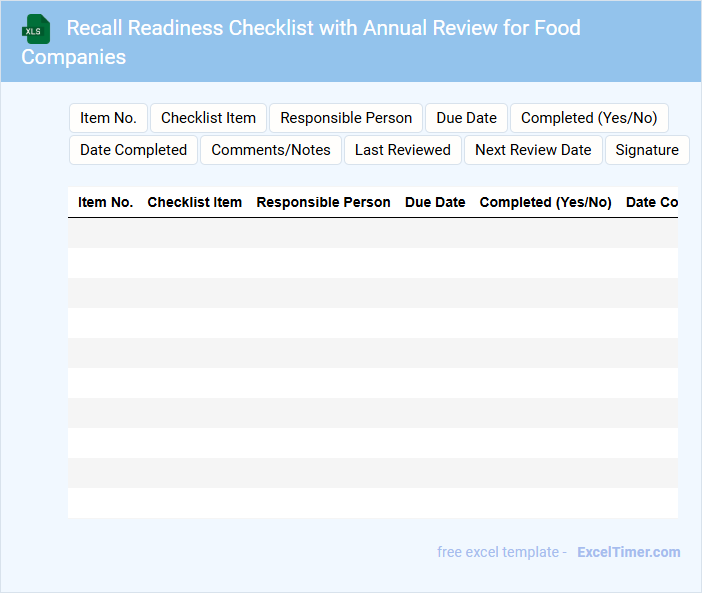

Recall Readiness Checklist with Annual Review for Food Companies

A Recall Readiness Checklist with Annual Review for food companies is a critical document designed to ensure preparedness for product recalls. It typically contains detailed steps for identifying, managing, and communicating recalls effectively. Regular annual reviews help maintain compliance and improve response strategies.

Important elements to include are clear roles and responsibilities, up-to-date contact information, and procedures for traceability and product retrieval. Emphasizing timely communication with regulatory authorities and consumers is essential. Regular training and audit schedules should also be incorporated for ongoing readiness.

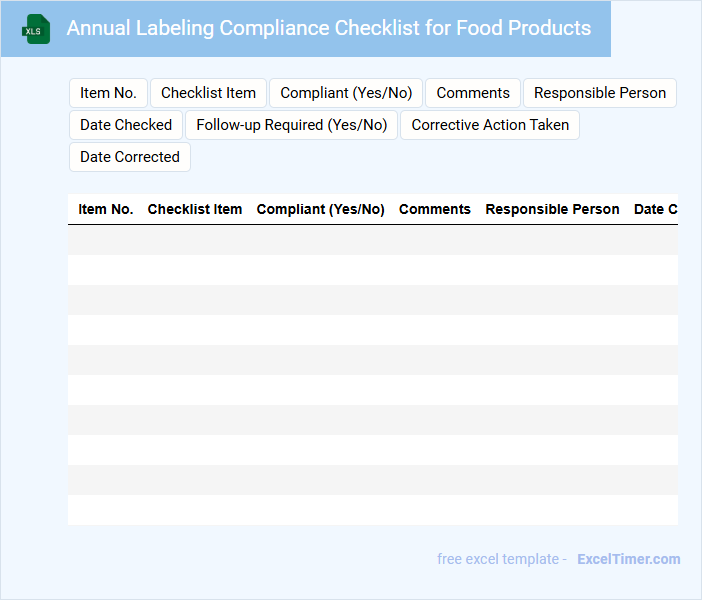

Annual Labeling Compliance Checklist for Food Products

What does an Annual Labeling Compliance Checklist for Food Products usually contain? This document typically includes a detailed review of all labeling requirements such as ingredient lists, allergen declarations, nutritional information, and regulatory claims to ensure compliance with food safety laws. It serves as a systematic guide for food manufacturers to verify that their product labels meet current legal standards and avoid costly penalties.

Why is it important to update this checklist annually? Regulatory requirements for food labeling frequently change due to new health guidelines or legal amendments, so updating the checklist ensures continuous compliance. Keeping this document current helps companies maintain product safety transparency and reinforces consumer trust.

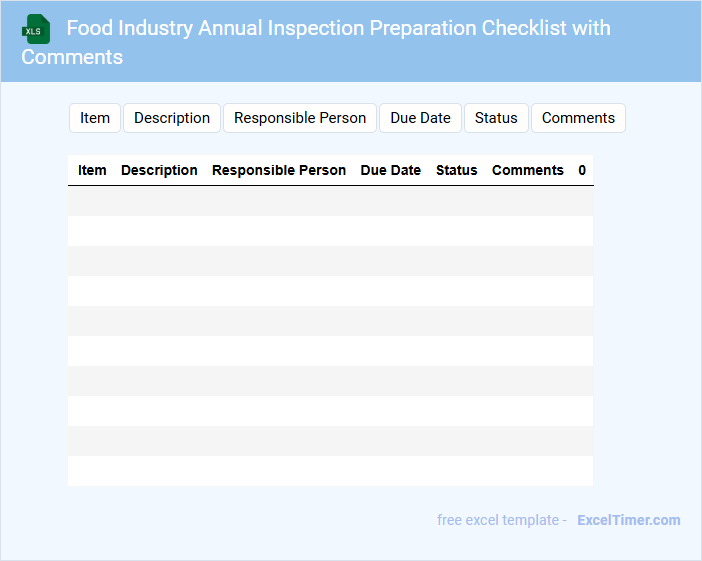

Food Industry Annual Inspection Preparation Checklist with Comments

The Food Industry Annual Inspection Preparation Checklist is a comprehensive document used to ensure compliance with health and safety regulations. It typically contains detailed items for verifying sanitation, equipment maintenance, and employee hygiene practices. Including comments helps clarify inspection points and provides actionable recommendations for improvements.

What key regulatory agencies' requirements must be included in the annual compliance checklist for the food industry?

Your annual compliance checklist for the food industry must include requirements from key regulatory agencies such as the Food and Drug Administration (FDA), the United States Department of Agriculture (USDA), and the Occupational Safety and Health Administration (OSHA). Incorporate guidelines from the Environmental Protection Agency (EPA) and state-level health departments to ensure comprehensive regulatory adherence. Meeting these agencies' standards is critical for maintaining safety, quality, and legal compliance in your food operations.

Which records and documentation are legally required to be updated and maintained yearly?

Your annually compliance checklist for the food industry must include updating and maintaining records such as food safety management plans, sanitation logs, employee training certifications, and supplier verification documents. Regulatory authorities require documentation of Hazard Analysis Critical Control Points (HACCP) reviews, allergen control measures, and product traceability records. Keeping these records compliant ensures your facility meets legal standards and passes inspections.

What critical food safety procedures must be verified for annual compliance?

Annual compliance in the food industry requires verification of HACCP plan accuracy, allergen control measures, and sanitation protocols. Equipment calibration and employee food safety training records must be reviewed to ensure standards meet regulatory requirements. Documented corrective actions from past audits should also be analyzed to confirm ongoing adherence.

Which employee training certifications and renewals are necessary for annual compliance?

Annual compliance in the food industry requires employee training certifications including Food Safety Training, HACCP Certification, and Allergen Awareness. Renewal of these certifications typically occurs every 12 months to meet regulatory standards. Documentation of completed trainings and renewal dates must be maintained for audit readiness.

What facility inspections or equipment maintenance checks should be scheduled for annual compliance?

Annual compliance for the food industry requires facility inspections including sanitation audits, pest control evaluations, and structural integrity assessments. Equipment maintenance checks must cover calibration of temperature controls, cleaning and servicing of refrigeration units, and verification of safety mechanisms on processing machinery. Documenting these scheduled inspections ensures adherence to food safety regulations and reduces risk of contamination.