The Daily Production Log Excel Template for Manufacturing Teams streamlines tracking of daily output, machine performance, and labor efficiency in a single spreadsheet. This template enhances accuracy by allowing real-time data entry and helps identify production bottlenecks quickly. Key benefits include improved productivity monitoring, easy customization, and seamless integration with other manufacturing process tools.

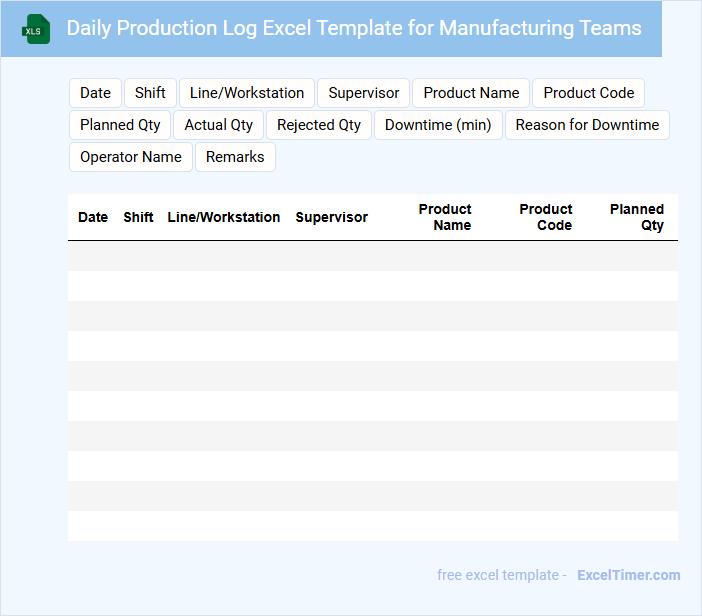

Daily Production Log Excel Template for Manufacturing Teams

The Daily Production Log Excel Template is a crucial document used by manufacturing teams to track daily output, monitor equipment performance, and record workforce allocation. It typically contains fields for production quantities, shift timings, machine status, and any issues encountered during the day. This log aids in maintaining transparency, improving efficiency, and identifying bottlenecks in the manufacturing process.

Important elements to include in the template are clear column headers for date, product type, quantity produced, downtime reasons, and operator details. Incorporating dropdown menus for status updates and automated calculations for totals can increase accuracy and usability. Regular updates and real-time data entry are essential to ensure the log's reliability and effectiveness in decision-making.

Production Tracking Sheet for Daily Operations

A Production Tracking Sheet for daily operations is a crucial document that records the quantity and quality of products manufactured each day. It helps monitor workflow efficiency and identify bottlenecks in the production process.

This sheet typically contains data such as production targets, actual output, downtime, and reasons for delays. Including accurate timestamps and department-specific details is essential for effective analysis and decision-making.

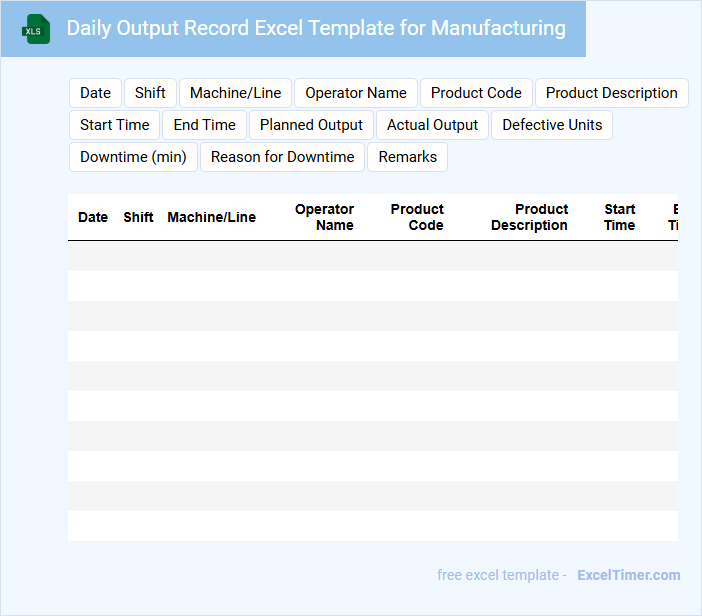

Daily Output Record Excel Template for Manufacturing

What information is typically included in a Daily Output Record Excel Template for Manufacturing? This document usually contains data like production quantities, types of products manufactured, machine statuses, and operator details. It is designed to help track daily manufacturing output efficiently and ensure accurate record-keeping for performance analysis and reporting.

Why is it important to use a Daily Output Record Excel Template in manufacturing? Maintaining detailed daily records helps identify production trends, monitor productivity, and quickly address any issues causing delays or defects. Ensuring data accuracy, consistency, and ease of use in the template are crucial for effective manufacturing management.

Manufacturing Production Logbook with Daily Summary

A Manufacturing Production Logbook with Daily Summary is a detailed record of daily production activities and performance metrics.

- Production Details: Document specific production quantities, batch numbers, and shift timings.

- Quality Checks: Include inspection results and any defects identified during the process.

- Operational Issues: Record any equipment malfunctions or delays affecting production.

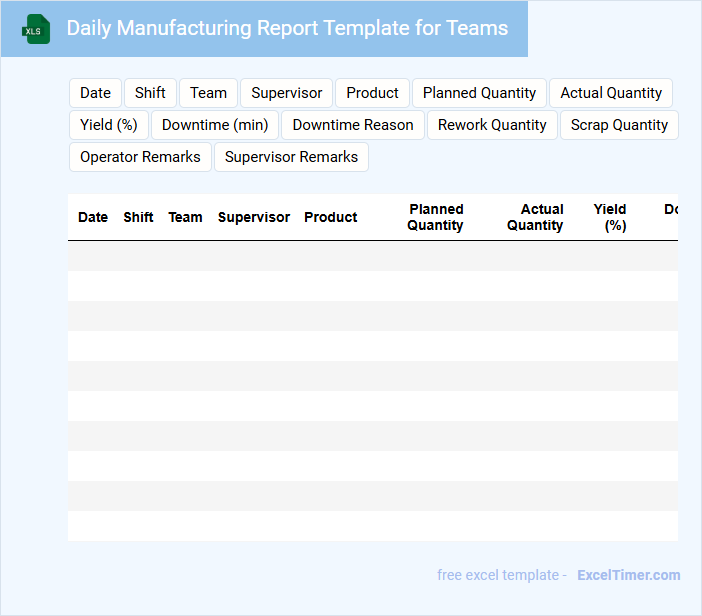

Daily Manufacturing Report Template for Teams

The Daily Manufacturing Report is a crucial document that captures the production activities and operational performance of a manufacturing team within a single day. It typically includes key metrics such as output quantity, downtime, and quality issues to provide a clear overview of daily manufacturing efficiency.

For teams, this report helps track progress, identify bottlenecks, and communicate status updates effectively. It is important to ensure the report is concise, accurate, and easily accessible to support timely decision-making and continuous improvement.

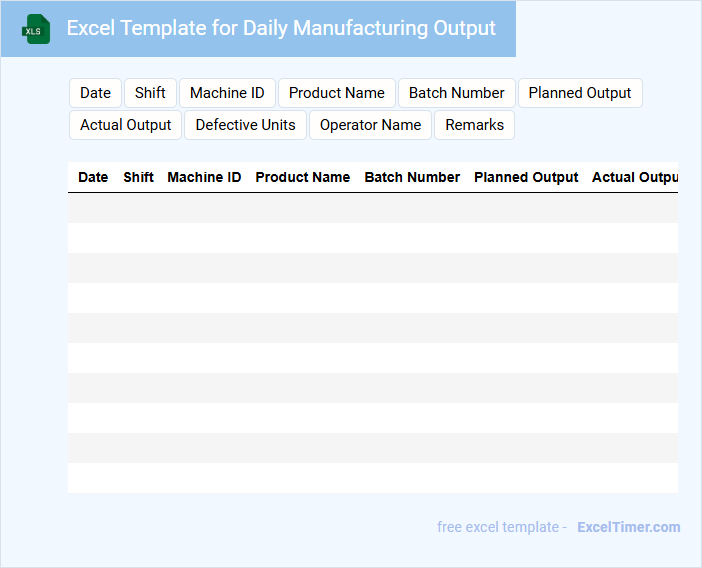

Excel Template for Daily Manufacturing Output

What does an Excel Template for Daily Manufacturing Output typically contain? This type of document usually includes fields for tracking production metrics such as the quantity produced, production time, machine efficiency, and defect rates on a daily basis. It is designed to help manufacturers monitor performance, identify bottlenecks, and improve overall productivity efficiently.

What is an important consideration when using this template? It is crucial to ensure accurate and timely data entry to maintain reliable records and facilitate meaningful analysis. Including customizable sections for specific production lines or product types can enhance the template's flexibility and relevance to different manufacturing environments.

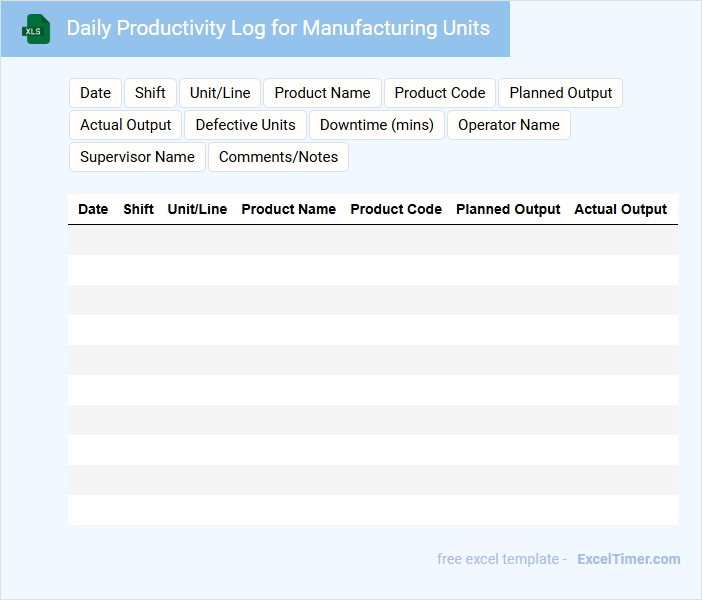

Daily Productivity Log for Manufacturing Units

A Daily Productivity Log for Manufacturing Units typically contains detailed records of production activities, including output levels, machine performance, and workforce efficiency. It serves as a tool for monitoring daily operational performance and identifying areas for improvement.

- Record accurate production quantities and any deviations from planned output.

- Note equipment downtime and reasons to track maintenance needs.

- Include shift-wise performance to assess workforce productivity and issues.

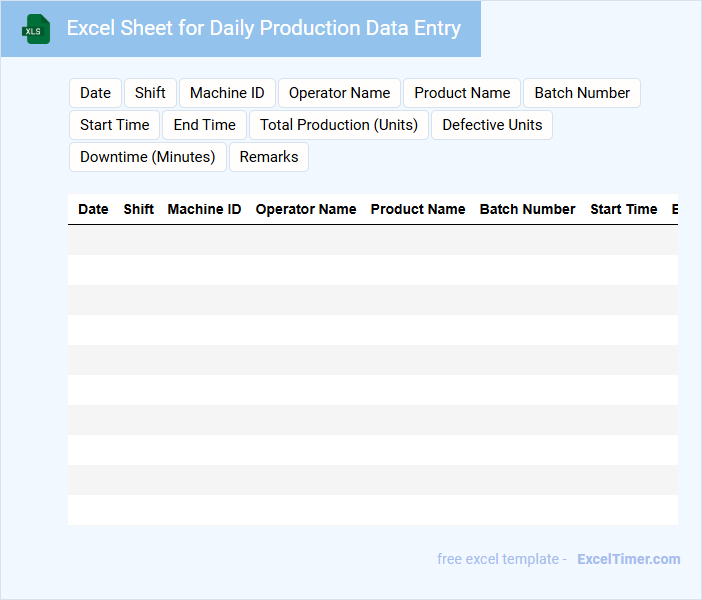

Excel Sheet for Daily Production Data Entry

What information is typically included in an Excel sheet for daily production data entry? This type of document usually contains detailed records of production quantities, machine or line numbers, operator names, and timestamps. It helps track daily output and identify trends or issues in the manufacturing process for improved efficiency.

What important elements should be considered when designing this Excel sheet? It is essential to include clear data validation rules to minimize input errors and use organized columns for easy filtering and analysis. Additionally, incorporating summary sections and automated calculations can enhance data accuracy and provide quick insights into production performance.

Daily Production Tracker with Shift Details

What information does a Daily Production Tracker with Shift Details typically contain? It usually includes data on the quantity of products produced, the specific shifts during which production occurred, and the performance metrics for each shift. This document helps monitor productivity, identify bottlenecks, and ensure that production targets are met efficiently.

What important aspects should be considered when using a Daily Production Tracker with Shift Details? It is crucial to accurately record shift timings, employee attendance, and any downtime or issues that affect production. Consistent updates and clear communication between shifts are essential for maintaining smooth operations and timely interventions.

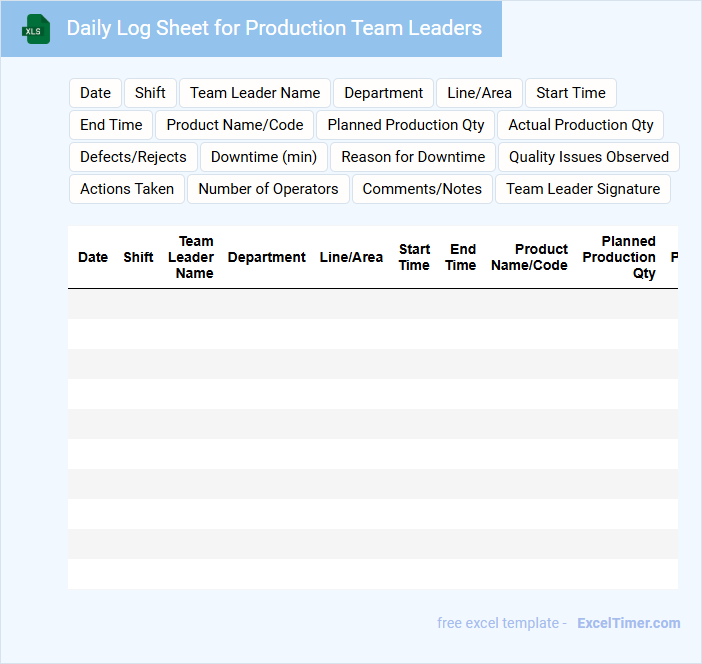

Daily Log Sheet for Production Team Leaders

What information does a Daily Log Sheet for Production Team Leaders typically contain? It usually includes detailed records of daily production activities, team attendance, machinery status, and any incidents or delays encountered. This document helps in tracking productivity, managing resources efficiently, and identifying issues for timely resolution.

What is an important aspect to consider when maintaining a Daily Log Sheet for Production Team Leaders? Accuracy and consistency are crucial to ensure reliable data for decision-making and performance assessment. Team leaders should update the log promptly and clearly to support effective communication and continuous improvement.

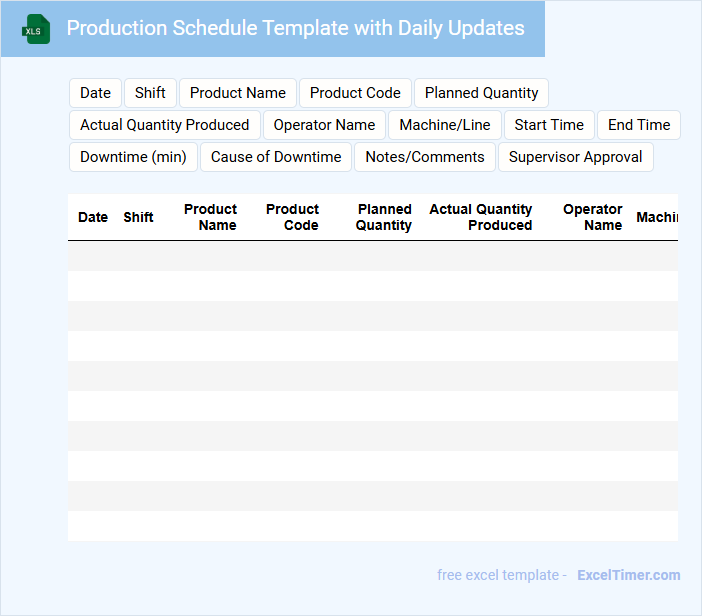

Production Schedule Template with Daily Updates

A Production Schedule Template with Daily Updates is a document used to organize and track production activities on a day-to-day basis. It helps ensure timely completion and efficient resource management.

- Include clearly defined tasks and assigned personnel for each day to maintain accountability.

- Incorporate deadlines and milestones to monitor progress effectively.

- Allow space for daily notes or issues to address real-time adjustments.

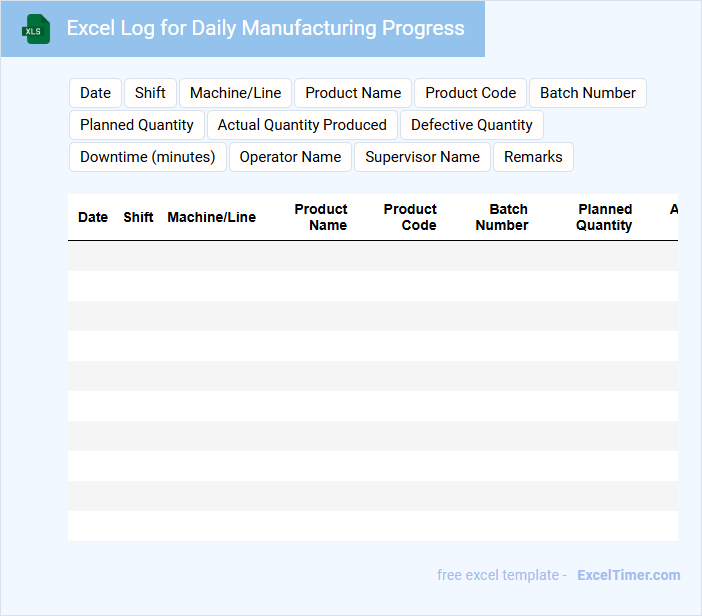

Excel Log for Daily Manufacturing Progress

An Excel Log for Daily Manufacturing Progress typically contains detailed entries of production activities, including quantities produced, machine usage, and operator details. It serves as a comprehensive record to monitor daily output and identify any discrepancies quickly.

Such a document is essential for tracking efficiency and ensuring quality control throughout the manufacturing process. Consistently updating the log helps maintain accurate data for performance analysis and decision-making.

Important suggestions include regularly reviewing the log for errors and including timestamps for each entry to enhance traceability.

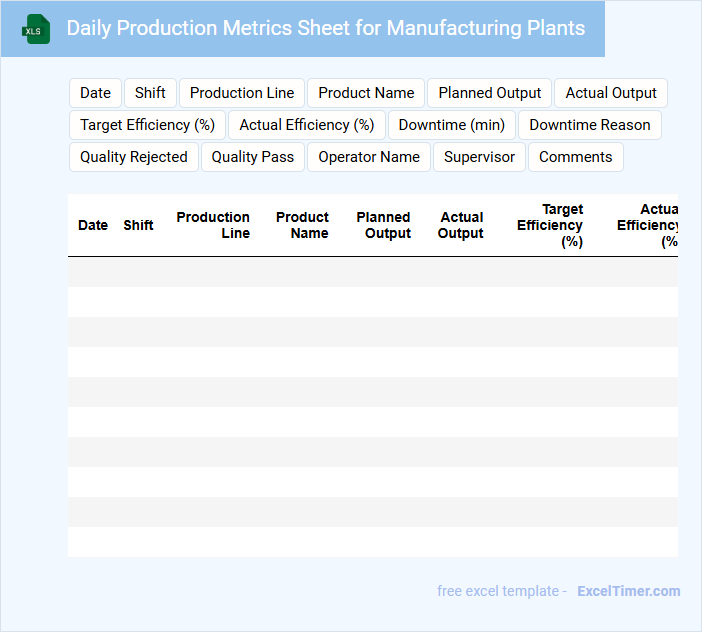

Daily Production Metrics Sheet for Manufacturing Plants

A Daily Production Metrics Sheet for manufacturing plants typically contains detailed data on daily output, machine performance, and quality control statistics. It helps track productivity, identify bottlenecks, and maintain consistent product standards. Key elements include shift-wise production numbers, downtime reports, and defect rates to ensure efficient operations.

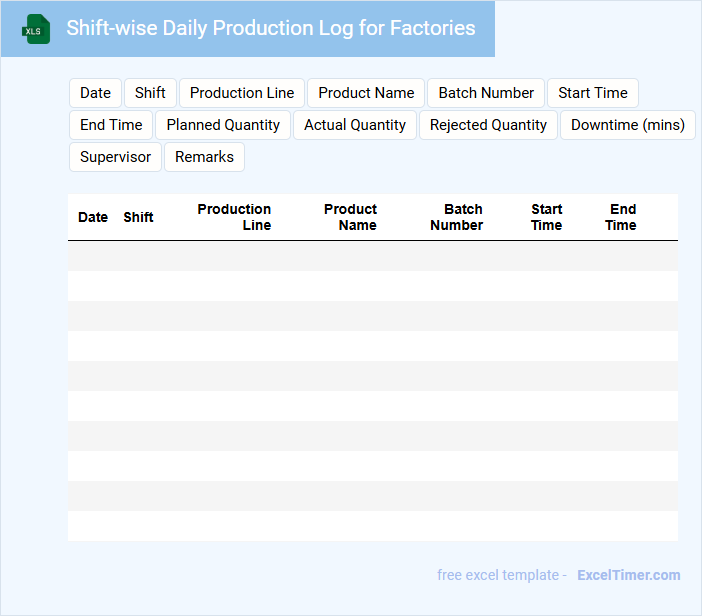

Shift-wise Daily Production Log for Factories

A Shift-wise Daily Production Log for Factories typically contains detailed records of production activities segmented by each shift to monitor and improve operational efficiency.

- Shift Timings: Clearly define the start and end times of each shift to track production periods accurately.

- Production Output: Record the quantity and quality of products produced during each shift for performance analysis.

- Issues and Downtime: Document any equipment failures or interruptions to identify areas for process improvement.

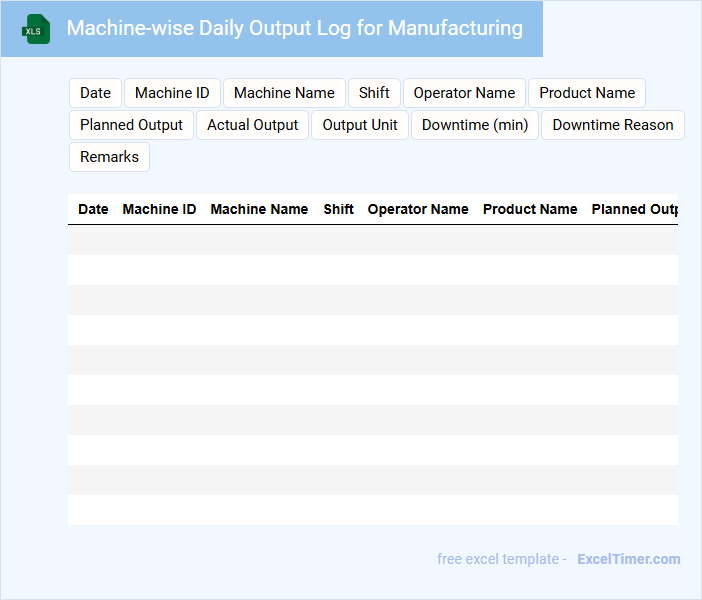

Machine-wise Daily Output Log for Manufacturing

The Machine-wise Daily Output Log is a document that records the production details of each machine on a daily basis in a manufacturing environment. It typically contains data such as machine identification, output quantity, operating hours, and any downtime with reasons. This log helps in tracking performance, identifying bottlenecks, and maintaining operational efficiency.

To optimize its usefulness, the log should include clear timestamps, standardized units of measurement, and sections for remarks or issues encountered. Consistent updating and accuracy are crucial for effective analysis and decision-making. Additionally, integrating this log with overall production records can enhance process improvement initiatives.

What key data fields should be included in a daily production log for effective tracking (e.g., date, shift, product type, quantities produced, downtime)?

Your daily production log should include key data fields such as date, shift, product type, quantities produced, machine or line ID, operator name, and downtime duration with reasons. Recording quality checks, raw material batch numbers, and scrap or rework quantities enhances traceability and performance analysis. Accurate and detailed entries in these fields drive effective tracking and continuous improvement in manufacturing operations.

How does the daily production log integrate with inventory and supply chain management in manufacturing workflows?

The Daily Production Log captures real-time manufacturing output data, enabling accurate updates to inventory levels and material usage. It synchronizes production records with supply chain management systems to forecast material requirements and prevent stockouts. This integration enhances workflow efficiency by aligning production schedules with inventory availability and supplier deliveries.

Which Excel features (such as data validation, conditional formatting, or pivot tables) can enhance the accuracy and usability of daily production logs?

Data validation ensures accurate data entry by restricting inputs to predefined criteria, reducing errors in daily production logs. Conditional formatting highlights key metrics like low output or delays, enhancing quick visual analysis. Pivot tables enable efficient summarization and trend analysis of production data, improving decision-making for manufacturing teams.

What methods can be used in Excel to identify production variances or bottlenecks from daily log data?

Excel's conditional formatting highlights production variances by visually flagging data outside set thresholds in your Daily Production Log. PivotTables summarize daily outputs and identify bottlenecks by comparing team performance metrics efficiently. Formulas like IF, VLOOKUP, and SUMIF analyze discrepancies and highlight patterns affecting production flow for manufacturing teams.

How can sharing and updating the daily production log in Excel support cross-functional team communication and continuous improvement?

Sharing and updating the Daily Production Log in Excel enhances cross-functional team communication by providing real-time visibility into manufacturing metrics such as output rates, downtime, and defect counts. Your team can identify bottlenecks and quality issues quickly, enabling data-driven decisions that drive continuous improvement. Centralized access to accurate production data fosters collaboration and accountability across departments, streamlining workflow efficiency.