The Daily Production Report Excel Template for Manufacturing streamlines tracking of daily output, machine efficiency, and labor productivity. It enables manufacturers to monitor production targets, identify bottlenecks, and maintain quality control with ease. This template is essential for improving manufacturing processes and ensuring accurate data-driven decision making.

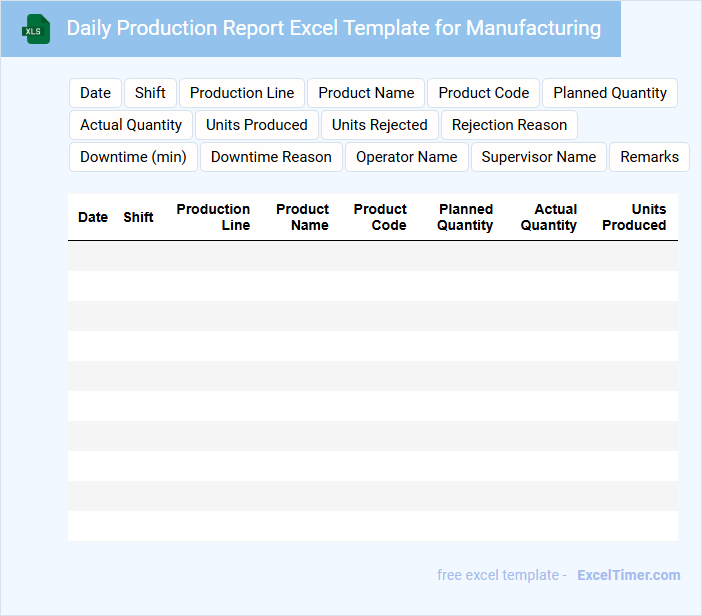

Daily Production Report Excel Template for Manufacturing

The Daily Production Report Excel template is designed to track the daily output of manufacturing processes. It typically contains data on production quantities, machine performance, and operator efficiency to monitor productivity.

Important aspects include accurate recording of defects, downtime, and material usage to identify bottlenecks. This report helps managers make informed decisions to optimize production and maintain quality standards.

Production Output Tracking Sheet for Factory Operations

A Production Output Tracking Sheet for Factory Operations records daily manufacturing data to monitor efficiency and output quality. It helps management identify trends and make informed decisions to optimize production processes.

- Include columns for date, shift, machine/operator ID, and quantity produced to ensure comprehensive tracking.

- Incorporate fields for defect rates and downtime to monitor quality and operational interruptions.

- Regularly update and review the sheet to maintain accurate and actionable production insights.

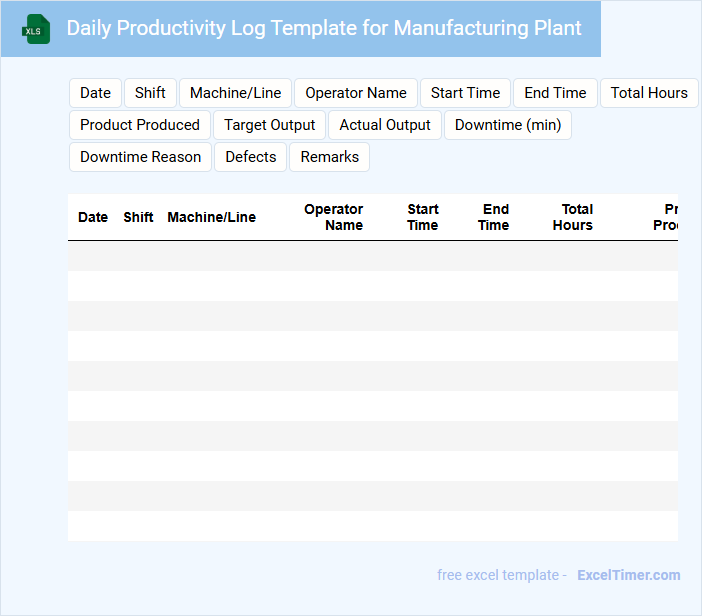

Daily Productivity Log Template for Manufacturing Plant

What information does a Daily Productivity Log Template for a Manufacturing Plant typically contain? It usually includes key data such as employee attendance, machine operational hours, units produced, and any downtime or delays. This document helps track daily performance and identify areas for improvement in production efficiency.

What important elements should be included in this log template? It should have clear fields for date, shift details, production targets versus actual output, reasons for delays, and notes on equipment maintenance or issues. Including these ensures accurate record-keeping and supports timely decision-making to enhance plant productivity.

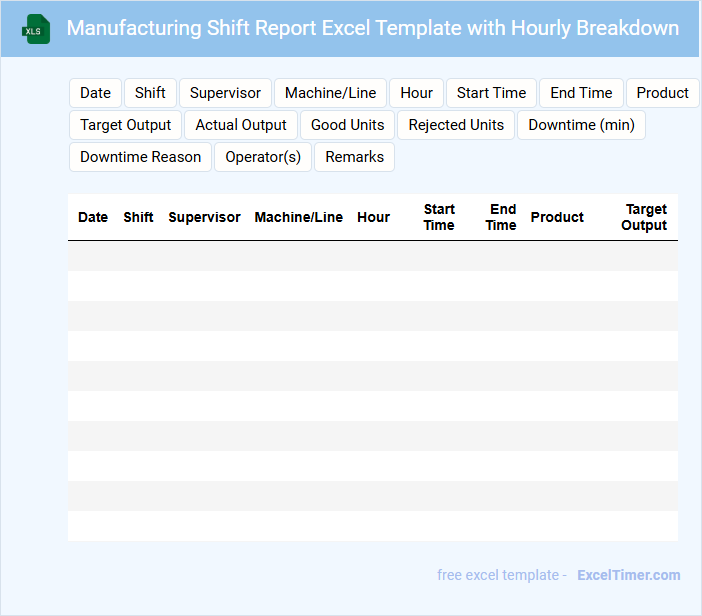

Manufacturing Shift Report Excel Template with Hourly Breakdown

Manufacturing Shift Report Excel Template with Hourly Breakdown is a crucial document used to monitor production activities on an hourly basis during a manufacturing shift. It typically contains data such as machine performance, employee attendance, production output, downtime, and quality issues. Shift reports help managers identify bottlenecks quickly and make informed decisions to improve operational efficiency.

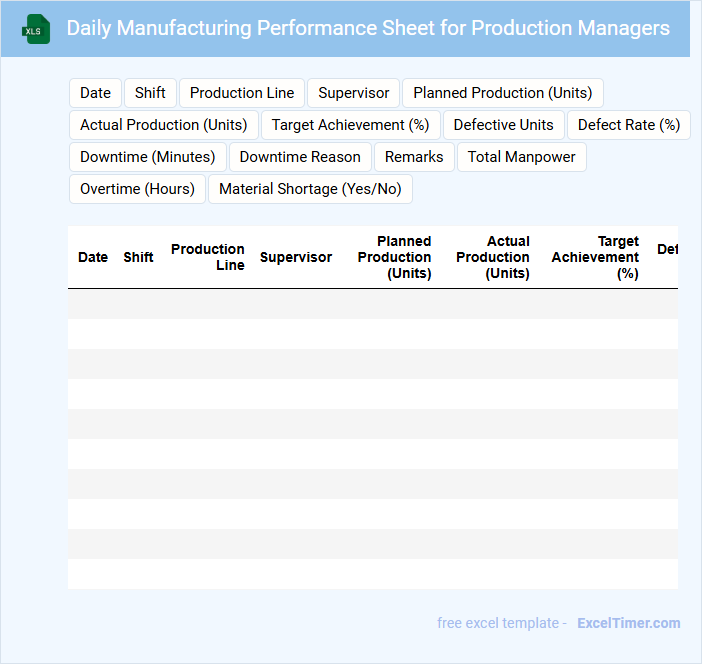

Daily Manufacturing Performance Sheet for Production Managers

The Daily Manufacturing Performance Sheet is a critical document used by production managers to monitor and evaluate the daily operational efficiency. It provides a snapshot of production metrics, helping identify issues and track progress towards targets.

- Include key performance indicators such as units produced, downtime, and quality defects.

- Track shift-wise data to pinpoint performance variations and optimize labor allocation.

- Incorporate space for remarks to record observations, delays, or corrective actions taken.

Production Line Efficiency Report with Downtime Analysis

A Production Line Efficiency Report with Downtime Analysis typically contains detailed metrics on the performance and operational time of a manufacturing line. It highlights periods of inactivity, their causes, and the impact on overall productivity. This document is essential for identifying bottlenecks and opportunities for process improvement.

Key elements include downtime duration, reasons for stoppages, and efficiency percentages. Visual aids such as charts or graphs are highly recommended to clearly communicate trends and problem areas. Additionally, suggesting actionable recommendations based on the findings helps drive operational decisions.

Regularly updating the report ensures continuous monitoring and timely interventions. Including comparative data over different time periods can uncover persistent issues. Accurate data collection and validation are critical for reliable results and effective analysis.

Manufacturing Plant Daily Output Tracker for Quality Control

The Manufacturing Plant Daily Output Tracker is a critical document used to record the daily production data and monitor quality control parameters. It typically contains details such as production volume, defect rates, equipment status, and operator performance. This information helps ensure that manufacturing processes meet quality standards consistently.

For optimal use, it is important to include real-time data entry, clear defect categorization, and automated alerts for deviations. Incorporating visual charts can enhance quick analysis and decision-making. Regularly updating the tracker fosters continuous improvement and operational efficiency.

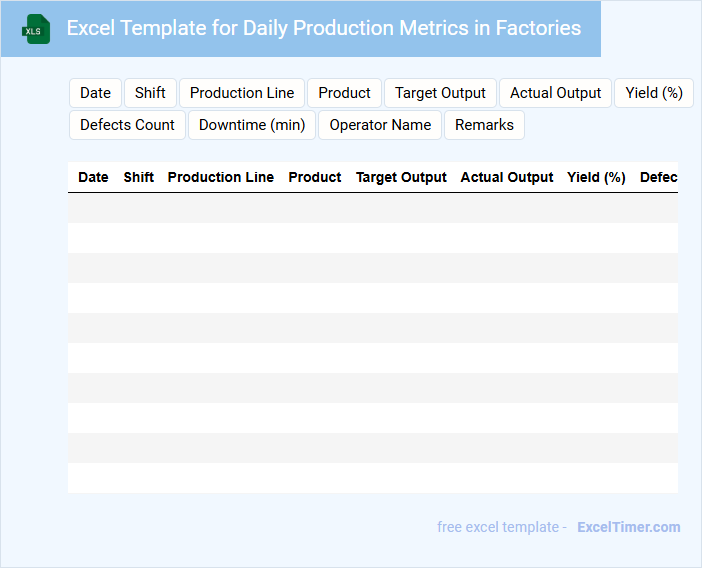

Excel Template for Daily Production Metrics in Factories

An Excel Template for Daily Production Metrics in factories typically contains organized data fields to track daily output, efficiency, and downtime. It often includes charts and tables for visualizing production trends and identifying bottlenecks. Ensuring accuracy and consistency in data entry is crucial for making informed operational decisions.

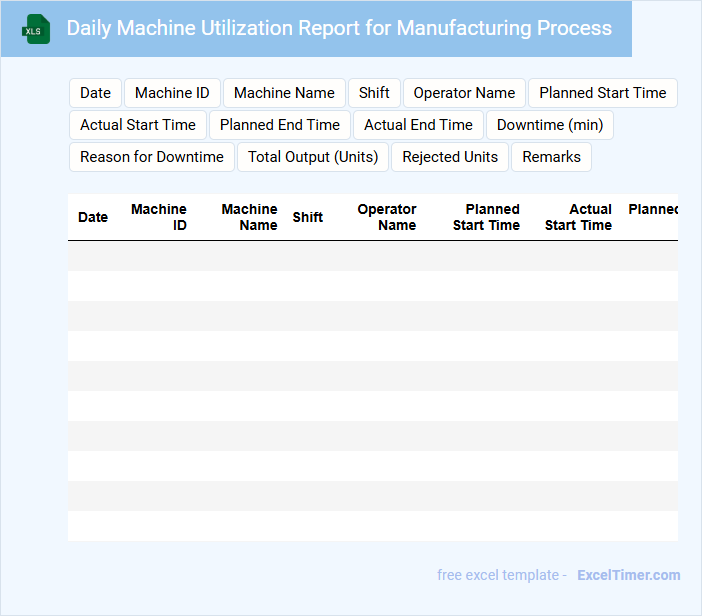

Daily Machine Utilization Report for Manufacturing Process

The Daily Machine Utilization Report typically contains detailed data on machine operation times, downtime, and production output for manufacturing processes. It is essential for assessing equipment efficiency and identifying bottlenecks in production.

Such reports often include metrics like utilization rate, maintenance logs, and operator notes to provide a comprehensive overview of machine performance. Consistently tracking these factors helps in optimizing scheduling and reducing unplanned downtime.

An important suggestion for this document is to ensure real-time data accuracy and highlight any deviations from standard operating procedures to enable quick corrective actions.

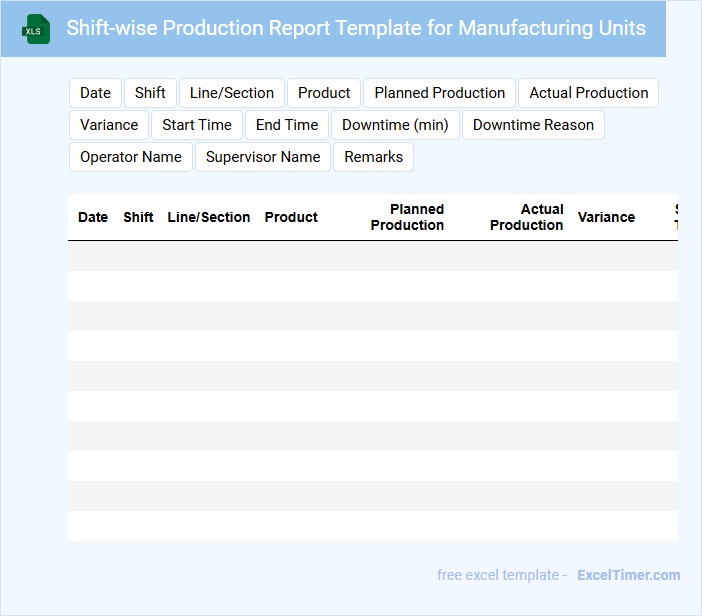

Shift-wise Production Report Template for Manufacturing Units

A Shift-wise Production Report Template for manufacturing units is designed to systematically document production data for each shift operated during a day. It typically contains details such as the quantity produced, machine performance, downtime reasons, and worker attendance. This structured report helps in monitoring productivity, identifying bottlenecks, and ensuring consistent quality across shifts.

Important elements to include are precise time intervals for each shift, clearly defined metrics for production output, and sections for noting issues or observations. Incorporating real-time data entry features and summaries for overall daily performance can enhance decision-making. Additionally, linking the report to inventory and maintenance schedules optimizes resource management and downtime reduction.

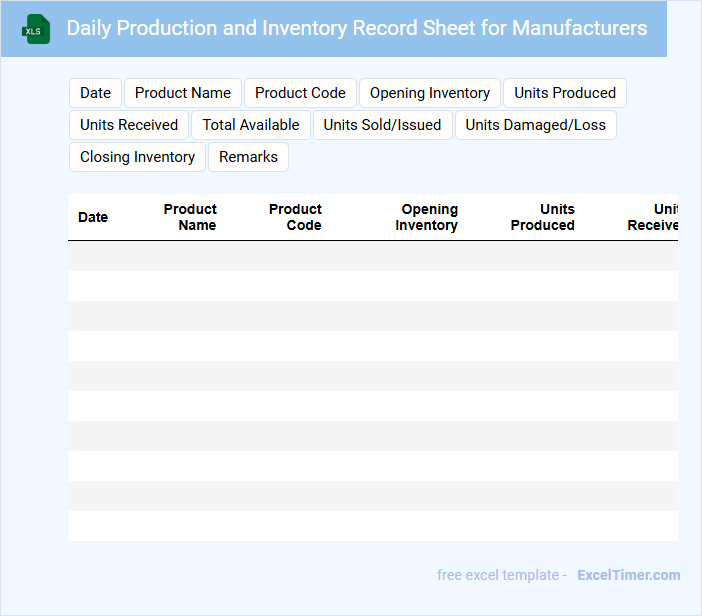

Daily Production and Inventory Record Sheet for Manufacturers

A Daily Production and Inventory Record Sheet for Manufacturers is a document used to track daily manufacturing output and inventory levels. It ensures accurate monitoring of production efficiency and stock management.

- Include detailed records of quantities produced and materials used each day.

- Record inventory adjustments to maintain accurate stock levels.

- Ensure time-stamped entries to trace production and inventory changes effectively.

Operator-wise Production Report with Defect Tracking

An Operator-wise Production Report with Defect Tracking is a document that details the quantity and quality of output produced by each operator over a specific period. It usually contains key metrics such as the number of units produced, types and counts of defects, and operator performance trends. This report helps in identifying areas for improvement and ensuring accountability in the production process.

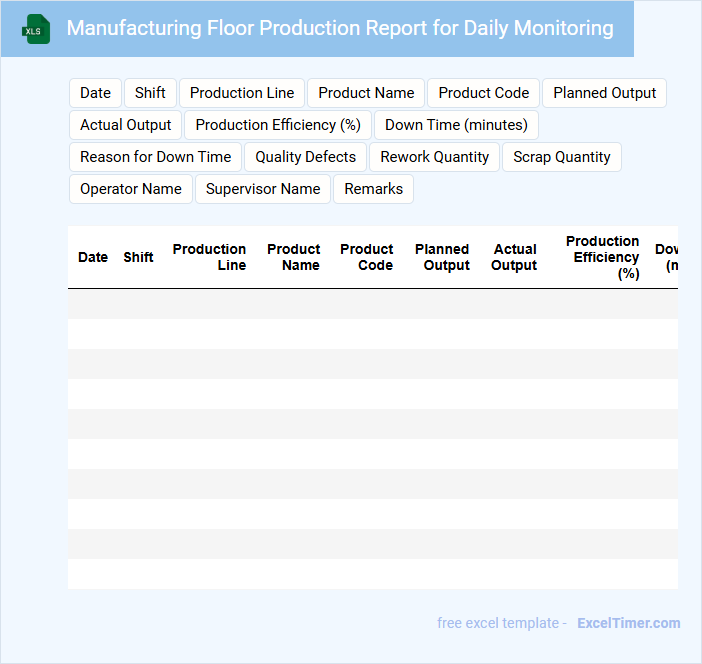

Manufacturing Floor Production Report for Daily Monitoring

A Manufacturing Floor Production Report typically contains detailed data on daily output, machine performance, and labor efficiency. It is designed to track production progress and identify any bottlenecks or delays in the manufacturing process. This report aids supervisors in making informed decisions to enhance productivity and maintain quality control.

Key components include total units produced, downtime reasons, and operator shifts. Including real-time data collection and clear visual charts can significantly improve report effectiveness. Consistent documentation of issues and corrective actions is essential for continuous improvement and accountability.

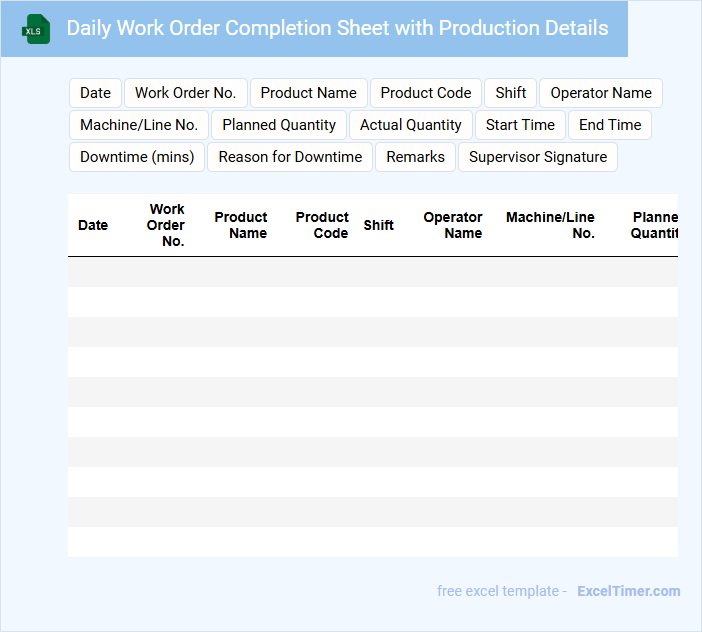

Daily Work Order Completion Sheet with Production Details

A Daily Work Order Completion Sheet typically contains detailed records of tasks completed within a production cycle, including specific job orders and associated timelines. It usually outlines the quantity of items produced, any discrepancies encountered, and the names of personnel involved in the production process. Ensuring accuracy and real-time updates in this document is crucial for tracking productivity and maintaining efficient workflow management.

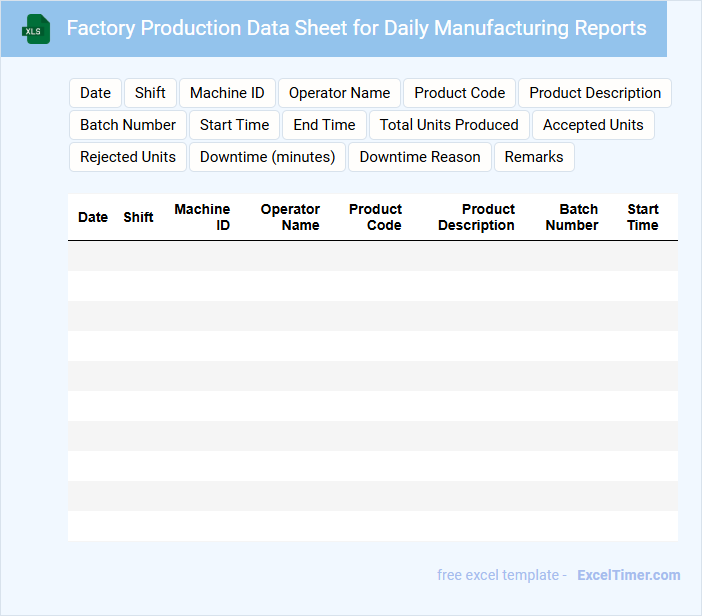

Factory Production Data Sheet for Daily Manufacturing Reports

What information is typically included in a Factory Production Data Sheet for Daily Manufacturing Reports? This document usually contains detailed records of daily production activities, such as quantities produced, machine performance, and any encountered issues. It helps in monitoring production efficiency and ensuring quality control throughout the manufacturing process.

What important aspects should be considered when creating this report? Accuracy in recording data and timely updates are crucial to maintain reliable tracking of production progress. Including observations about equipment status and staff shift performance can further enhance decision-making and process improvements.

What key metrics should be tracked in a Daily Production Report for manufacturing?

A Daily Production Report for manufacturing should track key metrics such as total units produced, machine uptime and downtime, production yield rate, defect rate, and labor hours. Monitoring these metrics provides insights into operational efficiency, quality control, and resource utilization. Accurate daily data helps identify bottlenecks and optimize manufacturing processes.

How is production output versus target documented and analyzed?

Your Daily Production Report in Excel captures production output and target data through structured tables and charts, enabling clear comparison of actual versus planned metrics. Automated calculations highlight variances and performance trends, supporting effective analysis for manufacturing efficiency. Conditional formatting visually flags underperformance, allowing timely decision-making and continuous improvement.

Which data fields are essential for monitoring downtime and its reasons?

Essential data fields for monitoring downtime in a Daily Production Report include Downtime Duration, Downtime Start and End Times, Downtime Reason Codes, and Affected Equipment or Production Line. Collecting Operator or Shift Information aids in pinpointing responsibility and correlation. Recording Production Impact such as Lost Units or Output Delay quantifies downtime effects.

How can quality defects and scrap rates be efficiently recorded in the report?

To efficiently record quality defects and scrap rates in the Daily Production Report, create dedicated columns for defect types and scrap quantities linked to each production batch. Use dropdown menus and data validation to ensure consistent entries, which simplifies tracking trends and identifying problem areas. You can also integrate automated formulas to calculate defect percentages and scrap rates, enabling quick analysis and decision-making.

What process is used to verify the accuracy and integrity of entered production data?

The process used to verify the accuracy and integrity of entered production data in a Daily Production Report includes data validation checks, cross-referencing with machine logs, and timestamp verification. Automated formulas detect outliers and inconsistencies, ensuring reliable data capture. Regular audits by quality control teams confirm adherence to reporting standards and data accuracy.