The Daily Production Schedule Excel Template for Manufacturing streamlines workflow by organizing daily tasks, tracking production progress, and managing resource allocation efficiently. It enhances productivity and helps identify bottlenecks, ensuring deadlines are met. This template is essential for maintaining operational clarity and optimizing manufacturing output.

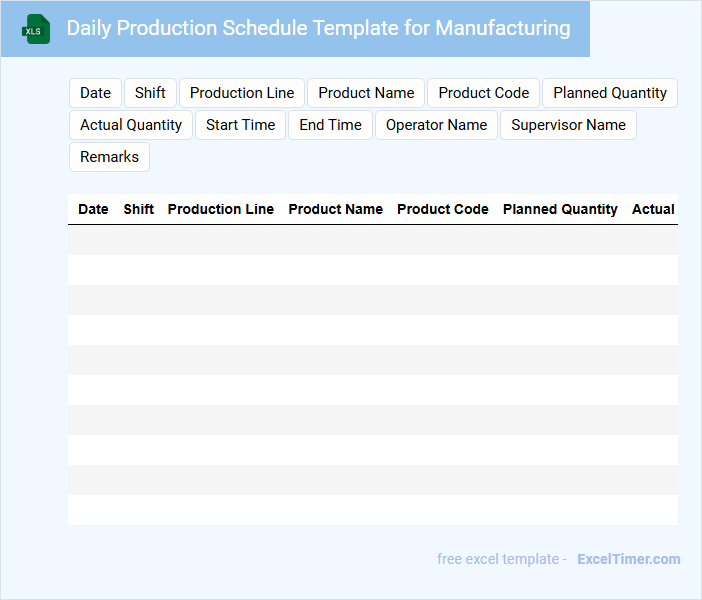

Daily Production Schedule Template for Manufacturing

What information is typically included in a Daily Production Schedule Template for Manufacturing? This document usually contains details on production tasks, timelines, machine assignments, and workforce allocation to ensure smooth daily operations. It helps manufacturers organize their workflow, monitor progress, and optimize resource usage efficiently.

Why is it important to track key metrics and update the schedule regularly? Tracking metrics such as output, downtime, and material availability allows quick adjustments to prevent delays or bottlenecks. Regular updates keep the team informed and aligned with changing priorities or unexpected issues, ensuring consistent production quality and meeting deadlines.

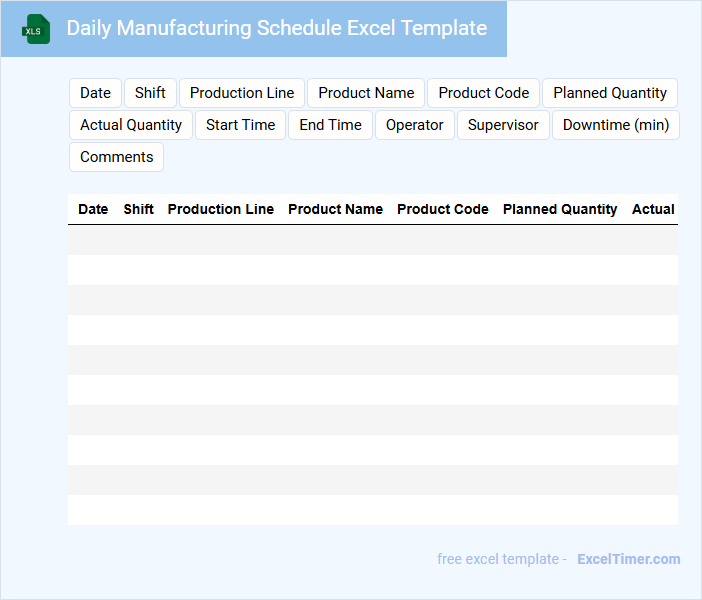

Daily Manufacturing Schedule Excel Template

The Daily Manufacturing Schedule Excel Template is a crucial document used to organize and track production activities within a manufacturing facility. It typically contains information such as work orders, machine assignments, shift timings, and production targets.

This template helps streamline operations by providing a clear overview of daily tasks and resource allocation. An important suggestion is to ensure real-time updates and integration with inventory systems for accurate scheduling.

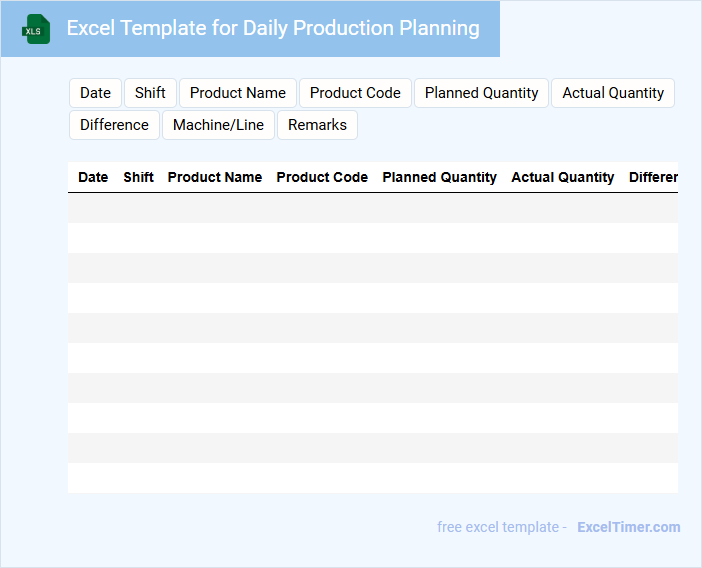

Excel Template for Daily Production Planning

An Excel Template for Daily Production Planning typically contains detailed schedules, resource allocation, and real-time tracking data to optimize manufacturing processes. It provides a structured format to record daily production targets, actual outputs, and any deviations encountered during the day.

Ensuring accurate data entry and maintaining up-to-date information within the template is crucial for effective planning and decision-making. Regularly reviewing and adjusting the plan based on performance metrics helps improve productivity and reduce downtime.

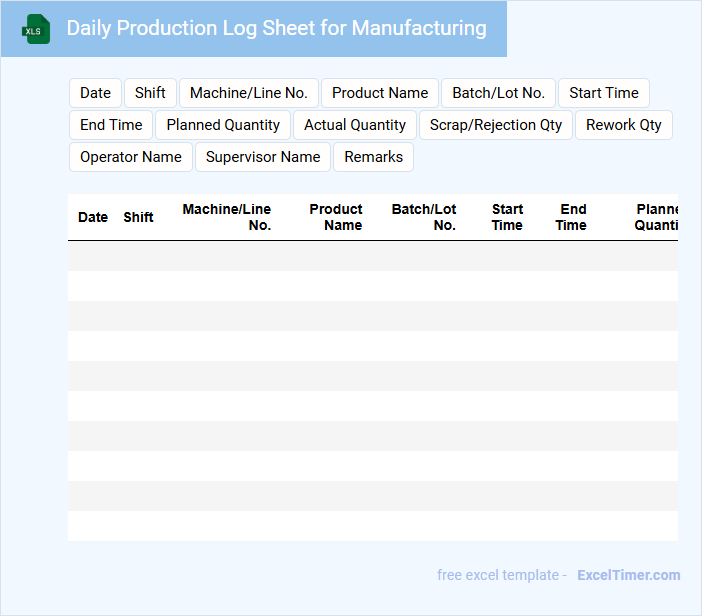

Daily Production Log Sheet for Manufacturing

What information is typically recorded in a Daily Production Log Sheet for Manufacturing? This document usually contains detailed records of the production activities completed during a specific day, including quantities produced, machine performance, and any issues encountered. It serves as an essential tool to monitor productivity, ensure quality control, and identify areas for improvement in the manufacturing process.

What important elements should be included in a Daily Production Log Sheet? Key components include the date, shift details, operator names, production targets versus actual output, machine status, quality checks, and notes on any interruptions or defects. Including these details helps maintain accurate records, facilitates communication across teams, and supports data-driven decision-making.

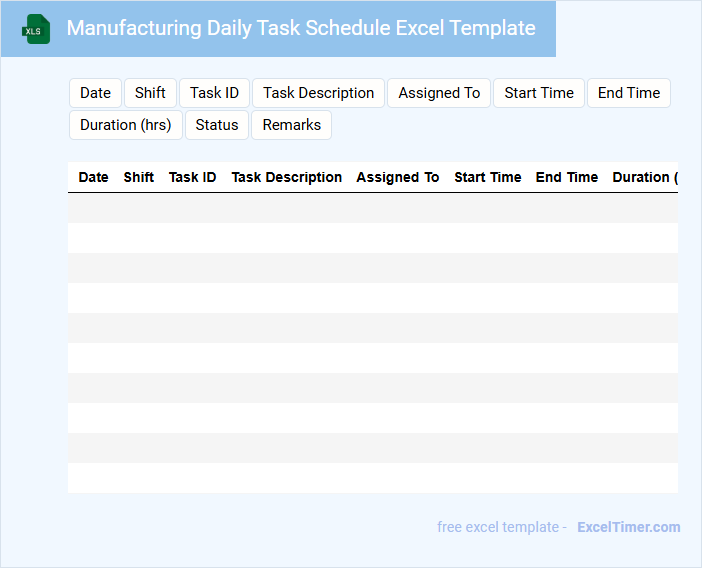

Manufacturing Daily Task Schedule Excel Template

The Manufacturing Daily Task Schedule Excel Template is designed to organize and streamline daily production activities. It typically contains sections for task descriptions, assigned personnel, start and end times, and status updates. Utilizing this template helps ensure efficient workflow management and timely completion of manufacturing tasks.

Excel Sheet for Daily Production Output Tracking

An Excel Sheet for Daily Production Output Tracking is a structured document used to monitor and record the quantity of products manufactured each day. It helps in analyzing productivity trends and managing workflow efficiently.

- Include columns for date, shift, product type, and quantity produced.

- Add formulas to calculate totals and averages automatically.

- Use conditional formatting to highlight deviations or targets not met.

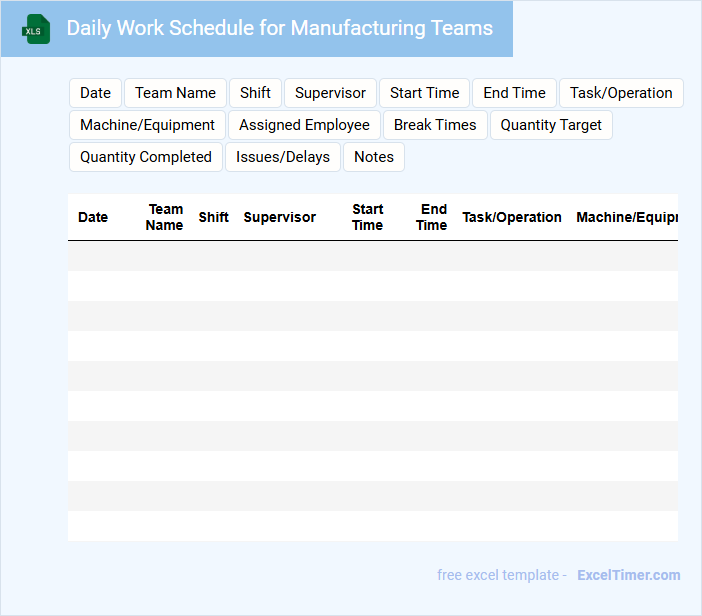

Daily Work Schedule for Manufacturing Teams

The Daily Work Schedule for manufacturing teams typically contains detailed task assignments and time allocations to ensure efficient workflow. It outlines specific duties, machinery usage, and break times to optimize production.

Including clear shift timings and priority tasks helps maintain consistency and track progress throughout the day. A suggestion is to incorporate a contingency plan for unexpected downtime or delays.

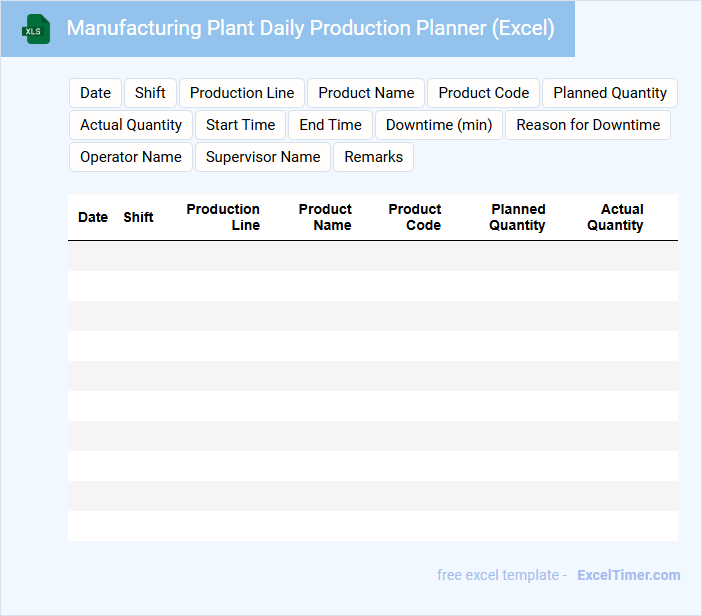

Manufacturing Plant Daily Production Planner (Excel)

A Manufacturing Plant Daily Production Planner (Excel) is a document used to schedule and track daily production activities in a manufacturing facility. It helps in organizing tasks, resources, and timelines to ensure efficient production flow.

- Include detailed production targets and machine allocation for each shift.

- Track raw material availability and consumption to avoid delays.

- Document machine downtime and maintenance schedules for better planning.

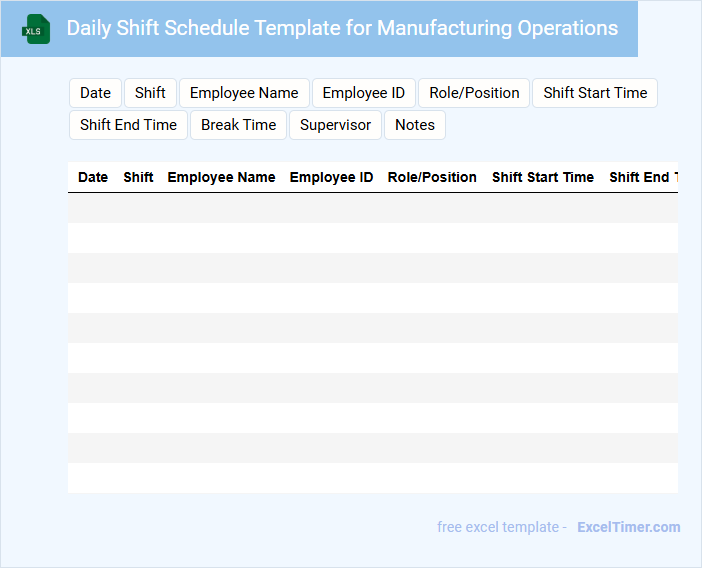

Daily Shift Schedule Template for Manufacturing Operations

Daily Shift Schedule Templates for Manufacturing Operations typically contain a detailed plan for employee shifts, tasks, and production targets to ensure smooth workflow and efficient resource management.

- Clear shift timings: Specify the exact start and end times for each shift to avoid confusion and overlap.

- Task assignments: Allocate specific tasks or production areas to employees to enhance accountability and productivity.

- Break schedules: Incorporate regular break times to maintain worker welfare and compliance with labor regulations.

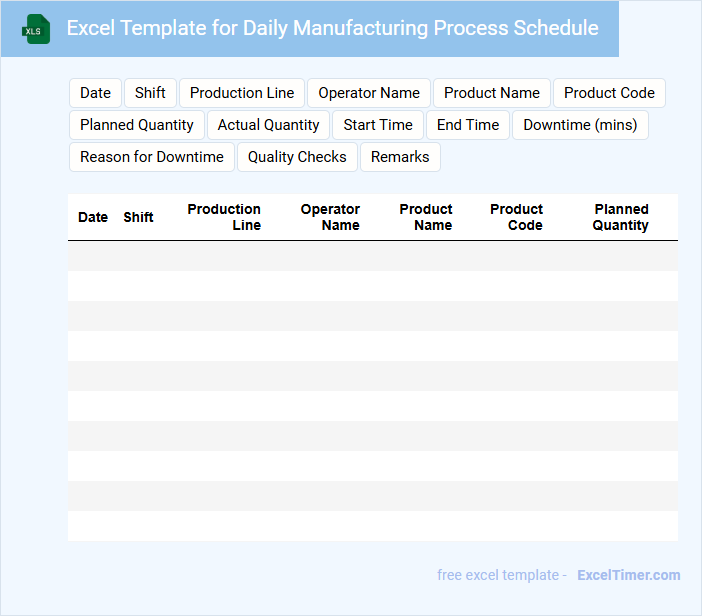

Excel Template for Daily Manufacturing Process Schedule

An Excel Template for Daily Manufacturing Process Schedule is typically a structured document used to plan and track production activities on a daily basis, ensuring efficient workflow and resource management. It helps in organizing tasks, monitoring progress, and identifying bottlenecks in manufacturing operations.

- Include clear time slots or shifts to allocate tasks effectively throughout the day.

- Incorporate columns for machine status and operator assignment to streamline communication.

- Provide space for notes or issues encountered to facilitate continuous improvement.

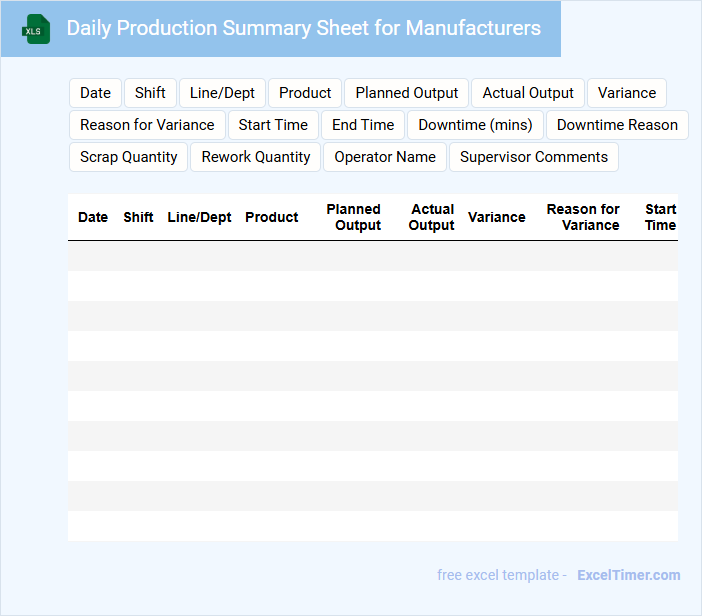

Daily Production Summary Sheet for Manufacturers

The Daily Production Summary Sheet is a crucial document used by manufacturers to record the daily output of production lines. It typically contains details like quantities produced, machine performance, and labor hours.

This sheet helps track productivity and identify any issues in the manufacturing process quickly. Including accurate timestamps and shift details is important for effective monitoring and reporting.

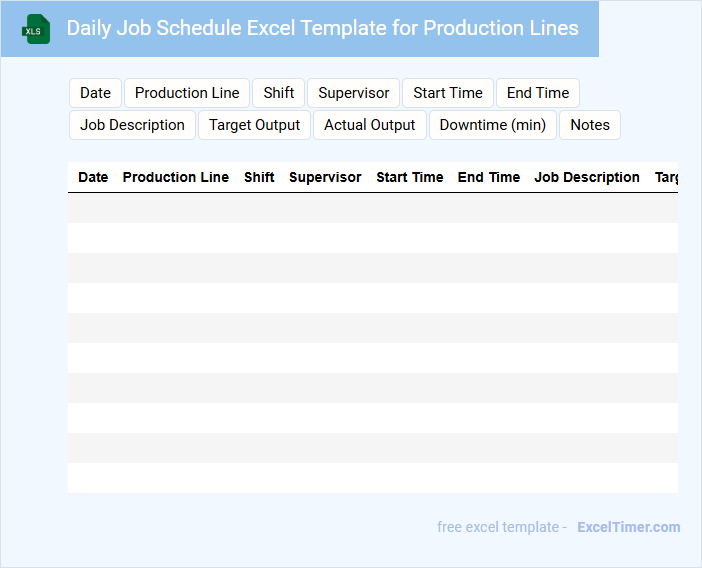

Daily Job Schedule Excel Template for Production Lines

What information is typically included in a Daily Job Schedule Excel Template for Production Lines? This type of document usually contains detailed task assignments, production targets, and timing for each job on the assembly or production line. It helps streamline workflow by clearly outlining daily responsibilities and tracking progress to ensure efficiency and timely completion of tasks.

What are important features to include in this template? Key elements include columns for job descriptions, start and end times, assigned personnel, machine or workstation details, and status updates. Incorporating conditional formatting for delays and automated total time calculations can greatly enhance usability and clarity.

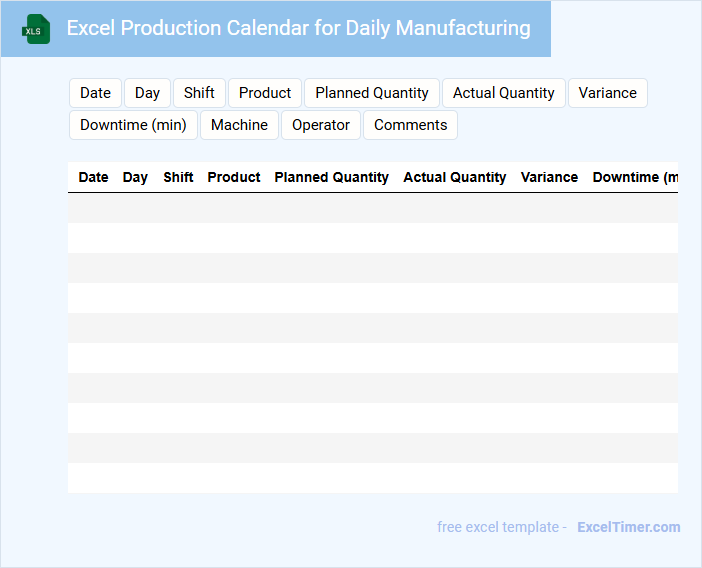

Excel Production Calendar for Daily Manufacturing

An Excel Production Calendar for daily manufacturing typically contains detailed schedules that track production timelines, resource allocation, and key milestones. It is designed to enhance workflow efficiency by providing a clear visual overview of daily tasks and deadlines. Important elements include shift schedules, machine maintenance planning, and inventory management to ensure continuous production flow.

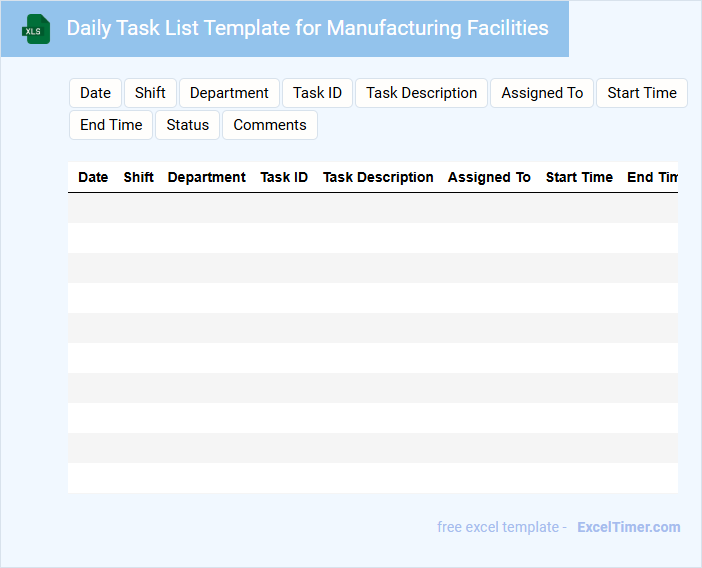

Daily Task List Template for Manufacturing Facilities

What information is typically included in a Daily Task List Template for Manufacturing Facilities? This type of document usually contains scheduled tasks, assigned personnel, and priority levels to ensure efficient operations. It helps streamline workflow by clearly outlining daily responsibilities and tracking progress.

What is an important consideration when using this template? It is crucial to include detailed descriptions of tasks and safety precautions to minimize errors and maintain compliance with industry standards. Regular updates and easy accessibility also enhance productivity and communication among teams.

Daily Order Tracker for Manufacturing in Excel

The Daily Order Tracker for manufacturing in Excel is a crucial document used to monitor daily production orders and their statuses. It typically contains order IDs, quantities, delivery deadlines, and progress updates to ensure timely completion. This tracker helps managers identify bottlenecks and maintain efficient workflow throughout the manufacturing process.

What key data columns are essential in a Daily Production Schedule Excel document for manufacturing operations?

Essential data columns in a Daily Production Schedule Excel for manufacturing include Production Date, Work Order Number, Product ID, Quantity to Produce, Machine/Line Assigned, Shift Timing, Operator Name, Start Time, End Time, and Status. Including these columns ensures clear tracking of production tasks, resource allocation, and progress monitoring. Accurate data entry in these fields facilitates efficient operational planning and timely decision-making.

How does the schedule account for machine capacity and available labor shifts each day?

The Daily Production Schedule integrates machine capacity by allocating tasks based on each machine's maximum output per shift. It incorporates available labor shifts by matching workforce hours to production demands, ensuring optimal utilization without overloading. This alignment minimizes downtime and balances workload across machines and labor resources efficiently.

What method is used within the Excel sheet to track and update work-in-progress versus completed units?

Your Daily Production Schedule Excel document uses conditional formatting and real-time data entry to track and update work-in-progress versus completed units. It integrates progress bars and dynamic formulas to visually represent production status and calculate completion percentages. This method ensures accurate monitoring and timely adjustments in manufacturing workflows.

How does the schedule handle unexpected changes, such as equipment downtime or supply delays?

The Daily Production Schedule incorporates real-time updates to adjust timelines and resource allocations promptly during equipment downtime or supply delays. It integrates automated alerts and contingency plans to minimize disruptions and maintain workflow efficiency. Historical data analysis supports proactive decision-making for rapid schedule adjustments and risk mitigation.

What visualization features (e.g., Gantt chart, conditional formatting) are incorporated to highlight bottlenecks or missed targets in the schedule?

Your Daily Production Schedule in Excel incorporates conditional formatting to highlight bottlenecks by marking delayed tasks in red, while a Gantt chart visually represents production timelines for easy tracking. Key performance indicators (KPIs) like missed targets are flagged automatically, enabling quick identification of production issues. This combination ensures you can proactively manage workflow and optimize manufacturing efficiency.