The Daily Quality Control Excel Template for Food Processing Units streamlines the documentation and monitoring of quality parameters, ensuring consistent product safety and compliance with industry standards. It enables precise tracking of critical control points, ingredient measurements, and hygiene standards, which helps in identifying deviations promptly. Regular use of this template enhances operational efficiency and supports regulatory audits by maintaining accurate and well-organized quality records.

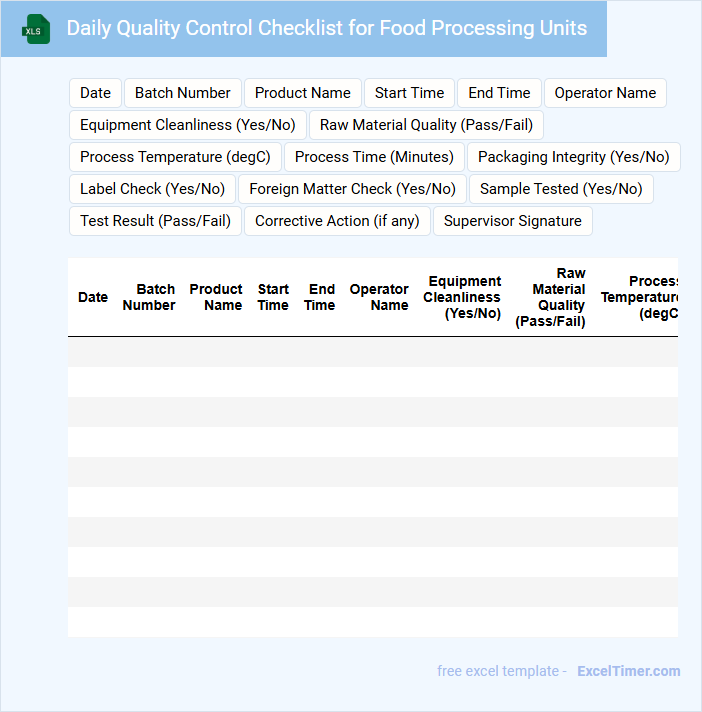

Daily Quality Control Checklist for Food Processing Units

The Daily Quality Control Checklist for food processing units typically contains detailed records of cleanliness, equipment functionality, and ingredient verification to ensure compliance with food safety standards. It helps in monitoring critical control points to prevent contamination and maintain product quality.

Key elements often include measurements of temperature, sanitation checks, and verification of packaging integrity. Regular use of this checklist enhances traceability and accountability within the food production process.

Ensure that the checklist is consistently updated and reviewed by quality assurance personnel to promptly address any deviations or issues.

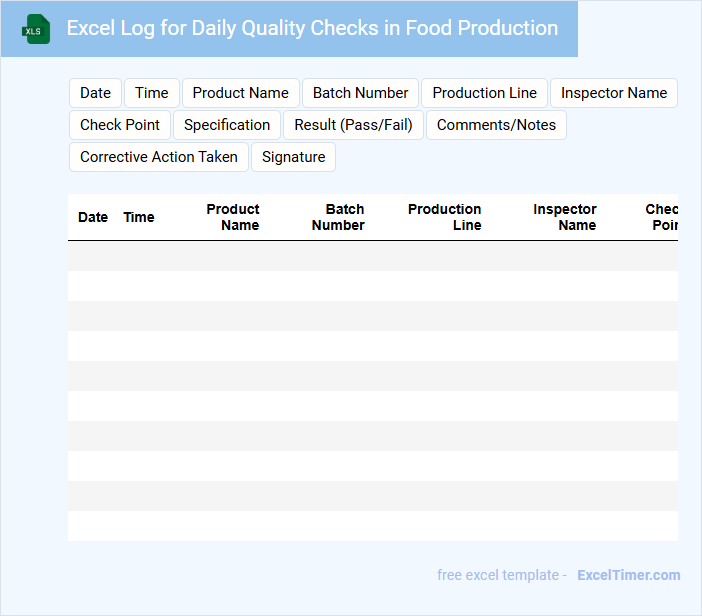

Excel Log for Daily Quality Checks in Food Production

An Excel Log for Daily Quality Checks in Food Production is a structured document used to systematically record and monitor the quality parameters of food products each day. It helps ensure compliance with safety standards and traceability in the production process.

- Include columns for date, time, product batch, and specific quality metrics like temperature and contamination levels.

- Incorporate space for comments to document any deviations or corrective actions taken.

- Regularly update and review the log to maintain consistency and identify trends in product quality.

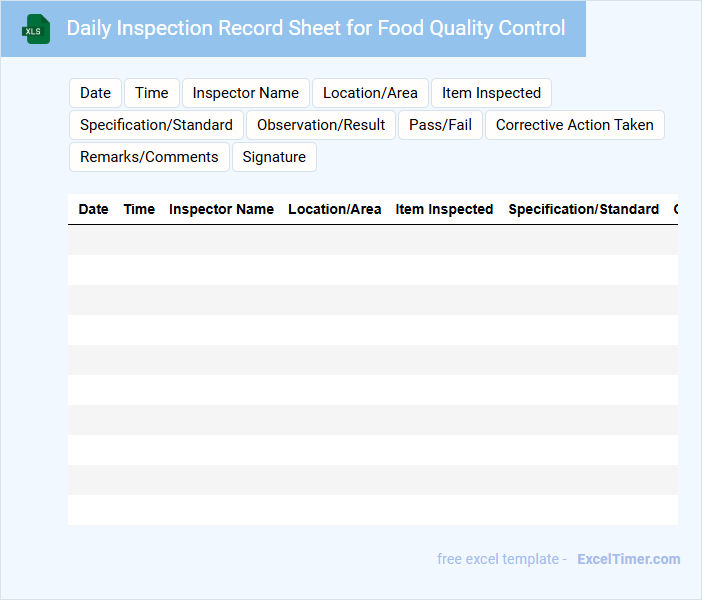

Daily Inspection Record Sheet for Food Quality Control

A Daily Inspection Record Sheet for Food Quality Control typically contains detailed entries documenting the condition, cleanliness, and compliance of food products and preparation areas to ensure safety and quality standards are consistently met.

- Inspection Date and Time must be accurately recorded to track the daily monitoring schedule.

- Temperature Logs are crucial for verifying that food is stored and cooked at safe temperatures.

- Sanitation Checks should detail cleanliness of equipment and surfaces to prevent contamination risks.

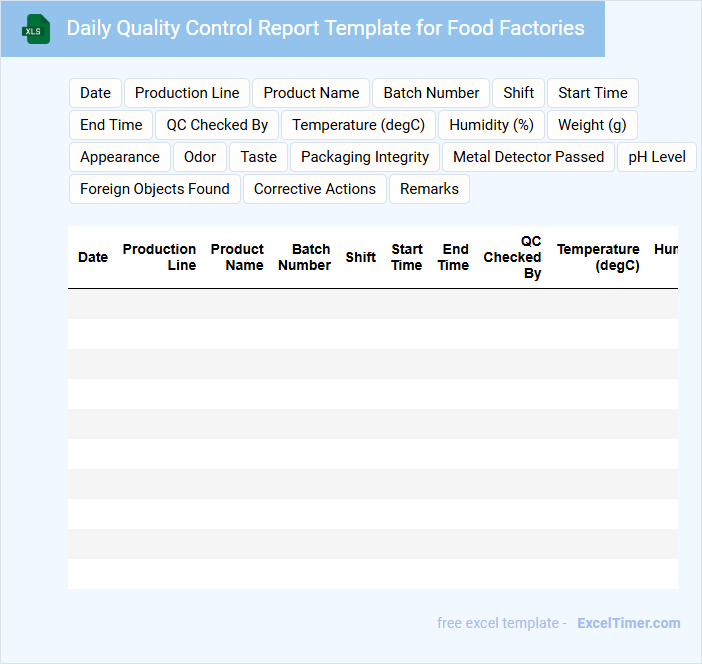

Daily Quality Control Report Template for Food Factories

A Daily Quality Control Report Template for Food Factories is a structured document used to monitor and ensure product safety and quality throughout production.

- Inspection Records: Detailed logs of daily checks on raw materials, processing, and finished products to identify any deviations.

- Environmental Monitoring: Documentation of sanitation, temperature, and hygiene conditions within the production facility.

- Corrective Actions: Clear notes on any issues found and immediate steps taken to maintain compliance with quality standards.

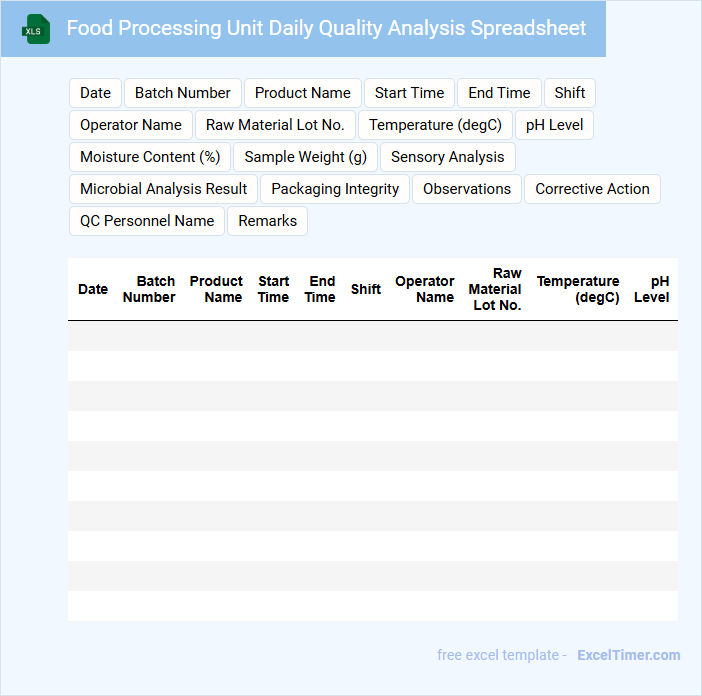

Food Processing Unit Daily Quality Analysis Spreadsheet

A Food Processing Unit Daily Quality Analysis Spreadsheet typically contains detailed records of product quality parameters, including testing results, batch numbers, and timestamps. It serves as a crucial tool for monitoring consistency and identifying any deviations in the production process. Maintaining accurate and timely entries ensures compliance with food safety standards and aids in continuous improvement efforts.

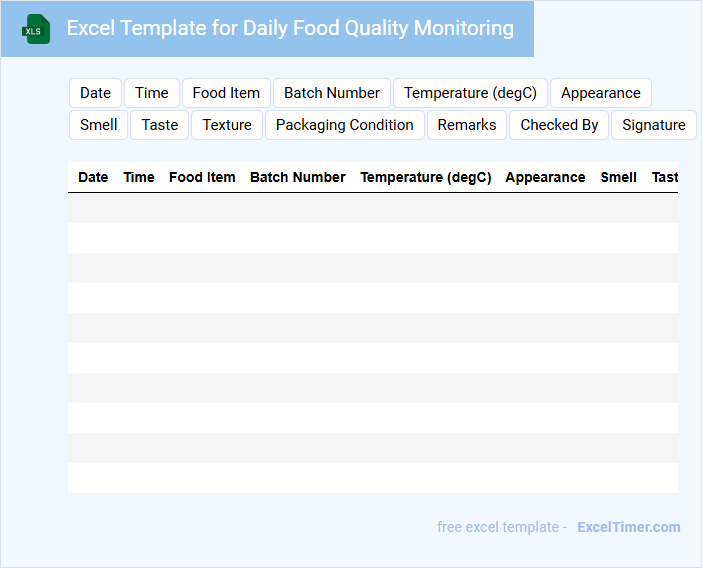

Excel Template for Daily Food Quality Monitoring

An Excel Template for Daily Food Quality Monitoring typically contains structured fields to record food quality parameters such as temperature, appearance, and hygiene checks. It helps maintain consistent quality by tracking daily observations and identifying trends or anomalies in food safety. Including clear, easy-to-understand instructions within the template ensures accurate and reliable data entry by staff members.

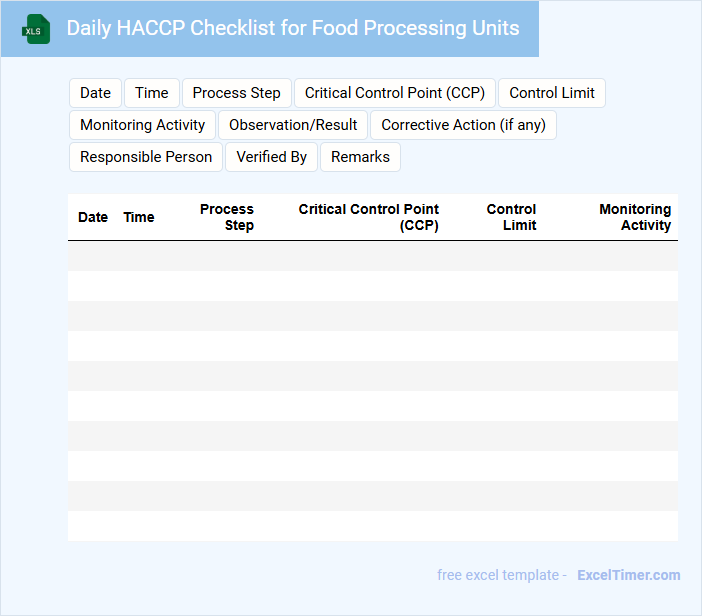

Daily HACCP Checklist for Food Processing Units

A Daily HACCP Checklist for Food Processing Units is a crucial document used to ensure food safety by systematically monitoring critical control points each day. It helps in maintaining compliance with hygiene standards and preventing contamination during food production.

- Check temperature controls of storage and processing equipment daily to prevent foodborne illnesses.

- Verify that all sanitation and cleaning procedures have been properly completed before production begins.

- Ensure all staff follow personal hygiene protocols and wear appropriate protective gear.

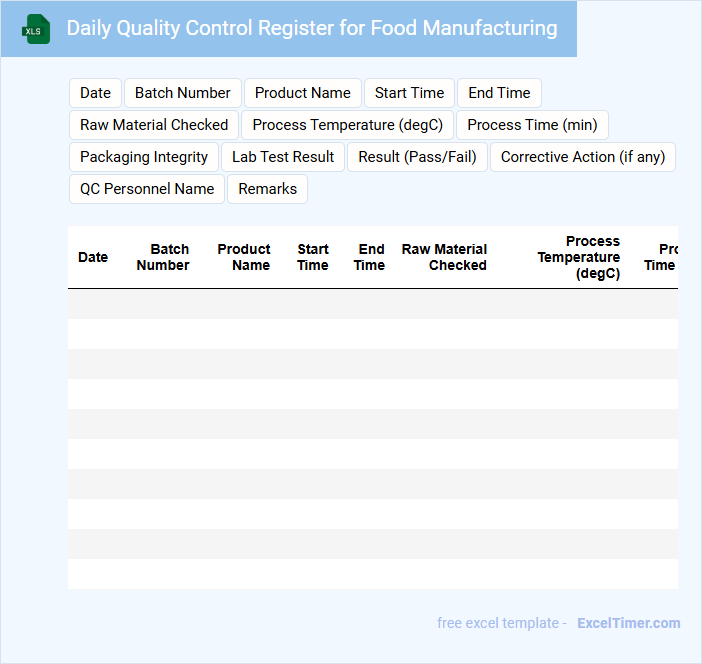

Daily Quality Control Register for Food Manufacturing

The Daily Quality Control Register for food manufacturing is a crucial document that records all quality checks performed throughout the production process. It typically includes details such as raw material inspection, in-process monitoring, and final product evaluation to ensure compliance with safety standards. Maintaining accurate and timely entries in this register helps identify deviations and ensures consistent product quality.

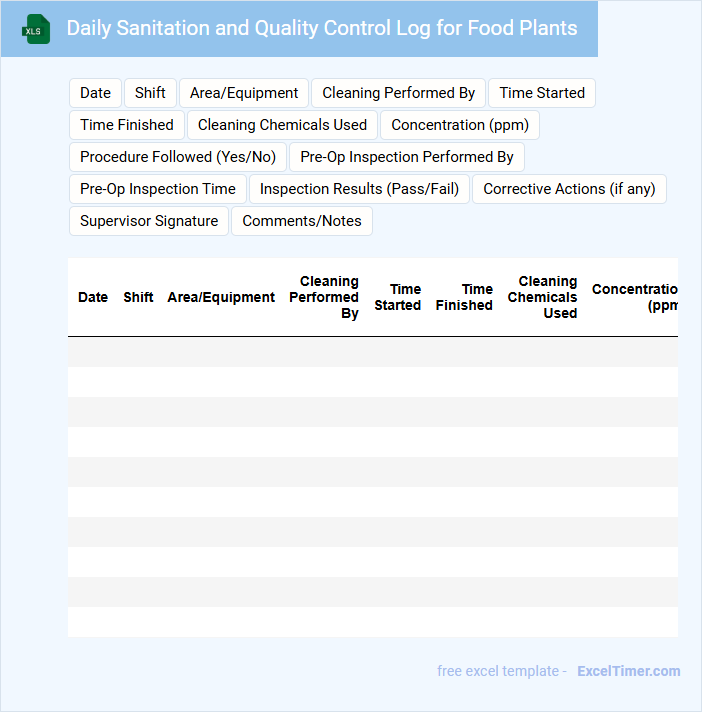

Daily Sanitation and Quality Control Log for Food Plants

The Daily Sanitation and Quality Control Log is a crucial document used in food plants to record cleaning activities and monitor quality standards. It ensures compliance with health regulations by tracking daily sanitation practices and identifying potential hazards.

Maintaining accurate log entries helps in preventing contamination and verifying that cleaning protocols are consistently followed. Regular review of this document supports continuous improvement in food safety management.

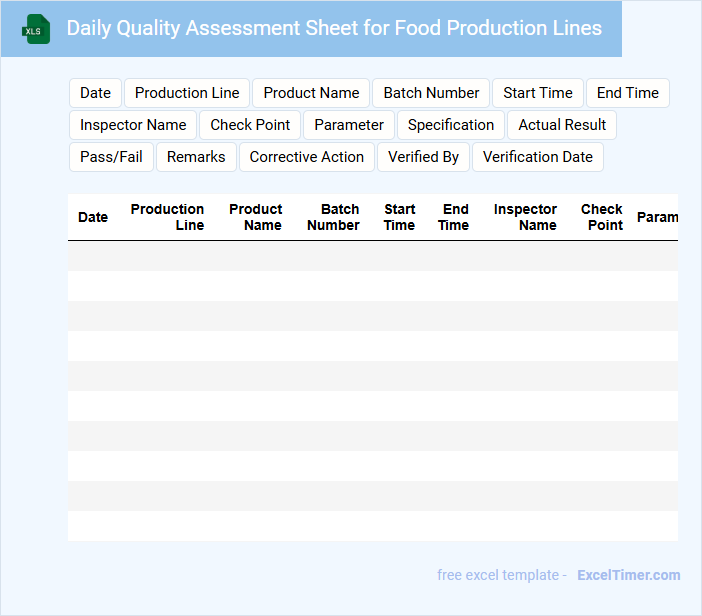

Daily Quality Assessment Sheet for Food Production Lines

The Daily Quality Assessment Sheet for Food Production Lines is a critical document used to monitor and record the quality parameters of food products on a daily basis. It typically contains sections for checking raw material quality, process controls, and finished product specifications. Ensuring accuracy and completeness in this document is essential for maintaining food safety and compliance with industry standards.

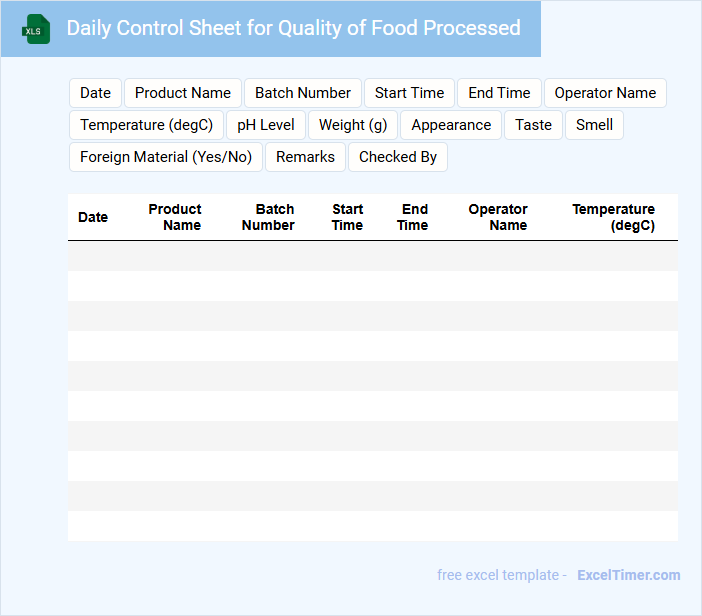

Daily Control Sheet for Quality of Food Processed

What information is typically included in a Daily Control Sheet for Quality of Food Processed? This document usually contains detailed records of the food processing parameters, such as temperature, processing times, and hygiene checks, to ensure consistent quality. It also tracks any deviations or corrective actions taken to maintain safety and compliance with food standards.

Why is maintaining accurate daily records important for food quality control? Accurate records help identify trends, prevent contamination, and ensure traceability in the food production process. They also support regulatory compliance and improve overall product safety and customer satisfaction.

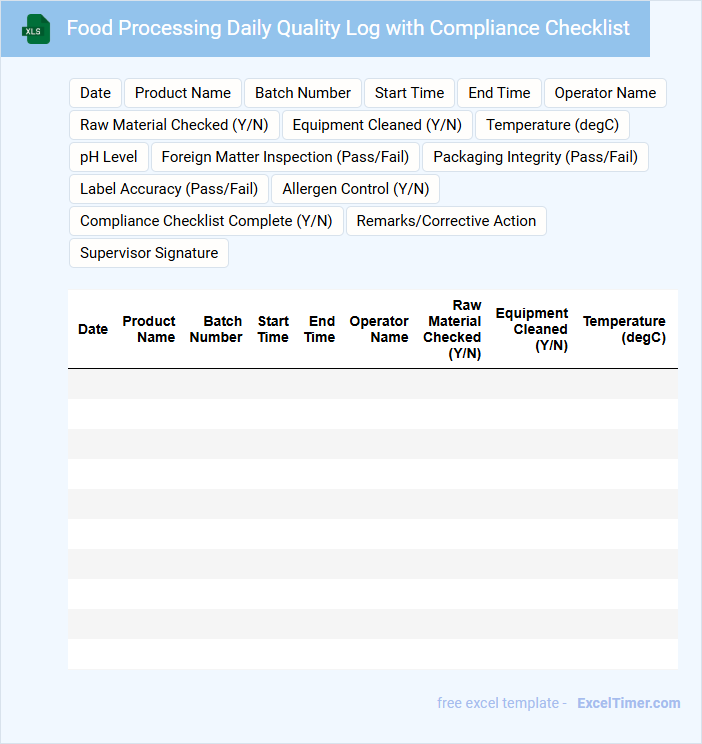

Food Processing Daily Quality Log with Compliance Checklist

What information is typically included in a Food Processing Daily Quality Log with Compliance Checklist? This document usually contains detailed daily records of food production processes, quality control checks, and compliance measures to ensure safety and standards are met. It serves as a critical tool for tracking consistency, identifying issues early, and verifying adherence to regulatory requirements.

What important aspects should be emphasized in this log? It is essential to include clear documentation of temperature controls, sanitation procedures, and any deviations or corrective actions taken. Additionally, integrating a compliance checklist helps ensure all operational standards are consistently evaluated and maintained.

Daily Defect Tracking Sheet for Food Processing Units

A Daily Defect Tracking Sheet for Food Processing Units is typically a document that records and monitors product defects encountered during the production process to ensure quality control and continuous improvement.

- Defect Identification: Clearly list and categorize all types of defects observed each day.

- Quantity Tracking: Record the number of defects for accurate analysis and reporting.

- Corrective Actions: Note the measures taken or recommended to address and prevent recurring defects.

Excel Tracker for Daily Food Quality Observations

This document typically contains detailed daily records of food quality observations to ensure safety and consistency in food services.

- Accurate Data Entry: Maintain precise records of food appearance, taste, and temperature to monitor quality effectively.

- Timely Updates: Update the tracker daily to promptly identify and address any food quality issues.

- Consistent Criteria: Use standardized evaluation criteria to ensure reliable and comparable quality assessments.

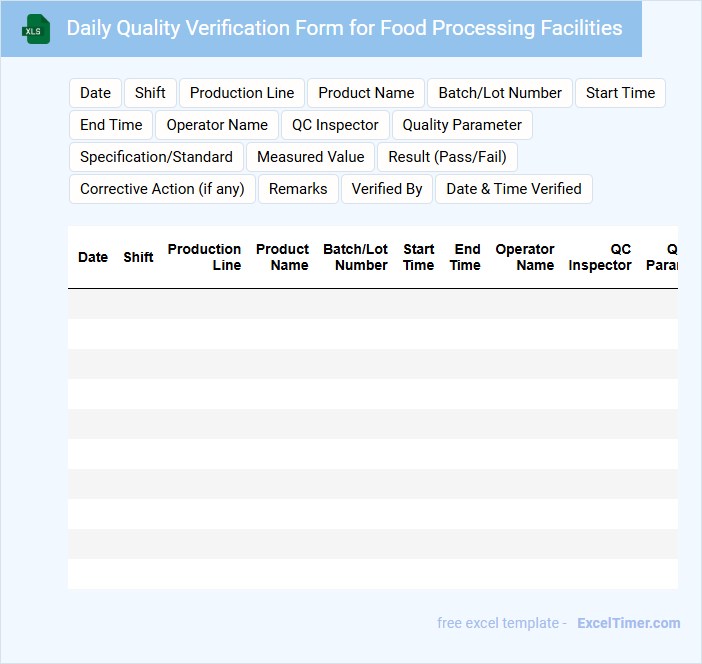

Daily Quality Verification Form for Food Processing Facilities

Daily Quality Verification Forms for Food Processing Facilities typically document routine checks to ensure product safety, hygiene, and compliance with regulatory standards.

- Product Quality: records key quality parameters such as temperature, texture, and appearance.

- Sanitation Checks: monitors cleanliness of equipment, tools, and work areas to prevent contamination.

- Compliance Verification: confirms adherence to safety protocols and corrective actions for deviations.

What standardized procedures are documented for daily quality control in food processing units?

Daily quality control in food processing units includes standardized procedures such as temperature monitoring, microbial testing, and equipment sanitation checks documented in your Excel tracking sheet. Each entry records critical data points like batch numbers, inspection times, and compliance status to ensure food safety standards are met consistently. This systematic approach helps maintain product integrity and traceability throughout the production process.

How are critical control points (CCPs) identified and recorded in daily Excel logs?

Critical control points (CCPs) are identified by analyzing each stage of the food processing workflow for potential hazards such as biological, chemical, or physical risks. These CCPs are then documented in daily Excel logs under specific columns like "Control Point," "Hazard Description," "Monitoring Procedures," and "Corrective Actions" to ensure consistent tracking. The Excel sheet typically includes timestamps and responsible personnel to maintain accountability and facilitate quality control audits.

Which parameters (e.g., temperature, pH, humidity) are regularly monitored and updated in the Excel document?

Your Excel document for Daily Quality Control in Food Processing Units regularly monitors and updates key parameters such as temperature, pH levels, and humidity. Consistent tracking of these critical factors ensures compliance with safety standards and optimal product quality. Accurate recording of these values in the Excel sheet supports effective quality management and traceability.

How is non-conformance or deviation from standards tracked and flagged within the daily quality control sheets?

Your daily quality control sheets for food processing units track non-conformance by recording deviations from established safety and quality standards in detailed columns. Automated flagging systems highlight these discrepancies with color codes or alerts, enabling quick identification and corrective action. Data entries include timestamps, responsible personnel, and specific deviation descriptions to maintain traceability.

What automated alerts or formulas are implemented in Excel to highlight potential risks or compliance failures?

Excel for Daily Quality Control in Food Processing Units often uses conditional formatting formulas like =IF(A2