The Quarterly Manufacturing Production Excel Template for Factories streamlines tracking and analyzing production output across different quarters, enhancing operational efficiency. This template includes pre-built formulas and customizable sections tailored for factory settings to monitor key performance indicators like production volume, downtime, and resource usage. Its user-friendly design ensures accurate data entry and real-time insights critical for decision-making and boosting manufacturing productivity.

Quarterly Production Tracking Dashboard for Factories

The Quarterly Production Tracking Dashboard is a critical document that captures detailed data on factory output, efficiency, and machinery performance over a three-month period. It consolidates key production metrics to help managers monitor progress and identify trends.

This document typically includes production volume, defect rates, downtime, and resource utilization to provide a comprehensive view of factory operations. For optimal use, ensuring real-time data updates and clear visualization through graphs and charts is essential for quick decision-making.

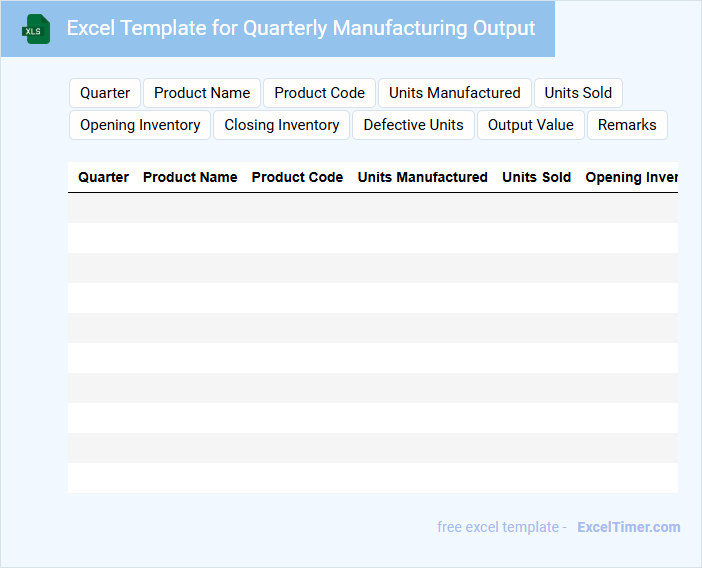

Excel Template for Quarterly Manufacturing Output

An Excel Template for Quarterly Manufacturing Output typically contains detailed production data organized by month and product category to track efficiency and productivity.

- Production Metrics: Includes quantities produced, defect rates, and machine utilization for comprehensive performance analysis.

- Time Period Segmentation: Divides data into quarters and months for clear trend identification and comparison.

- Visual Charts: Incorporates graphs and pivot tables to easily interpret data patterns and highlight key insights.

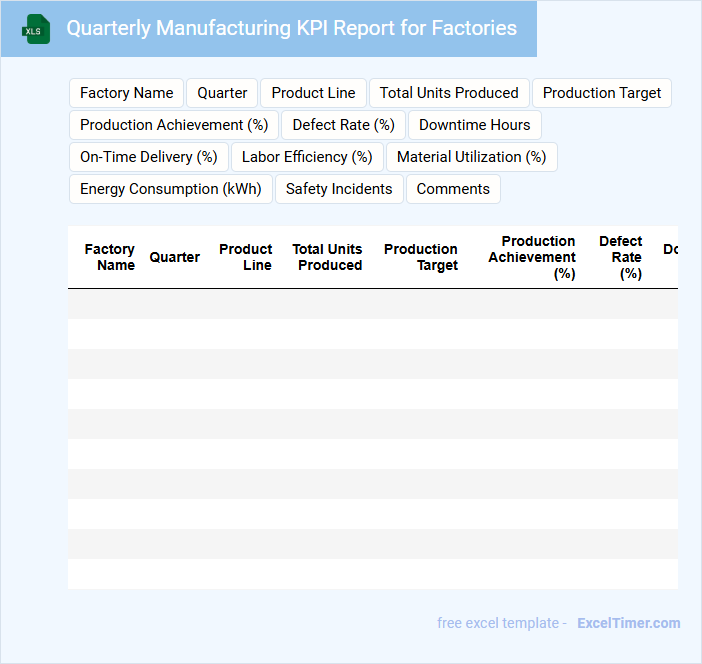

Quarterly Manufacturing KPI Report for Factories

A Quarterly Manufacturing KPI Report for Factories typically contains data-driven insights into production performance, efficiency, and quality metrics to guide operational improvements.

- Production Output: Tracks the total units produced versus targets to assess manufacturing capacity and identify bottlenecks.

- Quality Metrics: Monitors defect rates and compliance with quality standards to ensure product reliability.

- Operational Efficiency: Measures equipment utilization and downtime to optimize resource allocation and reduce costs.

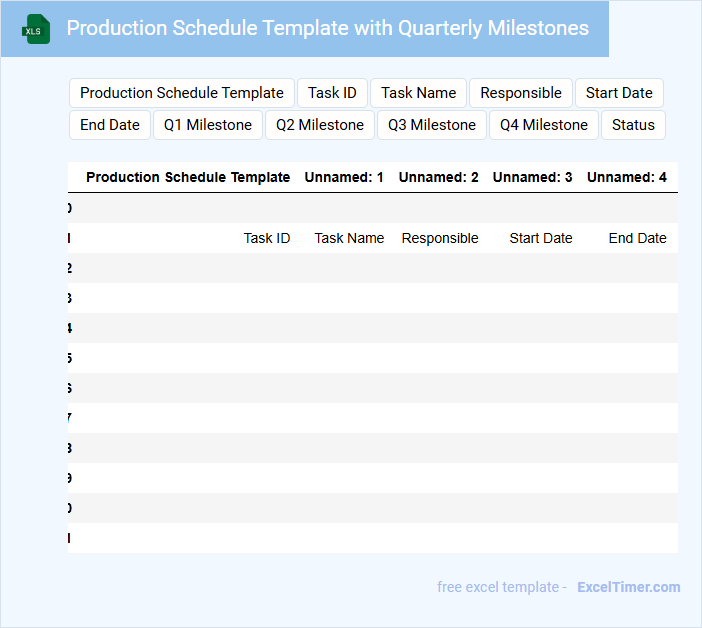

Production Schedule Template with Quarterly Milestones

What information is typically included in a Production Schedule Template with Quarterly Milestones? This type of document usually contains a detailed timeline of production activities, key deliverables, and specific milestones set for each quarter to track progress effectively. It helps teams coordinate tasks, allocate resources efficiently, and ensure timely completion of production goals.

What is an important consideration when using this template? It is crucial to regularly update the schedule to reflect any changes in production timelines or priorities, and to clearly define milestone criteria to measure success accurately. Additionally, including contingency plans for potential delays can improve overall project management and reduce risks.

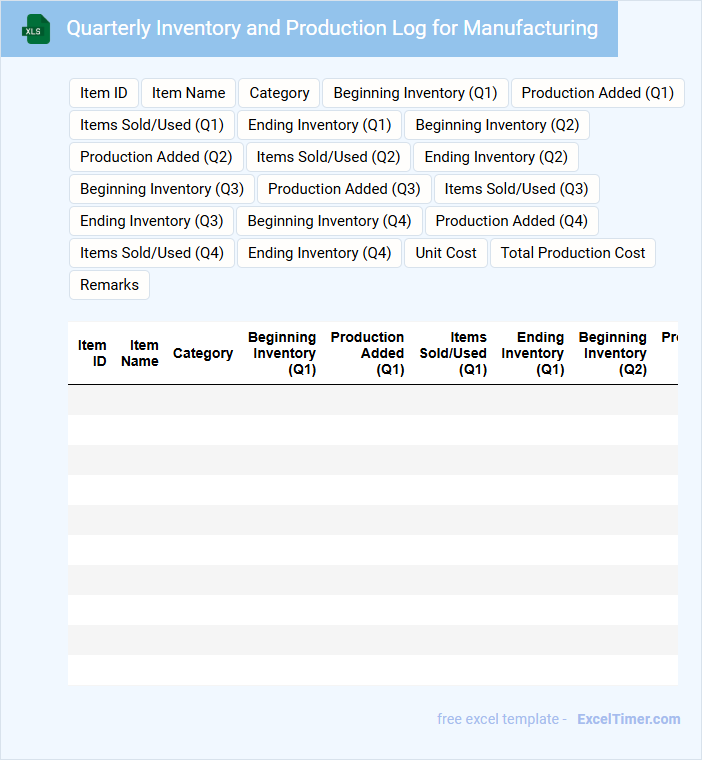

Quarterly Inventory and Production Log for Manufacturing

The Quarterly Inventory and Production Log is a vital document in manufacturing that tracks the quantity and status of raw materials, work-in-progress, and finished goods over a three-month period. It helps in monitoring production efficiency, inventory levels, and identifying discrepancies or shortages. Maintaining accurate records ensures smooth operations and supports decision-making for supply chain management.

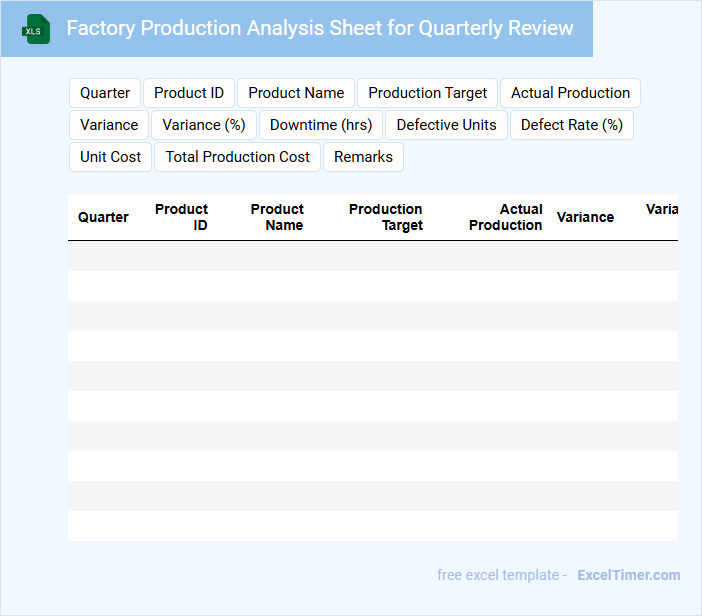

Factory Production Analysis Sheet for Quarterly Review

Factory Production Analysis Sheet for Quarterly Review typically contains detailed production data, including output quantities, defect rates, and machine performance metrics. It serves as a vital document for assessing the efficiency and productivity of the manufacturing process over a three-month period. Key insights derived from this sheet help inform strategic decisions and identify areas needing improvement. For an effective review, it is important to ensure data accuracy, include comparative analysis with previous quarters, and highlight critical production bottlenecks. Consistent formatting and clear visualization of trends also enhance understanding and decision-making. Regular updates and cross-functional input from manufacturing, quality control, and maintenance teams are recommended to maintain the document's relevance and comprehensiveness.

Excel Tracker for Quarterly Factory Production Volumes

An Excel Tracker for Quarterly Factory Production Volumes typically contains detailed records of production output, organized by quarter and factory location to monitor efficiency and capacity. It includes metrics such as total units produced, downtime, and defect rates to provide a comprehensive overview of manufacturing performance.

This type of document is essential for identifying trends, setting production targets, and facilitating data-driven decision-making. Regular updates and accuracy in data entry are important to ensure the tracker remains a reliable tool for operational planning.

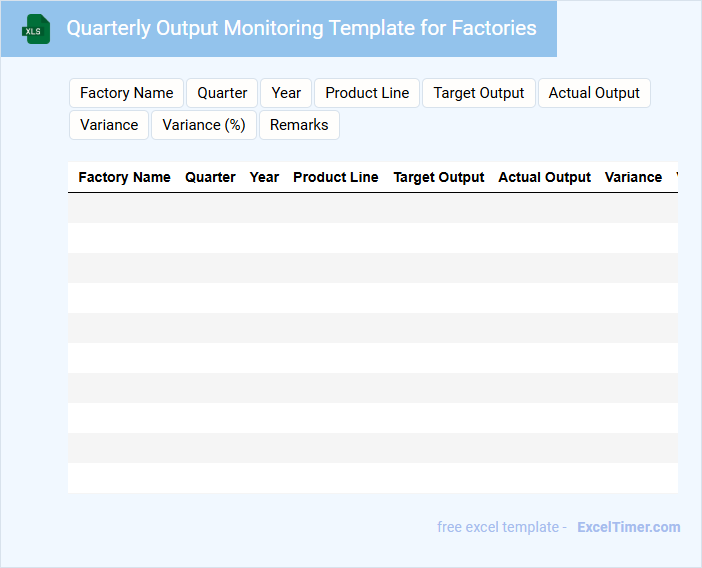

Quarterly Output Monitoring Template for Factories

The Quarterly Output Monitoring Template is designed to systematically track the production performance of factories over three-month periods. It typically contains data on total output, efficiency rates, and quality control metrics.

This document is essential for identifying trends and potential issues in factory operations to ensure continuous improvement. Including clear targets and variance analysis sections is an important feature for effective monitoring.

Manufacturing Defect Log with Quarterly Summary

A Manufacturing Defect Log typically contains detailed records of defects identified during production, including descriptions, defect categories, and timestamps. It provides a chronological account to help trace and analyze recurring issues.

The Quarterly Summary consolidates these defect logs into comprehensive reports highlighting trends, root causes, and corrective actions taken over the quarter. It aids in strategic decision-making and continuous improvement efforts.

For optimal use, ensure entries are consistently detailed and accurate, and regularly review summaries to identify persistent problems and implement effective solutions.

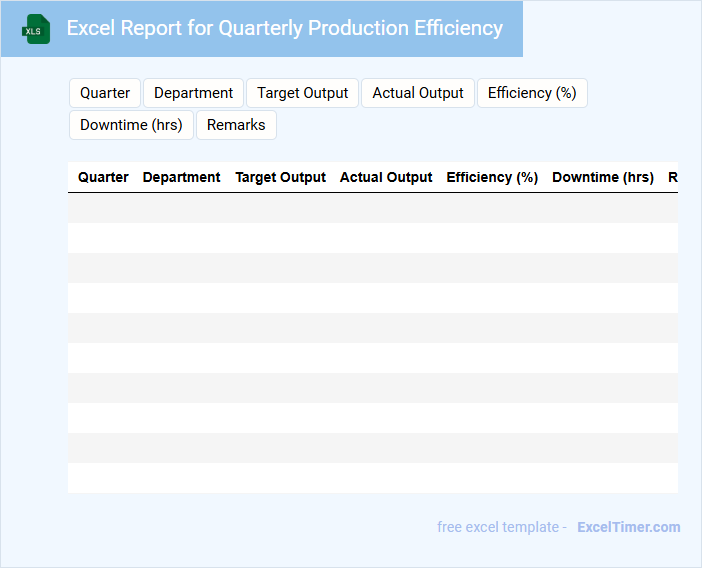

Excel Report for Quarterly Production Efficiency

An Excel Report for Quarterly Production Efficiency typically contains detailed data on manufacturing output, operational hours, and efficiency metrics. This document is crucial for analyzing production trends and identifying areas for improvement. Including charts and tables helps visualize performance over the quarter for better decision-making.

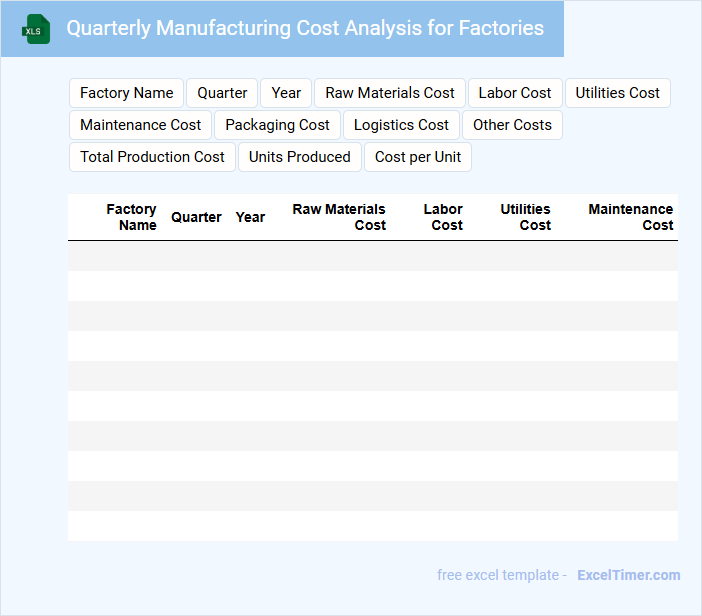

Quarterly Manufacturing Cost Analysis for Factories

The Quarterly Manufacturing Cost Analysis document typically contains detailed breakdowns of production expenses, including raw materials, labor, and overhead costs. It helps factories evaluate financial performance over the quarter, identifying cost-saving opportunities and efficiency improvements. Accurate data collection and trend comparison are essential for informed decision-making in manufacturing operations.

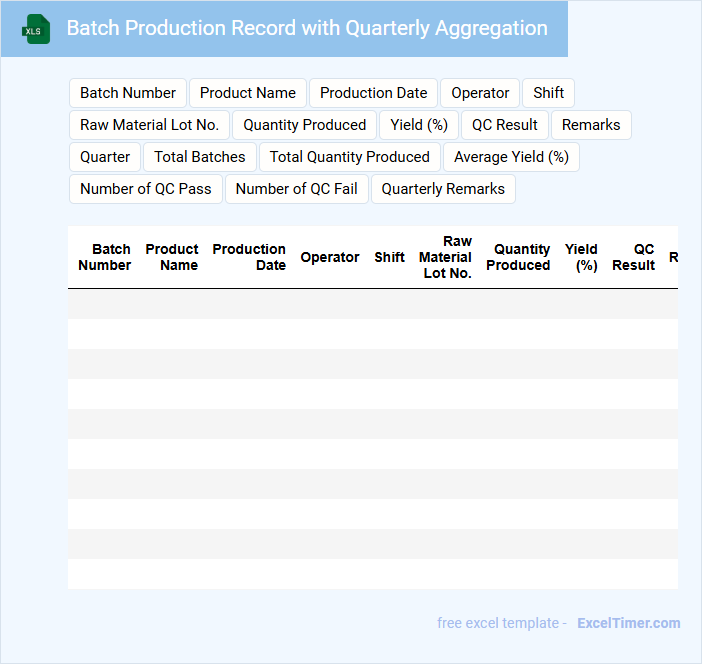

Batch Production Record with Quarterly Aggregation

The Batch Production Record with Quarterly Aggregation documents detailed information about the manufacturing process for each batch of products over a specific quarter. It typically includes raw material details, processing steps, and quality control results to ensure traceability and compliance. This record is essential for tracking production efficiency and identifying trends over time.

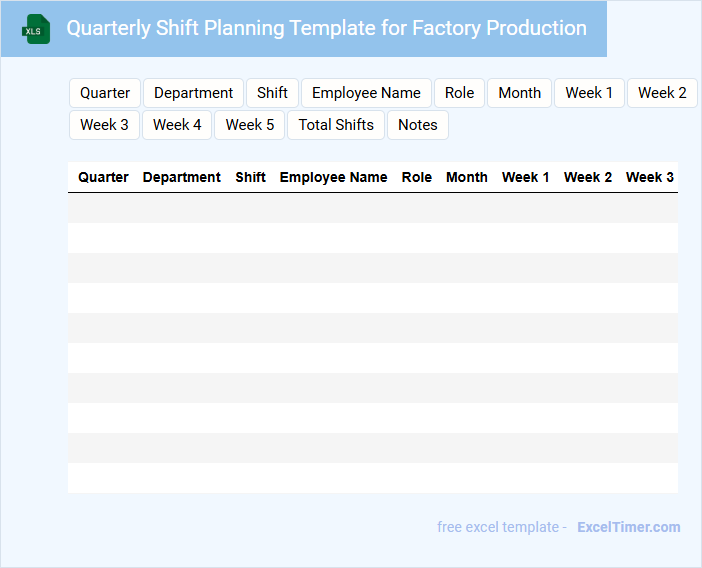

Quarterly Shift Planning Template for Factory Production

A Quarterly Shift Planning Template for Factory Production typically contains detailed schedules to optimize workforce allocation and ensure continuous operational efficiency.

- Shift Timings: Clearly outlined start and end times for each shift to manage worker attendance.

- Worker Assignments: Specific roles and personnel assigned to each shift to maintain productivity levels.

- Break Schedules: Designated break periods to comply with labor laws and promote employee well-being.

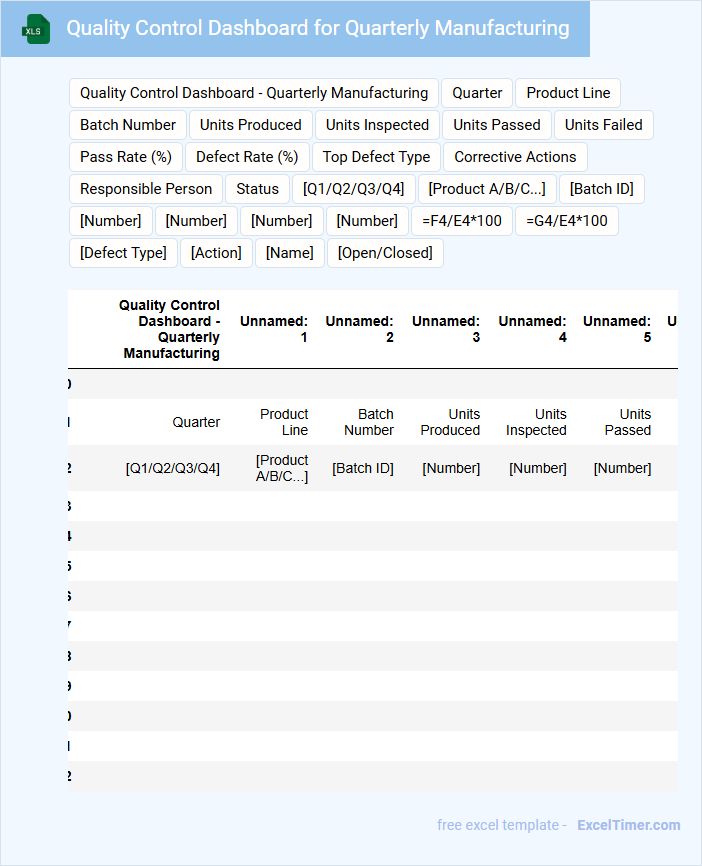

Quality Control Dashboard for Quarterly Manufacturing

The Quality Control Dashboard for Quarterly Manufacturing typically contains key metrics and performance indicators related to product quality, production efficiency, and defect rates. It consolidates data from various stages of the manufacturing process to provide a comprehensive view of quality trends over the quarter.

Important elements include detailed charts, real-time anomaly detection, and actionable insights to support decision-making. Prioritizing clear visualization and accuracy ensures stakeholders can quickly identify issues and improve manufacturing standards.

Excel Sheet for Quarterly Product Yield Tracking

What information is typically contained in an Excel Sheet for Quarterly Product Yield Tracking? This type of document usually includes data on production volume, yield percentages, and quality metrics for products over each quarter. It helps businesses monitor performance trends, identify issues, and make informed decisions to improve efficiency.

What is an important consideration when creating this Excel sheet? Ensuring accurate data entry and consistent formatting is crucial for reliable analysis. Including clear labels and summary charts can also enhance readability and facilitate quick insights for stakeholders.

What is the definition and significance of Quarterly Manufacturing Production in a factory setting?

Quarterly Manufacturing Production measures the total output of goods produced by a factory within a three-month period. This metric is crucial for assessing operational efficiency, resource utilization, and meeting market demand. Tracking quarterly production helps identify trends, optimize workflows, and support strategic planning in manufacturing operations.

Which key metrics should be tracked to accurately report quarterly manufacturing output?

To accurately report quarterly manufacturing output, track total units produced, production cycle time, and defect rates for each factory. Monitor machine utilization rates and labor productivity to identify operational efficiency. Your focus on these key metrics ensures comprehensive insights into overall manufacturing performance.

How can seasonal trends and demand fluctuations affect quarterly production volumes?

Seasonal trends cause variations in raw material availability and workforce capacity, directly impacting quarterly production volumes. Demand fluctuations influence inventory levels and production scheduling, requiring factories to adjust output to prevent overproduction or stockouts. Analyzing historical production data guides accurate forecasting and resource allocation for each quarter.

What challenges might a factory face when aggregating and analyzing production data quarterly?

Factories may encounter data consistency issues when aggregating production figures from multiple sources, impacting the accuracy of quarterly reports. Variations in reporting formats and timeframes can lead to difficulties in standardizing data for meaningful analysis. Limited real-time insights pose challenges in identifying production inefficiencies and addressing bottlenecks promptly.

How does quarterly production reporting support strategic planning and resource allocation?

Quarterly manufacturing production reporting provides detailed insights into factory performance trends, enabling precise analysis of output variations and efficiency. Your strategic planning benefits from accurate data that identifies high-demand periods and underutilized resources, enhancing decision-making for capacity adjustments. Resource allocation becomes optimized through timely identification of production bottlenecks and inventory needs, improving overall operational effectiveness.