The Quarterly Production Planning Excel Template for Manufacturing Units streamlines the scheduling of production activities by providing a clear, organized format for tracking output goals and resource allocation. It helps manufacturing managers optimize workflow, manage inventory levels, and adjust schedules based on demand fluctuations. This template enhances decision-making efficiency and improves overall operational productivity.

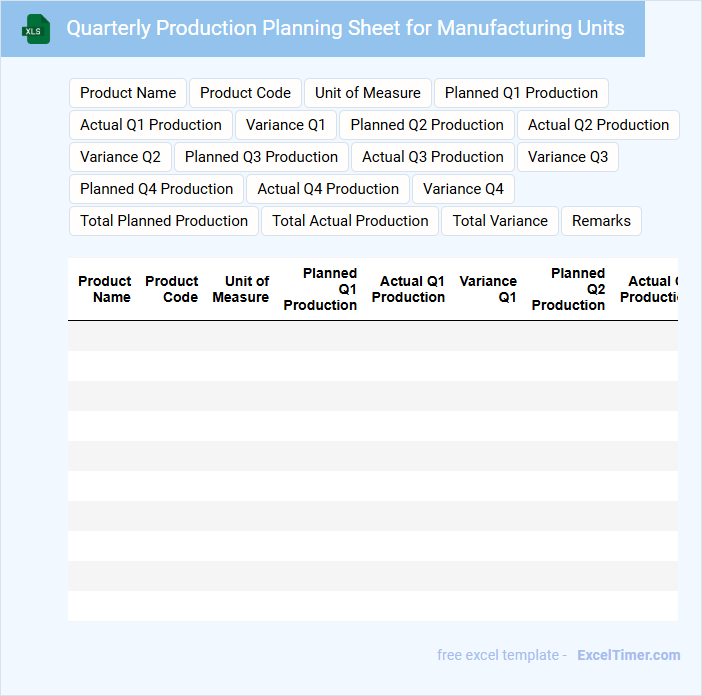

Quarterly Production Planning Sheet for Manufacturing Units

What information is typically included in a Quarterly Production Planning Sheet for Manufacturing Units? This document usually contains detailed schedules of production activities, resource allocation, and inventory levels for the upcoming quarter. It helps manufacturing units coordinate operations, optimize workflow, and meet production targets efficiently.

What important aspects should be considered when preparing this sheet? It is crucial to ensure accurate demand forecasting, realistic capacity planning, and clear communication of deadlines. Additionally, incorporating flexibility for unexpected changes and continuous monitoring can significantly improve production outcomes.

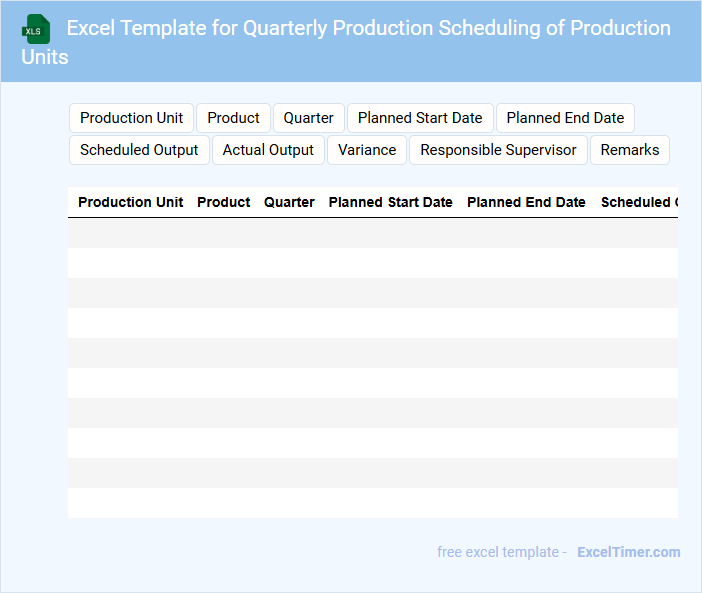

Excel Template for Quarterly Production Scheduling of Production Units

This document typically contains structured data and formulas to efficiently plan and track the quarterly production schedules of various production units.

- Production Timeline: Detailed schedule outlining start and end dates for each production phase within the quarter.

- Resource Allocation: Clearly defined assignment of machinery, labor, and materials needed for each production unit.

- Performance Metrics: Key indicators such as output volume, downtime, and efficiency rates to monitor progress and adjust plans.

Quarterly Manufacturing Output Planning with Inventory Tracking

Quarterly Manufacturing Output Planning documents typically contain detailed production schedules, capacity forecasts, and resource allocation strategies. The main objective is to align manufacturing output with demand projections to optimize efficiency and meet delivery deadlines.

Additionally, these documents include comprehensive inventory tracking to monitor raw materials, work-in-progress, and finished goods levels. Accurate inventory management helps prevent stockouts and overstock situations, ensuring smooth production flow.

For effective quarterly planning, it is essential to maintain real-time data integration and perform regular reviews to adjust for any supply chain disruptions or demand fluctuations.

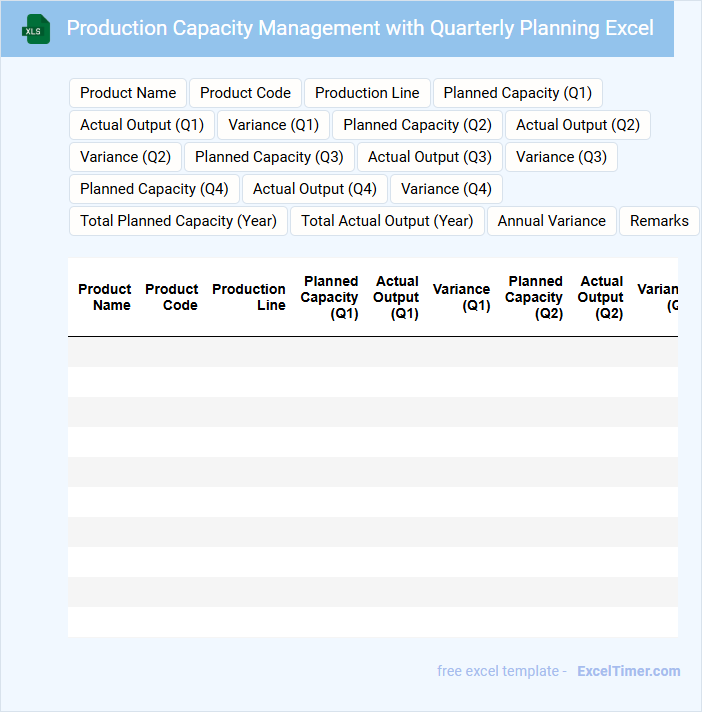

Production Capacity Management with Quarterly Planning Excel

This document typically contains detailed production capacity data, including machinery capabilities, labor availability, and material constraints to forecast output. It includes quarterly planning to align resources with production goals, ensuring efficient workflow management and demand fulfillment.

Key elements involve tracking utilization rates, setting realistic targets, and adjusting for seasonal fluctuations. Ensuring accurate data entry and regularly updating forecasts are crucial for effective production capacity management.

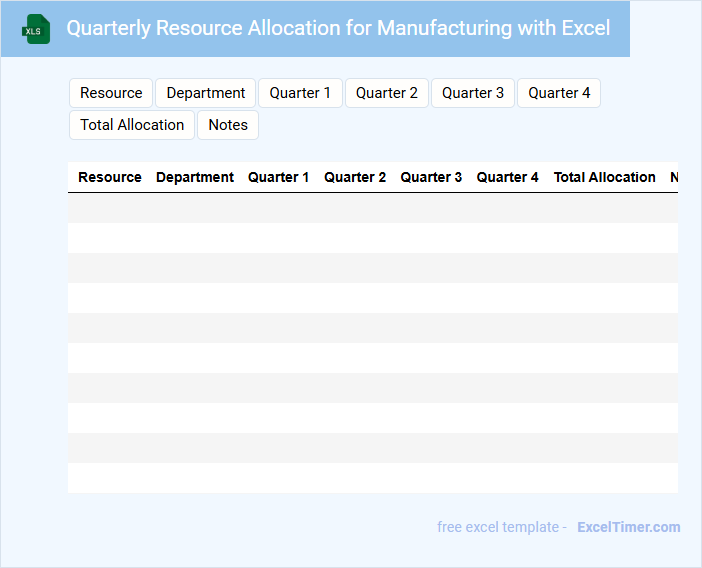

Quarterly Resource Allocation for Manufacturing with Excel

What information is typically included in a Quarterly Resource Allocation document for manufacturing using Excel? This type of document usually contains detailed data on resource distribution such as labor hours, machinery utilization, and raw material inventory for the upcoming quarter. It helps in forecasting needs, managing costs, and optimizing production efficiency by clearly outlining resource assignments and timelines.

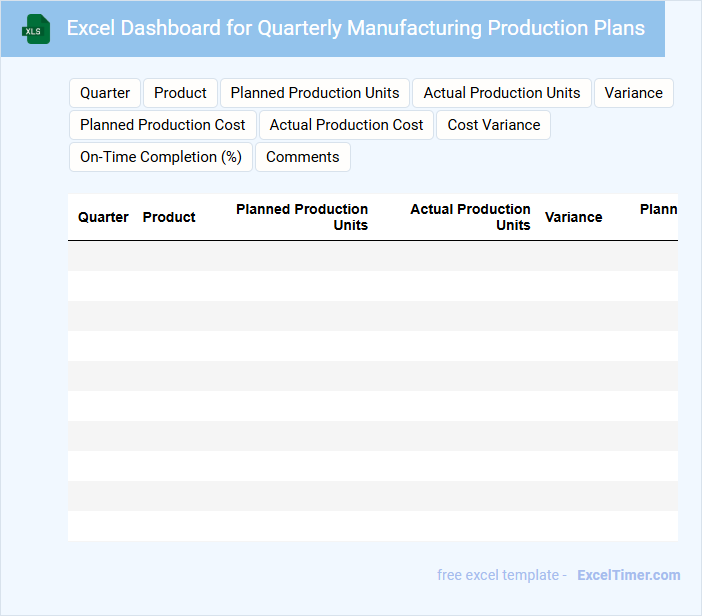

Excel Dashboard for Quarterly Manufacturing Production Plans

An Excel Dashboard for Quarterly Manufacturing Production Plans typically contains key performance indicators (KPIs), production targets, and progress tracking charts. It visually summarizes data to help teams monitor output and identify bottlenecks efficiently. Including dynamic graphs and real-time data updates ensures informed decision-making throughout the quarter.

Quarterly Demand Forecasting Template for Production Units

What information does a Quarterly Demand Forecasting Template for Production Units usually contain? This type of document typically includes estimated demand quantities, production schedules, and inventory levels for the upcoming quarter. It helps production units align resources and manage supply chain activities effectively.

What is an important consideration when using this template? Accuracy in data input and regular updates based on market trends are essential to ensure reliable forecasting and avoid overproduction or stockouts.

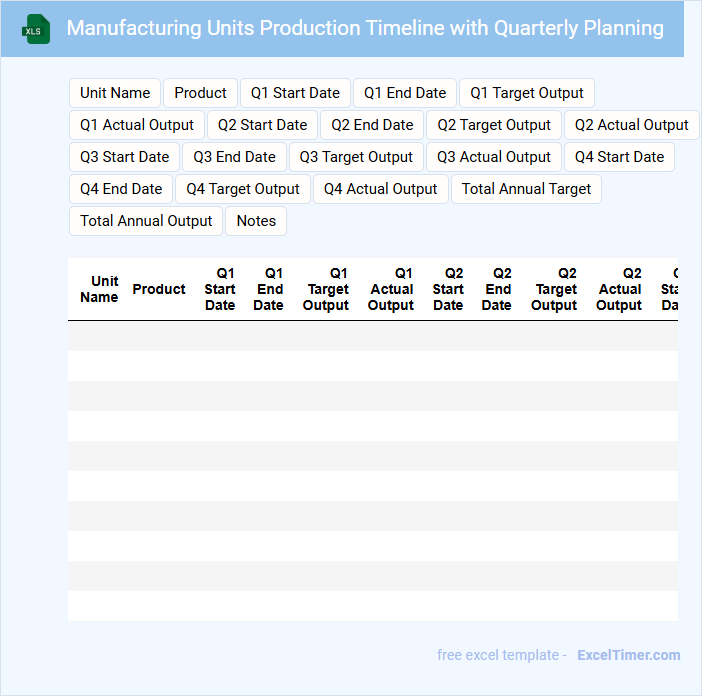

Manufacturing Units Production Timeline with Quarterly Planning

Manufacturing Units Production Timeline with Quarterly Planning is a strategic document that outlines the scheduled production activities over specific quarters. It typically contains detailed timelines, resource allocation, and milestone tracking for manufacturing processes. This document ensures that production goals are aligned with operational capabilities and market demand. Key suggestions for an effective timeline include setting clear deadlines, incorporating buffer periods for unforeseen delays, and regularly reviewing progress to adjust plans accordingly.

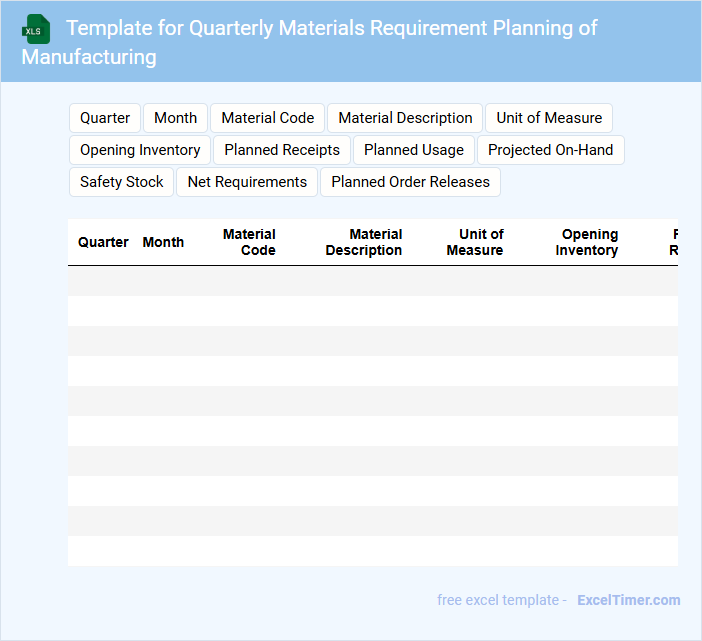

Template for Quarterly Materials Requirement Planning of Manufacturing

The Materials Requirement Planning (MRP) template for quarterly use is designed to organize and forecast the quantity of raw materials needed for manufacturing processes. It typically contains data on inventory levels, production schedules, and supplier lead times, ensuring that materials are available when required to avoid delays. This document helps streamline operations by aligning material procurement with production demands over a three-month period.

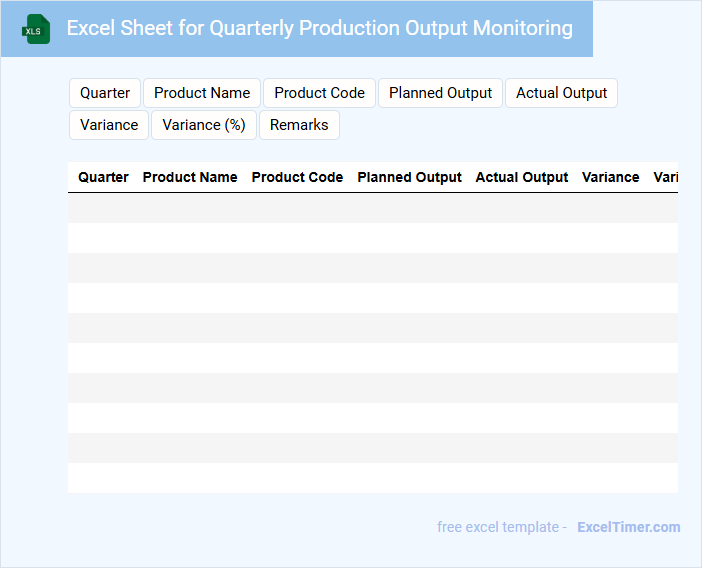

Excel Sheet for Quarterly Production Output Monitoring

What information does an Excel Sheet for Quarterly Production Output Monitoring usually contain? This type of document typically includes data on production volumes, efficiency rates, and any discrepancies noted during the quarter. It serves as a crucial tool for tracking performance and identifying trends for better decision-making.

Why is it important to maintain accuracy and consistency in this document? Ensuring data accuracy helps in making reliable assessments of production output, while consistency facilitates easy comparison across different quarters. These factors contribute to effective production planning and resource allocation.

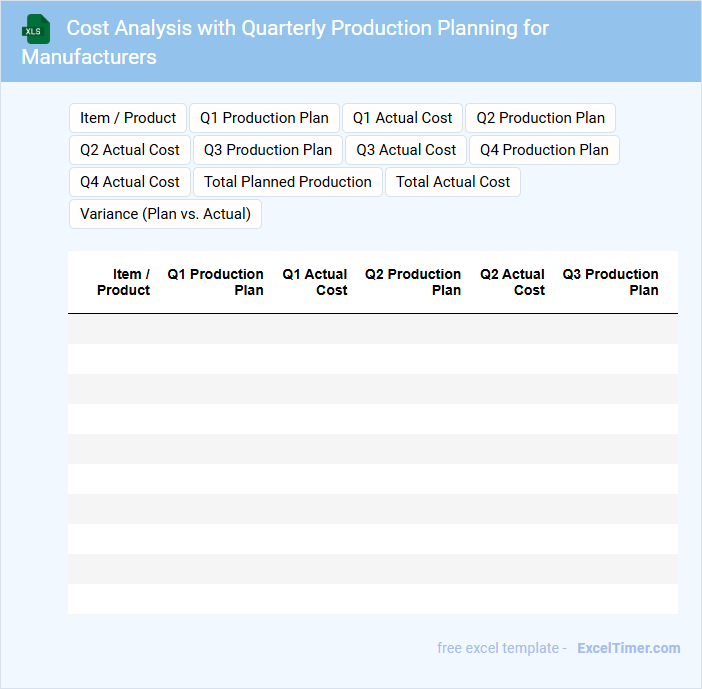

Cost Analysis with Quarterly Production Planning for Manufacturers

Cost Analysis documents typically include detailed financial assessments that outline production expenses, resource allocation, and overhead costs. These documents help manufacturers identify cost-saving opportunities and improve profitability. Including historical data and trend analysis is essential for accuracy.

Quarterly Production Planning focuses on scheduling, capacity utilization, and inventory management to meet demand efficiently. This plan aligns production goals with market forecasts and raw material availability. Emphasizing realistic timelines and supplier coordination is crucial for success.

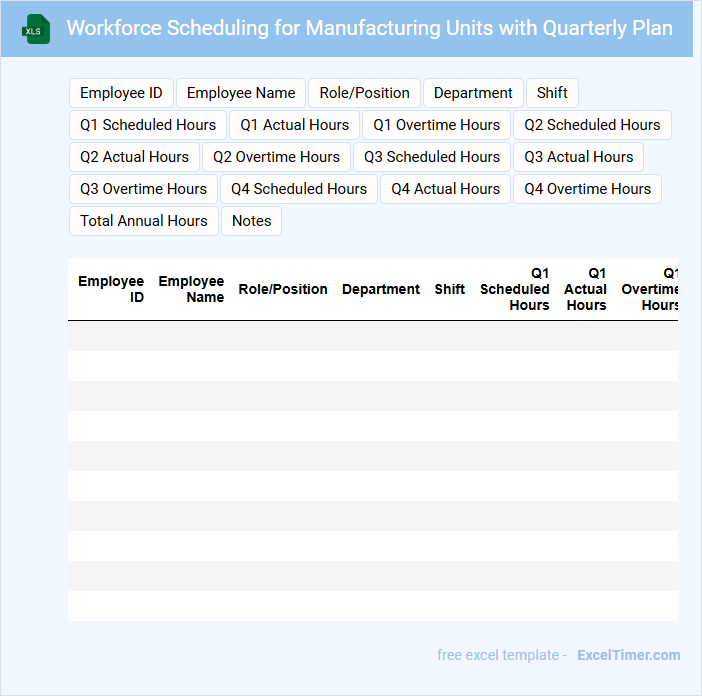

Workforce Scheduling for Manufacturing Units with Quarterly Plan

Workforce Scheduling for Manufacturing Units with Quarterly Plan typically contains detailed employee shift assignments aligned with production goals, resource allocation, and compliance regulations.

- Shift Assignments: Clearly defined shifts ensure optimal coverage and productivity across all manufacturing processes.

- Resource Allocation: Efficient allocation of labor resources balances workload and reduces bottlenecks.

- Compliance and Flexibility: The schedule adheres to labor laws while allowing flexibility for unexpected changes and workforce needs.

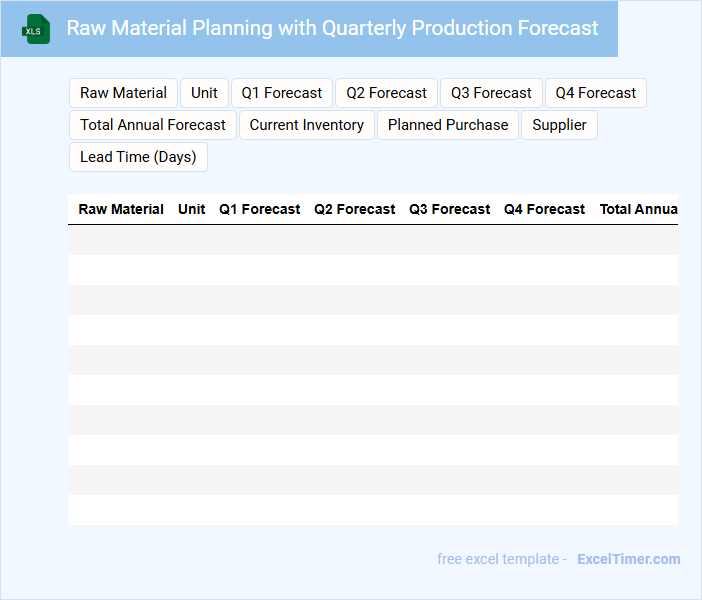

Raw Material Planning with Quarterly Production Forecast

Raw Material Planning with Quarterly Production Forecast is a strategic document used to align raw material procurement with anticipated production needs over a three-month period.

- Accurate demand forecasting: ensures raw materials are ordered in quantities that meet production schedules without excess inventory.

- Supplier coordination: maintains strong communication with suppliers to secure timely delivery of raw materials aligned with forecasted production.

- Inventory management: balances raw material stock levels to optimize storage costs while preventing production delays.

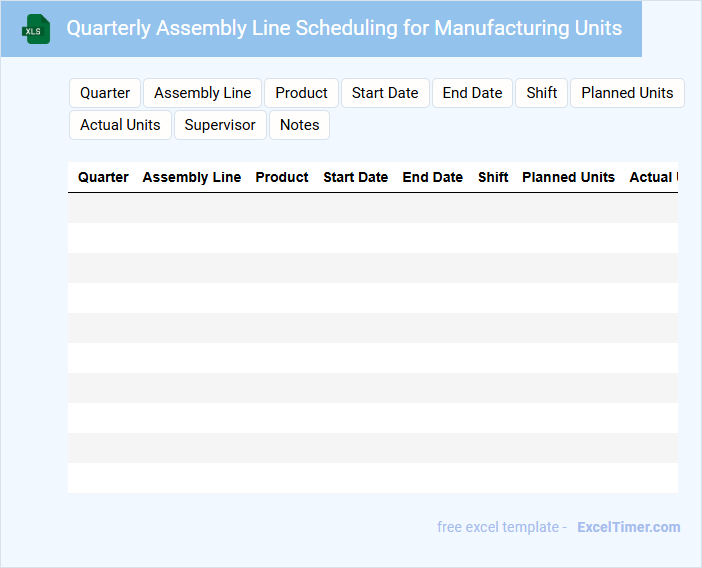

Quarterly Assembly Line Scheduling for Manufacturing Units

This document typically outlines the planned schedule for assembly line operations over a quarter, detailing timelines, resource allocation, and workflow sequences. It aims to optimize production efficiency and ensure timely completion of manufacturing targets.

- Include clear timelines and deadlines for each production phase.

- Highlight resource availability and potential bottlenecks.

- Incorporate contingency plans for unexpected delays or disruptions.

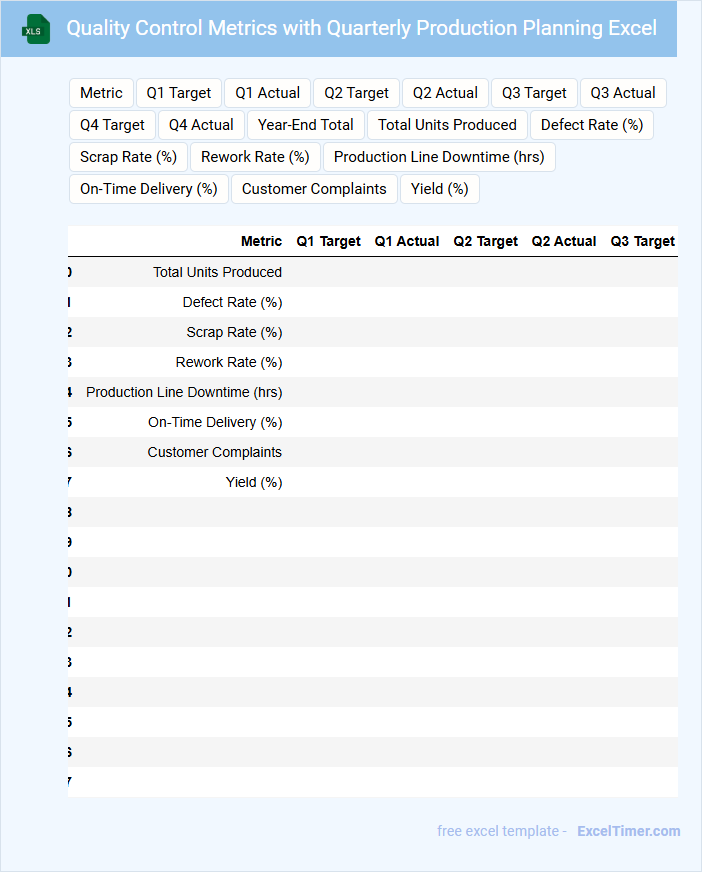

Quality Control Metrics with Quarterly Production Planning Excel

What information is typically included in a Quality Control Metrics with Quarterly Production Planning Excel document? This document usually contains data on production output, quality measurements, defect rates, and compliance standards for each quarter. It integrates production schedules with quality assessment metrics to help monitor performance and make informed operational decisions.

What important factors should be considered when creating this type of document? It is essential to ensure accurate data entry for both production and quality parameters, include clear visualizations like charts for trend analysis, and update the plan regularly to reflect any changes in production capacity or quality standards. This helps maintain product consistency and improve overall manufacturing efficiency.

How do you forecast quarterly production demand using historical sales data in an Excel document?

Forecast quarterly production demand by importing historical sales data into Excel and organizing it by time periods. Use Excel functions like TREND or LINEST to analyze sales patterns and apply moving averages for smoothing demand fluctuations. Create a forecast model incorporating seasonality and growth trends to predict future production needs accurately.

What key metrics should be tracked in Excel for effective quarterly production planning?

Track key metrics such as production output, machine utilization rate, and inventory levels in Excel to optimize quarterly production planning. Monitor labor hours, order fulfillment rates, and downtime incidents for accurate resource allocation and schedule adjustments. Analyze defect rates and production costs to enhance quality control and cost efficiency across manufacturing units.

How can seasonal trends be identified and visualized in quarterly production data using Excel tools?

You can identify seasonal trends in quarterly production data by using Excel tools such as PivotTables to aggregate and analyze data by time periods. Creating line charts or column charts with time series helps visualize fluctuations and patterns across different quarters. Leveraging conditional formatting highlights significant changes, making seasonal trends easier to interpret for your manufacturing units' planning.

What formulas or functions in Excel help assess material requirements and inventory levels for each quarter?

Excel functions like SUMIFS and IF enable precise calculation of material requirements by summing specific criteria-based data per quarter. The VLOOKUP or INDEX-MATCH functions retrieve inventory levels from datasets matching production schedules. Combining these with basic arithmetic formulas helps balance production demands against available inventory efficiently.

How can Excel be used to compare planned versus actual production output for process optimization each quarter?

Excel enables you to track and compare planned versus actual production output by using pivot tables and customizable charts to visualize discrepancies each quarter. Automated formulas and conditional formatting highlight variances, facilitating targeted adjustments in manufacturing processes. This data-driven approach supports continuous process optimization and efficient quarterly production planning.