The Annually Production Schedule Excel Template for Food Manufacturers streamlines planning by providing a clear overview of production timelines and capacity throughout the year. It helps manufacturers optimize resource allocation, manage inventory, and track product batches effectively. Accurate scheduling ensures timely delivery and maintains product quality in a competitive food industry.

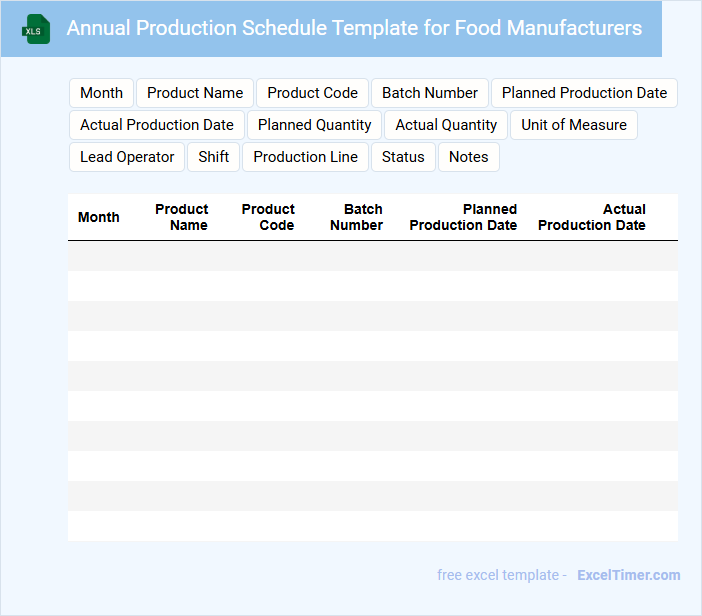

Annual Production Schedule Template for Food Manufacturers

An Annual Production Schedule Template for Food Manufacturers typically outlines the timeline and quantity of food products to be produced throughout the year. It helps coordinate resources, equipment, and workforce to meet production targets efficiently. This document ensures consistency and timely delivery of food products to the market.

Key elements include production timelines, batch sizes, product types, and inventory management details. Incorporating seasonal variations and regulatory compliance is crucial for accuracy. Regularly updating the schedule based on market demand and supply chain changes is highly recommended.

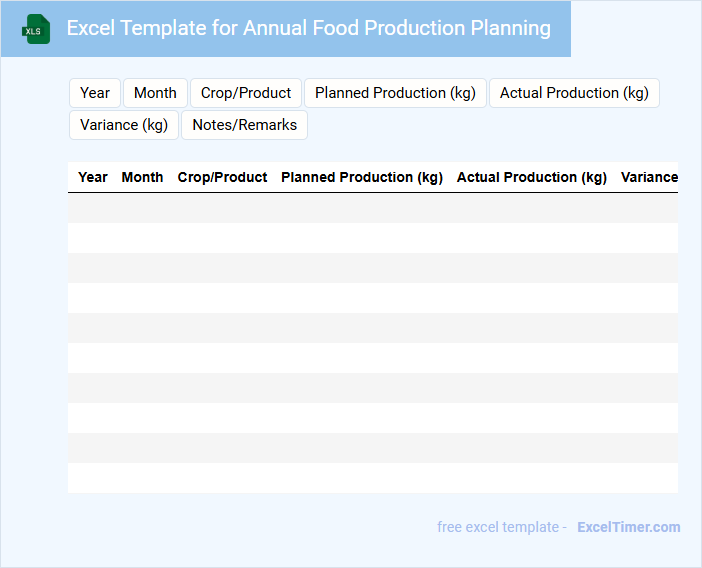

Excel Template for Annual Food Production Planning

An Annual Food Production Planning Excel Template typically contains detailed information on projected food quantities, ingredient requirements, and production schedules. It helps in managing inventory, budgeting, and optimizing resource allocation throughout the year.

Key components often include monthly forecasts, recipe yield data, and cost analysis to ensure efficiency and minimize waste. For best results, ensure the template allows for easy updates and integrates historical consumption data for accurate planning.

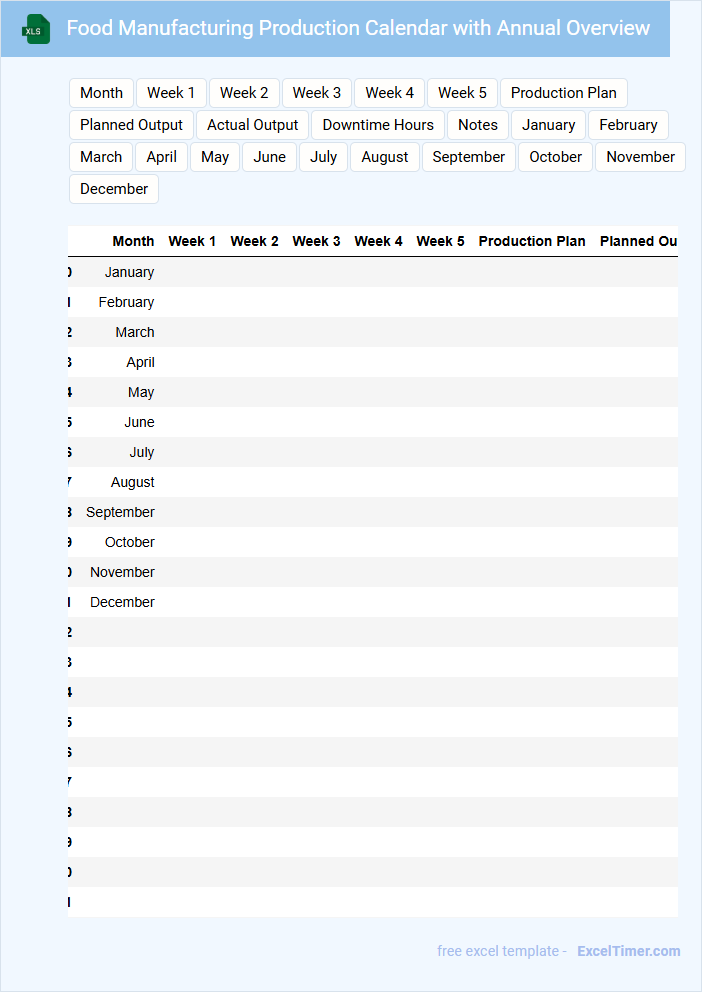

Food Manufacturing Production Calendar with Annual Overview

A Food Manufacturing Production Calendar outlines the scheduled production activities within a manufacturing facility, detailing key processes and timelines. It provides a comprehensive annual overview to ensure efficient workflow and resource allocation.

This document typically contains production dates, batch quantities, equipment schedules, and quality control checkpoints. Emphasizing accurate forecasting and coordination with supply chain management is crucial for optimal results.

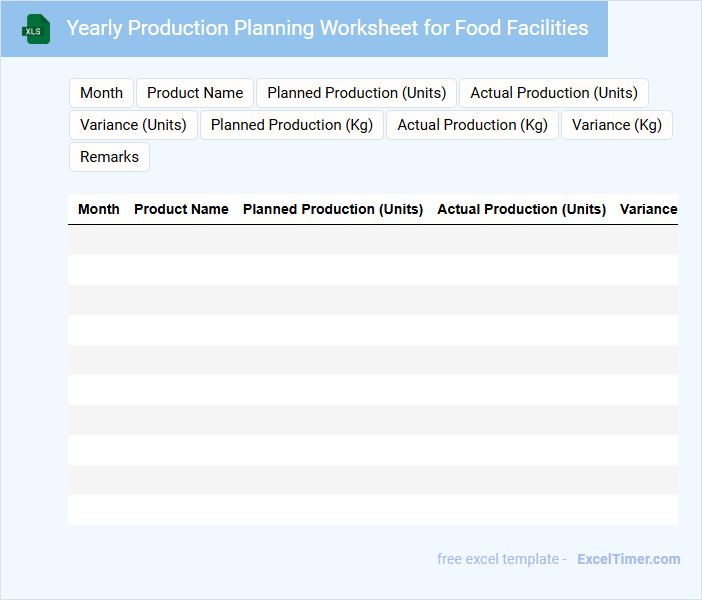

Yearly Production Planning Worksheet for Food Facilities

The Yearly Production Planning Worksheet for food facilities typically contains detailed schedules for production tasks, inventory management, and resource allocation across the year. It serves as a strategic tool to ensure consistent output and meet demand forecasts efficiently.

Key elements often include ingredient requirements, batch sizes, and maintenance timelines to optimize operations. Prioritizing accurate data collection and regular updates enhances the worksheet's effectiveness in minimizing waste and maximizing productivity.

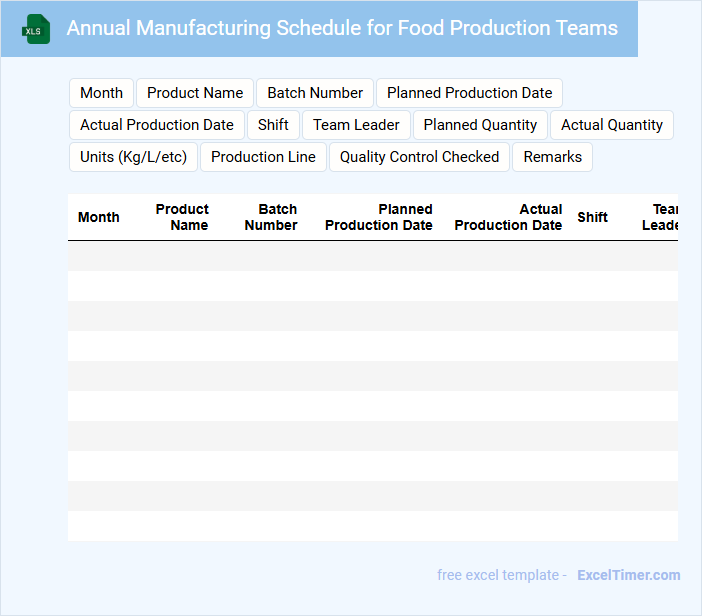

Annual Manufacturing Schedule for Food Production Teams

What information is typically included in an Annual Manufacturing Schedule for Food Production Teams? This document usually contains detailed timelines for production activities, resource allocation, and quality control measures throughout the year. It helps coordinate workflows, manage inventory, and ensure timely delivery of products while maintaining safety standards.

Food Production Schedule with Yearly Tracking in Excel

A Food Production Schedule with Yearly Tracking in Excel is typically a detailed document used to plan and monitor food production activities throughout the year.

- Production Planning: It includes timelines and quantities for food items to ensure consistent output.

- Resource Management: Tracks ingredients, labor, and equipment needed for efficient operations.

- Performance Monitoring: Allows yearly comparison of production data to improve forecasting and reduce waste.

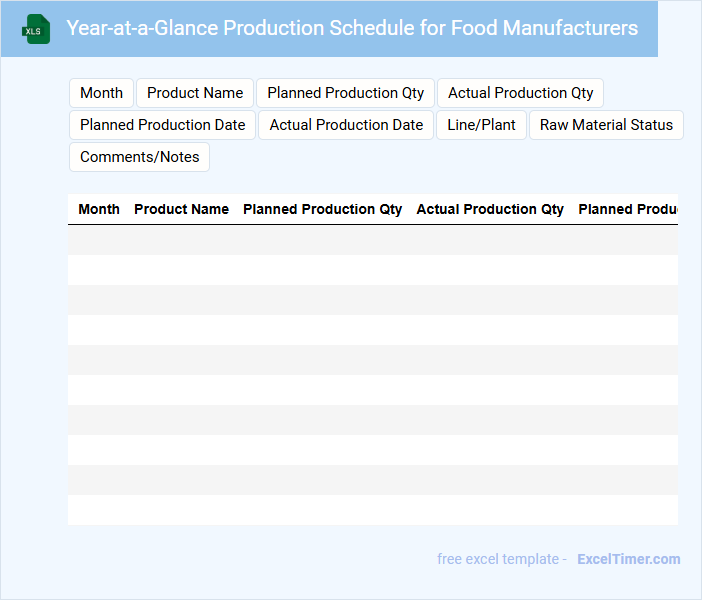

Year-at-a-Glance Production Schedule for Food Manufacturers

The Year-at-a-Glance Production Schedule is a comprehensive document that outlines the production timeline for food manufacturers, detailing key dates and milestones throughout the year. It typically includes information on planned manufacturing runs, maintenance periods, and critical deadlines to ensure efficient workflow. This schedule helps synchronize resources, manage inventory, and maintain consistent product output.

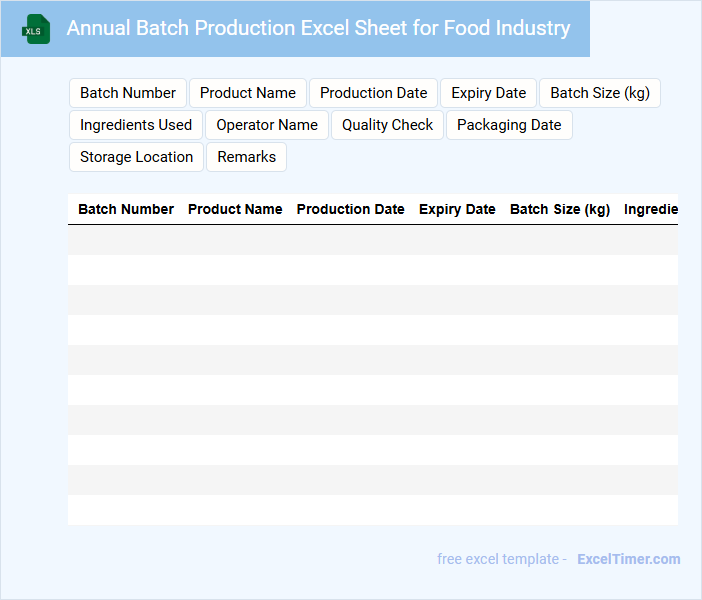

Annual Batch Production Excel Sheet for Food Industry

An Annual Batch Production Excel Sheet for the Food Industry is a structured document used to track and manage production batches over a year. It provides detailed insights into production volumes, ingredient usage, and quality control metrics.

- This sheet should include batch numbers, production dates, and quantities produced for accurate record-keeping.

- Ingredient usage and supplier information are crucial for traceability and cost management.

- Quality control results and compliance checks ensure product safety and regulatory adherence.

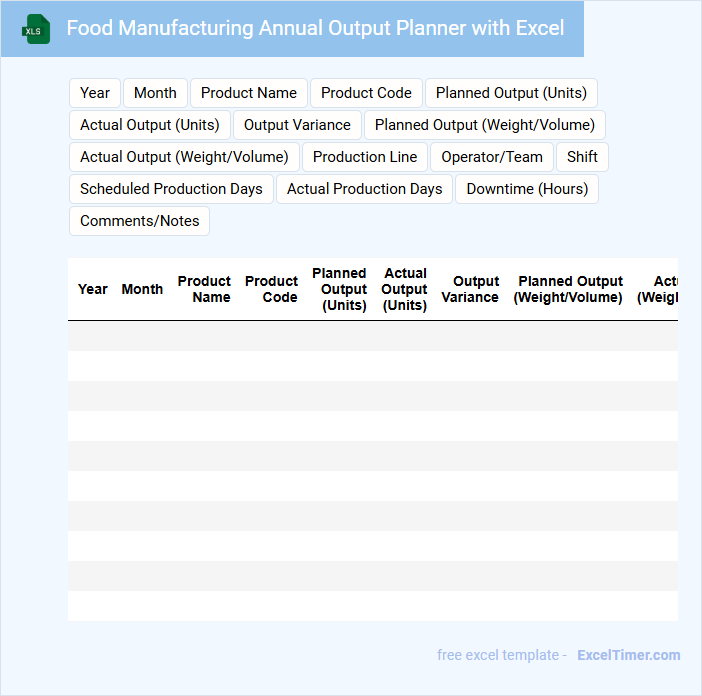

Food Manufacturing Annual Output Planner with Excel

The Food Manufacturing Annual Output Planner is a comprehensive document designed to outline expected production volumes, scheduling, and resource allocation for the entire year. It typically includes forecasts, capacity planning, and inventory management details.

Using Excel for this planner allows for dynamic data manipulation, easy updates, and detailed analysis through formulas and charts. It is highly recommended to incorporate clear timelines, monthly breakdowns, and contingency plans for unexpected supply chain issues.

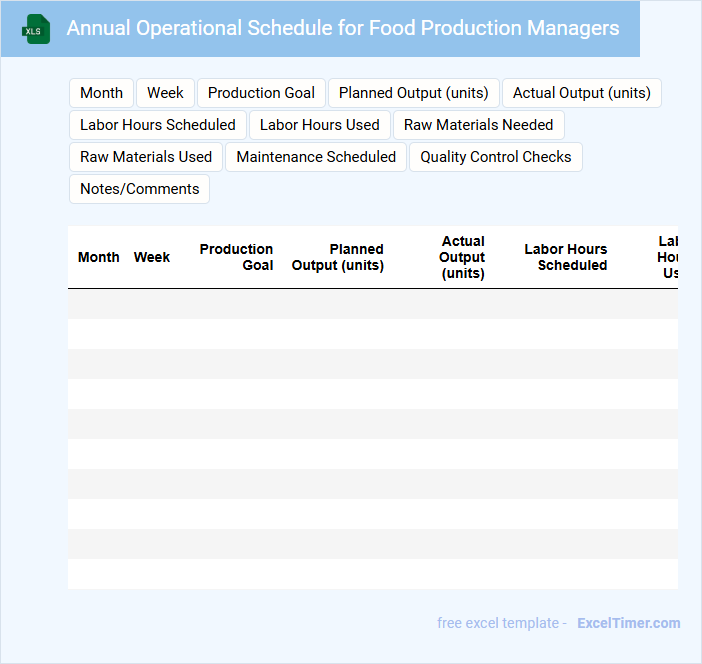

Annual Operational Schedule for Food Production Managers

An Annual Operational Schedule for Food Production Managers outlines the planned activities and timelines critical for effective food production throughout the year. It typically includes production targets, maintenance schedules, and compliance check dates to ensure smooth operations. This document serves as a strategic guide to optimize resources and meet production goals efficiently.

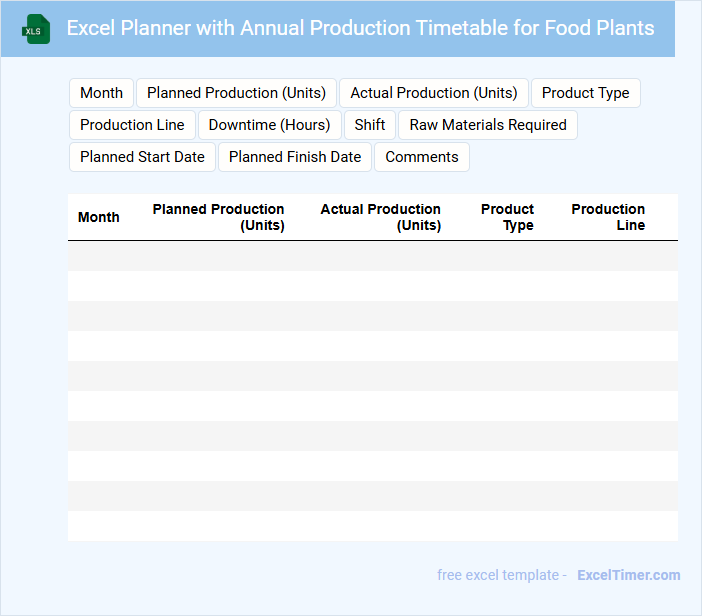

Excel Planner with Annual Production Timetable for Food Plants

An Excel Planner with an Annual Production Timetable for Food Plants typically contains detailed scheduling data to optimize manufacturing processes and ensure consistent output.

- Production Schedule: Outlines specific timelines for each product batch to maximize efficiency and meet demand.

- Resource Allocation: Tracks allocation of machinery, materials, and labor to avoid bottlenecks and downtime.

- Quality Control Milestones: Incorporates checkpoints to monitor compliance with food safety and quality standards.

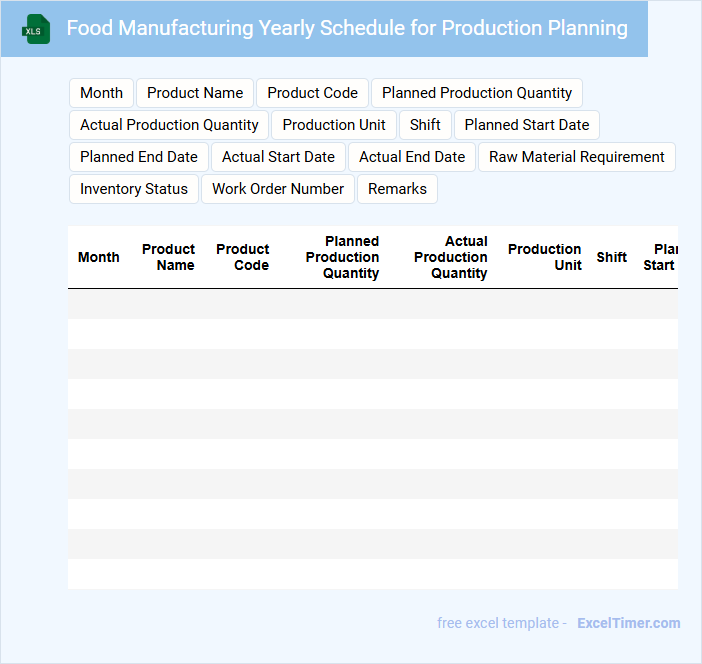

Food Manufacturing Yearly Schedule for Production Planning

This type of document, known as a Food Manufacturing Yearly Schedule, typically contains detailed timelines for production batches, ingredient procurement, and equipment maintenance. It helps streamline operations by aligning production goals with available resources and market demand. Effective planning in this schedule ensures consistent product quality and timely delivery.

For optimal use, it is important to incorporate seasonal variations in raw material availability, include buffer periods for quality control, and regularly update the schedule based on real-time production data to avoid delays or shortages.

Annual Recipe Production Tracker with Excel for Food Companies

What is typically included in an Annual Recipe Production Tracker with Excel for Food Companies? This document usually contains detailed records of all recipes produced throughout the year, including ingredient quantities, production dates, batch numbers, and cost analysis. It helps food companies monitor production efficiency, maintain consistency, and manage inventory effectively.

What is an important feature to focus on in this tracker? Ensuring accurate data entry and automated calculations within the Excel sheet is crucial for reliable tracking. Additionally, incorporating sections for quality control notes and production adjustments enhances decision-making and operational improvements.

Excel Dashboard for Annual Food Production Tracking

An Excel Dashboard for Annual Food Production Tracking typically contains organized data visualizations such as charts, graphs, and tables that summarize yearly production metrics. It allows users to monitor trends, compare performance, and identify key areas for improvement.

The document often includes essential elements like total output, production targets, and breakdowns by product type or region to provide a comprehensive overview. For optimal use, it is important to ensure data accuracy and update the dashboard regularly for timely decision-making.

Comprehensive Annual Production Tracker with Excel for Food Manufacturers

The Comprehensive Annual Production Tracker with Excel for Food Manufacturers is a detailed document that monitors and records the yearly production data of food manufacturing facilities. It is essential for managing output, quality, and compliance throughout the year.

- Include monthly production volumes and corresponding product types for accurate tracking.

- Integrate quality control metrics and batch testing results to ensure product standards.

- Maintain a section for supply chain and raw material usage to optimize procurement.

How does the Annually Production Schedule align with forecasted demand and inventory targets?

Your Annually Production Schedule is designed to closely align with forecasted demand by balancing production volumes to meet anticipated sales while minimizing excess inventory. It integrates historical sales data and market trends to optimize manufacturing timelines, ensuring inventory targets are maintained without overproduction. This alignment helps food manufacturers reduce waste, improve resource allocation, and meet customer demand efficiently.

Which key ingredients and resources are scheduled for peak production periods?

Your Annual Production Schedule for Food Manufacturers highlights key ingredients like grains, dairy, and fresh produce scheduled during peak harvest months. Essential resources such as packaging materials, labor shifts, and machinery maintenance are strategically timed to optimize efficiency. This ensures seamless production flow and timely product delivery throughout the year.

How are maintenance and downtime integrated into the annual schedule to minimize disruption?

Your annual production schedule for food manufacturers incorporates planned maintenance and downtime during low-demand periods to minimize disruption. Scheduled equipment checks and cleaning are strategically aligned with production lulls to ensure consistent output. This approach enhances operational efficiency and reduces unexpected downtime throughout the year.

What methods are used to track production variances and adjust plans within the Excel document?

Your Annually Production Schedule Excel document for Food Manufacturers uses variance analysis to compare actual output against planned production, highlighting deviations. Conditional formatting and pivot tables visually track these variances for quick identification of issues. Built-in formulas then adjust production plans dynamically to optimize efficiency and meet targets.

How does the schedule account for regulatory compliance and food safety checks throughout the year?

Your annual production schedule integrates regulatory compliance by incorporating mandatory food safety audits and quality control checkpoints at key intervals. Scheduled inspections align with FDA and USDA guidelines to ensure adherence to food safety standards. Regular monitoring minimizes risks and maintains consistent product quality across all manufacturing cycles.