The Daily Machine Downtime Excel Template for Factories helps track and analyze equipment stoppages, improving overall productivity. It allows factory managers to record downtime causes, durations, and frequencies, facilitating targeted maintenance strategies. Accurate downtime data supports proactive decision-making to minimize disruptions and increase operational efficiency.

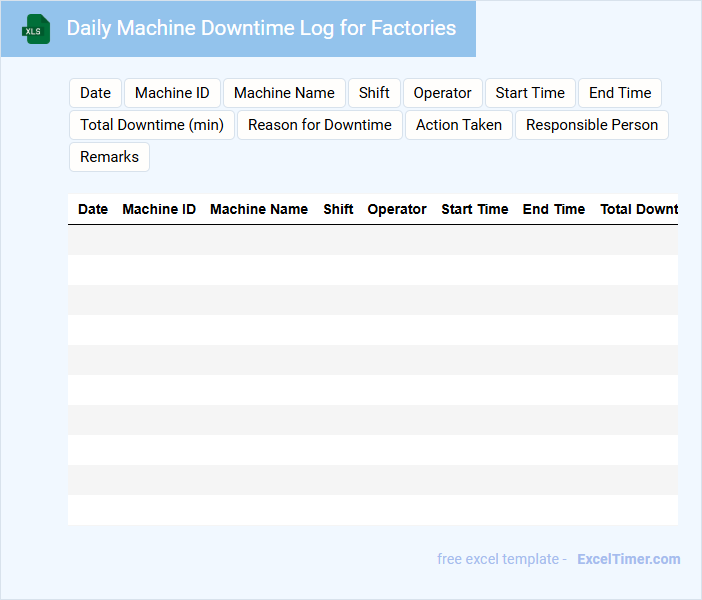

Daily Machine Downtime Log for Factories

A Daily Machine Downtime Log for factories records the time periods when machinery is not operational due to maintenance, breakdowns, or other issues, helping to track productivity losses. This document typically includes fields for time stamps, reasons for downtime, affected machines, and actions taken to resolve issues.

Maintaining an accurate log is crucial for identifying recurring problems and improving maintenance schedules, thereby enhancing overall equipment effectiveness. It is important to ensure that all entries are timely and detailed to facilitate effective analysis and decision-making.

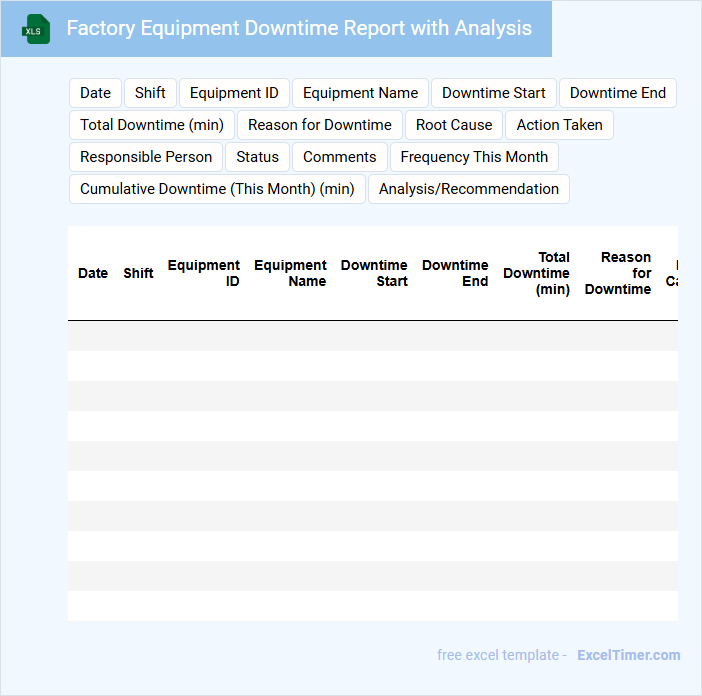

Factory Equipment Downtime Report with Analysis

A Factory Equipment Downtime Report with Analysis documents periods when machinery is not operational, detailing causes and durations. It is essential for identifying inefficiencies and guiding maintenance decisions.

- Include precise timestamps and duration of each downtime event.

- Provide clear categorization of downtime causes (e.g., mechanical failure, scheduled maintenance).

- Suggest actionable recommendations to reduce future downtime occurrences.

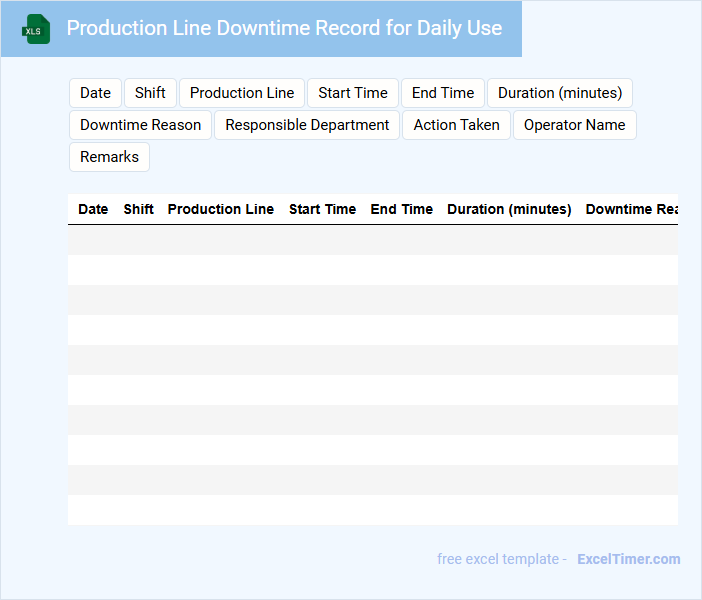

Production Line Downtime Record for Daily Use

A Production Line Downtime Record for Daily Use is a document that tracks interruptions in manufacturing processes to identify and address issues promptly. It helps optimize productivity by detailing the duration and reasons for downtime events.

- The record typically includes date, start and end times of downtime, and affected machinery.

- It is important to note the specific cause of each interruption to facilitate targeted improvements.

- Consistent daily entries enable trend analysis and better maintenance planning.

Daily Machine Performance Tracker with Downtime

The Daily Machine Performance Tracker is a vital document used to record and analyze the operational efficiency of machinery on a daily basis. It typically contains data on machine run times, output levels, and instances of downtime. Monitoring these parameters helps in identifying performance issues and improving maintenance schedules.

To enhance the effectiveness of this document, it is important to consistently log accurate timestamps for each downtime event and categorize the reasons for stoppages. Including fields for operator notes and maintenance actions can provide valuable context. Additionally, summarizing daily performance metrics allows for quick assessment and trend analysis.

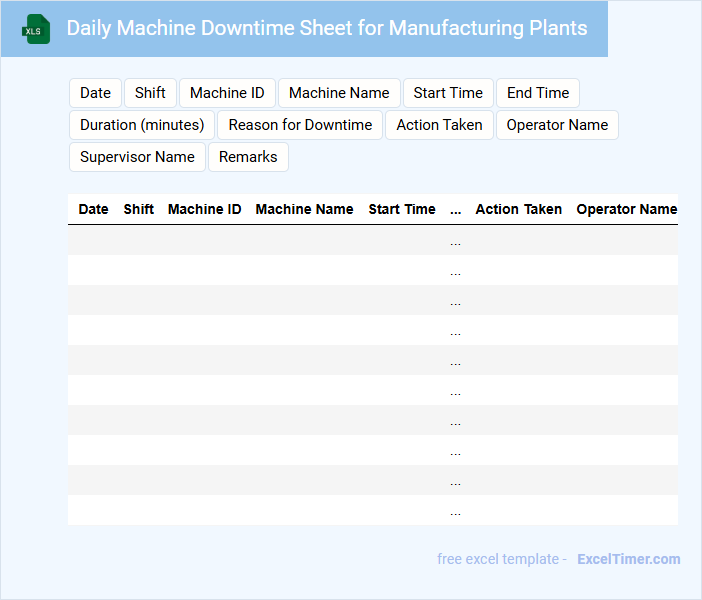

Daily Machine Downtime Sheet for Manufacturing Plants

A Daily Machine Downtime Sheet is a crucial document used in manufacturing plants to record all instances of machine stoppages. It typically contains details such as the time of downtime, duration, affected machines, and reasons for the stoppage.

This sheet helps in analyzing and reducing machine downtime to improve overall plant efficiency. A key suggestion is to ensure accurate and timely entries to facilitate effective maintenance and decision-making processes.

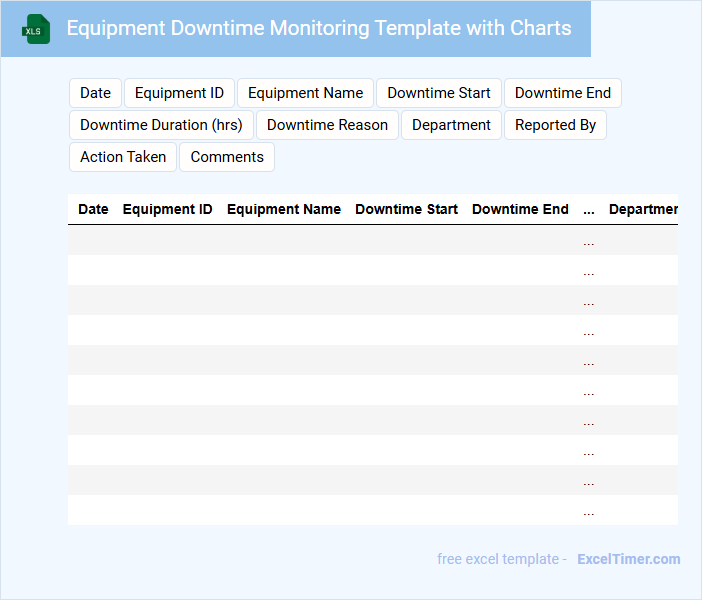

Equipment Downtime Monitoring Template with Charts

An Equipment Downtime Monitoring Template typically contains detailed records of machinery downtime events, including start and end times, reasons for downtime, and affected equipment. It often features charts to visualize trends and patterns for effective analysis. This documentation is crucial for identifying bottlenecks and improving operational efficiency.

Including important elements such as accurate timestamps, categorization of downtime causes, and summary charts enhances clarity and usability. These features aid maintenance teams in making data-driven decisions to reduce equipment failures. Implementing real-time data updates in the template can further optimize monitoring and response times.

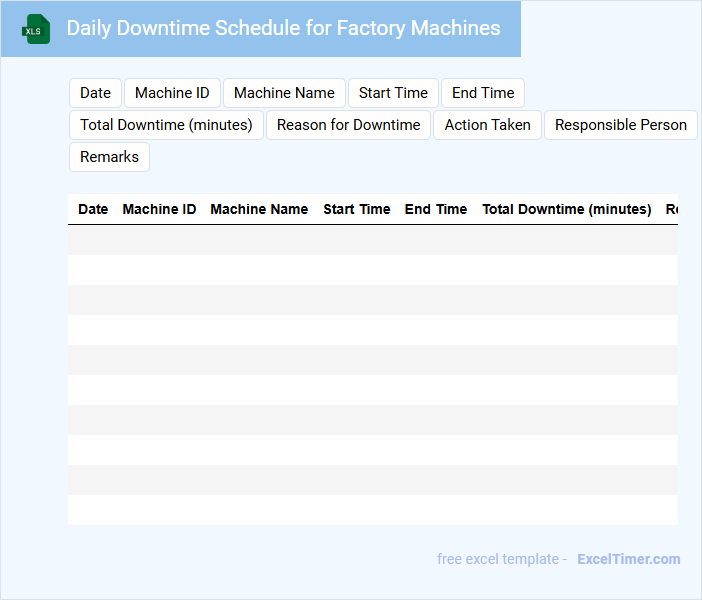

Daily Downtime Schedule for Factory Machines

This type of document typically contains a detailed schedule outlining the planned downtime for factory machines, including start and end times. It helps in coordinating maintenance and minimizing production disruption. A clear timeline ensures all departments are aligned and prepared.

Important elements usually include machine identification, reason for downtime, and responsible personnel. Tracking this information supports efficient maintenance management and operational planning. Regular updates to the schedule improve communication and reduce unexpected delays.

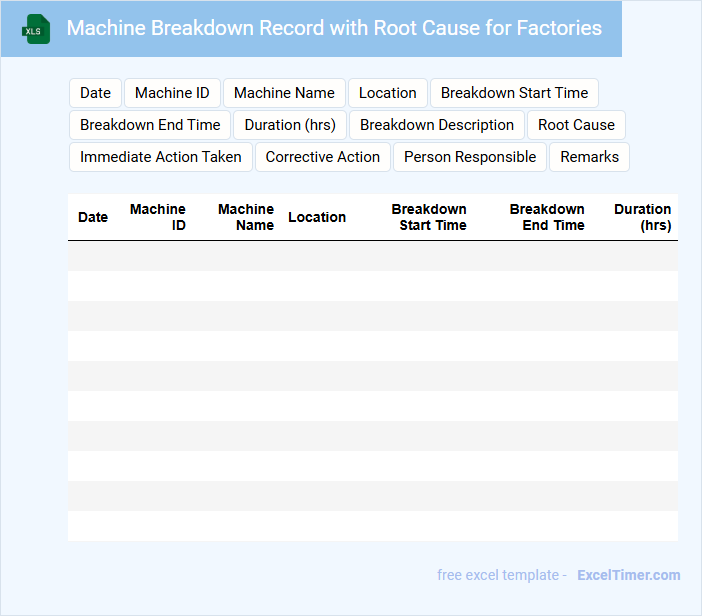

Machine Breakdown Record with Root Cause for Factories

This Machine Breakdown Record document typically contains detailed information about the time, duration, and nature of machinery failures in factories. It also includes the identification of the faulty equipment and immediate corrective actions taken.

An essential component is the Root Cause Analysis, which helps in diagnosing the underlying issues leading to breakdowns to prevent future occurrences. Maintaining accurate and timely records is crucial for improving operational efficiency and reducing downtime.

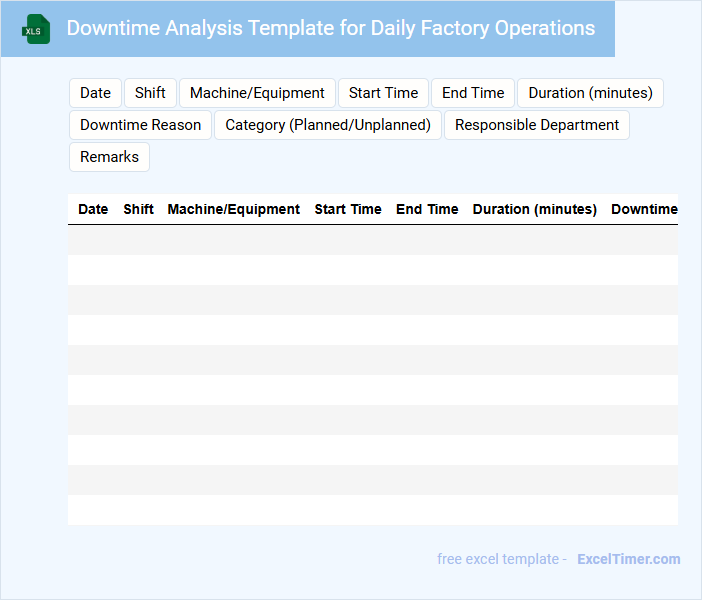

Downtime Analysis Template for Daily Factory Operations

A Downtime Analysis Template for Daily Factory Operations typically contains sections for recording the duration and cause of equipment stoppages, along with the impact on production output. It helps in identifying recurring issues and patterns that lead to inefficiencies. The template is essential for continuous improvement and minimizing unplanned downtime.

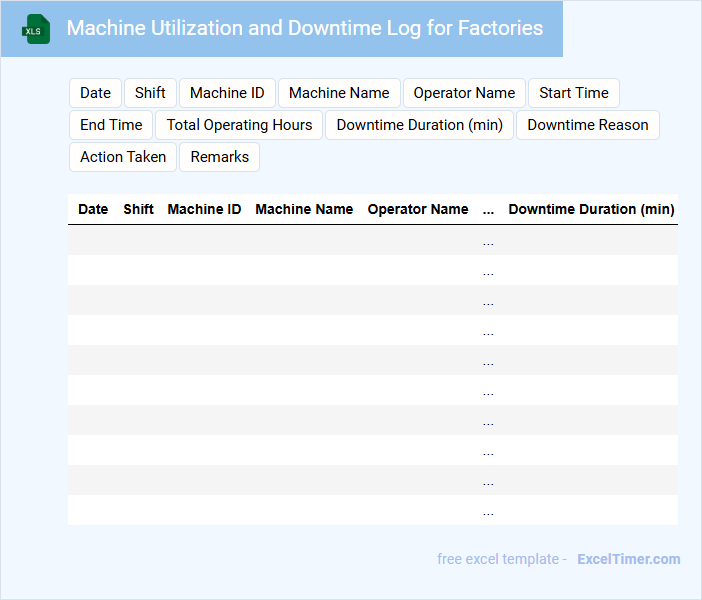

Machine Utilization and Downtime Log for Factories

This document records the operating times and inactivity periods of factory machinery to optimize production efficiency. It helps identify patterns that contribute to downtime and areas for improvement.

- Track start and stop times of each machine accurately.

- Note reasons for downtime including maintenance or malfunctions.

- Analyze data regularly to improve machine utilization rates.

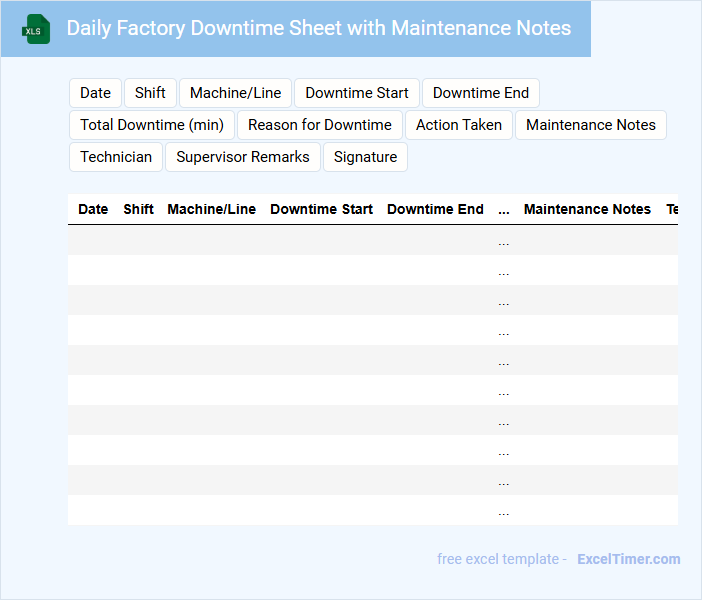

Daily Factory Downtime Sheet with Maintenance Notes

The Daily Factory Downtime Sheet is a crucial document that records all instances of machinery or production halts within a manufacturing facility. It typically contains the time, duration, and cause of each downtime event, along with detailed maintenance notes. This sheet helps track equipment performance and identify recurring issues to improve operational efficiency.

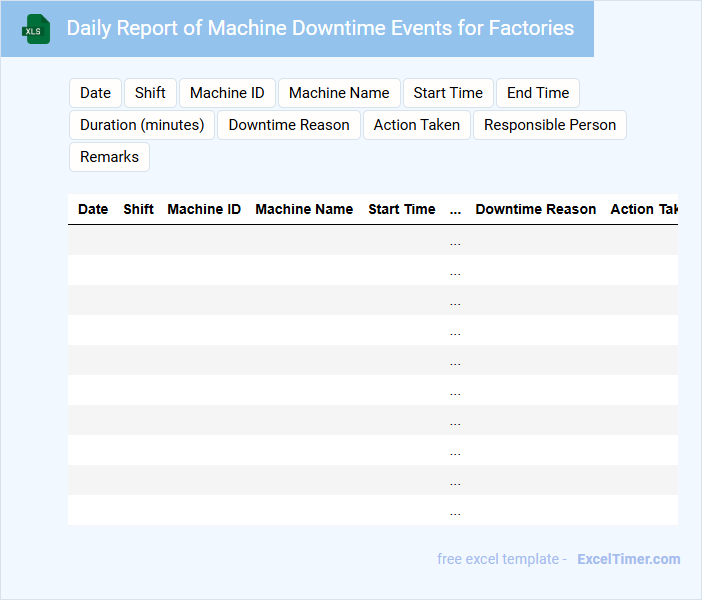

Daily Report of Machine Downtime Events for Factories

A Daily Report of Machine Downtime Events in factories details the specific instances when machinery is non-operational. It typically includes the time of failure, duration of downtime, and reasons or causes. This document is essential for monitoring production efficiency and facilitating timely maintenance.

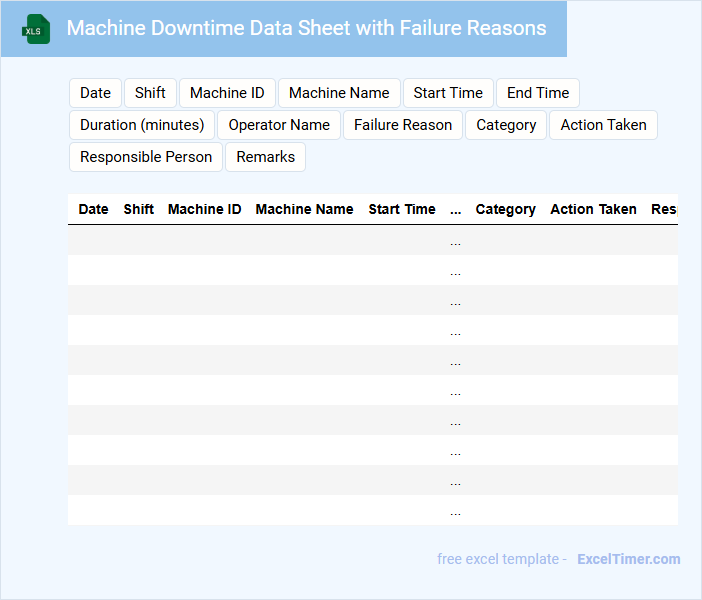

Machine Downtime Data Sheet with Failure Reasons

The Machine Downtime Data Sheet typically contains detailed records of periods when a machine is not operational, including start and end times, duration, and associated failure reasons. This document is essential for identifying patterns and causes of downtime to improve overall equipment efficiency.

Key information usually includes the type of failure, responsible components, and corrective actions taken. Regularly updating this data sheet helps in proactive maintenance and minimizing operational disruptions.

Daily Factory Operations Log with Downtime Tracking

The Daily Factory Operations Log is a document that records all activities and events occurring within a factory during a single day. It typically includes details on production output, worker shifts, equipment status, and material usage.

Downtime Tracking within the log highlights periods when machinery or processes are halted, specifying causes and durations. This information is crucial for identifying inefficiencies and improving overall operational effectiveness.

Ensuring accurate and timely entries in the log helps management make informed decisions to optimize factory performance and reduce downtime.

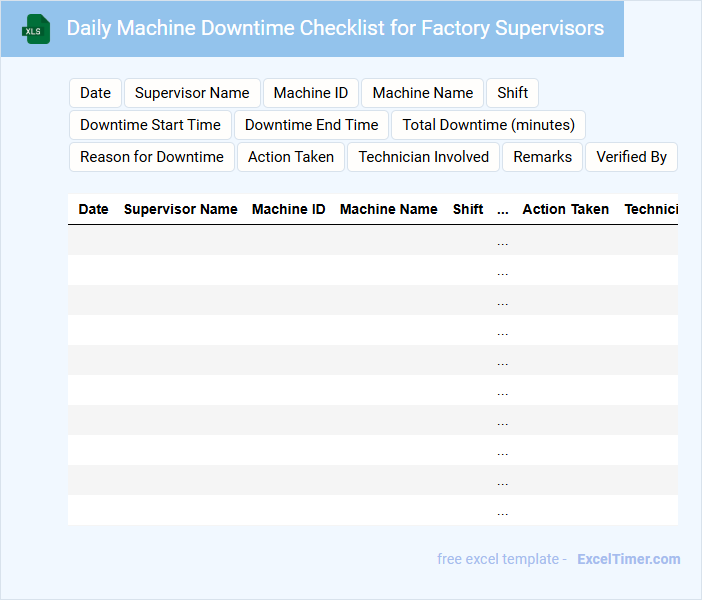

Daily Machine Downtime Checklist for Factory Supervisors

This document typically records the duration and reasons for machine downtime each day to help identify inefficiencies. It ensures supervisors can track machine performance and address issues promptly.

- Include accurate start and end times for each downtime period.

- Specify the exact reasons for machine stoppages to identify recurring problems.

- Ensure supervisors record any corrective actions taken or planned.

What key data fields should be included to accurately track daily machine downtime in Excel?

To accurately track daily machine downtime in Excel, include key data fields such as Date, Factory Location, Machine ID, Downtime Start Time, Downtime End Time, Total Downtime Duration, and Reason for Downtime. Incorporate fields for Operator Name and Maintenance Actions to enhance data insights. Your precise input in these fields ensures effective monitoring and analysis of machine performance.

How can Excel formulas be used to automatically calculate total downtime per machine each day?

Excel formulas like SUMIF or SUMIFS efficiently calculate total daily downtime per machine by summing downtime values based on machine names and specific dates. Using structured tables with columns for Machine ID, Date, and Downtime Duration allows dynamic aggregation with formulas such as =SUMIFS(DowntimeRange, MachineRange, "MachineName", DateRange, "Date"). PivotTables offer an alternative method to summarize downtime by machine and day, providing customizable and automatic updates as data changes.

Which columns are essential for identifying root causes of downtime in the document?

Essential columns for identifying root causes of daily machine downtime include Machine ID, Date, Downtime Duration, Downtime Reason/Code, Shift, and Operator. Including columns like Maintenance Actions Taken and Downtime Location within the factory enhances detailed analysis. Collecting data on Downtime Start and End Times also helps pinpoint patterns affecting production efficiency.

What Excel visualization tools (e.g., charts, conditional formatting) best highlight downtime trends?

Excel charts such as line graphs and bar charts effectively highlight daily machine downtime trends by visually representing fluctuations over time. Conditional formatting with color scales or data bars helps you quickly identify critical downtime periods in your factory data. PivotTables summarize downtime metrics, making it easier for your team to analyze and address operational inefficiencies.

How should the document be structured to easily filter downtime by shift, machine, or operator?

Structure the Excel document with clear columns for Date, Shift, Machine ID, Operator Name, Downtime Start, Downtime End, and Downtime Duration. Use Excel tables and enable filters on each column to quickly sort and filter downtime by shift, machine, or operator. Incorporate drop-down lists for shifts and machines to ensure consistent data entry and improve filtering accuracy.