The Daily Machine Inspection Excel Template for Workshops streamlines the process of monitoring equipment status, maintenance needs, and potential issues. This template helps ensure safety compliance and enhances machine longevity by providing a structured, easy-to-use checklist for daily inspections. Using this tool reduces downtime and supports proactive maintenance management.

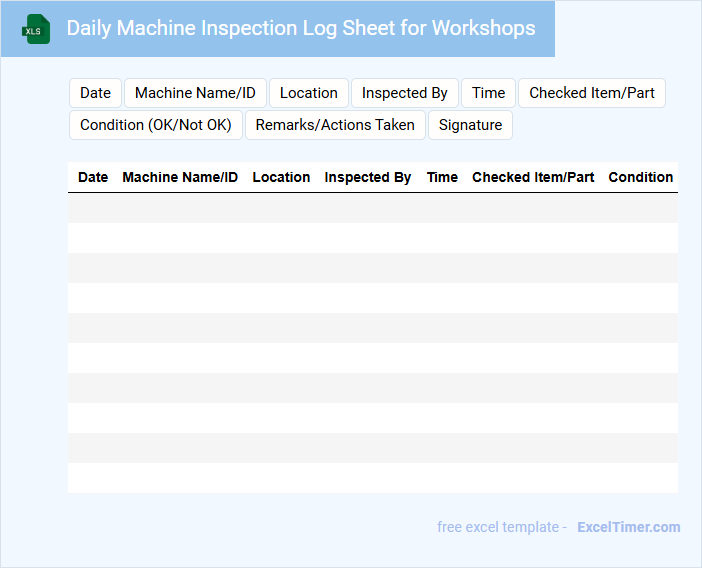

Daily Machine Inspection Log Sheet for Workshops

A Daily Machine Inspection Log Sheet is a vital document used in workshops to record the condition and performance of machinery every day. It helps in identifying potential issues early, ensuring safety and preventing downtime.

This log typically contains fields for machine ID, inspection date, checklist of components, observed defects, and inspector's notes. Regular use of this sheet supports maintenance planning and compliance with safety standards.

Important elements to include are clear inspection criteria, space for corrective actions, and a signature section for accountability.

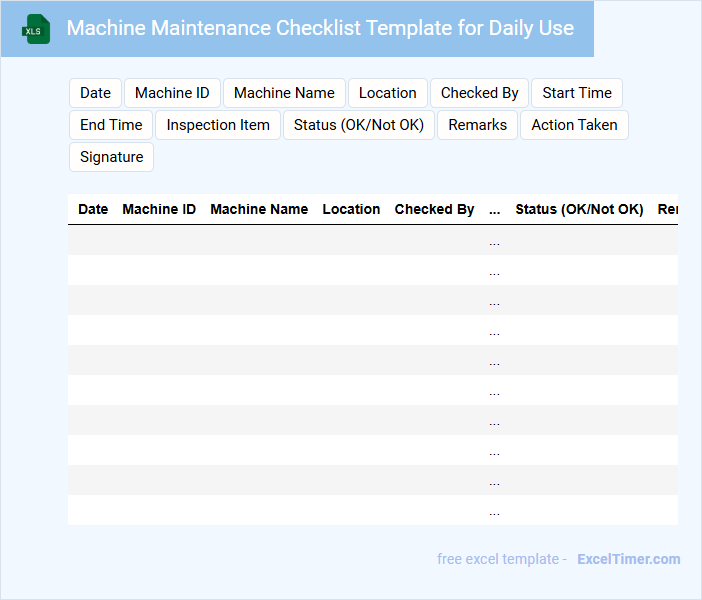

Machine Maintenance Checklist Template for Daily Use

A Machine Maintenance Checklist template for daily use typically contains a detailed list of routine tasks to ensure machines operate efficiently and safely. It includes inspection points, cleaning steps, lubrication schedules, and record-keeping fields to track maintenance activities. This document helps prevent breakdowns, extends equipment life, and promotes workplace safety by ensuring consistent and thorough daily machine care.

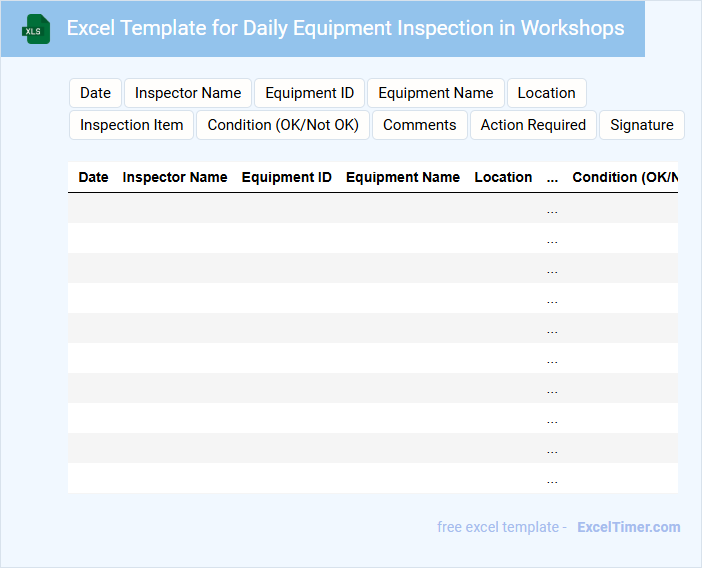

Excel Template for Daily Equipment Inspection in Workshops

An Excel Template for Daily Equipment Inspection is designed to systematically record the status and condition of tools and machines in workshops. It helps ensure all equipment is checked regularly to maintain safety and functionality.

Typically, this document contains fields for equipment identification, inspection dates, condition notes, and compliance checklists. Including clear instructions and standardized criteria for assessment is essential for consistent and accurate reporting.

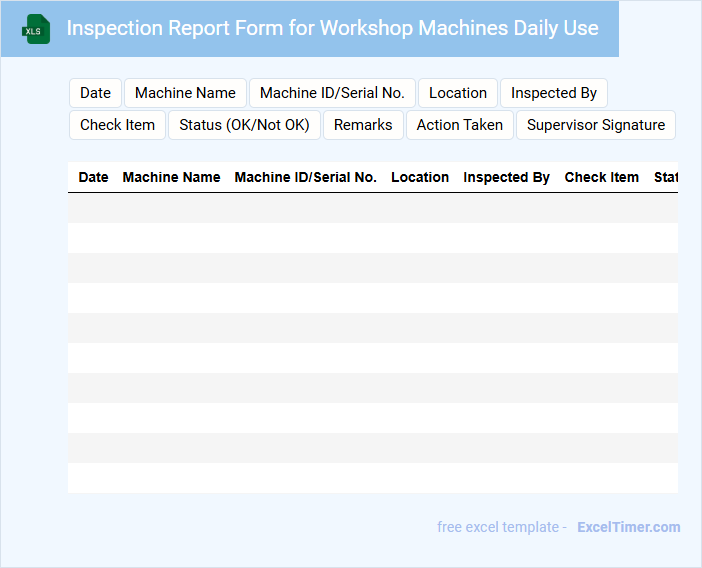

Inspection Report Form for Workshop Machines Daily Use

An Inspection Report Form for workshop machines daily use typically contains detailed observations on the operational status and safety conditions of the equipment. It includes sections for identifying machine details, noting any faults or irregularities, and recording maintenance actions taken. The form ensures consistent monitoring and promotes timely repairs to prevent breakdowns and accidents.

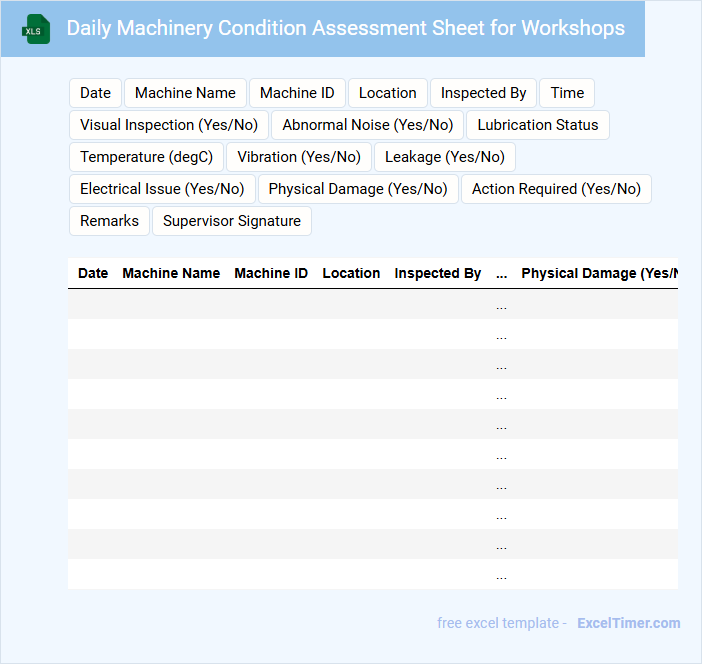

Daily Machinery Condition Assessment Sheet for Workshops

What does a Daily Machinery Condition Assessment Sheet for Workshops typically contain? It usually includes fields for recording machine identification, operational status, and any detected issues or maintenance actions performed during the day. This document helps ensure consistent monitoring of equipment health to prevent unexpected breakdowns and maintain workflow efficiency.

Why is it important to use this type of document regularly in workshops? Regular use promotes early detection of mechanical problems, supports safety compliance, and aids in scheduling timely repairs. Keeping detailed daily records enhances communication between operators and maintenance teams, ultimately extending machinery lifespan.

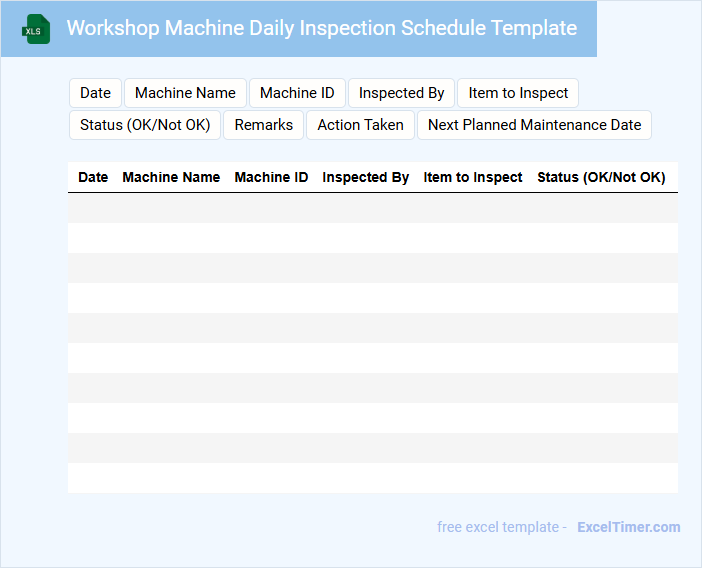

Workshop Machine Daily Inspection Schedule Template

A Workshop Machine Daily Inspection Schedule Template is a structured document used to track the condition and performance of machinery on a daily basis. It typically includes checklists for operational parameters, safety checks, and maintenance needs to ensure machines function efficiently.

Using this template helps identify issues early, preventing costly breakdowns and ensuring workplace safety. An important suggestion is to regularly update the schedule based on machine usage and observed wear and tear.

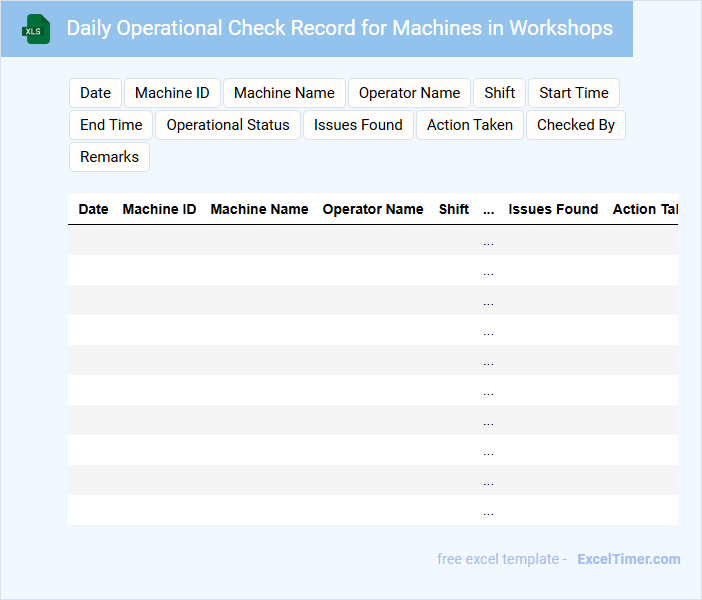

Daily Operational Check Record for Machines in Workshops

A Daily Operational Check Record for Machines in Workshops typically contains detailed logs of machine status, functionality, and maintenance activities to ensure smooth operations.

- Machine Status: Document the operational condition, noting any irregularities or malfunctions.

- Maintenance Actions: Record any performed inspections, repairs, or adjustments made during the day.

- Operator Sign-off: Include the responsible technician's signature to verify the accuracy of the recorded information.

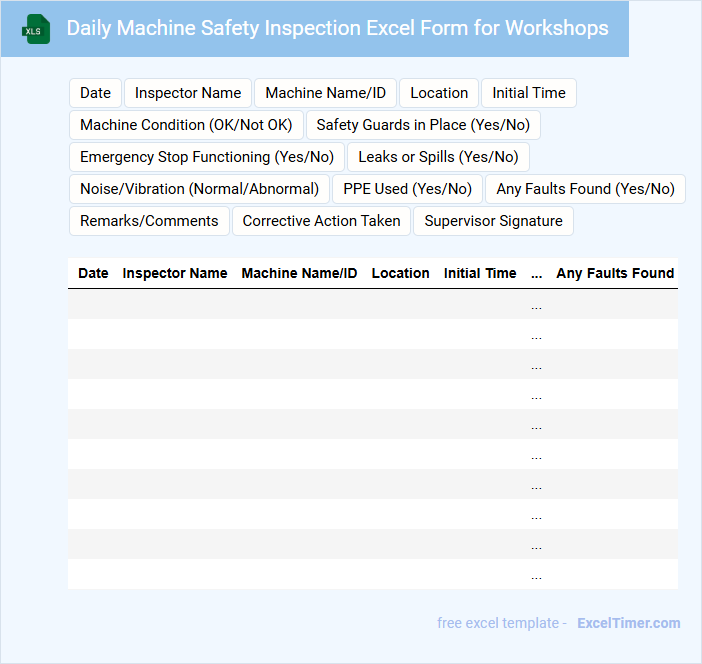

Daily Machine Safety Inspection Excel Form for Workshops

A Daily Machine Safety Inspection Excel Form is a structured document used in workshops to record the daily checks on machinery condition and operational safety. It ensures that machines meet safety standards to prevent accidents and maintain efficient workflow.

Typically, this form includes sections for machine identification, inspection date, specific safety criteria, and notes on faults or maintenance actions needed. It is important to include a clear checklist, signature fields for accountability, and space for immediate corrective measures.

Equipment Inspection Checklist Template with Daily Tracking

An Equipment Inspection Checklist Template is a structured document designed to ensure all machinery and tools are routinely checked for safety and functionality. It typically contains sections for equipment identification, inspection criteria, condition status, and maintenance notes.

Daily tracking is crucial to monitor ongoing equipment performance and detect issues early, minimizing downtime. This template helps streamline inspections by providing a consistent format for recording data and scheduling follow-ups.

To maximize effectiveness, include clear instructions, regular update fields, and a designated area for inspector signatures to maintain accountability and accuracy.

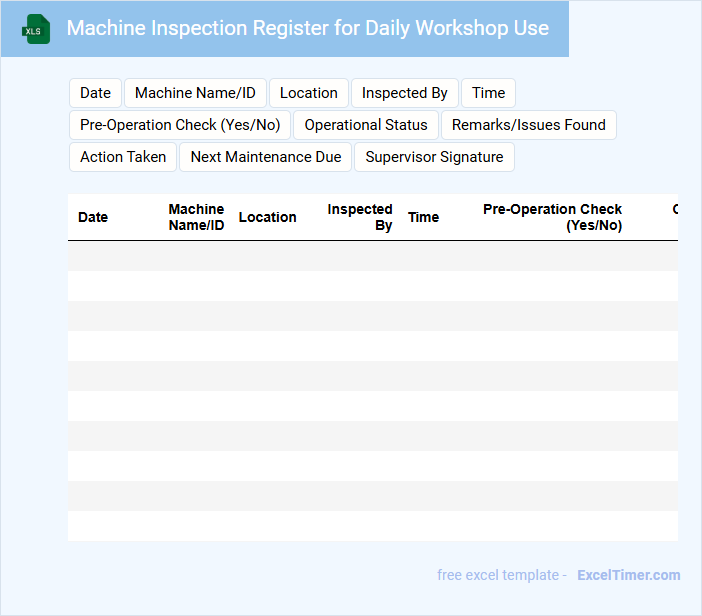

Machine Inspection Register for Daily Workshop Use

The Machine Inspection Register is a critical document used daily in workshops to systematically record the condition and performance of machinery. It ensures that all equipment undergoes routine checks to maintain operational safety and efficiency.

This register typically contains sections for machine identification, inspection dates, observed faults, and maintenance actions taken. Keeping detailed entries helps in early detection of issues, preventing costly breakdowns and promoting workplace safety.

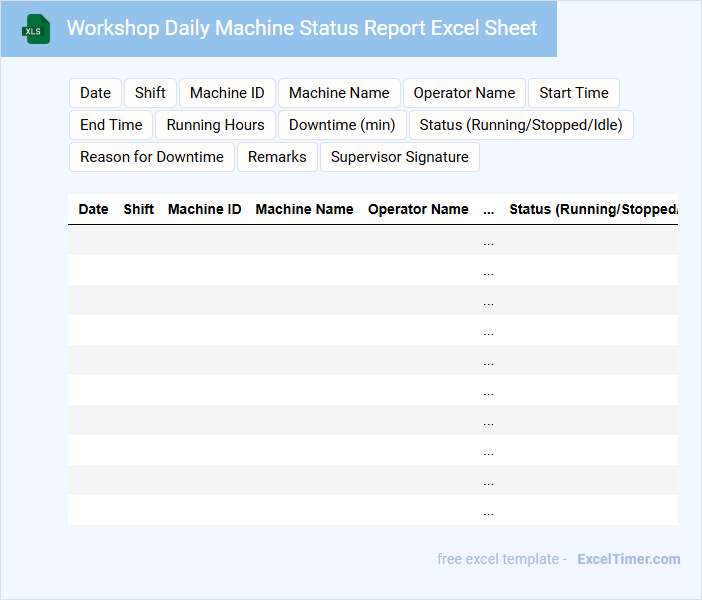

Workshop Daily Machine Status Report Excel Sheet

A Workshop Daily Machine Status Report Excel sheet typically contains detailed information about machine operations, including uptime, downtime, and maintenance activities. It helps track performance metrics to ensure optimal productivity and identify potential issues early. Accuracy and timely updates are crucial for effective monitoring and decision-making.

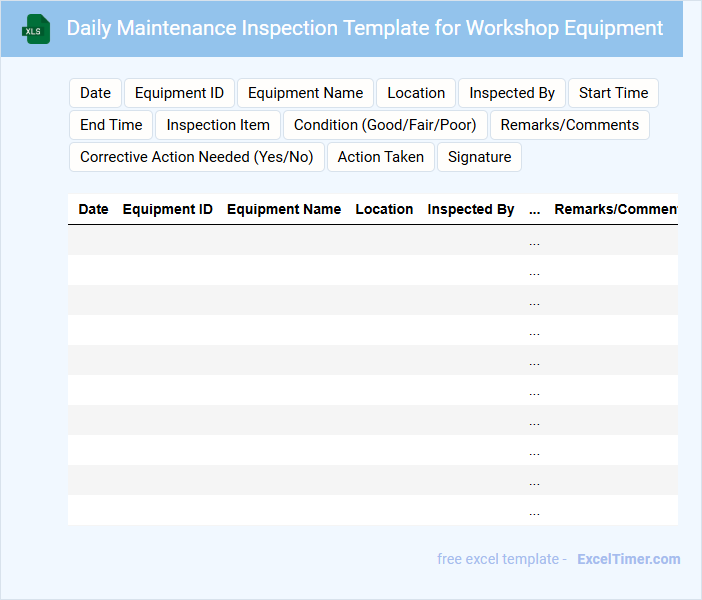

Daily Maintenance Inspection Template for Workshop Equipment

What information is typically included in a Daily Maintenance Inspection Template for Workshop Equipment?

This document usually contains detailed checklists that cover the condition and functionality of various workshop tools and machinery. It helps ensure safety, efficiency, and early detection of potential faults by guiding daily inspections and recording observations systematically.

What important aspects should be emphasized when using this template?

It is crucial to include clear sections for inspection date, equipment identification, specific checkpoints, and remarks for follow-up actions. Emphasizing accuracy and consistency in recording findings promotes accountability and extends the lifespan of workshop equipment.

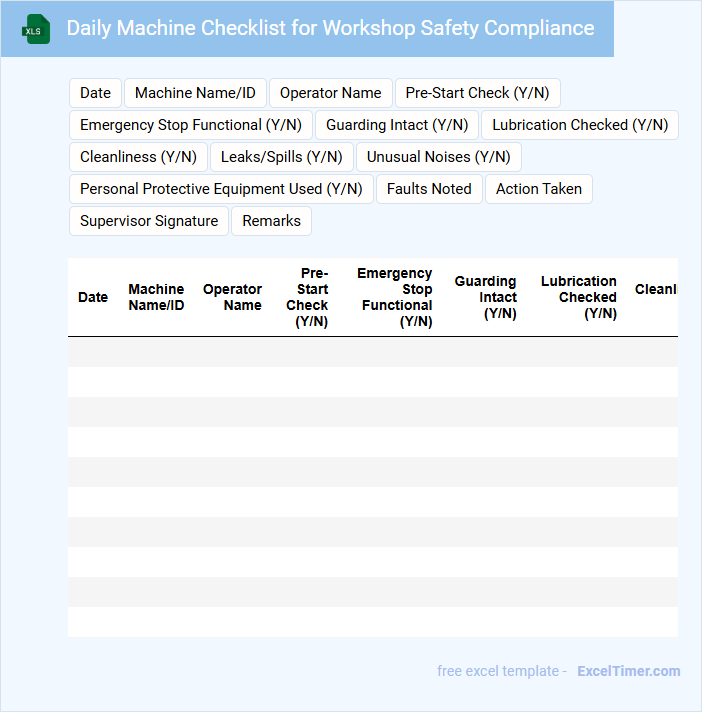

Daily Machine Checklist for Workshop Safety Compliance

A Daily Machine Checklist for Workshop Safety Compliance is a document used to ensure that all machinery is functioning correctly and safely before use each day. It helps prevent accidents and maintains a safe working environment by identifying potential hazards early.

- Include inspection of machine guards, emergency stops, and operational controls.

- Verify all safety labels and warnings are visible and legible.

- Check that all moving parts are lubricated and free from obstructions.

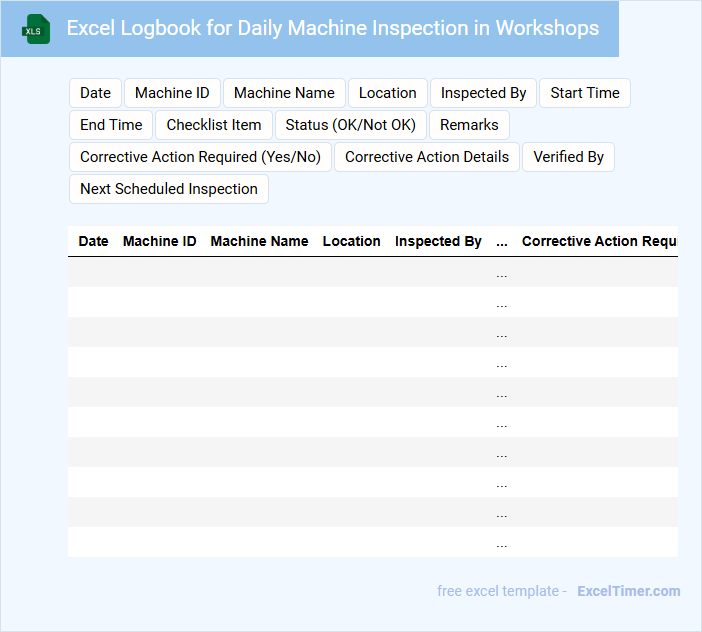

Excel Logbook for Daily Machine Inspection in Workshops

This document is typically used to record daily machine inspections in workshops to ensure equipment is functioning properly. It helps maintain safety standards and track maintenance needs over time.

- Include columns for date, machine ID, inspection details, and inspector's name.

- Ensure space for noting any issues found and actions taken.

- Use clear, consistent formatting to facilitate easy data entry and review.

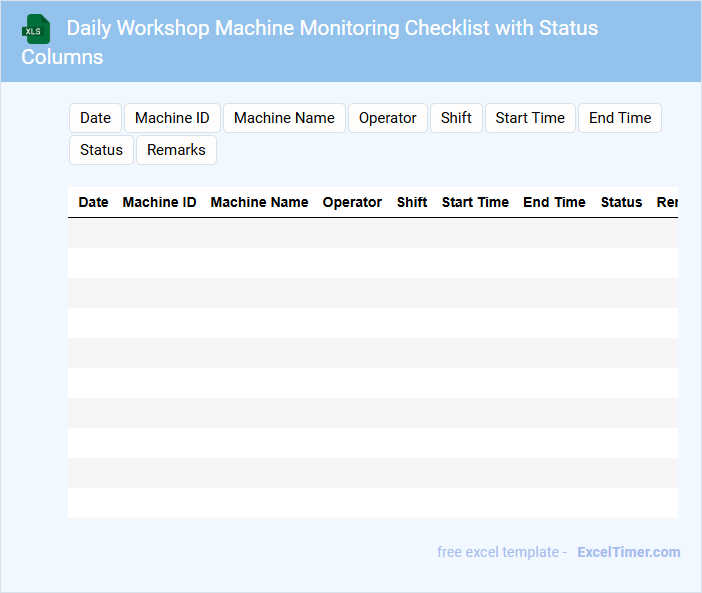

Daily Workshop Machine Monitoring Checklist with Status Columns

What information is typically included in a Daily Workshop Machine Monitoring Checklist with Status Columns? This document usually contains a list of machines to be checked daily, along with specific parameters such as operational status, maintenance needs, and safety checks. It helps ensure consistent monitoring and quick identification of any issues, enabling timely maintenance and reducing downtime.

What are the essential columns to include in a daily machine inspection checklist on Excel (e.g., Date, Machine ID, Inspector Name, Status, Comments)?

Your daily machine inspection checklist in Excel should include essential columns such as Date, Machine ID, Inspector Name, Inspection Time, Machine Status, Faults Detected, Maintenance Required, and Inspector Comments. These columns ensure accurate tracking of machine conditions and accountability for workshops. Including detailed data points helps streamline maintenance decisions and enhances machine reliability.

How can Excel's data validation feature help prevent incorrect entries in daily inspection records?

Excel's data validation feature restricts input to predefined criteria, ensuring accurate daily machine inspection records in workshops. It allows setting rules such as dropdown lists for inspection status, numeric ranges for measurements, and date limits to maintain consistent and error-free data. This reduces manual errors and improves reliability in tracking machine conditions.

Which Excel functions or conditional formatting can highlight machines that require urgent maintenance?

Use Excel functions like IF and TODAY to calculate maintenance due dates and apply conditional formatting with color scales or icon sets to highlight machines needing urgent maintenance. Your sheet can automatically flag inspections overdue by comparing dates, ensuring timely attention. This method improves workshop safety and productivity by prioritizing critical machine checks.

How could you use Excel filters and pivot tables to analyze inspection trends over time?

You can use Excel filters to quickly sort and highlight specific dates, machines, or inspection results in your Daily Machine Inspection data. Pivot tables summarize inspection trends over time by aggregating data based on dates, machine types, or defect categories, revealing patterns and reliability issues. Combining filters with pivot tables helps you efficiently monitor machine performance and schedule maintenance proactively.

What methods in Excel ensure secure and consistent logging of inspection records for accountability?

Excel's Data Validation feature enforces consistent entry formats in Daily Machine Inspection logs to maintain data integrity. Protecting the worksheet with password restrictions prevents unauthorized edits, ensuring the security of inspection records. Utilizing Excel Tables with structured references enables organized tracking and streamlined accountability for workshop inspections.