The Quarterly Production Schedule Excel Template for Manufacturing Plants streamlines production planning by organizing tasks, resources, and timelines efficiently. This template enhances workflow visibility, helping managers track progress and adjust schedules to meet production targets. It is crucial for optimizing manufacturing processes and minimizing downtime.

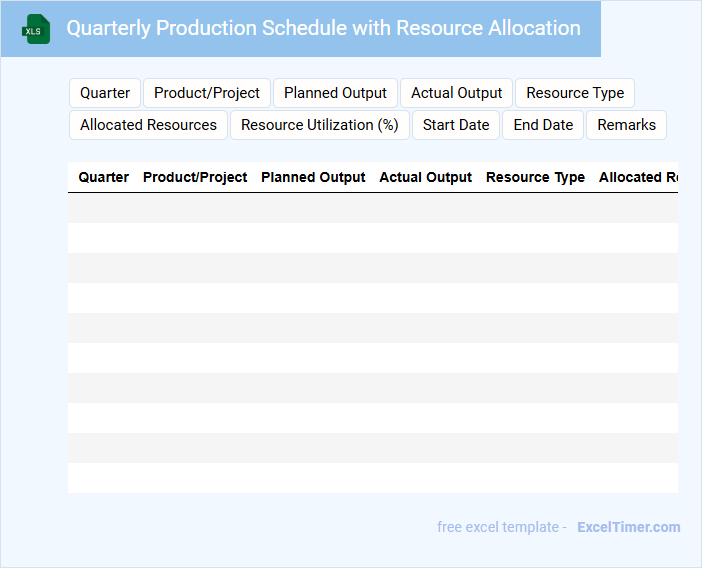

Quarterly Production Schedule with Resource Allocation

The Quarterly Production Schedule is a detailed plan outlining production activities over a three-month period. It includes timelines, tasks, and assigned resources to ensure efficient manufacturing processes.

Resource Allocation involves assigning the right personnel, machinery, and materials to specific production tasks. Proper allocation optimizes output and minimizes downtime.

When preparing this document, it is important to ensure accuracy in demand forecasting and consider potential constraints in resource availability.

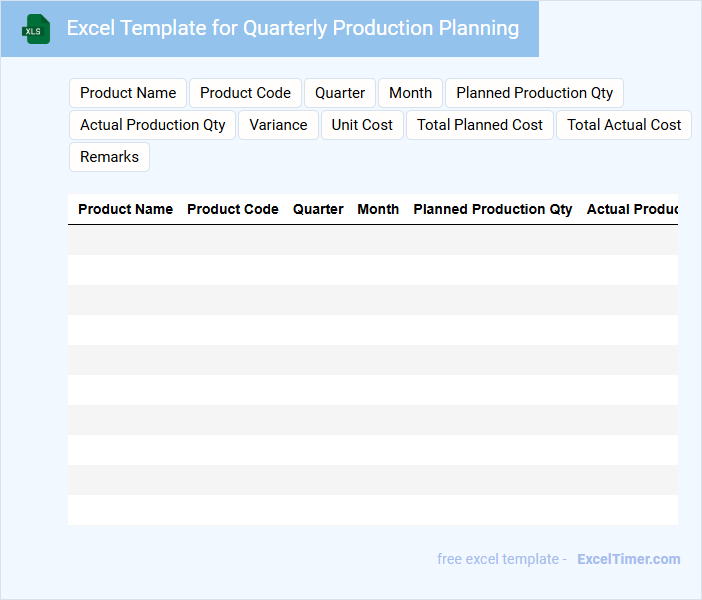

Excel Template for Quarterly Production Planning

This Excel Template for Quarterly Production Planning is typically used to organize and forecast production activities over a three-month period. It helps businesses track inventory, allocate resources, and meet production goals efficiently.

- Include clear fields for entering forecasted demand and actual production output.

- Incorporate formulas to automatically calculate production capacity and resource utilization.

- Design the layout for easy updates and summary reports to monitor progress.

Production Output Tracker for Quarterly Manufacturing

A Production Output Tracker for Quarterly Manufacturing typically contains detailed records of the quantity and quality of products produced within each quarter. It helps in monitoring production efficiency and identifying areas for improvement.

- Include key performance indicators such as total units produced, defect rates, and machine downtime.

- Provide clear timestamps and batch numbers for traceability.

- Incorporate summary charts to visualize trends over each quarter.

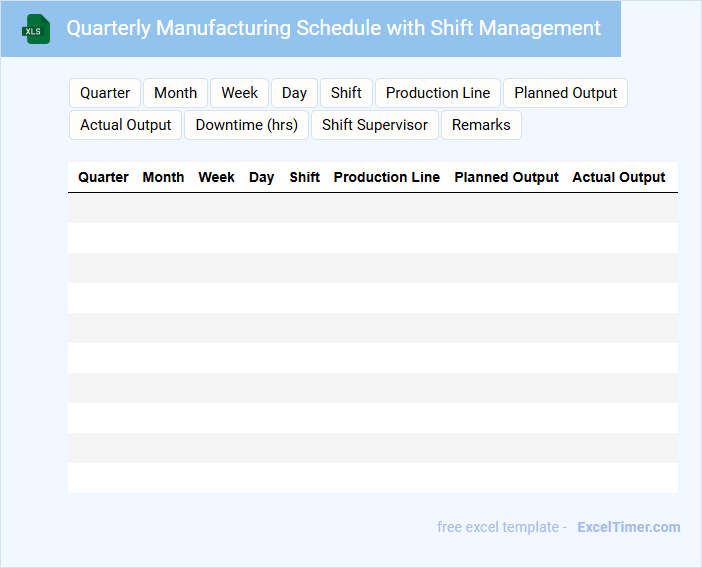

Quarterly Manufacturing Schedule with Shift Management

A Quarterly Manufacturing Schedule with Shift Management document typically contains detailed plans outlining production timelines, assigned shifts, and resource allocation for a manufacturing facility over a three-month period. It includes information on the production goals, employee shift patterns, and equipment usage to ensure efficient operations. This document is essential for coordinating workforce efforts and meeting production deadlines.

Key elements to focus on include clear shift assignments to avoid overlap, accurate production targets for each period, and effective communication channels for shift managers. Maintaining flexibility to accommodate unexpected changes and tracking performance metrics are also crucial. Ensuring the schedule is easily accessible and regularly updated will optimize productivity and workforce management.

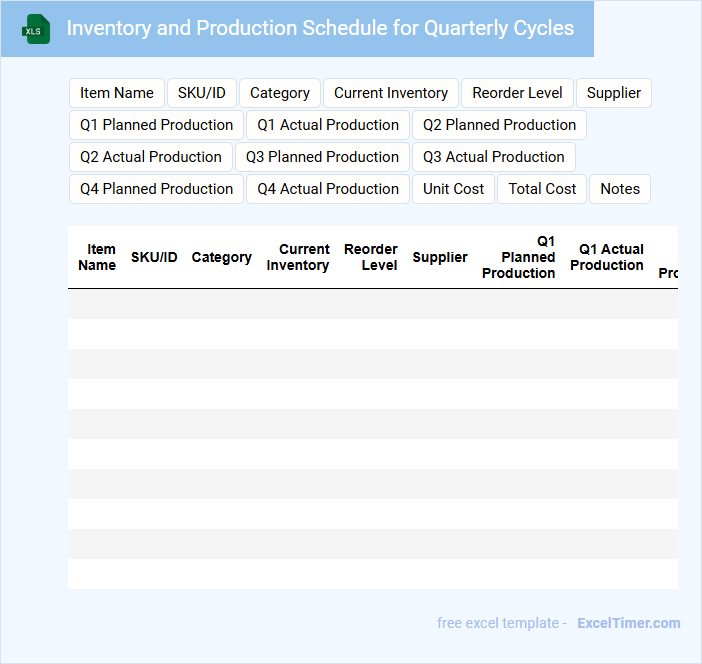

Inventory and Production Schedule for Quarterly Cycles

This document typically contains detailed listings of stock items and a timeline for production activities aligned with quarterly business cycles.

- Inventory Management: Tracks quantities and conditions of raw materials and finished products to ensure availability and reduce waste.

- Production Scheduling: Outlines timeframes and sequences for manufacturing processes to optimize efficiency and meet demand.

- Forecasting and Adjustments: Incorporates market trends and sales data to update inventory needs and production plans proactively.

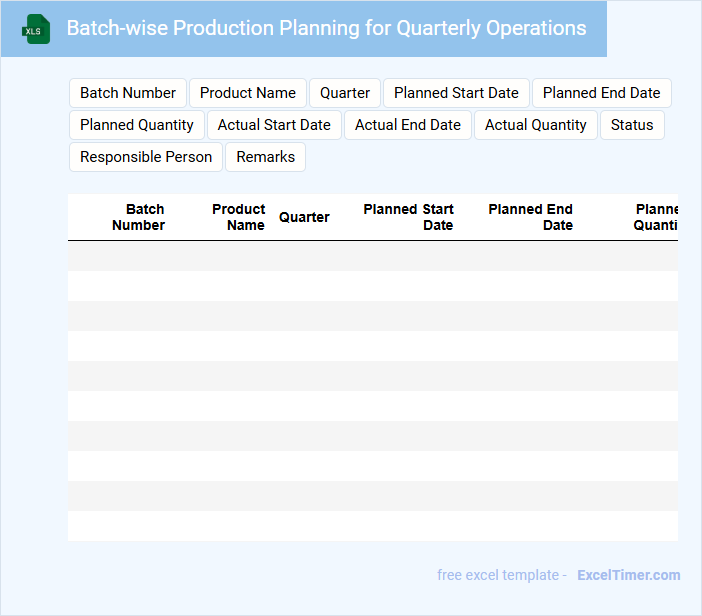

Batch-wise Production Planning for Quarterly Operations

Batch-wise Production Planning for Quarterly Operations typically contains detailed schedules, resource allocations, and performance metrics to optimize manufacturing efficiency over a three-month period.

- Accurate Forecasting: Ensures demand predictions align closely with production capacity to minimize waste and shortages.

- Resource Allocation: Assigns machinery, labor, and materials efficiently across batches to meet quarterly targets.

- Performance Monitoring: Tracks batch completion times and quality metrics to enable continuous improvement.

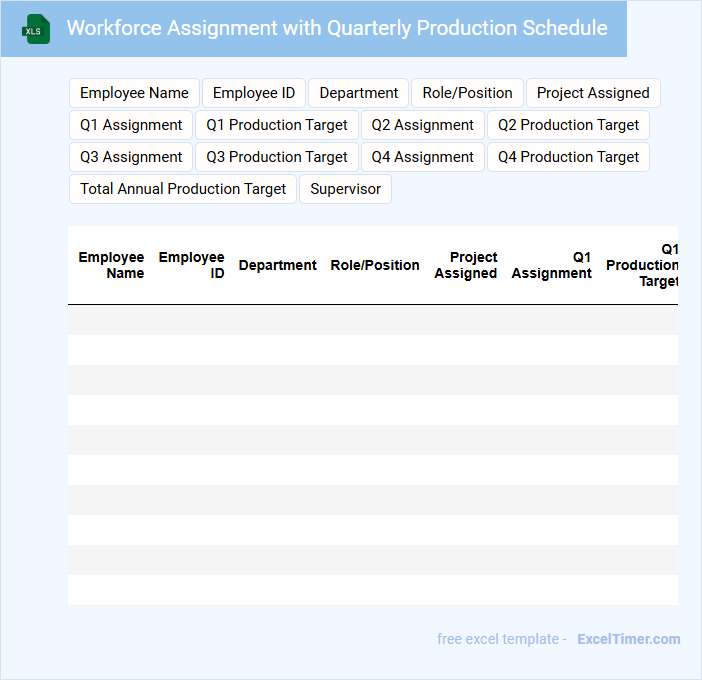

Workforce Assignment with Quarterly Production Schedule

A Workforce Assignment with a Quarterly Production Schedule typically includes detailed information on employee roles, work shifts, and task allocations aligned with production goals. This document ensures efficient resource utilization by matching workforce capabilities to production demands over the quarter. It also highlights deadlines and milestones essential for meeting production targets timely.

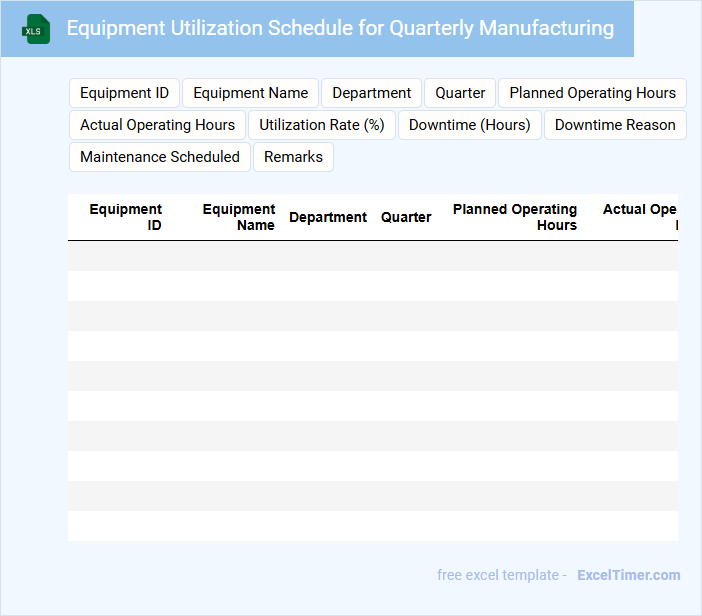

Equipment Utilization Schedule for Quarterly Manufacturing

An Equipment Utilization Schedule for quarterly manufacturing typically contains detailed timelines of machine usage, maintenance periods, and production shifts. It helps in tracking how efficiently the equipment is being used throughout the quarter.

Such a document is crucial for identifying downtime and scheduling preventive maintenance to avoid unexpected breakdowns. Consistently updating the schedule ensures optimal equipment performance and improved productivity.

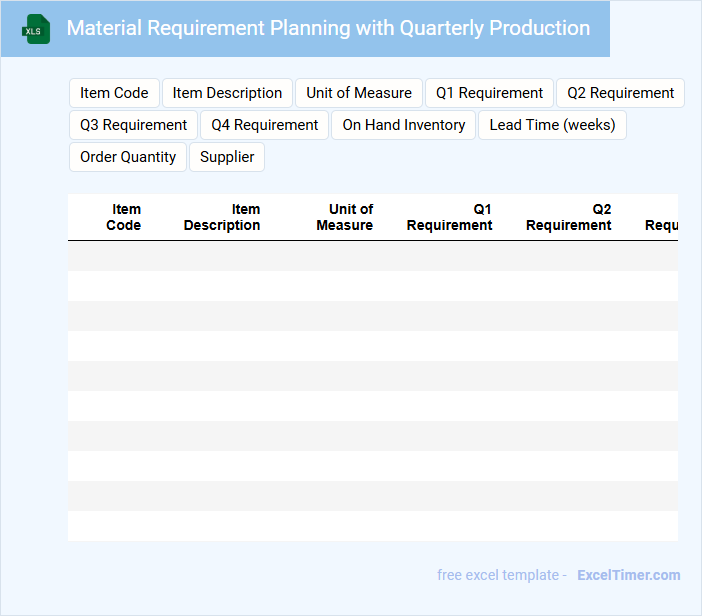

Material Requirement Planning with Quarterly Production

Material Requirement Planning (MRP) documents typically contain detailed scheduling information, inventory status, and procurement plans to ensure smooth production cycles. These documents help organizations forecast material needs and manage resources efficiently for upcoming periods. For quarterly production planning, it is crucial to emphasize accurate demand forecasting and timely supplier coordination to avoid delays.

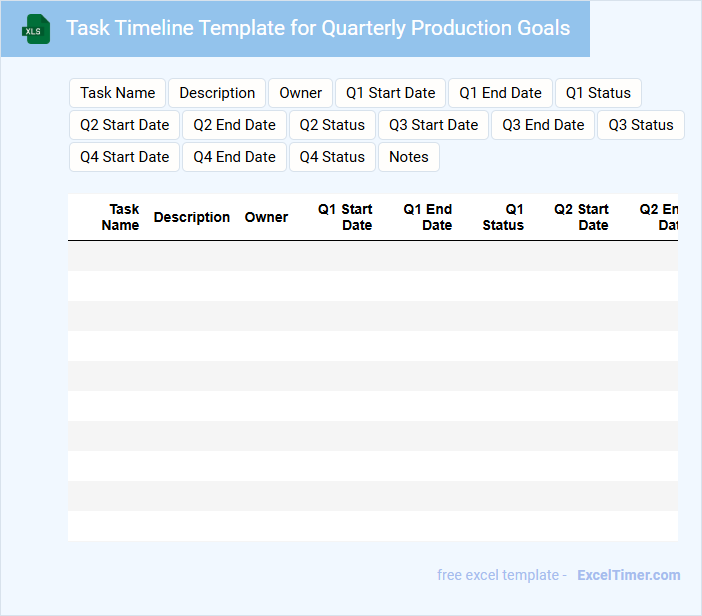

Task Timeline Template for Quarterly Production Goals

This document typically outlines the schedule and key milestones for achieving production goals over a quarter. It helps teams track progress and coordinate efforts efficiently.

- Include clear deadlines for each major task to ensure timely completion.

- Highlight dependencies between tasks to avoid bottlenecks.

- Incorporate regular review points to adjust plans as needed.

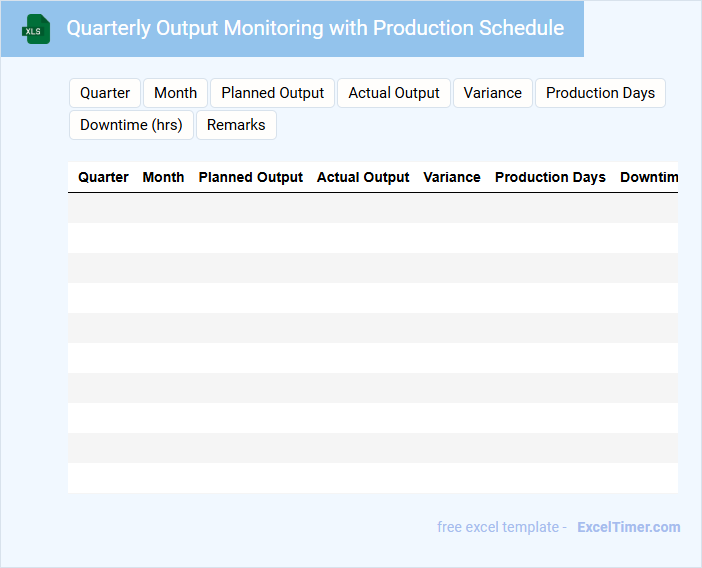

Quarterly Output Monitoring with Production Schedule

The Quarterly Output Monitoring document typically contains detailed records of production volumes and performance metrics over a three-month period. It highlights trends and identifies any discrepancies between planned and actual outputs.

The Production Schedule section outlines timelines, resource allocation, and key milestones necessary to achieve quarterly targets. Including a clear timeline is essential for timely adjustments and workflow optimization.

KPI Dashboard for Quarterly Production Schedules

What information is typically included in a KPI Dashboard for Quarterly Production Schedules? This type of document usually contains key performance indicators such as production volume, efficiency rates, downtime, and schedule adherence, all tracked on a quarterly basis. It is designed to provide a clear overview of production performance and highlight areas needing improvement.

What is an important consideration when creating a KPI Dashboard for Quarterly Production Schedules? Ensuring that the KPIs are relevant to the production goals and presented in an easily understandable format is crucial. Incorporating visual elements like graphs and color-coded alerts enhances quick decision-making and effective communication among stakeholders.

Order Fulfillment Tracker with Quarterly Production

The Order Fulfillment Tracker is a crucial document that records the status of customer orders from placement to delivery, ensuring accuracy and timely shipment. It typically contains details such as order dates, quantities, shipment status, and tracking information. For a tracker incorporating Quarterly Production, it is essential to include production targets, actual output, and any delays or bottlenecks to improve future planning and customer satisfaction.

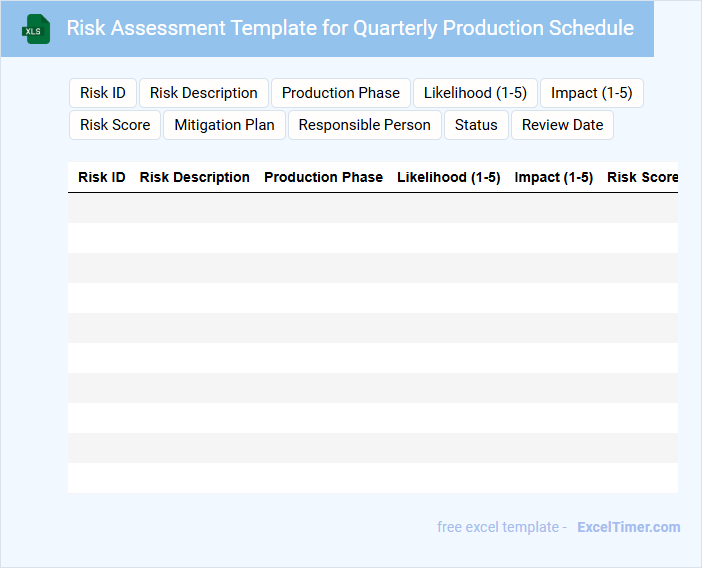

Risk Assessment Template for Quarterly Production Schedule

Risk Assessment Templates for Quarterly Production Schedules are crucial documents used to identify and evaluate potential hazards that could impact production timelines. This template generally contains sections for hazard identification, risk analysis, and mitigation strategies to minimize downtime and ensure safety. Including clear responsibilities, timelines, and contingency plans is essential for effective risk management.

Maintenance Planning with Quarterly Production Schedule

This type of document typically contains a detailed maintenance plan aligned with the quarterly production schedule to ensure minimal downtime. It outlines scheduled maintenance activities, resource allocation, and production targets within the given timeframe. An effective maintenance planning document helps optimize operational efficiency and prolong equipment lifespan.

Important elements to include are clear timelines for maintenance tasks, coordination with production deadlines, and contingency plans for unexpected breakdowns. Incorporating communication protocols between maintenance and production teams enhances collaboration and reduces scheduling conflicts. Additionally, tracking key performance indicators (KPIs) related to maintenance effectiveness supports continuous improvement.

Ensuring the document is regularly updated based on actual production performance and maintenance outcomes is crucial for accuracy. It should also incorporate safety guidelines and compliance requirements to protect personnel and equipment. Finally, integrating predictive maintenance data can further refine planning and prevent potential disruptions.

What key data fields should be included in an Excel quarterly production schedule for manufacturing plants?

A quarterly production schedule for manufacturing plants should include key data fields such as Plant Name, Product ID, Product Name, Production Start Date, Production End Date, Quantity Planned, Quantity Produced, Shift Details, Machine or Line ID, and Status. Including these fields ensures detailed tracking of production timelines, resource allocation, and output monitoring. This data supports efficient planning, reduces downtime, and optimizes manufacturing processes.

How can formulas be used to automatically calculate total output and variances for each production line?

Formulas in Excel can sum production quantities across weeks to calculate total output for each production line automatically. Variance formulas subtract planned production from actual output, highlighting discrepancies in performance. Using functions like SUM and simple arithmetic operators enables real-time tracking and analysis of quarterly manufacturing schedules.

Which Excel tools (e.g., conditional formatting, pivot tables) best visualize production trends and bottlenecks?

Conditional formatting highlights delays and bottlenecks in your Quarterly Production Schedule, making critical issues visually apparent. Pivot tables summarize production data across manufacturing plants, enabling efficient trend analysis and comparison by quarter or product line. Charts integrated with these tools provide dynamic visualizations to track performance and optimize workflow.

How is capacity planning integrated and adjusted within a quarterly schedule to meet demand fluctuations?

Capacity planning in a quarterly production schedule uses historical demand data and real-time sales forecasts to allocate resources effectively across manufacturing plants. Production volumes are adjusted dynamically by aligning workforce shifts, machine availability, and raw material procurement to anticipated demand changes. This approach ensures balanced utilization and minimizes bottlenecks, maintaining optimal output throughout fluctuating market conditions.

What methods ensure real-time schedule updates and version control when multiple departments access the document?

Implement cloud-based collaboration tools like Microsoft Excel Online or Google Sheets to ensure real-time schedule updates and version control for your Quarterly Production Schedule. Use integrated version history features to track changes and manage access permissions to prevent conflicts. These methods enable seamless coordination across multiple manufacturing departments.