The Semi-annually Excel Template for Equipment Maintenance Schedule allows systematic tracking of maintenance tasks every six months to ensure optimal equipment performance. This template helps prevent unexpected breakdowns by scheduling timely inspections and repairs. Maintaining accurate records within the template enhances operational efficiency and extends the lifespan of machinery.

Semi-Annually Excel Template for Equipment Maintenance Schedule

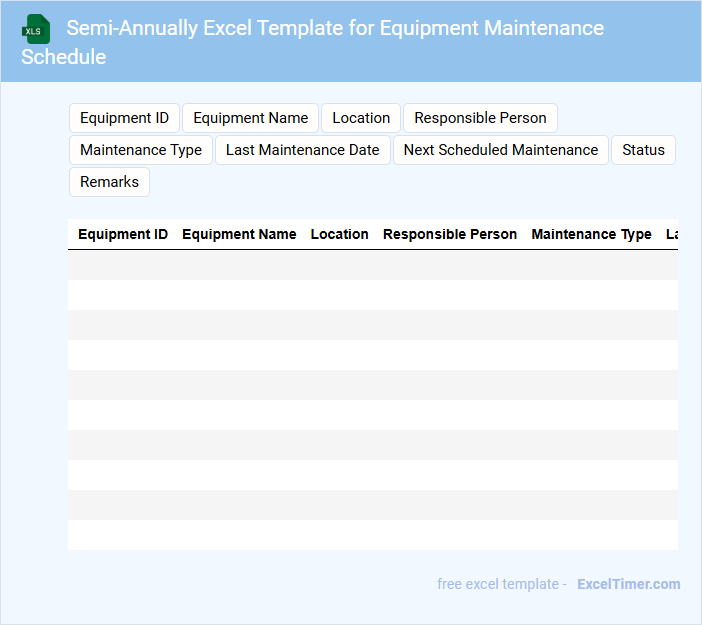

This type of document typically contains a structured schedule for equipment maintenance, detailing tasks to be performed every six months to ensure operational efficiency and prevent breakdowns. It is designed to be used with Excel for easy tracking and updating of maintenance activities.

- Include columns for equipment ID, maintenance tasks, and scheduled dates.

- Incorporate sections for technician notes and completed status to monitor progress.

- Use conditional formatting to highlight upcoming or overdue maintenance tasks.

Equipment Maintenance Schedule with Semi-Annual Tracking

An Equipment Maintenance Schedule is a document that outlines planned maintenance activities to ensure machinery and equipment operate efficiently and reliably. It typically contains details such as maintenance tasks, dates, responsible personnel, and required materials.

For a Semi-Annual Tracking system, the schedule is reviewed and updated every six months to monitor equipment condition and address potential issues proactively. This helps in minimizing downtime and extending equipment lifespan.

Ensure the schedule includes clear timestamps, detailed maintenance procedures, and a record-keeping system for all completed tasks to optimize equipment performance and safety.

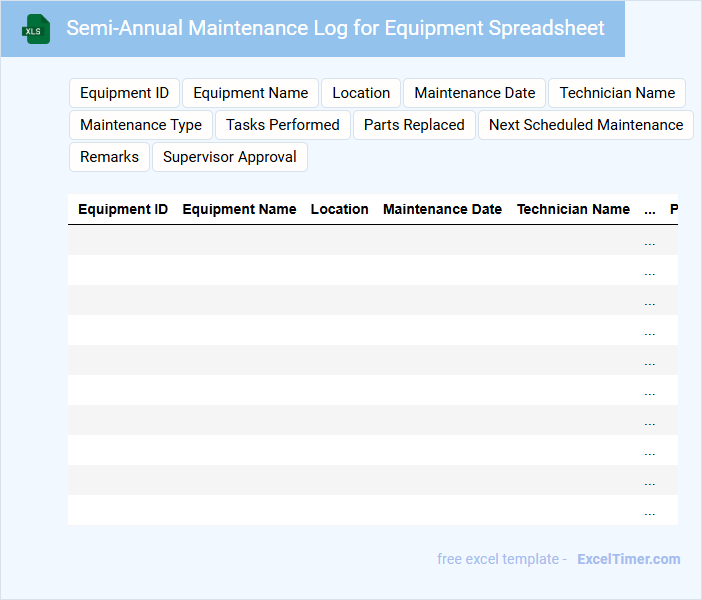

Semi-Annual Maintenance Log for Equipment Spreadsheet

A Semi-Annual Maintenance Log for Equipment Spreadsheet typically contains detailed records of maintenance activities performed on equipment every six months. It includes information such as dates of service, types of maintenance conducted, technician details, and any repairs or replacements made. This document helps track equipment performance and ensures compliance with safety standards. An important aspect to consider is accurately recording all maintenance actions to maintain a reliable history of the equipment's condition. Regular updates and clear categorization of equipment types enhance the spreadsheet's usability and effectiveness. Proper documentation supports preventive maintenance, reducing downtime and extending the lifespan of the equipment.

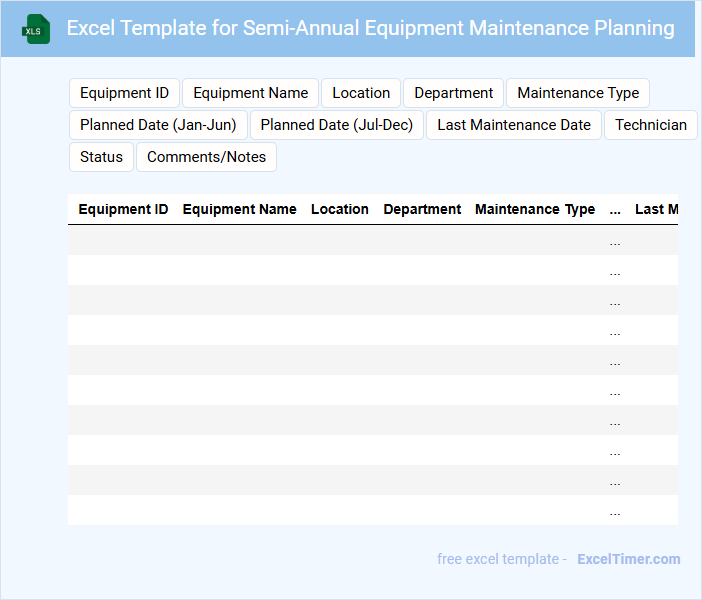

Excel Template for Semi-Annual Equipment Maintenance Planning

An Excel Template for Semi-Annual Equipment Maintenance Planning typically includes schedules, equipment lists, and task priorities to ensure timely upkeep. It helps track maintenance dates, assign responsibilities, and monitor completion status effectively.

Key components often feature maintenance checklists, cost estimates, and performance metrics to optimize equipment longevity. Including alerts for upcoming maintenance and space for notes can improve planning accuracy and accountability.

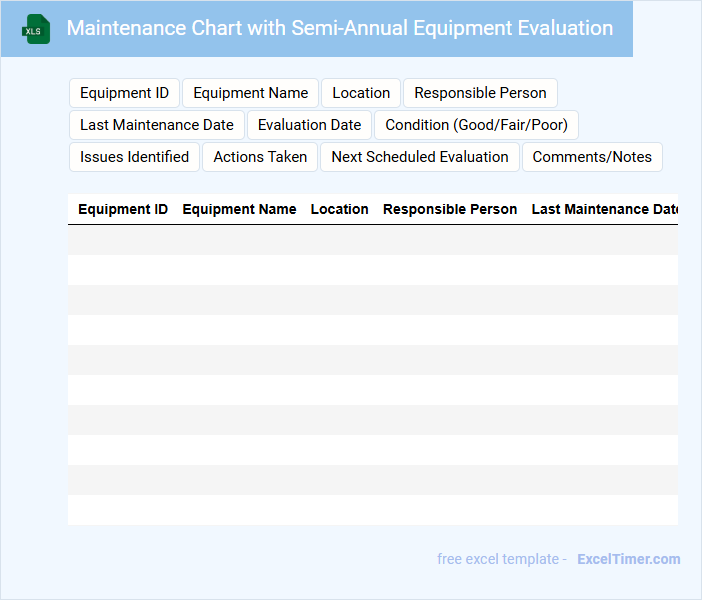

Maintenance Chart with Semi-Annual Equipment Evaluation

A Maintenance Chart with Semi-Annual Equipment Evaluation typically contains detailed records of machinery inspections, servicing schedules, and repair histories to ensure optimal performance and longevity. It highlights periodic checks, calibration dates, and parts replacement timelines crucial for preventive maintenance.

The document emphasizes the importance of a semi-annual evaluation to identify wear and tear issues before they escalate into major problems. It also includes performance metrics and compliance verification with safety standards. Prioritizing accurate and timely updates in this chart is essential for sustaining equipment reliability and operational safety.

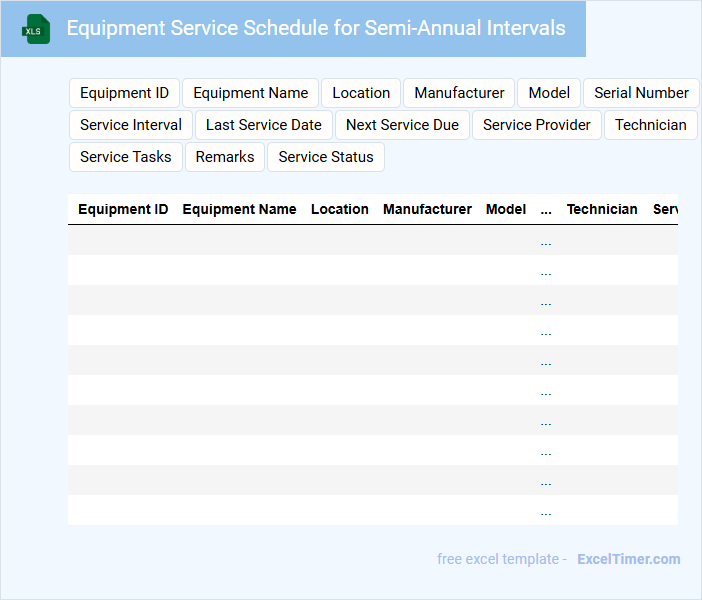

Equipment Service Schedule for Semi-Annual Intervals

The Equipment Service Schedule is a structured document outlining regular maintenance tasks and checks required for machinery or equipment. It typically details the frequency, such as semi-annual intervals, specific procedures to be performed, and responsible personnel. Ensuring this schedule is meticulously followed helps prevent equipment failure and extends operational lifespan.

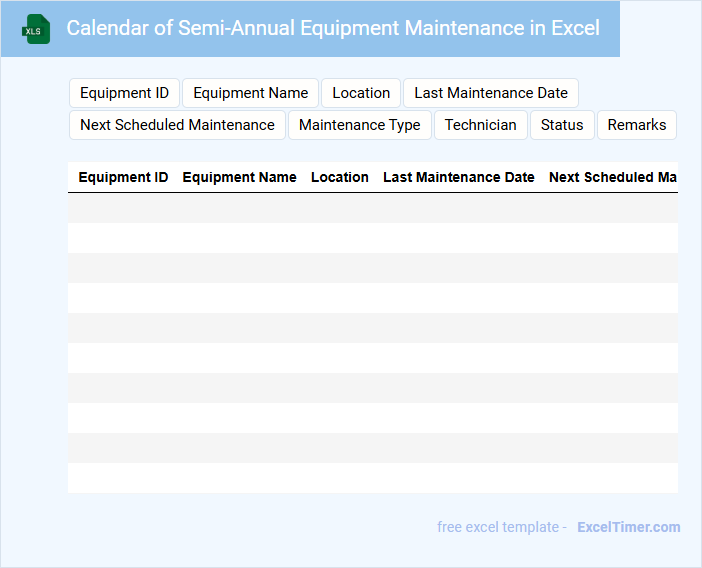

Calendar of Semi-Annual Equipment Maintenance in Excel

The Calendar of Semi-Annual Equipment Maintenance in Excel is a structured document used to schedule and track routine maintenance tasks. It typically contains dates, equipment details, maintenance activities, and responsible personnel to ensure timely upkeep. This helps prevent equipment failures by organizing scheduled inspections and repairs efficiently.

Important considerations for this document include clearly defined maintenance intervals, easy-to-read formatting for quick reference, and automated reminders or alerts to avoid missed tasks. Including contact information for maintenance teams and tracking completion status can enhance accountability. Customizable columns for notes and equipment conditions can also improve ongoing maintenance management.

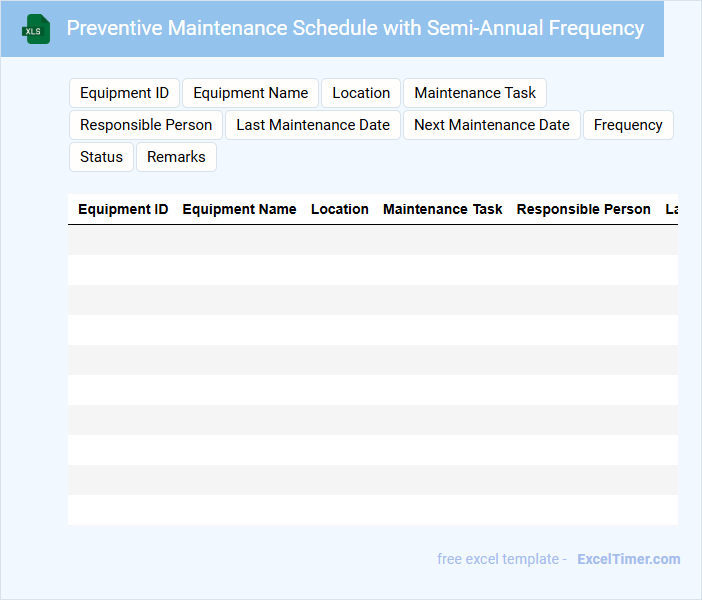

Preventive Maintenance Schedule with Semi-Annual Frequency

A Preventive Maintenance Schedule with a Semi-Annual Frequency outlines routine inspections and servicing tasks performed every six months to ensure equipment reliability and longevity. It typically includes detailed checklists, timelines, and responsible personnel to prevent unexpected breakdowns.

Important aspects to consider for such a schedule include accurate documentation of performed tasks and timely reminders for upcoming maintenance. This helps avoid costly downtime and extends the operational life of machinery.

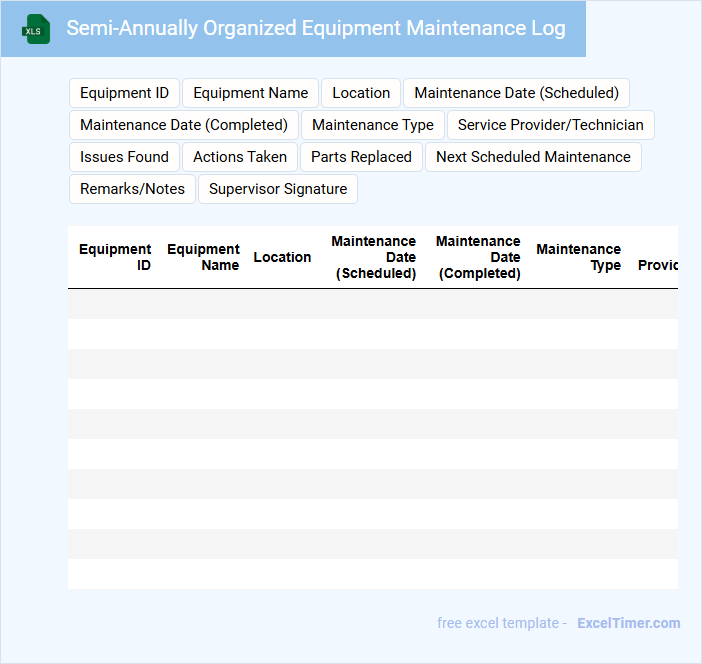

Semi-Annually Organized Equipment Maintenance Log

The Semi-Annually Organized Equipment Maintenance Log is a document that records maintenance activities performed on equipment every six months. It typically includes dates, types of maintenance tasks, and the personnel responsible.

This log helps ensure equipment reliability and prolongs its lifespan by tracking issues and repairs. A key suggestion is to consistently update the log immediately after maintenance is completed to maintain accuracy.

Excel Template for Semi-Annual Machinery Upkeep

An Excel Template for Semi-Annual Machinery Upkeep typically contains structured tables for recording maintenance schedules, parts replacements, and inspection checklists. It helps in tracking machinery performance and planning preventive maintenance efficiently. Including columns for dates, responsible personnel, and notes on observed issues is essential for detailed record-keeping.

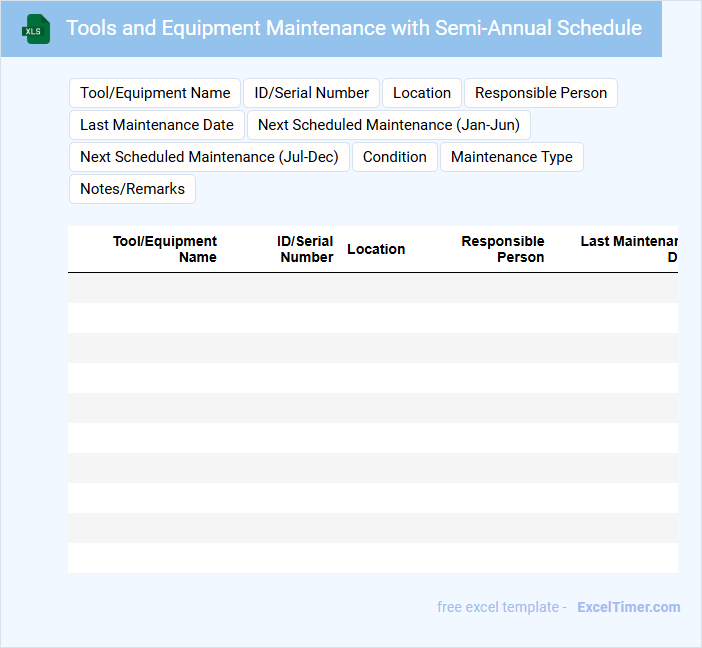

Tools and Equipment Maintenance with Semi-Annual Schedule

This document outlines the maintenance tasks required for tools and equipment to ensure optimal performance and longevity. It provides a structured semi-annual schedule specifying when each maintenance activity should be performed. The document is essential for preventing breakdowns and enhancing workplace safety through timely upkeep.

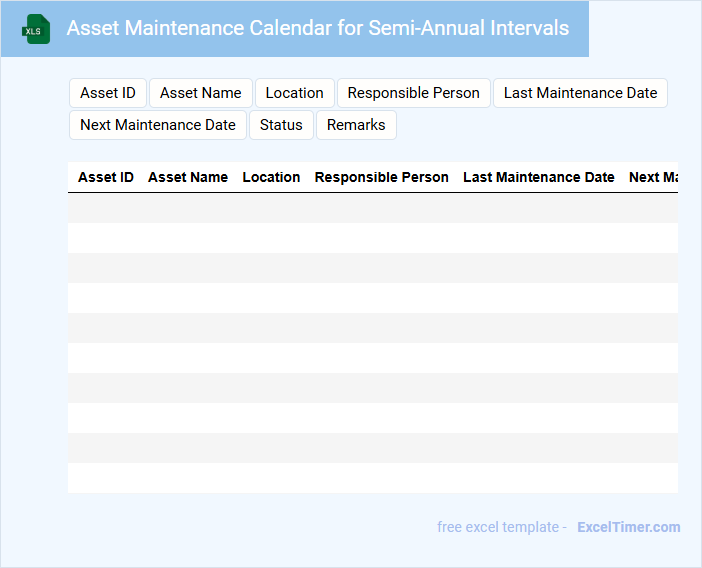

Asset Maintenance Calendar for Semi-Annual Intervals

An Asset Maintenance Calendar for Semi-Annual Intervals typically contains detailed schedules for equipment servicing that occur twice a year, ensuring optimal operational efficiency. It includes timelines, responsible personnel, and specific maintenance tasks to prevent unexpected breakdowns. This document helps organizations systematically plan and monitor preventive maintenance activities.

Key considerations for this calendar involve tracking adherence to service intervals and updating asset conditions post-maintenance. Consistent review and adjustment based on equipment performance history is critical. Prioritizing high-risk assets and compliance with safety standards enhances equipment longevity and reduces downtime.

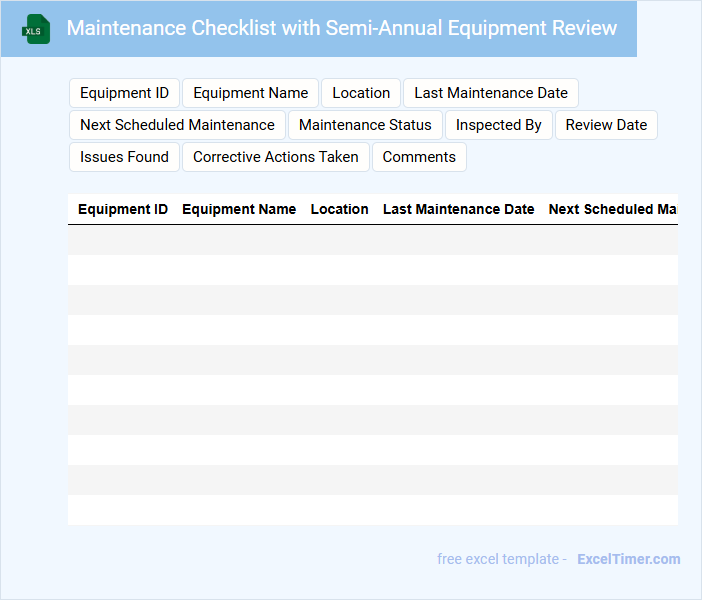

Maintenance Checklist with Semi-Annual Equipment Review

A Maintenance Checklist with Semi-Annual Equipment Review typically contains detailed tasks for regular upkeep along with evaluations to ensure equipment functionality and safety.

- Comprehensive Inspection: Include thorough checks for wear and tear, proper lubrication, and operational performance.

- Documentation: Maintain precise records of completed tasks, issues found, and corrective actions taken during the review.

- Preventative Measures: Highlight schedules for replacing parts and updating software to prevent failures and extend equipment life.

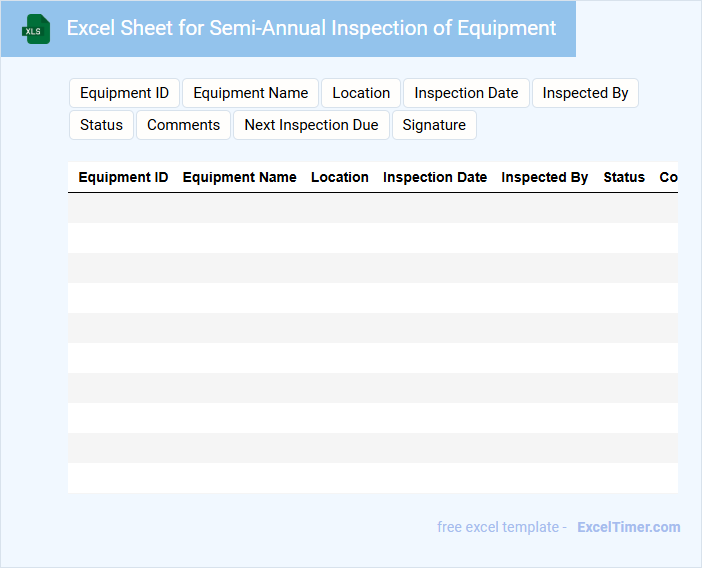

Excel Sheet for Semi-Annual Inspection of Equipment

This document typically contains detailed information for tracking and verifying the condition and maintenance status of equipment during semi-annual inspections to ensure operational safety and performance.

- Inspection Dates: Records the specific dates when inspections were conducted to maintain a regular maintenance schedule.

- Equipment Details: Includes identification numbers, descriptions, and locations for accurate tracking of each item inspected.

- Inspection Results: Documents findings, issues detected, and required corrective actions to ensure timely repairs and compliance.

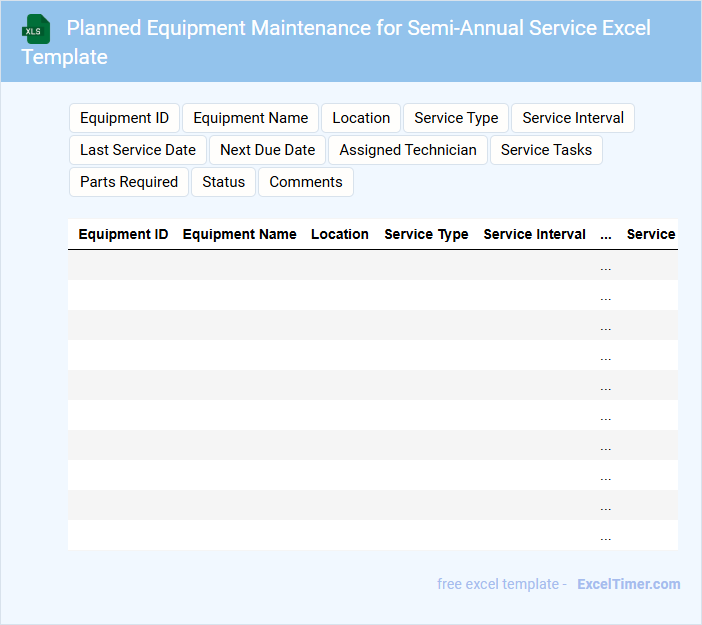

Planned Equipment Maintenance for Semi-Annual Service Excel Template

This type of document typically serves as a Planned Equipment Maintenance schedule, outlining tasks and timelines for servicing machinery every six months. It contains detailed equipment lists, maintenance activities, and tracking columns to ensure timely completion. Including clear service intervals and responsible personnel enhances efficiency and reduces downtime.

How is a semi-annual maintenance schedule structured in an Excel document for equipment tracking?

A semi-annual maintenance schedule in Excel includes columns for equipment ID, maintenance tasks, scheduled dates, and status updates set every six months. Conditional formatting highlights upcoming or overdue maintenance to ensure timely service. Pivot tables and filters enable easy tracking and reporting of equipment maintenance history.

Which Excel features are essential for setting up automated reminders for semi-annual maintenance tasks?

You can use Excel's conditional formatting and date functions like TODAY() combined with IF statements to highlight upcoming semi-annual maintenance tasks. Setting up data validation ensures accurate date entries, while leveraging Excel's Power Query or VBA macros can automate reminder notifications. These features streamline managing your equipment maintenance schedule efficiently.

What are the key columns required to record semi-annual equipment maintenance activities in Excel?

Key columns for a semi-annual equipment maintenance schedule in Excel include Equipment ID, Equipment Name, Maintenance Date, Maintenance Type, Technician Name, Maintenance Status, and Next Scheduled Maintenance Date. Recording Maintenance Description, Parts Used, and Maintenance Cost can enhance tracking accuracy. Including columns for Inspection Results and Follow-up Actions ensures comprehensive documentation.

How can you use Excel formulas to calculate the next scheduled semi-annual maintenance date?

Use the EDATE function in Excel to calculate your next semi-annual maintenance date by adding six months to the last maintenance date, for example: =EDATE(A2,6). This formula automatically updates the schedule based on the date in cell A2. Your equipment maintenance stays on track with precise semi-annual intervals using this method.

What data validation methods in Excel ensure only accurate semi-annual maintenance entries are recorded?

You can use Excel's Data Validation feature with a custom formula to ensure only semi-annual dates are entered, such as allowing dates that fall exactly six months apart. Setting a date range and using the MOD function helps restrict entries to accurate semi-annual intervals. This approach ensures your Equipment Maintenance Schedule remains consistent and error-free.