The Semi-annually Excel Template for Production Planning streamlines schedule management by breaking down tasks into six-month segments, ensuring efficient allocation of resources and timely completion of production goals. This template enhances forecasting accuracy by allowing users to monitor inventory levels, demand trends, and labor requirements within each half-year period. Its user-friendly format supports rapid adjustments, facilitating proactive decision-making and minimizing downtime in manufacturing processes.

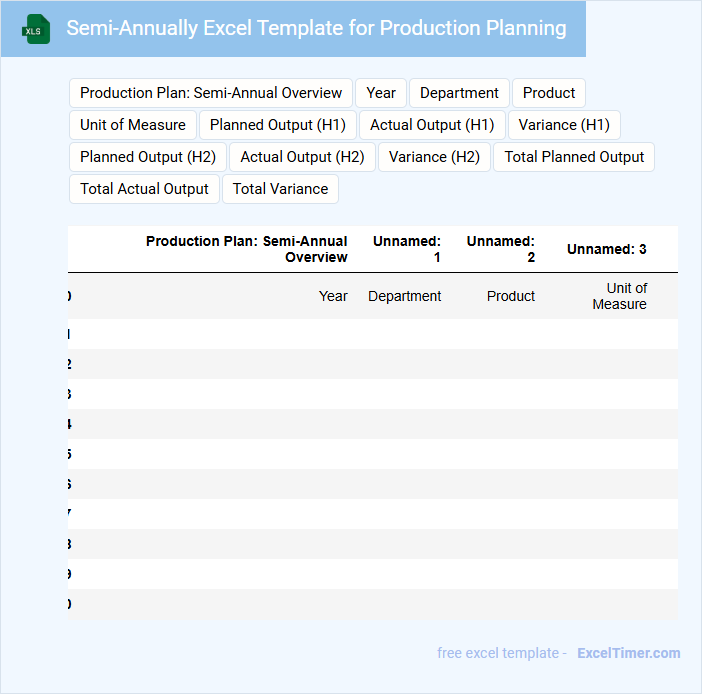

Semi-Annually Excel Template for Production Planning

The Semi-Annually Excel Template for Production Planning is designed to organize and forecast manufacturing activities over six months. It usually contains sections for tracking inventory levels, production schedules, and resource allocation.

This document helps managers optimize workflow and reduce downtime by providing clear visibility into production timelines. An important suggestion is to regularly update data and validate assumptions to ensure accuracy and efficiency.

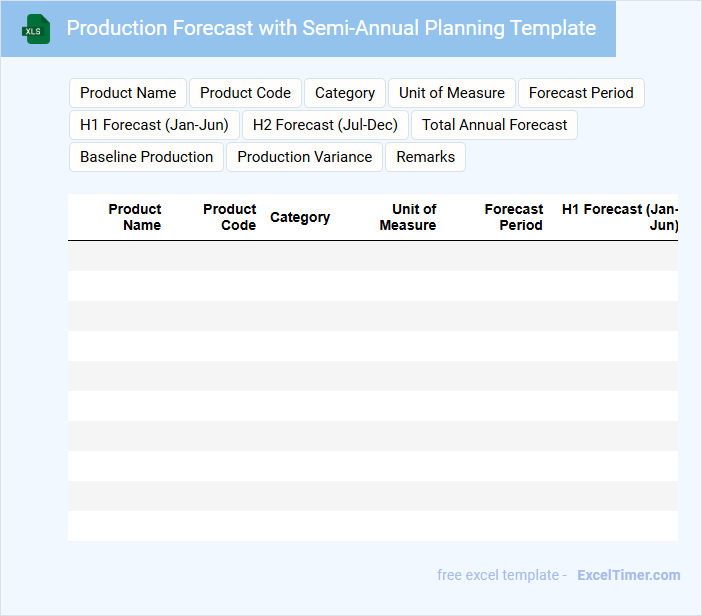

Production Forecast with Semi-Annual Planning Template

A Production Forecast with Semi-Annual Planning Template is a document that outlines expected production volumes and schedules for a six-month period, helping organizations anticipate resource needs and manage supply chain activities. It facilitates strategic planning by aligning production goals with market demand and operational capacity.

- Include accurate historical data to enhance forecast reliability.

- Regularly update the plan to reflect changes in demand or production capacity.

- Incorporate clear milestones and review points to track progress effectively.

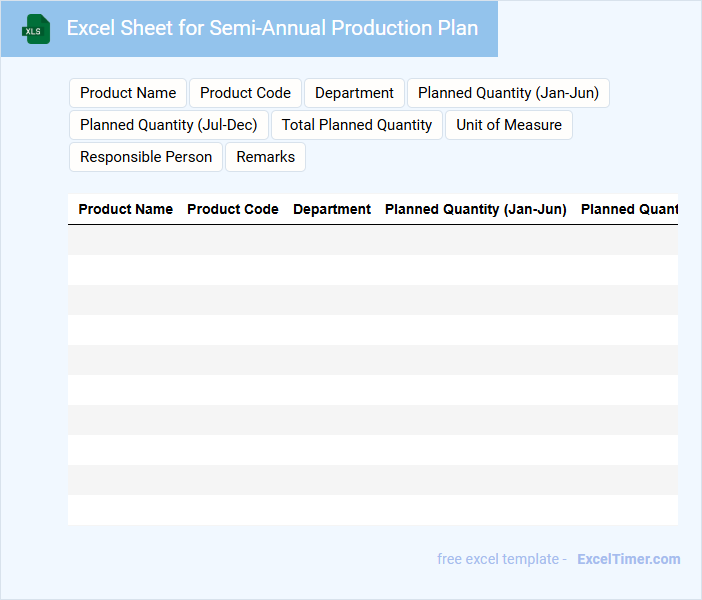

Excel Sheet for Semi-Annual Production Plan

An Excel Sheet for Semi-Annual Production Plan typically contains detailed scheduling and resource allocation data for production activities over a six-month period. It is essential for coordinating manufacturing efforts and forecasting output to meet demand.

- Include clear timelines and milestones to track progress effectively.

- Incorporate resource availability and capacity constraints for accurate planning.

- Ensure data is regularly updated to reflect any changes in production requirements.

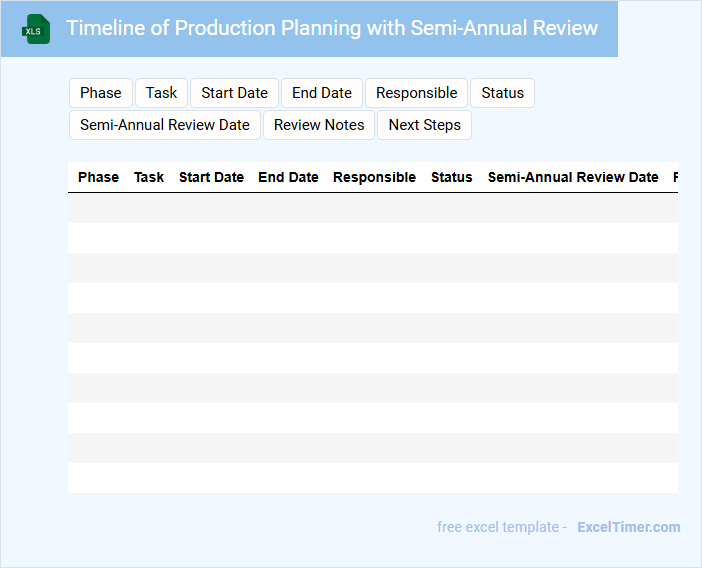

Timeline of Production Planning with Semi-Annual Review

The Timeline of Production Planning document outlines the schedule and key milestones for manufacturing processes over a specified period. It helps in coordinating resources and ensuring timely completion of production targets.

A Semi-Annual Review section evaluates progress and adjusts plans based on performance metrics and market changes. This review is crucial for maintaining flexibility and continuous improvement in production strategy.

Important considerations include setting clear deadlines, incorporating buffer periods, and aligning review cycles with business goals to enhance decision-making efficiency.

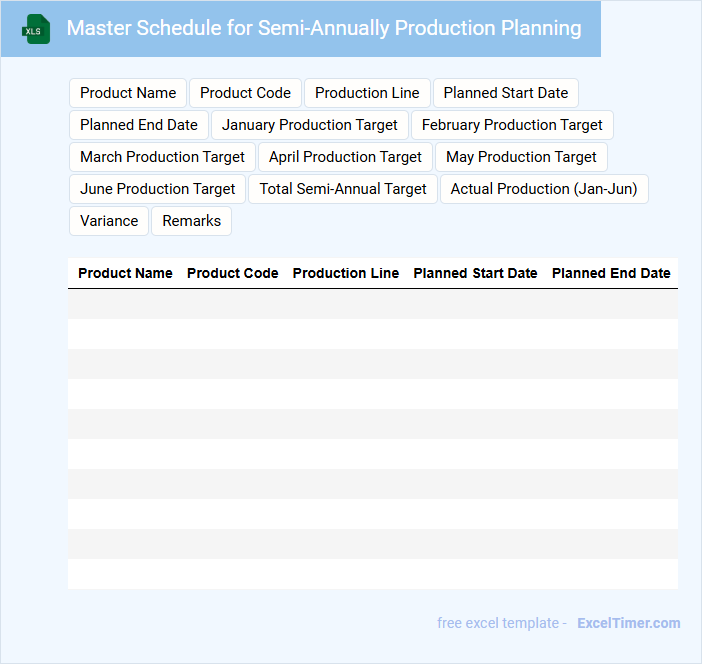

Master Schedule for Semi-Annually Production Planning

The Master Schedule is a comprehensive document that outlines production activities, timelines, and resource allocation. It helps in coordinating tasks to meet semi-annual targets efficiently.

Typically, it includes demand forecasts, inventory levels, and lead times to ensure smooth operations. For semi-annually planning, keeping an accurate forecast and buffer stock is crucial to handle fluctuations.

Semi-Anually Resource Allocation for Production Planning

What is typically contained in a Semi-Annually Resource Allocation for Production Planning document? This document usually includes detailed schedules of resource distribution, including labor, materials, and machinery allocation for optimal production efficiency. It outlines planned production targets and resource requirements to ensure smooth operations over the next six months.

What important factors should be considered when preparing this document? It is crucial to analyze past production performance and forecast demand accurately to allocate resources effectively. Additionally, the document should incorporate flexibility for unexpected changes and include contingency plans to mitigate potential risks in production scheduling.

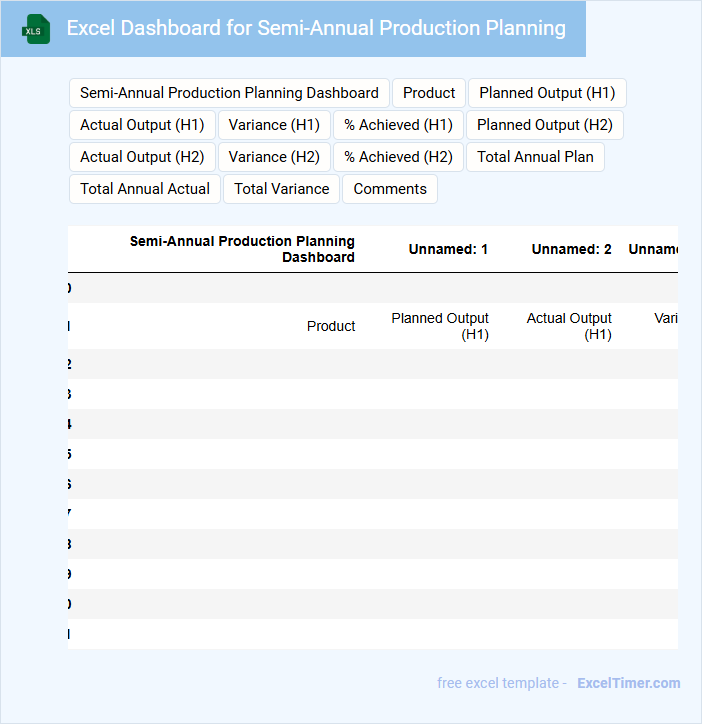

Excel Dashboard for Semi-Annual Production Planning

An Excel Dashboard for Semi-Annual Production Planning typically contains summarized data that tracks production targets, actual outputs, and resource allocation over a six-month period. It includes visual elements like charts and graphs to facilitate quick decision-making and trend analysis. Key performance indicators (KPIs) such as production volume, efficiency, and inventory levels are prominently displayed for better operational control.

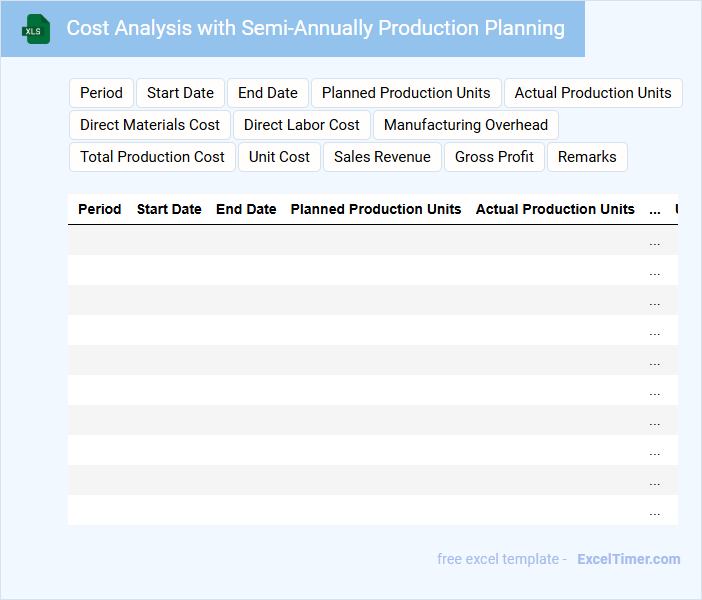

Cost Analysis with Semi-Annually Production Planning

A Cost Analysis document typically contains detailed information on the expenses involved in production, including raw materials, labor, overhead, and fixed costs. It helps in identifying cost-saving opportunities and ensuring budget adherence.

When combined with Semi-Annually Production Planning, the document outlines production schedules, resource allocation, and forecasted output for two periods within a year. This approach aids in optimizing inventory levels and managing cash flow efficiently.

Important considerations include accurate cost estimation, clear production timelines, and integration of market demand forecasts to align costs with business goals.

Semi-Annual KPI Tracking for Production Planning

Semi-Annual KPI Tracking for Production Planning documents the performance metrics and progress achieved in the production process over a six-month period. It is crucial for identifying trends, addressing inefficiencies, and aligning production goals with business objectives.

- Include clear definitions and targets for each KPI being measured.

- Use visual aids like charts or graphs to highlight performance trends.

- Provide actionable insights and recommendations based on the data analysis.

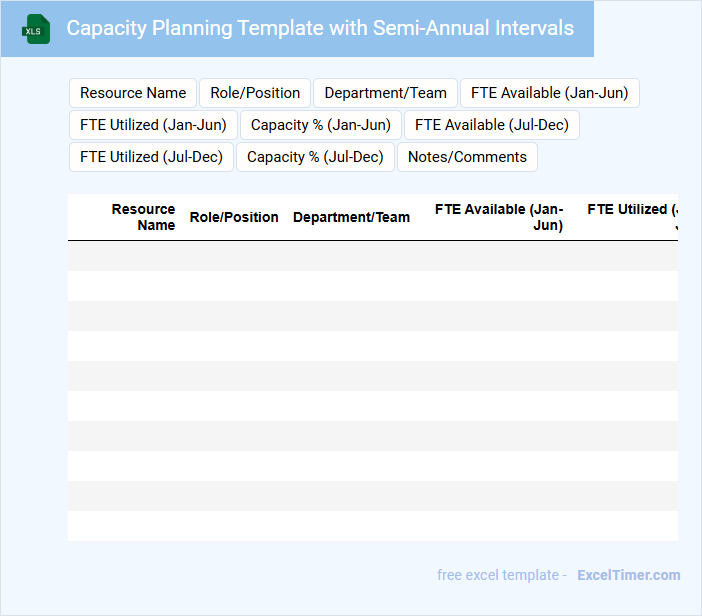

Capacity Planning Template with Semi-Annual Intervals

What information is typically included in a Capacity Planning Template with Semi-Annual Intervals? This document usually contains data on resource requirements, utilization rates, and projected capacity needs broken down over six-month periods. It helps organizations forecast demand and allocate resources efficiently to avoid bottlenecks or underutilization.

What important considerations should be taken into account when using this template? Accurate historical data and realistic growth projections are essential to ensure reliable planning. Additionally, regularly updating the template and incorporating flexibility for unexpected changes can improve decision-making and operational efficiency.

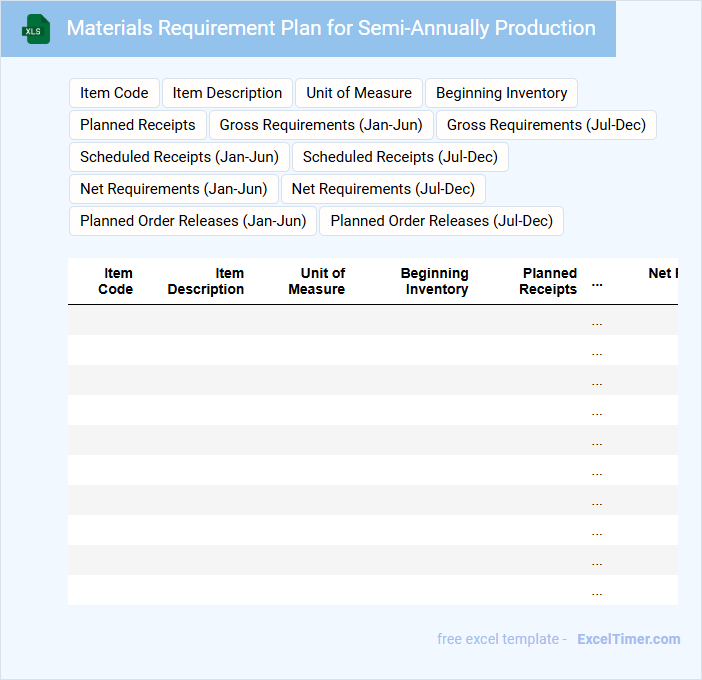

Materials Requirement Plan for Semi-Annually Production

Materials Requirement Plan for Semi-Annually Production is a strategic document used to forecast and schedule the procurement of raw materials and components needed for manufacturing over a six-month period. It ensures that materials are available when required, minimizing excess inventory and production delays. Key elements include demand forecasting, inventory levels, and supplier lead times to optimize the production process.

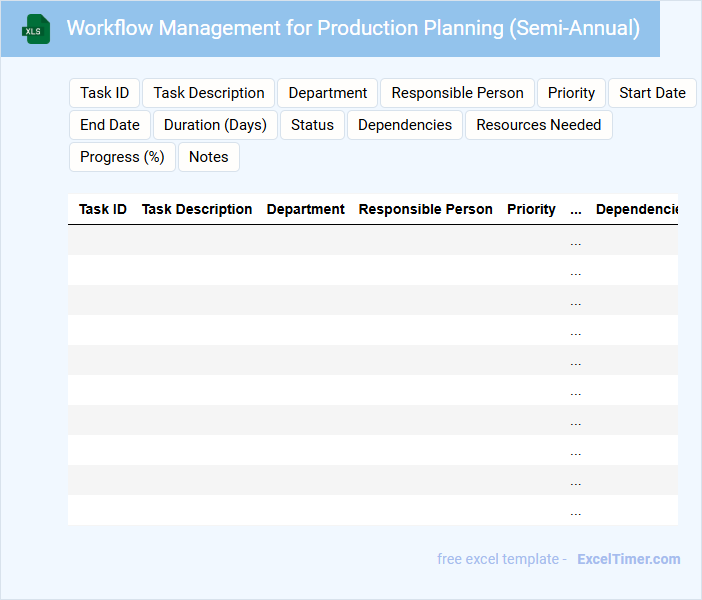

Workflow Management for Production Planning (Semi-Annual)

Workflow Management documents typically detail the processes and tasks essential for smooth operations in production planning. They outline roles, responsibilities, and timelines to ensure efficiency within the given timeframe.

This semi-annual document should prioritize clear scheduling and resource allocation to avoid bottlenecks. Regular review and updates help maintain alignment with production goals and market demands.

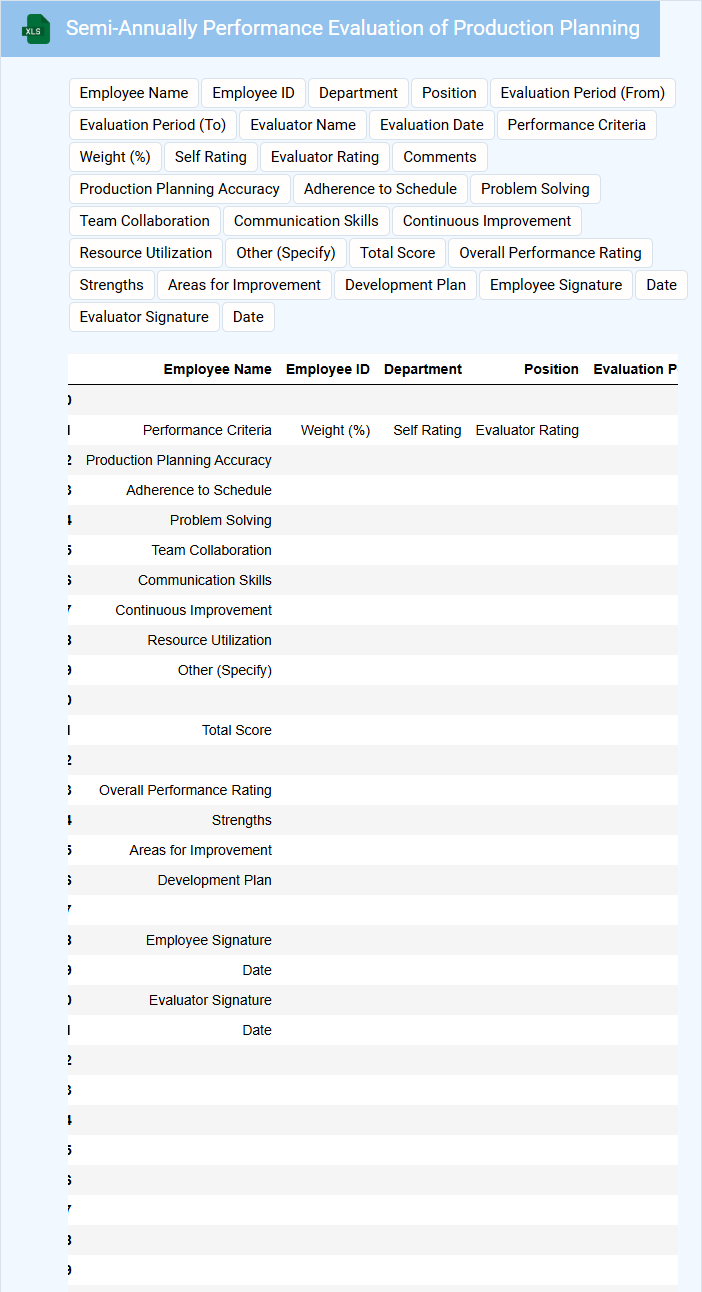

Semi-Annually Performance Evaluation of Production Planning

The Semi-Annual Performance Evaluation of Production Planning assesses the efficiency and effectiveness of production schedules over six months. It helps identify strengths and areas for improvement in the planning process.

- Review production targets versus actual output to measure goal achievement.

- Analyze resource utilization and capacity planning for optimization opportunities.

- Evaluate coordination between departments to ensure smooth workflow and timely delivery.

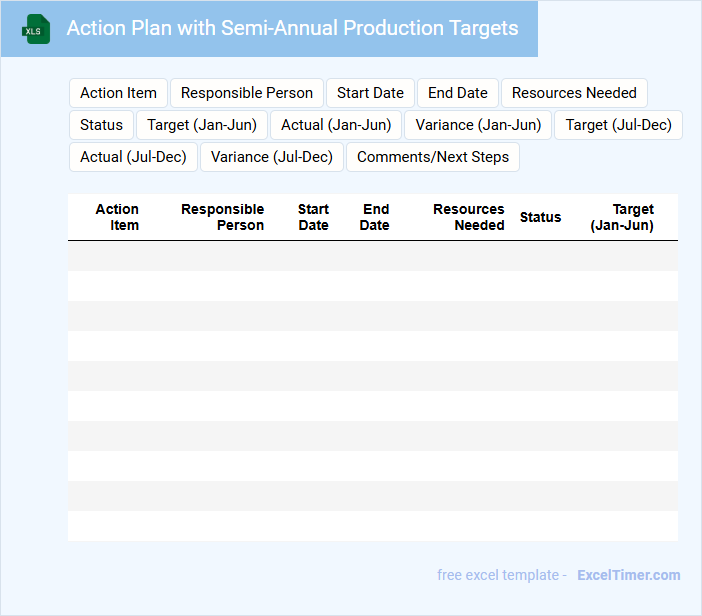

Action Plan with Semi-Annual Production Targets

An Action Plan with Semi-Annual Production Targets typically outlines specific goals, timelines, and resources allocated to achieve production objectives within six-month periods.

- Clear objectives: Define measurable and attainable production targets for each semi-annual period.

- Resource allocation: Assign necessary personnel, equipment, and budget to support the action plan efficiently.

- Monitoring and evaluation: Establish regular progress reviews to ensure targets are met and adjust strategies as needed.

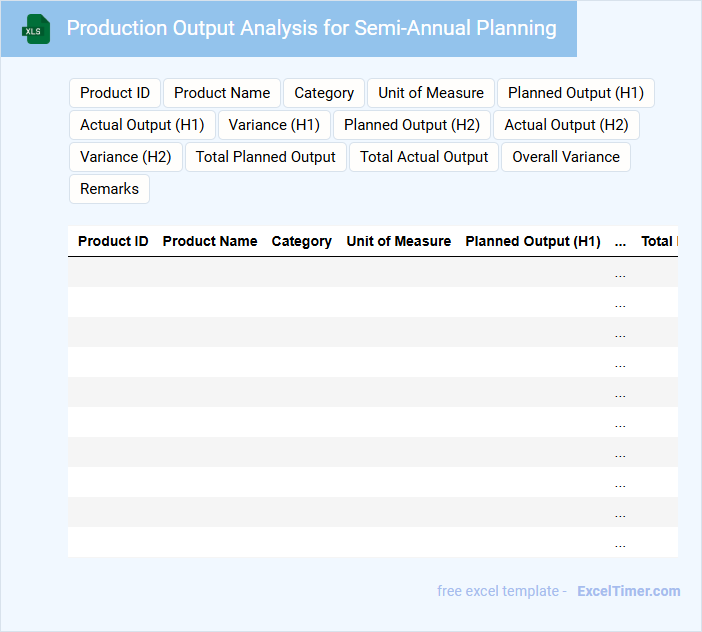

Production Output Analysis for Semi-Annual Planning

This document primarily contains a detailed production output analysis, highlighting the quantity and efficiency of goods produced over a specific period. It includes key performance indicators, trends, and comparisons with previous cycles to inform strategic decisions.

Suggestions for improving the semi-annual planning process emphasize data accuracy, clear visualization of output metrics, and alignment with business goals. Incorporating predictive analytics can further enhance forecasting and resource allocation.

How does semi-annual production planning affect inventory levels in Excel tracking?

Semi-annual production planning in Excel enables companies to forecast demand and schedule production every six months, reducing the frequency of inventory adjustments. This approach helps maintain optimal inventory levels by balancing supply with anticipated demand, minimizing stockouts and excess stock. Excel tracking provides clear visibility into inventory fluctuations, facilitating strategic decision-making for production and procurement.

What key metrics should be monitored semi-annually in an Excel production plan?

You should monitor key metrics such as production output, inventory levels, and machine utilization rates semi-annually in your Excel production plan. Tracking these metrics helps optimize resource allocation and identify potential bottlenecks. Accurate data analysis ensures improved forecasting and efficient decision-making.

How can Excel formulas automate demand forecasting on a semi-annual basis?

Excel formulas automate semi-annual demand forecasting by using functions like AVERAGE, TREND, and FORECAST.LINEAR to analyze past production data and predict future requirements. You can integrate date functions such as EOMONTH and IF to segment data into six-month periods for precise planning. This approach streamlines your production schedule by providing accurate, timely demand projections.

What data should be updated semi-annually in your Excel production planning sheet?

Update your production schedule, inventory levels, and demand forecasts semi-annually in your Excel production planning sheet. Incorporate supplier lead times and capacity constraints to ensure accurate resource allocation. Regularly revising these data points helps optimize efficiency and reduce downtime in your production cycle.

How does semi-annual review impact supplier scheduling in Excel production documents?

A semi-annual review in Excel production documents allows you to analyze supplier performance and adjust scheduling for the next six months. This biannual update helps optimize inventory levels and align supplier deliveries with production demand. Accurate timing improves cost efficiency and reduces the risk of stockouts or overstocking.