The Weekly Production Planning Excel Template for Manufacturing Units streamlines scheduling by organizing tasks, resources, and timelines effectively. It enhances productivity through clear visualization of production targets, ensuring timely completion and optimal resource allocation. This template is essential for manufacturers aiming to reduce downtime and improve workflow efficiency.

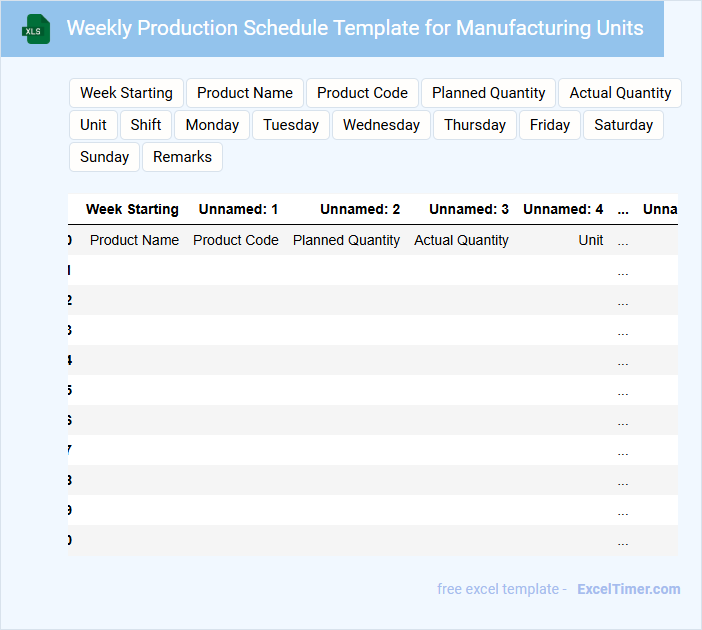

Weekly Production Schedule Template for Manufacturing Units

A Weekly Production Schedule Template for manufacturing units is a structured document outlining the planned production activities for the week. It typically includes details such as product types, quantity targets, assigned work shifts, and resource allocation. Ensuring accuracy and timely updates in this template is crucial for optimizing workflow and minimizing bottlenecks.

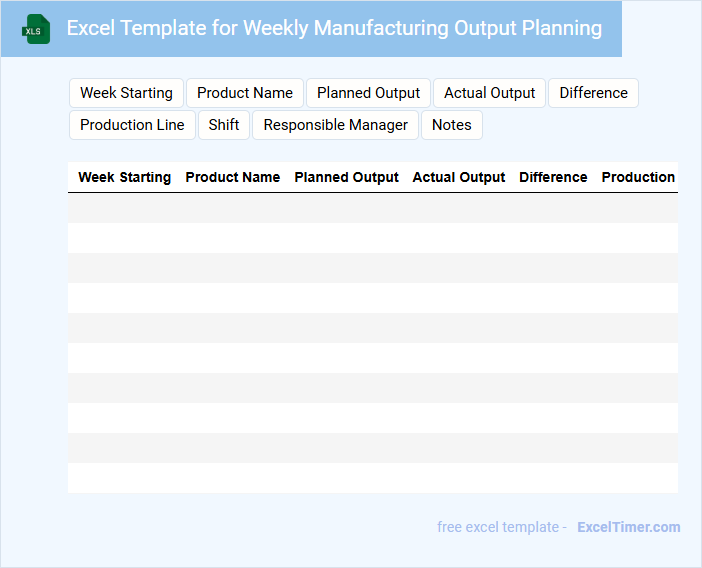

Excel Template for Weekly Manufacturing Output Planning

An Excel Template for Weekly Manufacturing Output Planning typically contains structured data to track production schedules, resource allocation, and output targets efficiently.

- Production Schedule: Detailed timelines for daily and weekly manufacturing activities to ensure timely completion.

- Resource Allocation: Clear assignment of machinery, labor, and materials to optimize workflow.

- Output Targets: Defined goals for units produced to monitor performance against planned objectives.

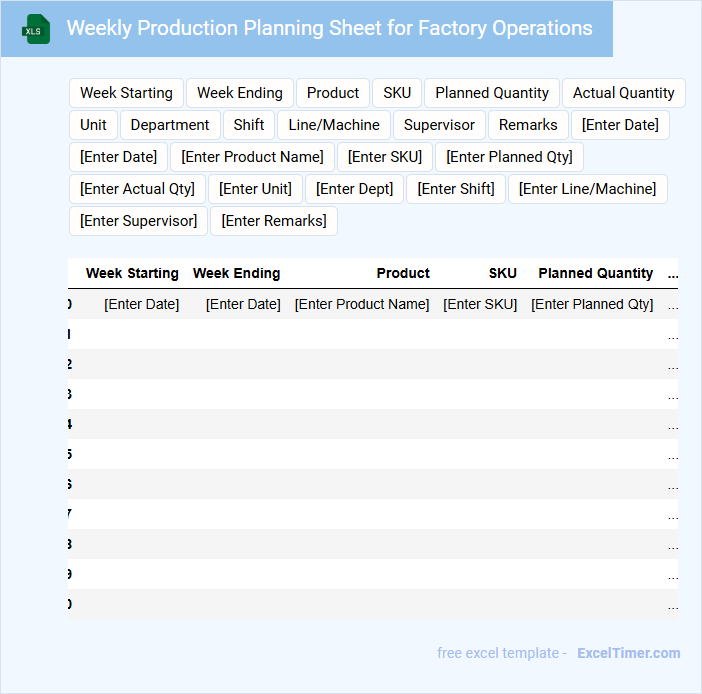

Weekly Production Planning Sheet for Factory Operations

A Weekly Production Planning Sheet for Factory Operations is a document used to organize and schedule manufacturing activities over a week, ensuring efficient resource allocation and meeting production targets. It typically contains detailed information on production goals, materials required, and workforce assignments.

- Include accurate timelines for each production phase to avoid delays.

- Track inventory levels to ensure necessary materials are available.

- Assign clear responsibilities to each team to enhance accountability.

Manufacturing Units Weekly Production Tracking in Excel

What information is typically included in a Manufacturing Units Weekly Production Tracking document in Excel? This type of document usually contains data on daily production quantities, machine utilization, downtime, and quality control metrics to monitor manufacturing efficiency. It helps managers track performance trends, identify bottlenecks, and ensure that production targets are met consistently.

What is an important consideration when creating a Manufacturing Units Weekly Production Tracking sheet? Ensuring accurate and timely data entry is crucial, as it directly impacts the reliability of production analysis and decision-making. Additionally, incorporating automated calculations and visual dashboards can enhance clarity and facilitate quick assessment of key performance indicators.

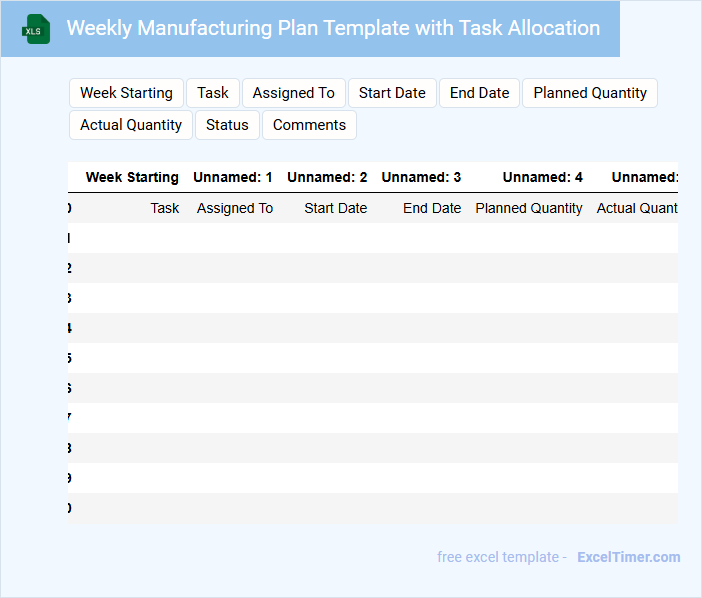

Weekly Manufacturing Plan Template with Task Allocation

A Weekly Manufacturing Plan Template typically contains detailed schedules, task assignments, resource allocations, and production targets. It helps streamline manufacturing processes and ensures timely completion of tasks.

Including a clear Task Allocation section is crucial for assigning responsibilities and avoiding confusion on the shop floor. It can improve team coordination and enhance overall productivity.

Consider adding milestones and regular review points to monitor progress and address any issues promptly.

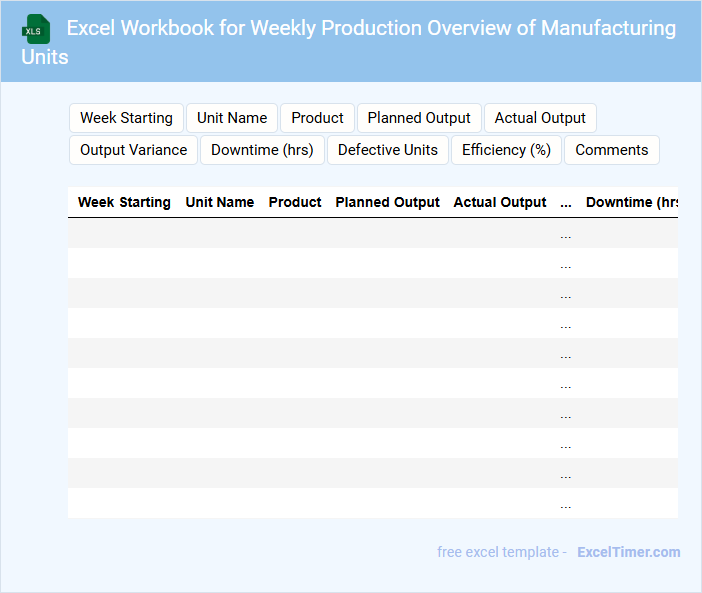

Excel Workbook for Weekly Production Overview of Manufacturing Units

An Excel Workbook for Weekly Production Overview consolidates vital data from various manufacturing units to monitor output efficiently. It typically contains production quantities, work shifts, and downtime records for each unit. This document aids in identifying trends and addressing production bottlenecks promptly.

Important elements to include are clear headers, consistent units of measurement, and automated formulas for calculating totals and averages. Incorporating visual aids like charts and color-coded status indicators enhances data comprehension. Ensuring data accuracy and timely updates is critical for reliable performance tracking.

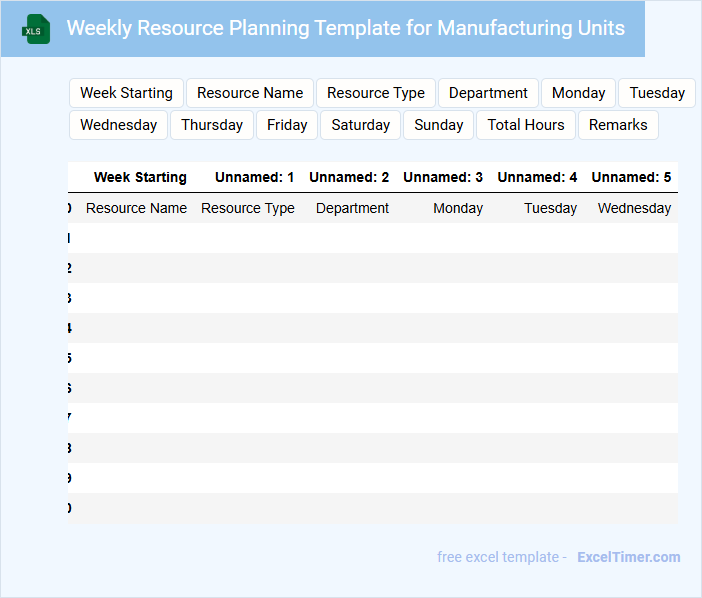

Weekly Resource Planning Template for Manufacturing Units

Weekly Resource Planning Templates for manufacturing units are essential tools for organizing and allocating the resources needed to meet production goals efficiently. These documents typically contain schedules, inventory levels, and workforce assignments to ensure optimal operation throughout the week. To maximize effectiveness, it is important to regularly update the template with real-time data and adjust plans based on production demands and equipment availability.

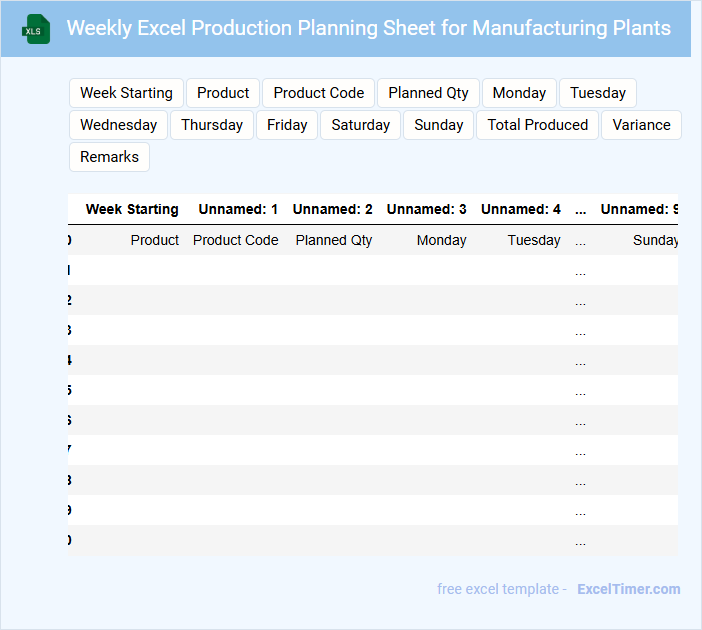

Weekly Excel Production Planning Sheet for Manufacturing Plants

A Weekly Excel Production Planning Sheet for Manufacturing Plants is typically a document used to schedule and track production activities over a one-week period. It helps ensure efficient resource allocation and timely product output.

- Include clear daily production targets to monitor progress.

- Incorporate columns for raw material availability and machine status.

- Allow space for notes on delays or quality control issues.

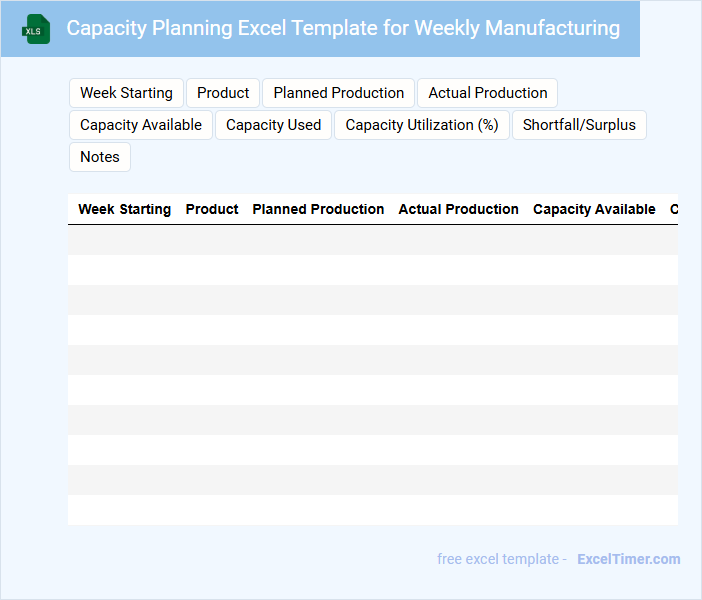

Capacity Planning Excel Template for Weekly Manufacturing

This document typically contains detailed weekly data and projections to efficiently manage manufacturing capacity and resources.

- Production schedules that outline planned output for each week to align with demand forecasts.

- Resource allocation including labor, machines, and materials needed to meet production goals.

- Capacity utilization rates to identify bottlenecks and optimize manufacturing efficiency.

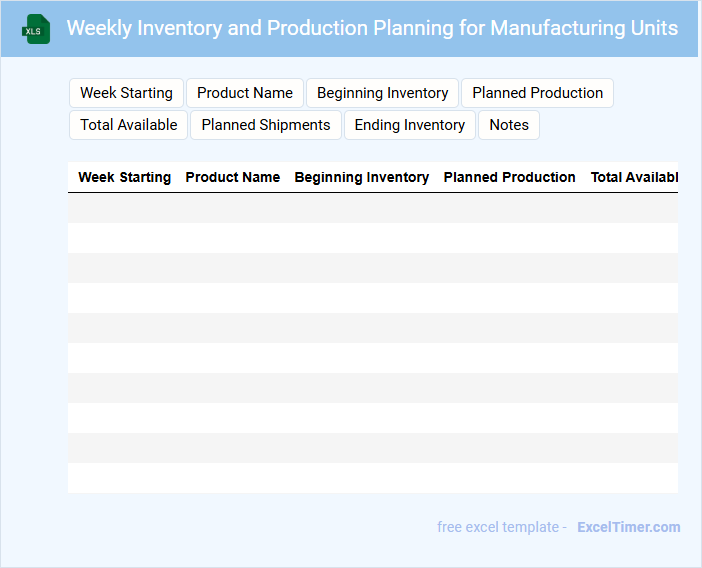

Weekly Inventory and Production Planning for Manufacturing Units

The Weekly Inventory and Production Planning document is essential for managing stock levels and scheduling manufacturing processes efficiently. It typically contains detailed information about raw materials, current inventory status, production targets, and deadlines. A crucial aspect is the alignment between inventory availability and production capacity to avoid delays and excess stock.

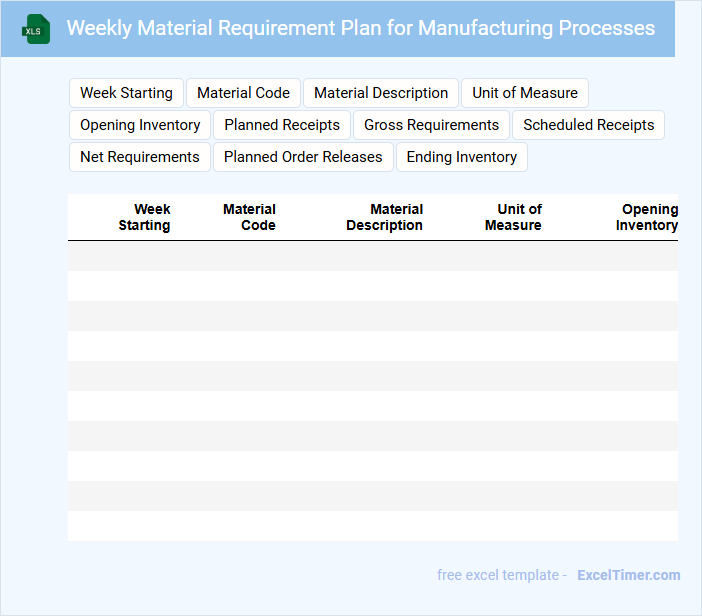

Weekly Material Requirement Plan for Manufacturing Processes

A Weekly Material Requirement Plan for manufacturing processes is a critical document that outlines the materials needed for production on a weekly basis. It typically includes details on inventory levels, order schedules, and delivery timelines to ensure the seamless flow of resources. This plan helps in minimizing production delays and optimizing supply chain efficiency.

Important considerations for an effective Weekly Material Requirement Plan include accurate demand forecasting, timely supplier coordination, and regular updates to reflect changes in production schedules. Integrating real-time data and cross-department communication can significantly enhance the plan's reliability. Prioritizing critical materials and monitoring stock levels closely prevents shortages and excess inventory.

Excel Template with Weekly Production Goals for Factory Units

An Excel Template with Weekly Production Goals is typically used to track and manage the output targets of various factory units. It includes fields for inputting planned versus actual production data, helping to monitor performance and identify bottlenecks.

This document is essential for maintaining operational efficiency and aligning team efforts with corporate objectives. Ensuring the template contains clear goal metrics, easy-to-read charts, and automated calculations is highly recommended for effective use.

Weekly Production Progress Tracker for Manufacturing Units

What information is typically contained in a Weekly Production Progress Tracker for Manufacturing Units? This document usually includes key metrics such as daily and weekly production volumes, efficiency rates, downtime incidents, and quality control results. It helps managers monitor performance trends, identify bottlenecks, and ensures that production targets are met consistently.

What are important considerations when using this tracker? Consistent and accurate data entry is essential to maintain reliability, along with clear visualizations like charts or graphs to easily interpret progress. Additionally, setting actionable goals and regularly reviewing the tracker with the team promotes continuous improvement in manufacturing operations.

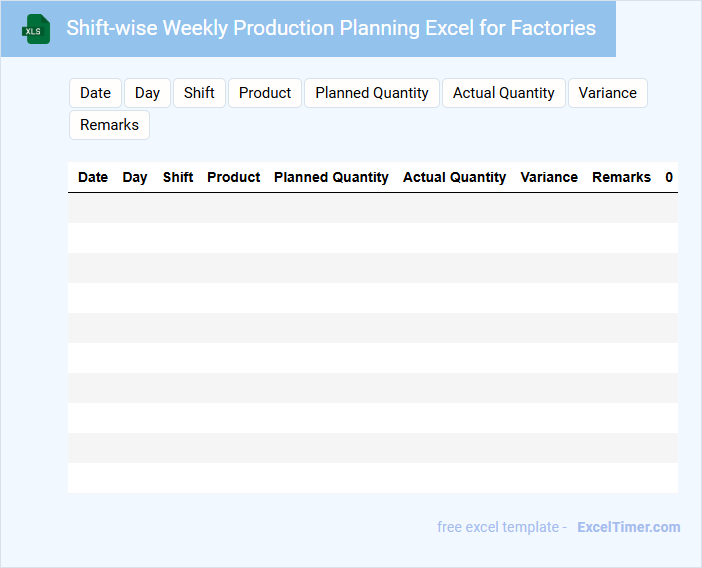

Shift-wise Weekly Production Planning Excel for Factories

What information is typically included in a Shift-wise Weekly Production Planning Excel for Factories? This document usually contains detailed schedules of production tasks distributed per shift across the week, enabling efficient resource allocation and workflow management. It also tracks output targets and actual performance, helping factories maintain optimal productivity and meet deadlines.

Why is accuracy and real-time update crucial in a Shift-wise Weekly Production Planning Excel? Accurate data entry ensures reliable planning and prevents production bottlenecks, while timely updates allow adjustments for unexpected changes such as workforce availability or machine maintenance. Incorporating clear shift-wise breakdowns and contingency plans within the document enhances operational flexibility and decision-making.

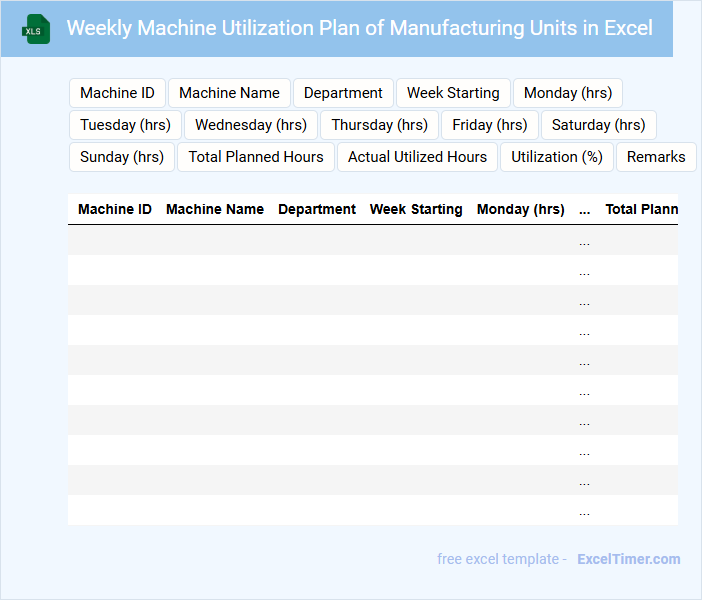

Weekly Machine Utilization Plan of Manufacturing Units in Excel

The Weekly Machine Utilization Plan of manufacturing units in Excel typically contains detailed schedules of machine usage, including operational hours, downtime, and maintenance activities. It helps in tracking the efficiency and productivity of each machine across the manufacturing floor. This document ensures optimal allocation of resources and timely identification of bottlenecks.

Important aspects to consider in this plan include clear machine identification, accurate time logging to avoid overlaps, and inclusion of maintenance periods to prevent unexpected breakdowns. Incorporating a color-coded system for different shifts or machine statuses can further enhance readability. Regular updates and review meetings are essential to adapt the plan based on real-time production demands.

What are the key data inputs required for effective weekly production planning in manufacturing units?

Key data inputs for effective weekly production planning in manufacturing units include current inventory levels, production capacity, and demand forecasts. Accurate machine availability and labor schedules ensure realistic planning. Incorporating raw material supply status minimizes production delays.

How does the Excel document calculate and allocate available production capacity across multiple product lines?

The Excel document calculates available production capacity by aggregating machine hours, labor availability, and shift durations for each manufacturing unit. It allocates capacity across multiple product lines using demand forecasts, priority weights, and production cycle times embedded in dynamic formulas. Real-time adjustments occur through capacity utilization rates and inventory buffer levels to optimize weekly production schedules.

What methods are used in Excel to track and update inventory levels versus production targets on a weekly basis?

Excel uses pivot tables and conditional formatting to track weekly inventory levels and compare them against production targets. Your data is organized with formulas like SUMIFS and COUNTIF to update stock quantities dynamically. Data validation ensures accurate input while charts visualize discrepancies between inventory and production goals.

How does the document highlight shortages, excess capacity, or potential bottlenecks for proactive planning?

The Weekly Production Planning Excel document uses color-coded cells and dynamic formulas to highlight shortages, excess capacity, and potential bottlenecks across manufacturing units. Your dashboard provides real-time alerts and detailed analytics to enable proactive adjustments in resource allocation and scheduling. This ensures optimal workflow efficiency and minimizes downtime risks.

What tools or formulas are incorporated in the Excel sheet to adjust schedules in response to changes in demand or supply constraints?

The Excel sheet for Weekly Production Planning integrates tools such as dynamic pivot tables, conditional formatting, and data validation to monitor and adjust schedules effectively. Formulas like VLOOKUP, INDEX-MATCH, and IFERROR enable real-time updates based on changing demand or supply constraints. Advanced functions like Solver and Goal Seek optimize production allocation by balancing resource availability and delivery deadlines.