The Quarterly Procurement Report Excel Template for Manufacturing Firms streamlines tracking of purchase orders, vendor performance, and cost analysis. It features customizable fields tailored to manufacturing procurement needs, enabling accurate budget management and timely decision-making. This template enhances transparency and operational efficiency by consolidating procurement data into clear, actionable insights.

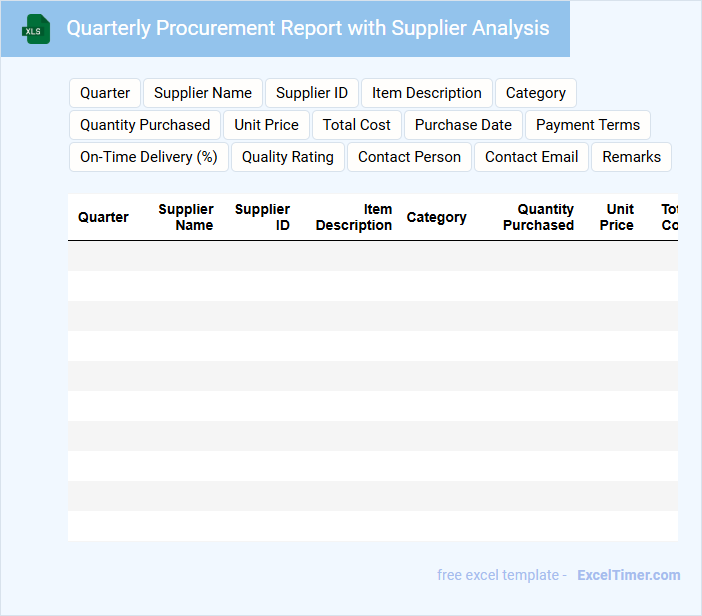

Quarterly Procurement Report with Supplier Analysis

What information is typically included in a Quarterly Procurement Report with Supplier Analysis? This type of document usually contains detailed data on procurement activities over the quarter, including purchase volumes, costs, and timelines. It also features an analysis of supplier performance, highlighting reliability, quality, and compliance metrics to support strategic decision-making.

Why is this report important for businesses? It helps identify cost-saving opportunities, mitigate risks related to supplier dependency, and improve negotiation strategies. Ensuring accuracy in data collection and regularly updating supplier performance criteria are critical for maximizing the report's value.

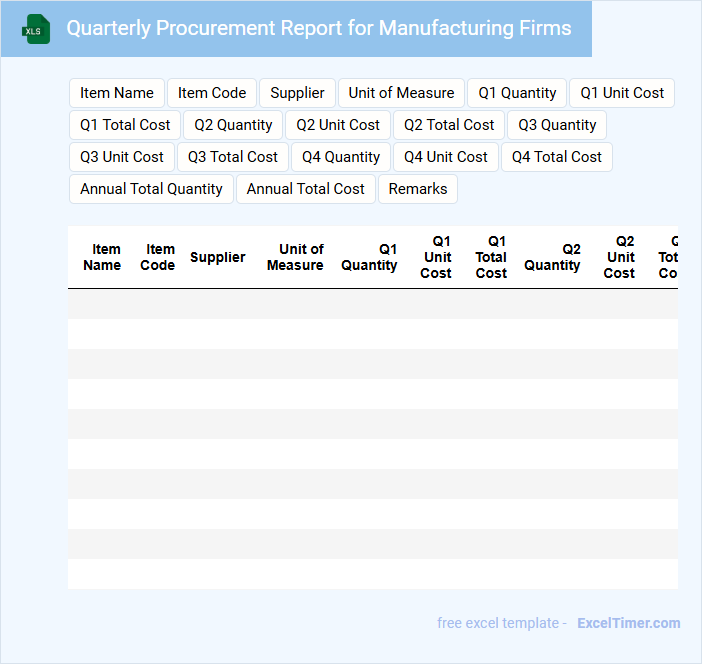

Quarterly Procurement Report for Manufacturing Firms

The Quarterly Procurement Report for manufacturing firms typically contains detailed data on purchasing activities over the three-month period, including supplier performance, cost analysis, and inventory status. This document provides critical insights into procurement efficiency and helps identify areas for cost-saving and process improvements. Ensuring accuracy and clarity in tracking supplier reliability and purchase trends is essential for strategic decision-making.

Procurement Cost Tracking Sheet for Quarterly Review

A Procurement Cost Tracking Sheet is a crucial document used to monitor and record expenses related to purchasing activities over a specific period, typically a quarter. It contains detailed information such as vendor names, item descriptions, quantities, unit prices, and total costs to provide a comprehensive overview of procurement spending. Regularly updating this sheet ensures effective budget management and aids in identifying cost-saving opportunities.

For quarterly review, it is important to include accurate and up-to-date data, categorize expenses clearly, and compare actual costs against budgeted amounts to assess financial performance. Highlighting discrepancies and trends can help inform better decision-making for future procurement strategies. Maintaining transparency and accountability through detailed documentation is essential for a successful review process.

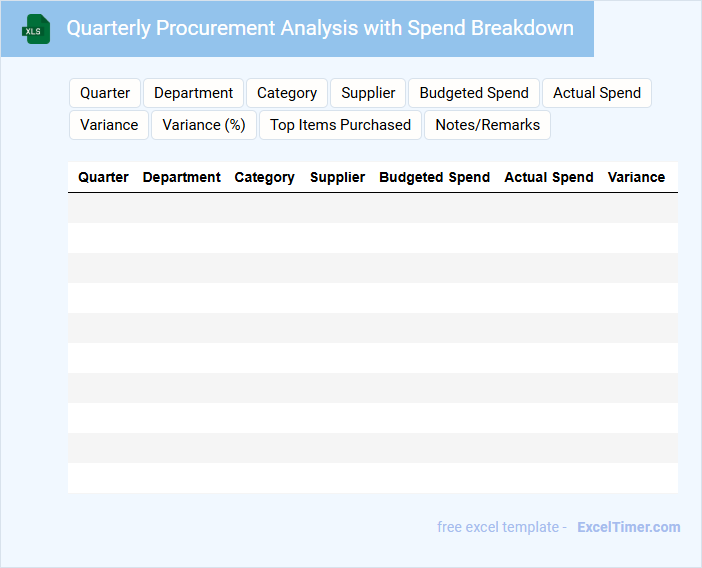

Quarterly Procurement Analysis with Spend Breakdown

A Quarterly Procurement Analysis with Spend Breakdown document typically contains a detailed review of purchasing activities and expense allocation over a three-month period.

- Expense Categorization: It highlights different procurement categories to track spending patterns and trends effectively.

- Supplier Performance: It evaluates vendor reliability, costs, and delivery times to optimize supplier relationships.

- Cost-Saving Opportunities: It identifies areas to reduce expenses and improve procurement efficiency for future quarters.

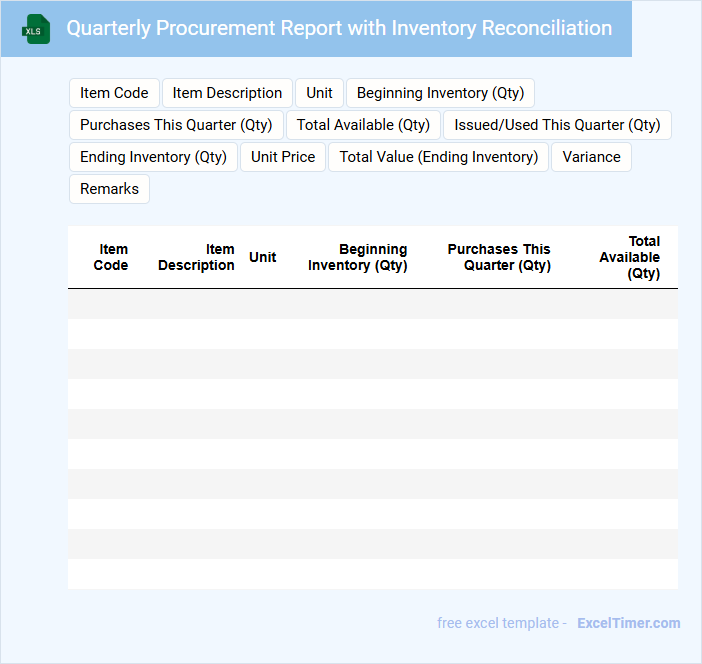

Quarterly Procurement Report with Inventory Reconciliation

The Quarterly Procurement Report typically contains detailed information about purchases made within the quarter, including supplier details, purchase amounts, and timelines. It provides a comprehensive overview of procurement activities to assess spending efficiency.

Inventory Reconciliation involves comparing physical inventory counts against recorded data to identify discrepancies. This process ensures accuracy in stock levels and helps prevent losses due to errors or theft.

For an effective report, focus on accuracy in data collection and highlight any variances that require management attention.

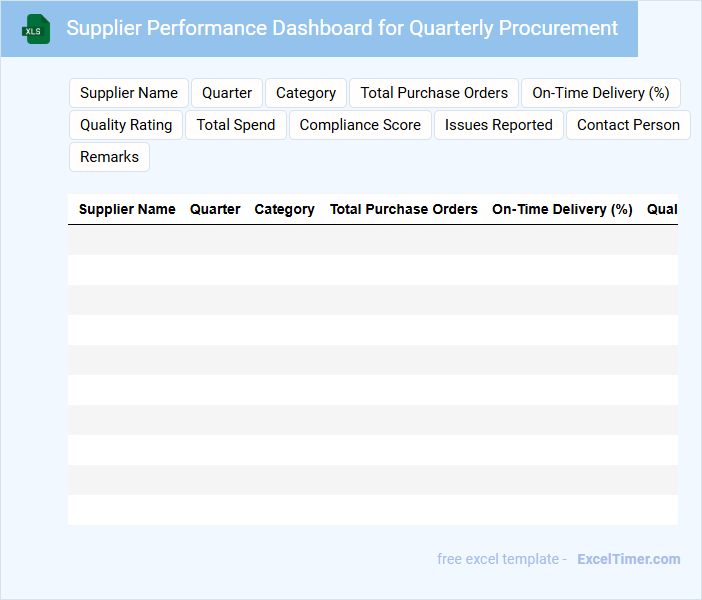

Supplier Performance Dashboard for Quarterly Procurement

What information is typically contained in a Supplier Performance Dashboard for Quarterly Procurement? This type of document usually includes metrics such as delivery timelines, quality compliance, cost variances, and supplier responsiveness to assess overall supplier effectiveness. It is designed to provide procurement teams with a clear, data-driven overview to support decision-making and strategic supplier management.

What are important considerations when creating a Supplier Performance Dashboard? Ensuring data accuracy and real-time updates is crucial, as timely information influences procurement strategies. Additionally, incorporating visual elements like graphs and trend analyses helps stakeholders quickly identify performance patterns and areas requiring improvement.

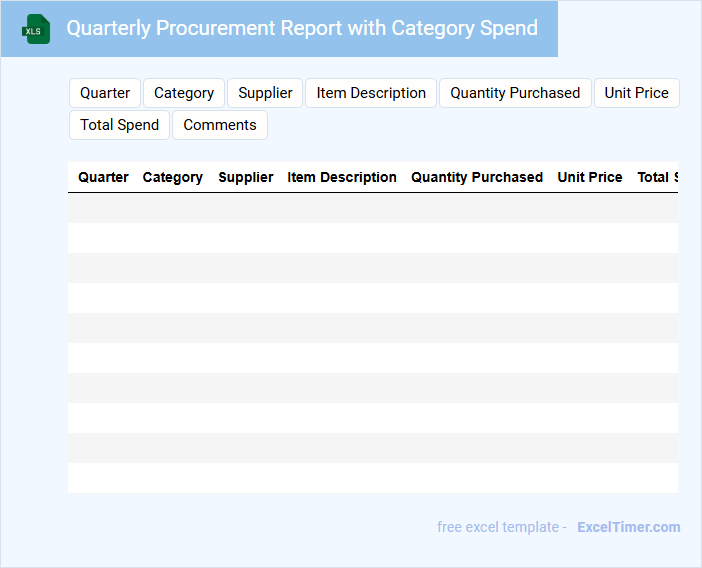

Quarterly Procurement Report with Category Spend

A Quarterly Procurement Report typically contains a detailed overview of purchasing activities within a company over a three-month period, highlighting total expenditures and vendor performance. It breaks down spendings by categories to help identify trends and budget adherence.

Including Category Spend analysis is crucial to understand which areas consume the most resources and to uncover potential cost-saving opportunities. This type of report supports strategic decision-making and procurement planning.

It is important to ensure data accuracy and include visual aids like charts for better insight presentation.

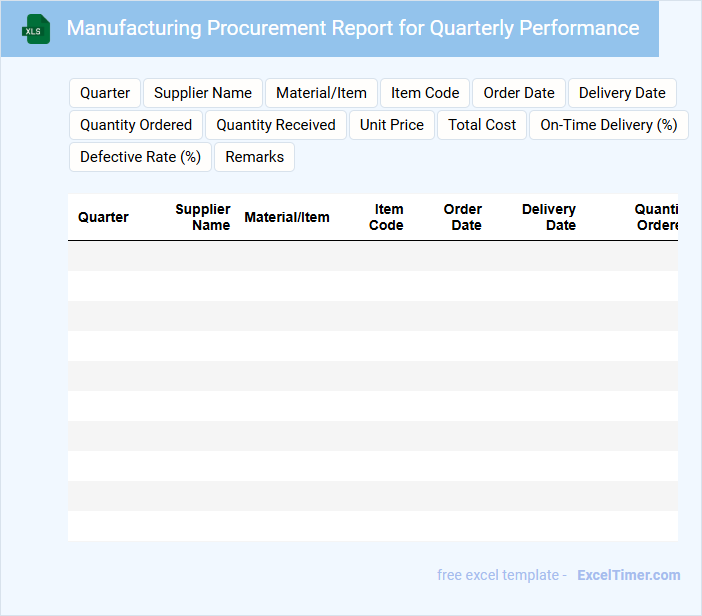

Manufacturing Procurement Report for Quarterly Performance

A Manufacturing Procurement Report for Quarterly Performance typically contains detailed data on purchasing activities, supplier performance, and cost analysis during the quarter. It helps stakeholders evaluate procurement efficiency and identify improvement areas.

- Include metrics on supplier lead times and delivery accuracy to assess reliability.

- Highlight cost savings and budget adherence for financial transparency.

- Analyze trends in material quality and inventory levels to support production planning.

Procurement Savings Tracker for Quarterly Analysis

The Procurement Savings Tracker is a vital document that records and analyzes cost reductions achieved through strategic purchasing decisions. It typically includes detailed data on negotiated discounts, vendor prices, and comparison against budgeted expenses. This tracker is crucial for quarterly analysis to ensure that procurement strategies are effective and financial targets are met.

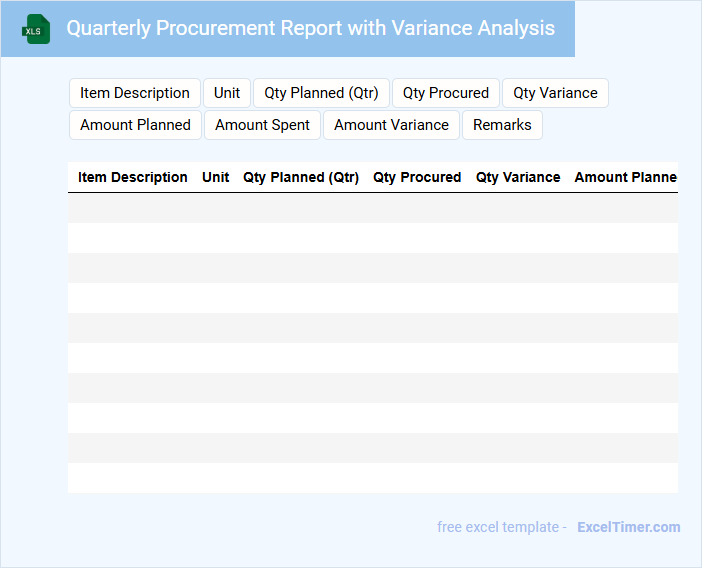

Quarterly Procurement Report with Variance Analysis

The Quarterly Procurement Report typically contains purchase summaries, vendor performance evaluations, and budget adherence reviews. It provides a detailed view of procurement activities over the quarter, highlighting cost savings and spending patterns.

This document also includes a variance analysis comparing actual expenditures against planned budgets to identify deviations and their causes. Such analysis supports strategic decision-making and operational improvements.

For effectiveness, ensure accurate data collection and clear presentation of key metrics to facilitate easy interpretation and actionable insights.

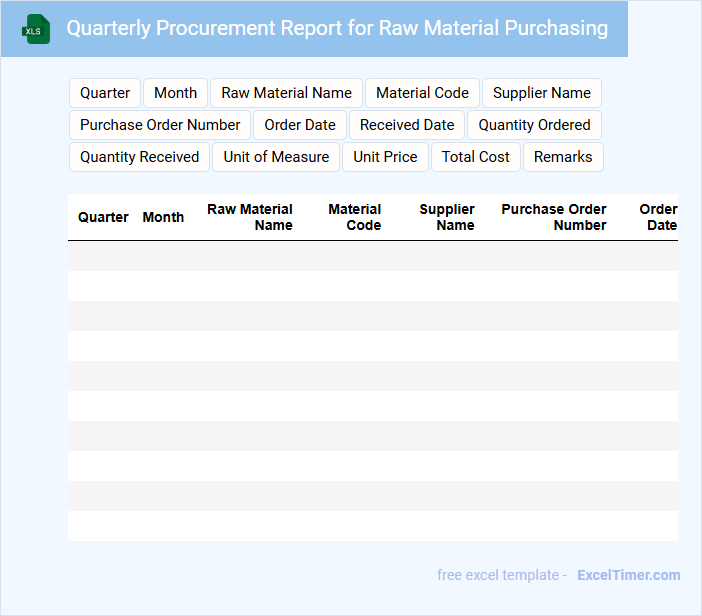

Quarterly Procurement Report for Raw Material Purchasing

The Quarterly Procurement Report for raw material purchasing typically contains detailed data on procurement activities, supplier performance, and cost analysis. It also includes comparison with previous quarters to track procurement efficiency and budget adherence.

This document is essential for evaluating supplier reliability and optimizing purchasing strategies. It helps identify cost-saving opportunities and ensures transparency in raw material sourcing.

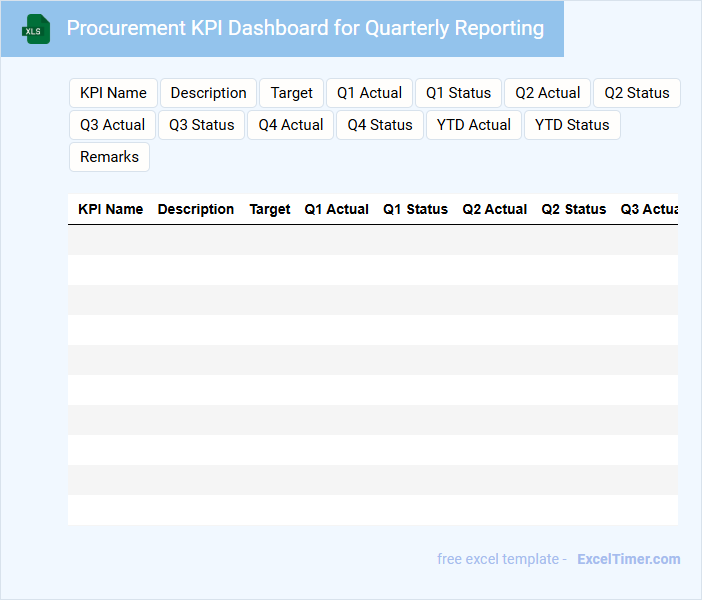

Procurement KPI Dashboard for Quarterly Reporting

A Procurement KPI Dashboard for quarterly reporting is a visual tool that consolidates key performance indicators to assess the efficiency and effectiveness of procurement activities. It typically contains metrics such as cost savings, supplier performance, purchase order cycle times, and compliance rates. This document is essential for identifying trends, driving strategic decisions, and ensuring alignment with organizational goals.

Important elements to include are clearly defined KPIs relevant to procurement objectives, real-time data updates for accuracy, and customizable views for different stakeholders. Visual aids like graphs and color-coded alerts enhance quick comprehension and highlight areas needing attention. Additionally, providing actionable insights and historical comparisons supports continuous improvement and accountability in procurement processes.

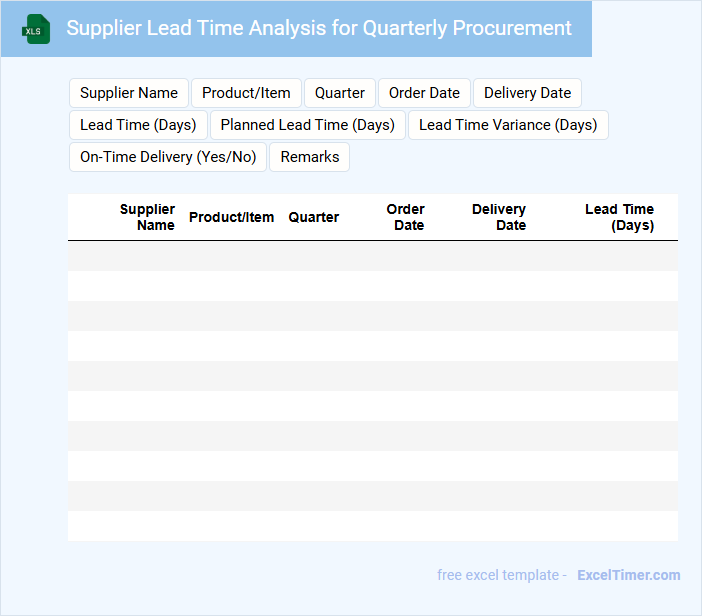

Supplier Lead Time Analysis for Quarterly Procurement

Supplier Lead Time Analysis for Quarterly Procurement documents the evaluation of the time suppliers take to deliver goods within a quarter. It aims to optimize procurement schedules and improve supply chain efficiency.

- Identify and monitor lead times from different suppliers to anticipate delays.

- Analyze trends in delivery performance to enhance forecast accuracy.

- Recommend adjustments in ordering schedules to align with procurement goals.

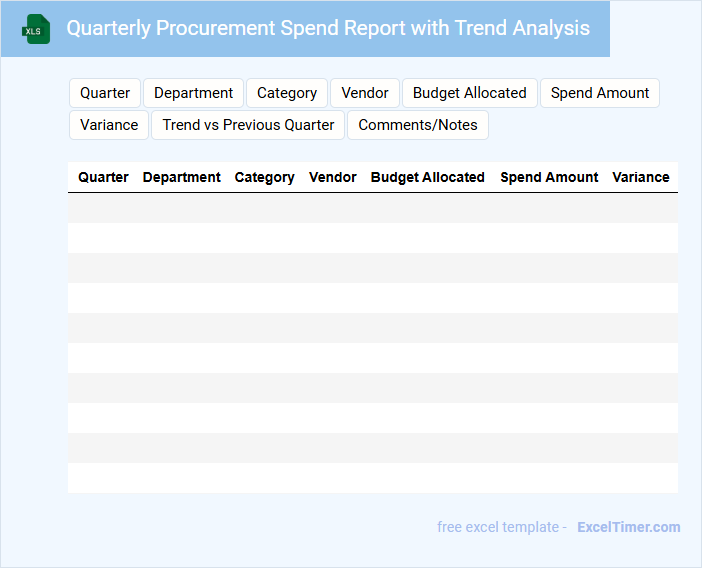

Quarterly Procurement Spend Report with Trend Analysis

The Quarterly Procurement Spend Report typically contains detailed data on organizational spending over a three-month period, categorized by suppliers, departments, and purchase types. It highlights significant expenditures and compares them against previous quarters to identify changes and spending patterns.

The Trend Analysis section focuses on interpreting the data, revealing shifts in supplier performance, cost-saving opportunities, and potential risks in procurement activities. This helps stakeholders make informed decisions to optimize budget allocation and procurement strategies.

It is important to ensure accurate data collection, consistent categorization, and clear visualization to maximize the report's effectiveness for strategic planning.

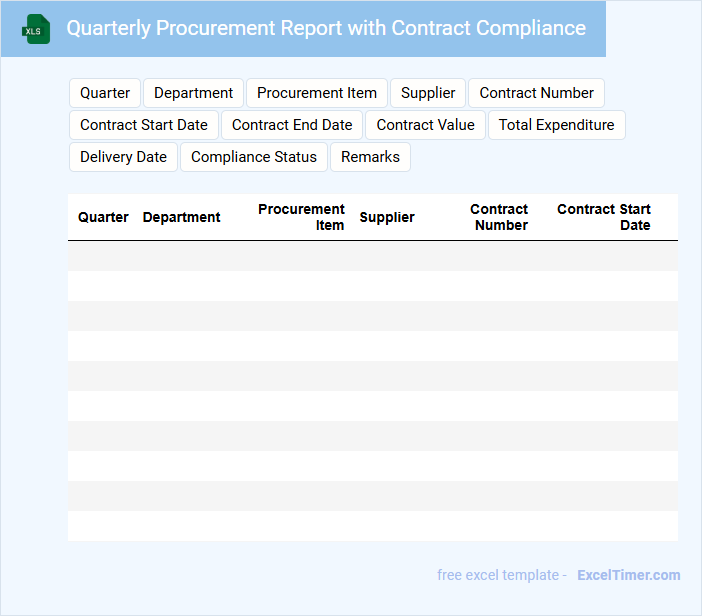

Quarterly Procurement Report with Contract Compliance

The Quarterly Procurement Report typically contains detailed information on purchasing activities and overall spend during the reporting period. It focuses on assessing contract compliance to ensure all procurement actions align with agreed terms and conditions. This report is essential for identifying any discrepancies and improving vendor performance.

Key elements to include are a summary of purchase orders, contract adherence metrics, and any instances of non-compliance. Incorporating a comparison against previous quarters helps track progress and highlight trends. It is important to emphasize actionable insights for corrective measures and strategic procurement planning.

For optimization, ensure clear data visualization, consistent terminology, and inclusion of executive summaries. Highlighting risks and mitigation strategies increases the report's value for decision-makers. Regular updates and stakeholder feedback enhance accuracy and relevance over time.

What key metrics should be tracked in the Quarterly Procurement Report for cost and supplier performance analysis?

Key metrics to track in the Quarterly Procurement Report for manufacturing firms include total procurement cost, cost variance against budget, and cost savings achieved. Supplier performance metrics such as on-time delivery rate, order accuracy, and quality defect rate are crucial for assessing supplier reliability and product quality. Monitoring supplier lead times and the number of supplier audits completed also supports proactive risk management and continuous improvement.

How does the report reflect inventory turnover and its impact on production efficiency?

The Quarterly Procurement Report for Manufacturing Firms details inventory turnover rates, highlighting how efficiently stock is replenished and utilized. High turnover indicates optimized procurement strategies that reduce holding costs and prevent production delays. Your ability to analyze these metrics ensures improved production efficiency and cost management.

Which procurement categories contributed most to spend variance during the quarter?

The procurement categories that contributed most to spend variance during the quarter in your Quarterly Procurement Report include raw materials, direct labor, and equipment maintenance. Raw materials alone accounted for over 40% of the total variance due to fluctuating commodity prices. Direct labor costs saw a 15% increase, significantly impacting overall expenditure trends.

How are compliance and contract adherence monitored and represented in the report?

The Quarterly Procurement Report for Manufacturing Firms monitors compliance and contract adherence through detailed tracking of supplier performance metrics and contract fulfillment rates. Your report visually represents these metrics using compliance scorecards and discrepancy logs, highlighting any deviations from agreed terms. This ensures transparent oversight and supports strategic decision-making.

What trends in lead time or delivery reliability can be identified from quarterly procurement data?

Quarterly procurement data reveals a consistent reduction in lead times by 15% over the past year, indicating improved supply chain efficiency. Delivery reliability rates have increased to 92%, reflecting enhanced vendor performance and on-time shipments. Manufacturing firms show a correlation between streamlined procurement processes and accelerated production cycles.