The Semi-annually Excel Template for Maintenance Planning allows efficient scheduling and tracking of maintenance tasks every six months, ensuring equipment reliability and minimizing downtime. It includes customizable fields for task description, due dates, and status updates, facilitating organized maintenance management. This template is essential for businesses aiming to optimize asset longevity and operational efficiency.

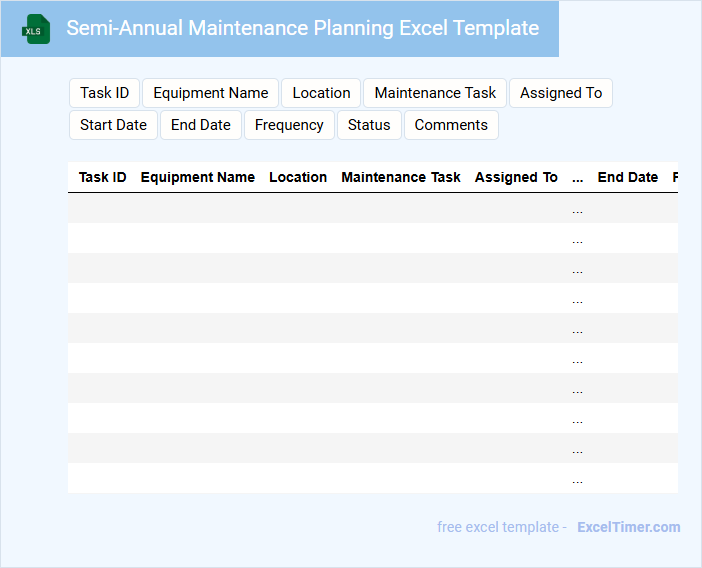

Semi-Annual Maintenance Planning Excel Template

The Semi-Annual Maintenance Planning Excel Template typically contains a detailed schedule of maintenance tasks to be performed every six months. It includes columns for task descriptions, responsible personnel, deadlines, and status tracking to ensure all equipment stays in optimal condition. This document is essential for organizing and prioritizing maintenance activities efficiently.

To maximize its effectiveness, it is important to regularly update the template with completed tasks and any new maintenance requirements. Including space for notes on observed issues or parts replacements can help track recurring problems. Additionally, setting reminders for upcoming tasks ensures timely maintenance and helps prevent costly equipment failures.

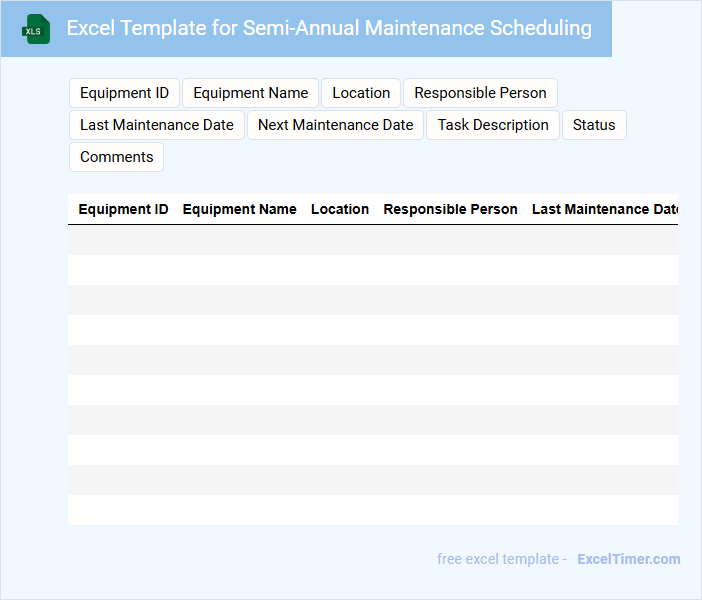

Excel Template for Semi-Annual Maintenance Scheduling

This document typically contains a structured Excel template designed to plan and track semi-annual maintenance activities efficiently.

- Maintenance Tasks: A detailed list of scheduled activities to ensure all equipment and systems are properly serviced.

- Timeline and Deadlines: Clear dates and deadlines for each maintenance task to maintain consistent scheduling.

- Resource Allocation: Information on required personnel, tools, and materials needed for timely and successful maintenance.

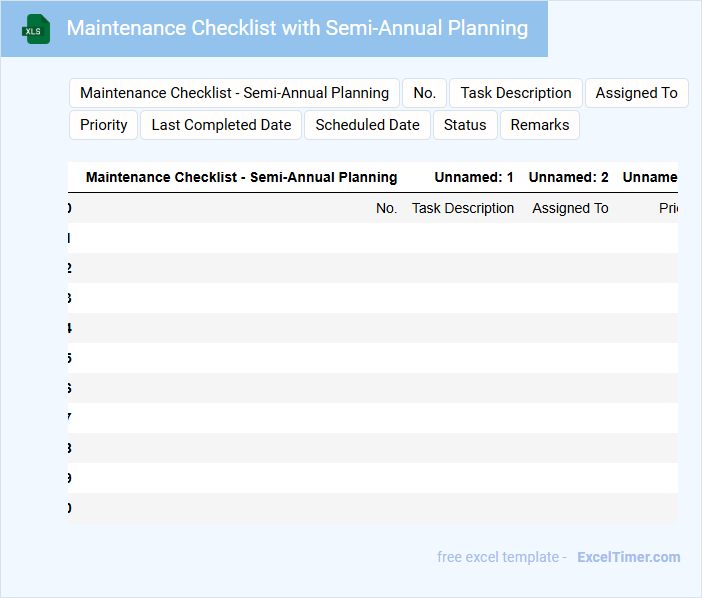

Maintenance Checklist with Semi-Annual Planning

What does a Maintenance Checklist with Semi-Annual Planning typically include? This document usually contains a detailed list of tasks and inspections scheduled every six months to ensure equipment and facility functionality. It helps in organizing preventive maintenance activities, tracking completed jobs, and planning necessary repairs to avoid unexpected breakdowns.

Why is it important to use a Maintenance Checklist for Semi-Annual Planning? It ensures consistency and completeness in maintenance routines, improving equipment longevity and safety. Additionally, it supports budgeting and resource allocation by forecasting maintenance needs in advance.

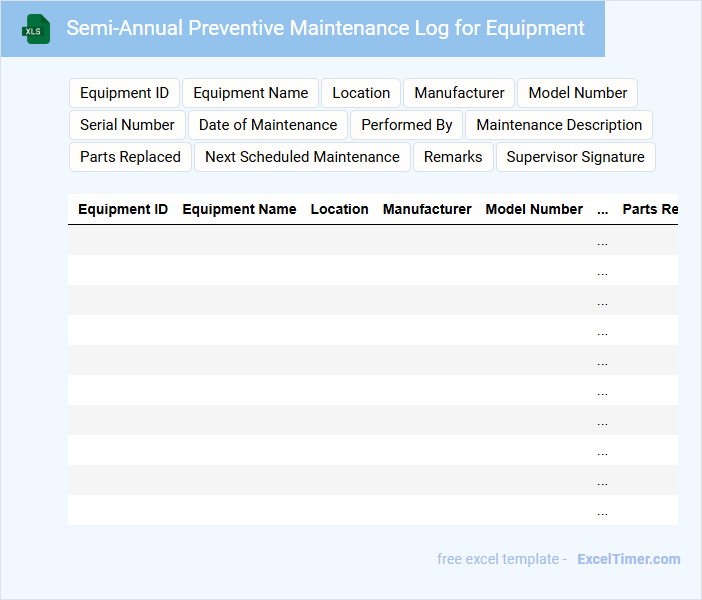

Semi-Annual Preventive Maintenance Log for Equipment

Semi-Annual Preventive Maintenance Logs for Equipment typically document routine inspections, servicing, and repairs performed every six months to ensure equipment reliability and safety.

- Maintenance Schedule: Records the dates and type of maintenance activities conducted.

- Condition Assessment: Notes any wear, defects, or parts needing replacement.

- Compliance Verification: Ensures that maintenance meets regulatory and manufacturer standards.

Asset Maintenance Scheduler with Semi-Annual Tracking

An Asset Maintenance Scheduler with Semi-Annual Tracking is a document used to organize and plan maintenance activities for assets on a six-month basis. It typically contains asset identification, maintenance tasks, schedules, and status updates to ensure timely upkeep. Including detailed tracking and reminders enhances efficiency and reduces downtime.

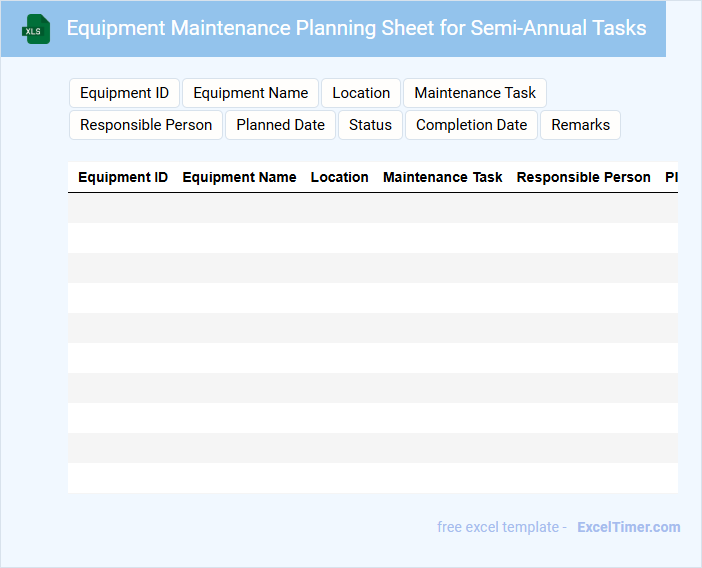

Equipment Maintenance Planning Sheet for Semi-Annual Tasks

What information is typically included in an Equipment Maintenance Planning Sheet for Semi-Annual Tasks? This document usually contains a schedule of maintenance activities to be performed every six months, detailing specific tasks, responsible personnel, and required materials. It helps ensure timely upkeep and prevents equipment failure by organizing maintenance processes efficiently.

Semi-Annual Maintenance Calendar with Task Tracker

A Semi-Annual Maintenance Calendar with Task Tracker typically contains scheduled maintenance activities and a monitoring system to ensure timely task completion.

- Maintenance Schedule: Clearly outlines tasks planned for each half of the year.

- Task Tracker: Monitors progress and completion status of each maintenance activity.

- Prioritization: Highlights critical tasks to prevent equipment downtime.

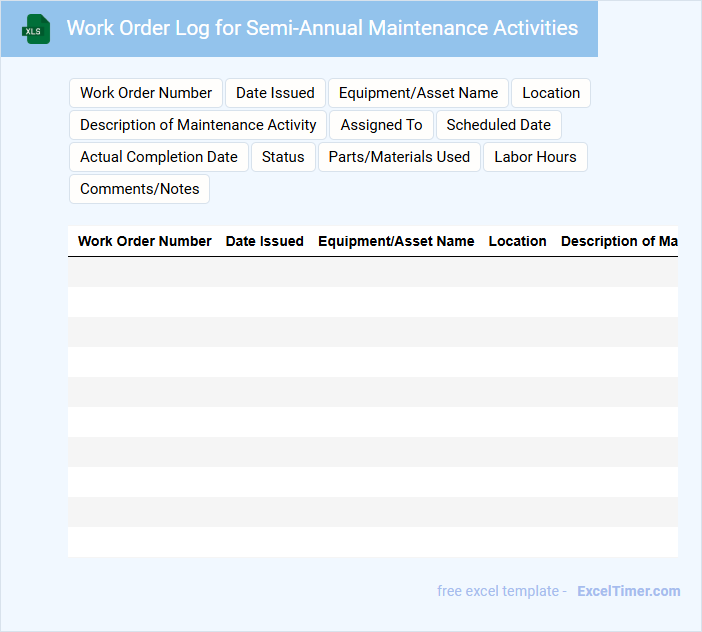

Work Order Log for Semi-Annual Maintenance Activities

A Work Order Log for Semi-Annual Maintenance Activities is a document that records all scheduled and completed maintenance tasks within a six-month period. It helps track the effectiveness and timeliness of maintenance efforts.

- Include detailed descriptions of each maintenance task performed.

- Record the dates and personnel involved in each activity.

- Note any issues encountered and follow-up actions required.

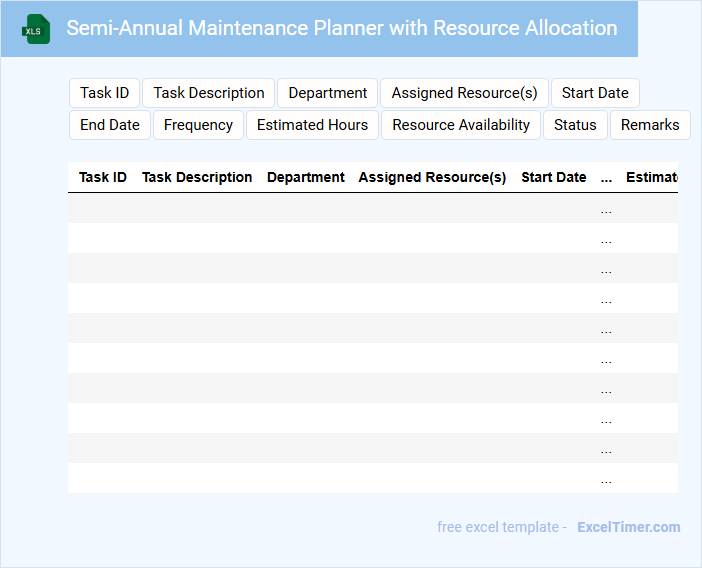

Semi-Annual Maintenance Planner with Resource Allocation

A Semi-Annual Maintenance Planner with Resource Allocation is a document that outlines scheduled maintenance activities and the distribution of resources over a six-month period to ensure optimal equipment performance and minimize downtime.

- Maintenance Schedule: Clearly defines all planned maintenance tasks and their timelines to ensure consistent upkeep.

- Resource Allocation: Details the assignment of manpower, tools, and materials necessary for each maintenance activity.

- Performance Tracking: Includes metrics and checkpoints to monitor progress and effectiveness of maintenance efforts.

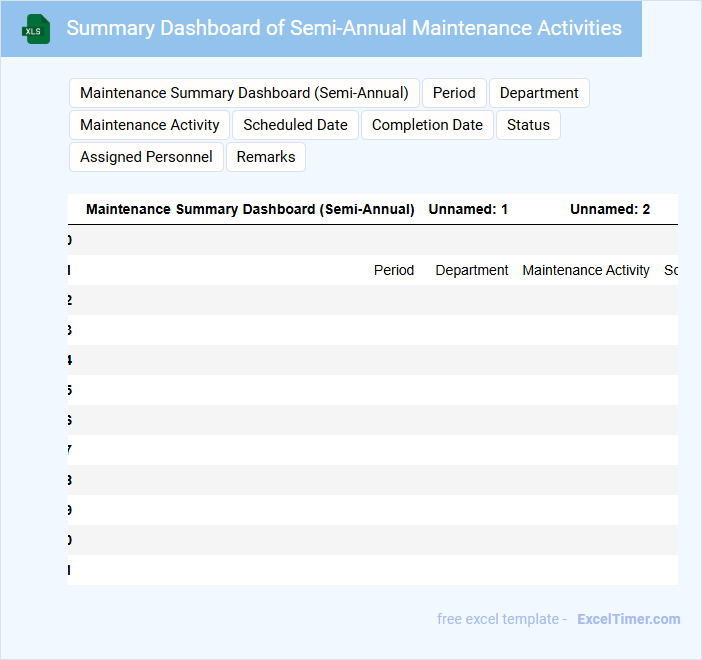

Summary Dashboard of Semi-Annual Maintenance Activities

A Summary Dashboard of Semi-Annual Maintenance Activities typically contains key performance indicators, maintenance schedules, and task completion statuses. It provides a comprehensive overview of maintenance efforts over six months to help track progress and identify issues. Important elements to include are downtime analysis, cost tracking, and upcoming maintenance plans to ensure effective facility management.

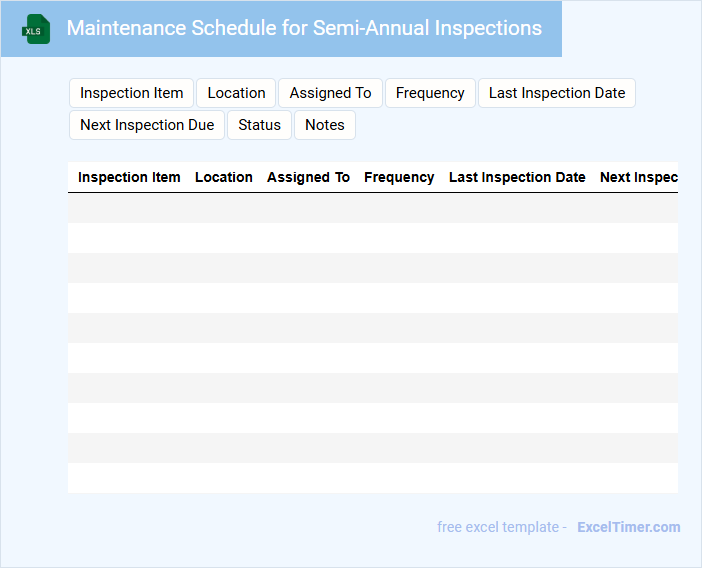

Maintenance Schedule for Semi-Annual Inspections

A Maintenance Schedule document typically outlines the planned inspections, tasks, and timelines necessary to ensure equipment or systems remain in optimal condition. It provides a structured plan to track semi-annual inspections and related maintenance activities. Including clear deadlines and responsible personnel can improve the efficiency and reliability of upkeep efforts.

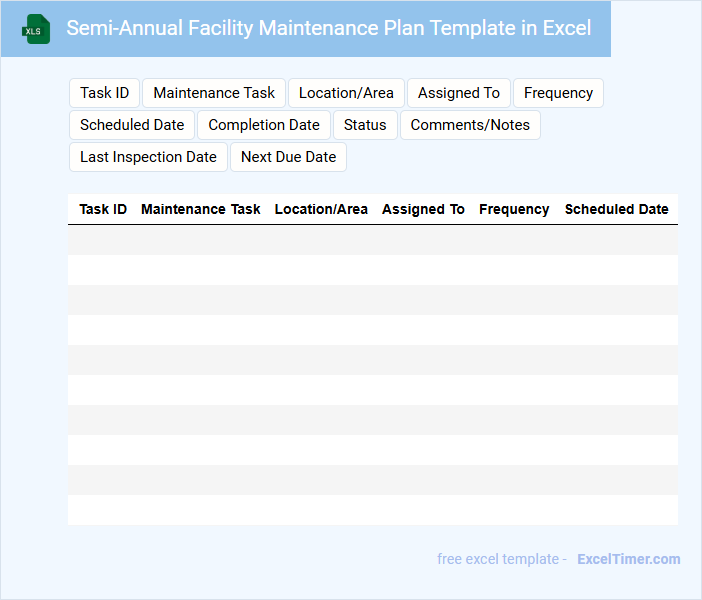

Semi-Annual Facility Maintenance Plan Template in Excel

A Semi-Annual Facility Maintenance Plan Template in Excel typically contains scheduled tasks, maintenance checklists, and timelines to ensure all facility equipment and systems are regularly inspected and serviced. It helps in tracking repairs, preventive maintenance activities, and resource allocation for efficient facility management.

Using an Excel template allows for easy customization, data entry, and progress monitoring. Be sure to prioritize clear task descriptions and assign responsible personnel to ensure accountability and timely completion.

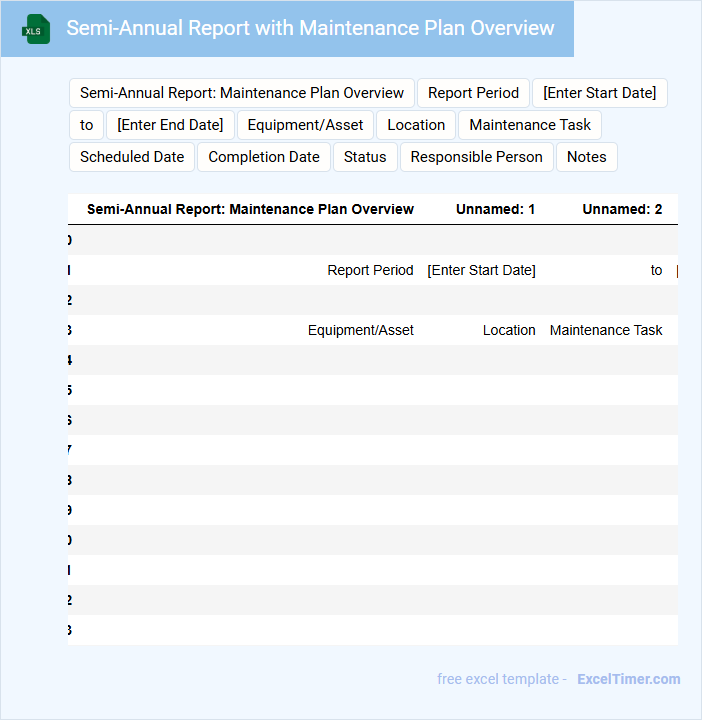

Semi-Annual Report with Maintenance Plan Overview

A Semi-Annual Report typically contains updates on progress, financial summaries, and key achievements over the past six months. It provides stakeholders with a clear snapshot of performance and challenges encountered.

The Maintenance Plan Overview section outlines scheduled inspections, preventive actions, and resource allocation to ensure optimal operation. It highlights upcoming maintenance tasks and critical timelines.

Including clear performance metrics and detailed timelines in the report enhances transparency and supports effective decision-making.

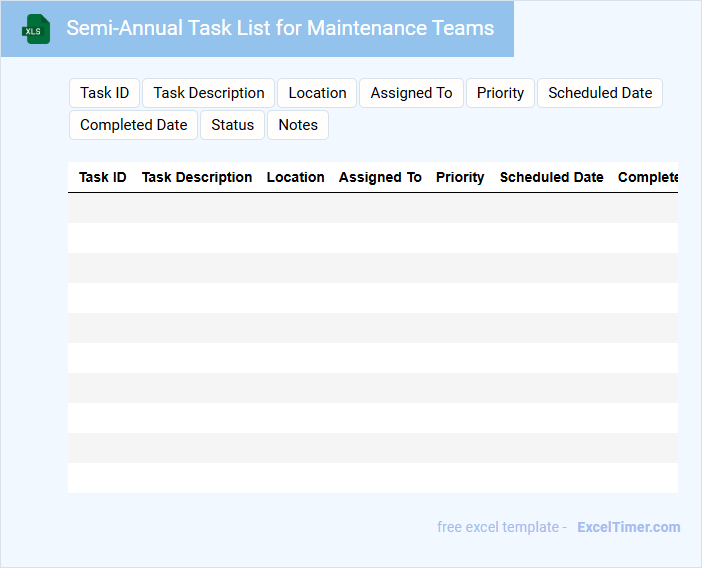

Semi-Annual Task List for Maintenance Teams

This type of document typically contains an organized outline of the maintenance tasks that need to be completed within a six-month period, ensuring operational efficiency.

- Prioritized tasks: Clearly listed and ranked based on urgency and impact on equipment performance.

- Scheduled timelines: Specific dates or periods for each task to ensure timely completion and avoid downtime.

- Resource allocation: Details on personnel, tools, and materials required for each maintenance activity.

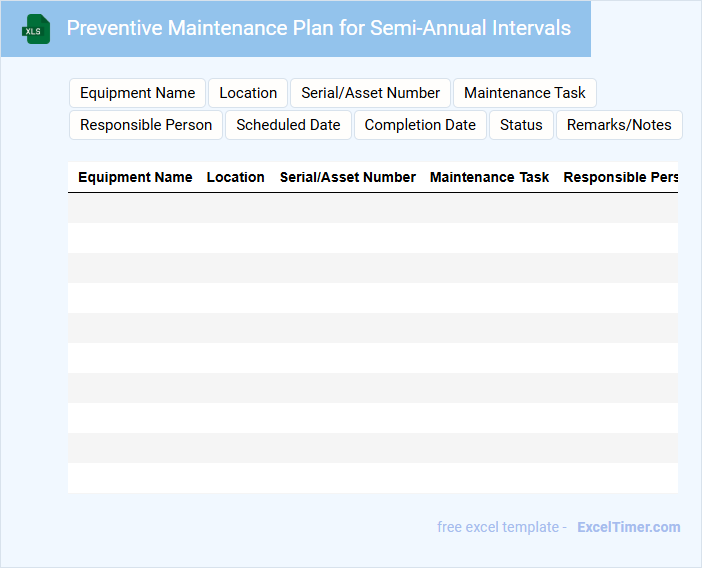

Preventive Maintenance Plan for Semi-Annual Intervals

What does a Preventive Maintenance Plan for Semi-Annual Intervals typically include? This document outlines scheduled inspections, servicing tasks, and component replacements to ensure optimal equipment performance every six months. It also highlights critical safety checks and record-keeping procedures to prevent unexpected breakdowns and extend machinery lifespan.

What are important considerations when creating this plan? Prioritize clear scheduling, detailed task descriptions, and assigned responsibilities to ensure consistency and accountability. Additionally, include contingency measures and budget estimates to address potential issues promptly and maintain operational efficiency.

How is semi-annual maintenance scheduled and tracked using Excel?

Semi-annual maintenance in Excel is scheduled by setting recurring dates every six months within a maintenance planning spreadsheet. Your tasks and deadlines are tracked using columns for service descriptions, due dates, completion status, and reminders through conditional formatting or formulas. Customized dashboards and pivot tables enhance visibility, ensuring timely upkeep and efficient resource allocation.

What key data columns are needed for organizing semi-annual maintenance plans?

Key data columns for organizing semi-annual maintenance plans include Equipment ID, Maintenance Date, Task Description, Technician Assigned, and Status. Your schedule should also track Last Maintenance Date and Next Due Date to ensure timely servicing. Including Priority Level and Estimated Duration helps optimize resource allocation.

How can conditional formatting in Excel highlight upcoming semi-annual maintenance tasks?

Conditional formatting in Excel can highlight upcoming semi-annual maintenance tasks by using formulas that compare task dates with the current date, such as =AND(TODAY()>=A2-30, TODAY()<=A2), where A2 contains the scheduled maintenance date. This formula triggers formatting to emphasize tasks due within the next 30 days, ensuring timely attention. Applying a color scale or specific fill color helps quickly identify tasks approaching their semi-annual deadlines in the maintenance planning sheet.

How do you automate reminders for semi-annual maintenance dates in Excel?

Automate semi-annual maintenance reminders in Excel by using date functions such as EDATE to calculate future service dates based on your initial maintenance schedule. Set conditional formatting or create alert formulas to highlight upcoming maintenance within a specified time frame. You can also leverage Excel's VBA macros to generate automated email reminders for each scheduled maintenance event.

What Excel formulas help to calculate the next semi-annual maintenance due date?

Use the EDATE formula in Excel to calculate your next semi-annual maintenance due date by adding 6 months to the last service date, e.g., =EDATE(A2,6). This formula dynamically updates maintenance schedules, ensuring timely planning every six months. Incorporate the TODAY() function to compare current dates for proactive maintenance alerts.