![]()

The Semi-annually Excel Template for Maintenance Tracking streamlines scheduling and monitoring biannual maintenance tasks efficiently. It includes customizable fields for equipment details, maintenance dates, and status updates to ensure timely upkeep. This template enhances asset longevity by providing clear, organized tracking and reducing the risk of missed maintenance.

Semi-Annual Maintenance Log with Tracking Features

What information is typically included in a Semi-Annual Maintenance Log with Tracking Features? This type of document usually contains detailed records of maintenance activities performed every six months, including dates, tasks completed, and personnel involved. It also incorporates tracking features to monitor progress and ensure timely completion of maintenance schedules for effective equipment management.

Why is it important to include tracking features in a Semi-Annual Maintenance Log? Tracking features help in identifying patterns of wear and tear, predicting potential failures, and improving the efficiency of maintenance operations. Including reminders and status updates ensures maintenance tasks are not overlooked and resources are allocated appropriately.

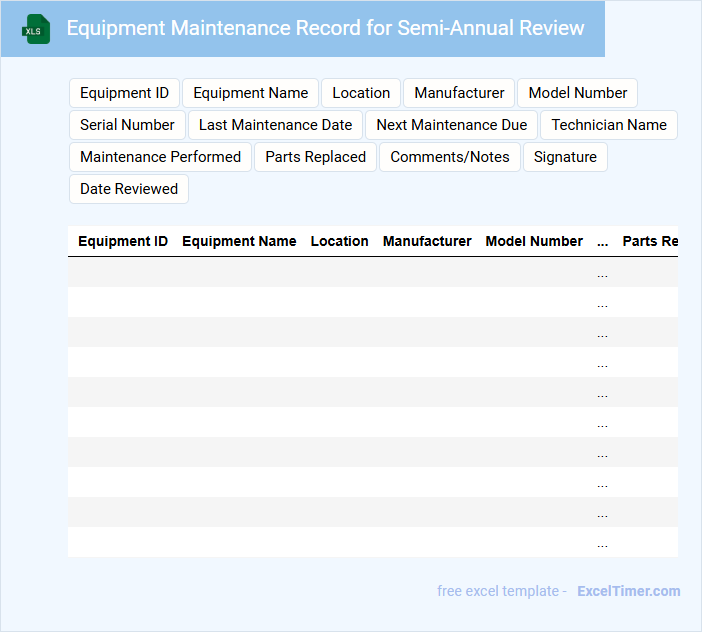

Equipment Maintenance Record for Semi-Annual Review

What information is typically included in an Equipment Maintenance Record for a Semi-Annual Review? This document usually contains detailed logs of all maintenance activities performed on equipment over the past six months, including dates, types of service, and personnel involved. It helps ensure equipment reliability, compliance with safety standards, and timely identification of potential issues.

What is an important consideration when maintaining this record? Consistent and accurate data entry is essential for effective tracking and auditing during reviews, along with including clear notes on any repairs or part replacements. Proper documentation supports informed decision-making for future maintenance schedules and budget planning.

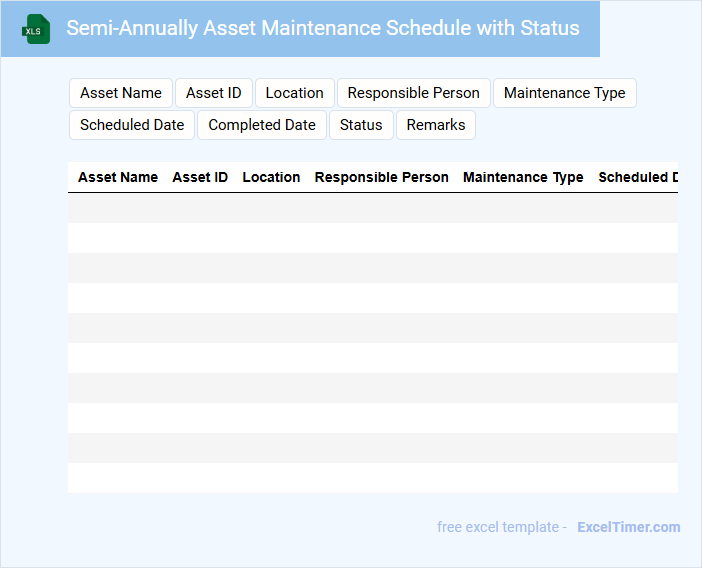

Semi-Annually Asset Maintenance Schedule with Status

The Semi-Annually Asset Maintenance Schedule is a structured document that outlines the planned maintenance activities for assets every six months. It typically includes the asset details, maintenance tasks, assigned personnel, and timelines to ensure operational efficiency.

The Status section provides real-time updates on the progress and condition of each maintenance activity, highlighting completed, pending, or overdue tasks. This helps in proactive management and decision-making for asset reliability.

It is important to regularly update this document and ensure accuracy to maintain asset performance and prevent unexpected breakdowns.

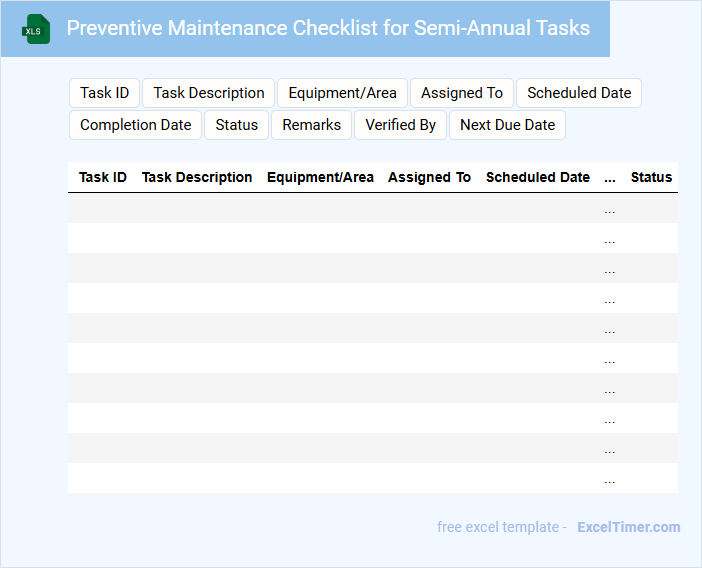

Preventive Maintenance Checklist for Semi-Annual Tasks

A Preventive Maintenance Checklist for Semi-Annual Tasks typically contains detailed steps and schedules to ensure regular upkeep of equipment or systems. It helps in identifying potential issues before they become major problems, improving reliability and safety. Key elements include task descriptions, required tools, responsible personnel, and completion dates.

Maintenance Tracker with Semi-Annual Frequency

A Maintenance Tracker with Semi-Annual Frequency is a document used to record and monitor maintenance activities that occur twice a year. It typically includes details such as dates, tasks performed, and responsible personnel. Keeping this document updated ensures timely upkeep of equipment and facilities.

This type of tracker helps organizations avoid unexpected breakdowns by scheduling routine checks and repairs every six months. It enhances asset longevity and operational efficiency. To optimize its use, include clear deadlines and assign accountability for each maintenance task.

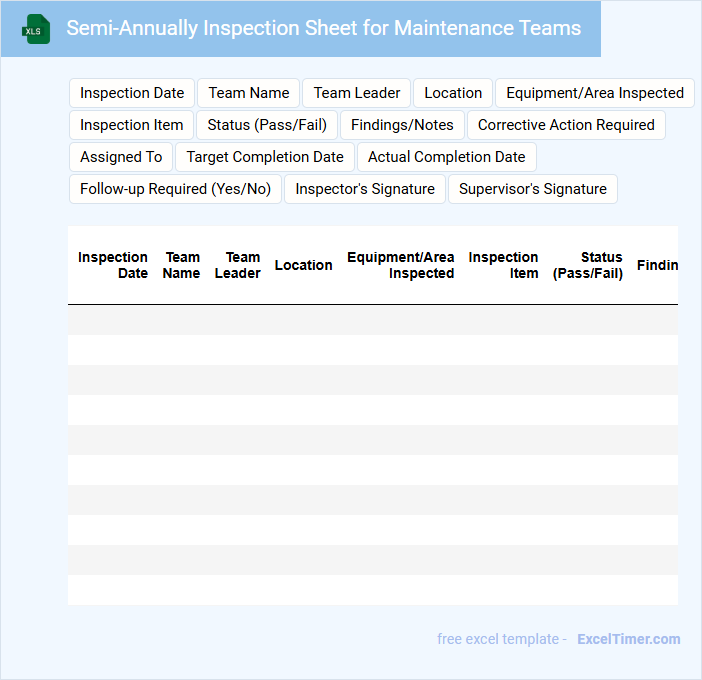

Semi-Annually Inspection Sheet for Maintenance Teams

The Semi-Annually Inspection Sheet is a crucial document used by maintenance teams to systematically assess equipment and facilities every six months. It typically contains detailed checklists, status reports, and recommendations for repairs or replacements.

Including sections for identifying potential safety hazards and tracking completed maintenance tasks ensures thorough inspections. A well-structured inspection sheet helps maintain operational efficiency and prolongs the lifecycle of assets.

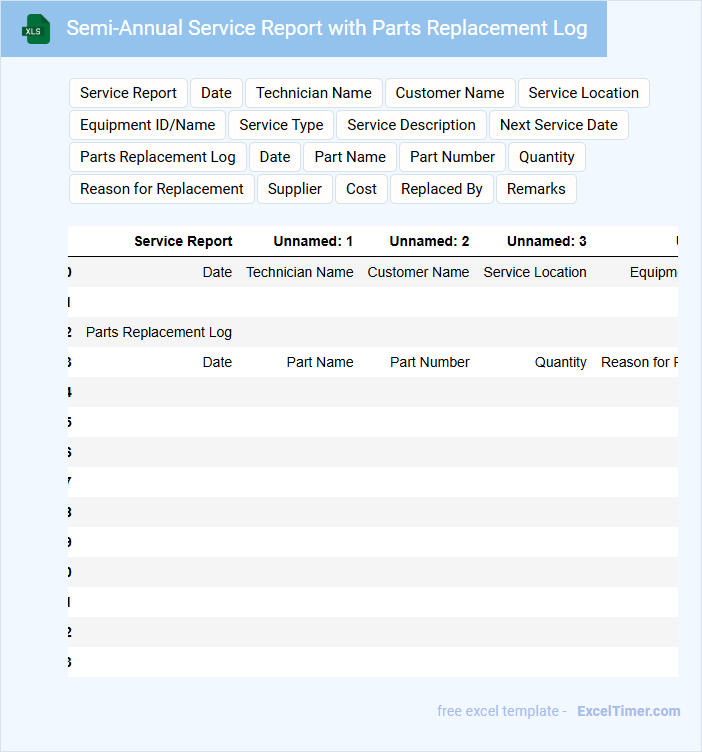

Semi-Annual Service Report with Parts Replacement Log

What information is typically included in a Semi-Annual Service Report with Parts Replacement Log? This document generally contains a detailed summary of maintenance activities performed over six months, including inspections, service tasks, and any parts that were replaced to ensure equipment functionality. It helps track the condition of machinery and highlights critical repairs or part changes to maintain operational efficiency and prevent future breakdowns.

What key elements should be emphasized when preparing this report? It is important to include accurate dates, part numbers, and descriptions of replacements, alongside the technician's observations and recommendations. Clear documentation supports accountability, aids in warranty claims, and assists in scheduling future maintenance effectively.

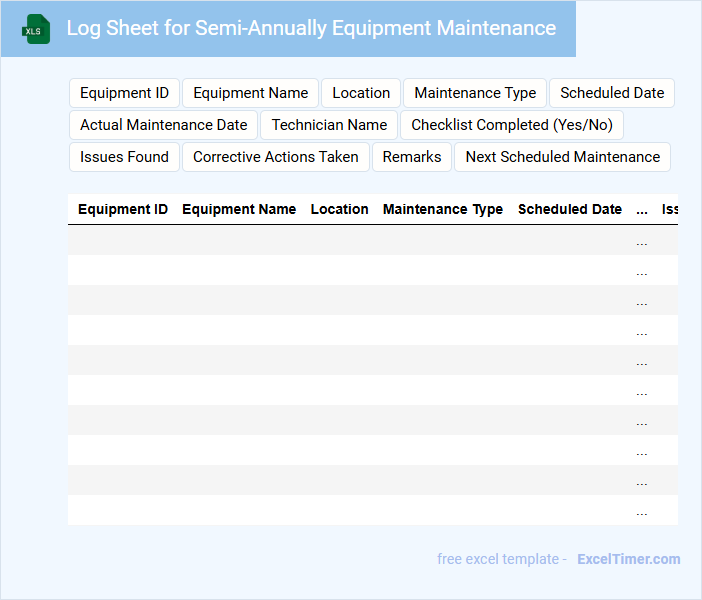

Log Sheet for Semi-Annually Equipment Maintenance

What information is typically recorded in a Log Sheet for Semi-Annually Equipment Maintenance? This document usually contains details such as the equipment identification, maintenance dates, procedures performed, and the technician's observations or recommendations. It helps ensure regular upkeep, identifies potential issues early, and maintains equipment reliability over time.

What important elements should be included to enhance its effectiveness? Including clear fields for the date, technician's name, type of maintenance performed, parts replaced, and any follow-up actions is essential. Additionally, notes on equipment condition and a signature section improve accountability and traceability for future reference.

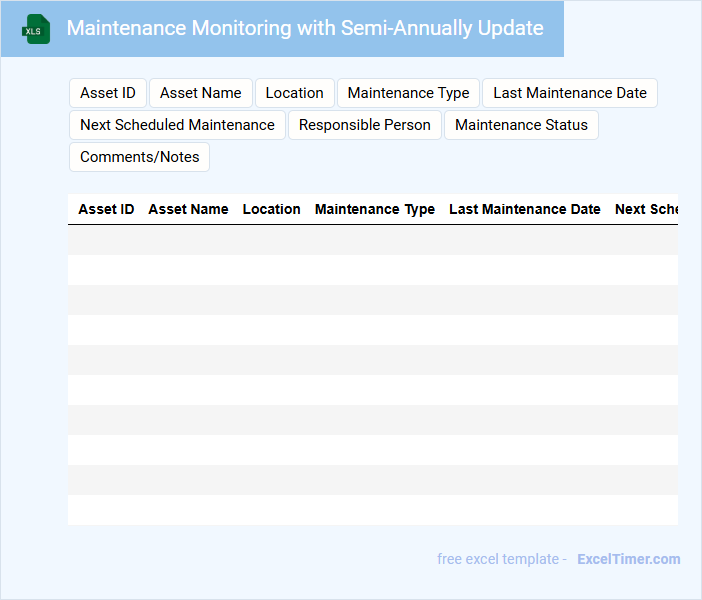

Maintenance Monitoring with Semi-Annually Update

Maintenance Monitoring with Semi-Annually Update documents the regular assessment and upkeep activities conducted every six months to ensure optimal performance.

- Timely Inspections: Schedule and record biannual checks to identify potential issues early.

- Performance Data: Include detailed logs of system function and maintenance actions taken.

- Compliance Tracking: Ensure all updates meet regulatory standards and document any deviations.

Semi-Annually Facility Maintenance Tracking Template

What information is typically included in a Semi-Annually Facility Maintenance Tracking Template? This type of document usually contains scheduled maintenance tasks, dates, assigned personnel, and status updates to ensure facilities are properly maintained every six months. It helps organizations track completed work and identify upcoming maintenance needs efficiently.

What important details should be included in this template? Key elements include a clear timeline, specific maintenance activities, equipment or areas involved, responsible team members, and a section for notes or issues discovered during inspections. Including these details ensures effective monitoring and timely maintenance interventions.

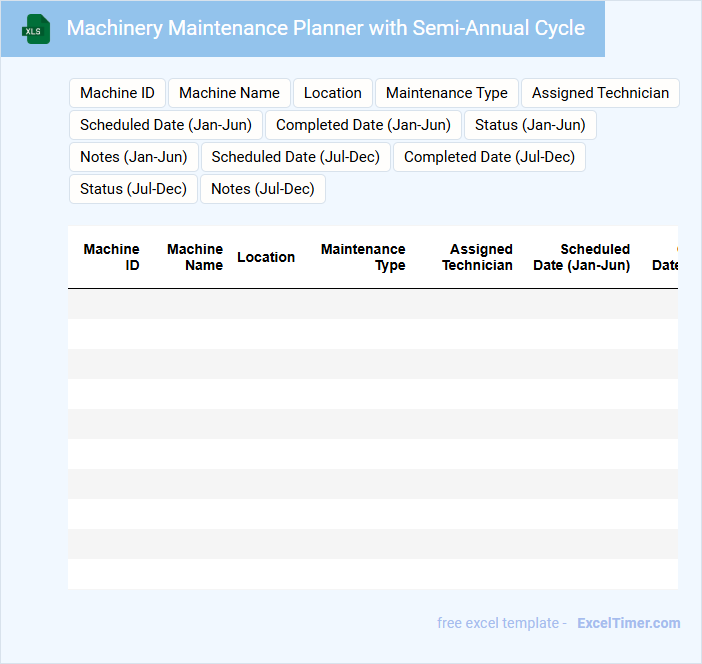

Machinery Maintenance Planner with Semi-Annual Cycle

A Machinery Maintenance Planner with a Semi-Annual Cycle is a document that outlines scheduled maintenance tasks to ensure the optimal performance and longevity of machinery. It typically includes inspection dates, maintenance procedures, and resource allocation.

This planner helps prevent unexpected breakdowns by providing a systematic approach to upkeep every six months. Clear documentation of tasks and deadlines is essential to maintain consistency and accountability.

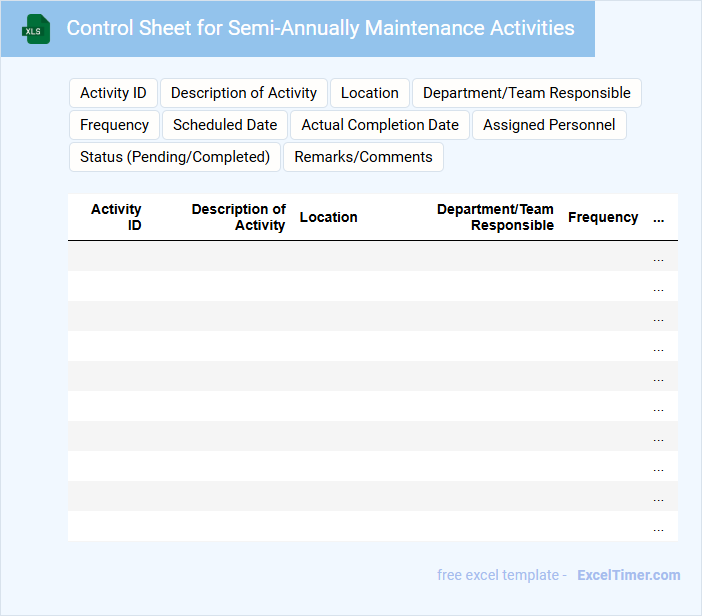

Control Sheet for Semi-Annually Maintenance Activities

The Control Sheet for Semi-Annually Maintenance Activities typically contains a detailed checklist and schedule of tasks to be performed every six months. It includes information on equipment condition, maintenance procedures, and responsible personnel to ensure systematic upkeep. This document is essential for tracking maintenance progress and preventing equipment failure.

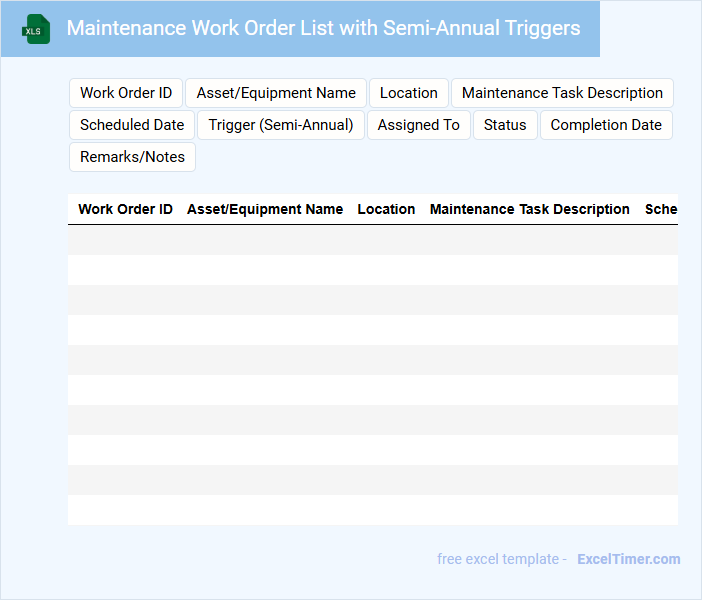

Maintenance Work Order List with Semi-Annual Triggers

Maintenance Work Order List with Semi-Annual Triggers is a document that organizes scheduled maintenance tasks to ensure equipment reliability and prevent unexpected breakdowns. It typically contains detailed work orders specifying the type of maintenance, assigned personnel, and deadlines triggered every six months. An important suggestion is to regularly update the list to reflect completed tasks and any changes in maintenance priorities.

Asset Performance Tracker for Semi-Annually Maintenance

What information is typically included in an Asset Performance Tracker for Semi-Annually Maintenance? This document usually contains detailed records of asset conditions, maintenance schedules, and performance metrics updated every six months. It helps organizations monitor asset reliability and plan timely interventions to prevent breakdowns and optimize productivity.

What key elements should be considered when creating this tracker? Important aspects include accurate tracking of asset usage, documented maintenance history, clear performance indicators, and alerts for upcoming service deadlines to ensure consistent upkeep and extended asset lifespan.

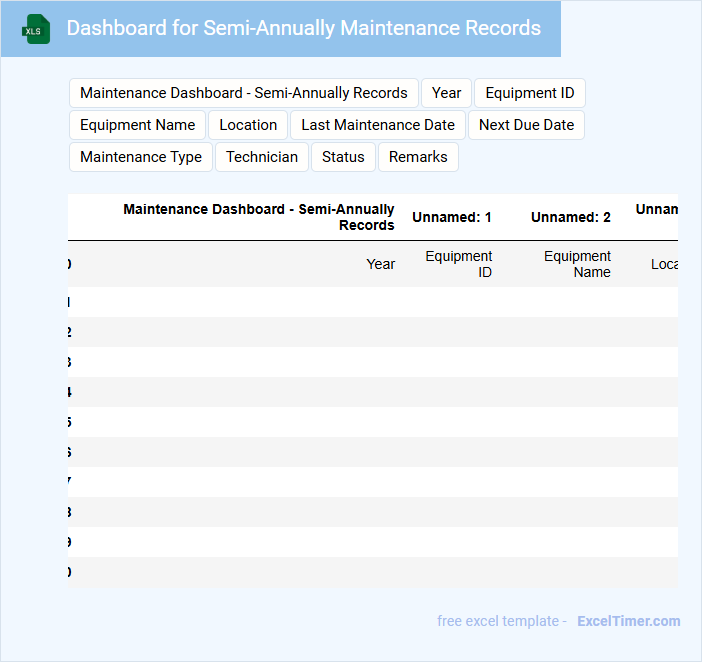

Dashboard for Semi-Annually Maintenance Records

A Dashboard for Semi-Annually Maintenance Records typically contains data summaries, visual charts, and status indicators to track maintenance activities over six-month periods. It provides a clear overview of completed, pending, and overdue tasks to ensure timely interventions.

Important elements include filter options by equipment, date ranges, and maintenance type for quick access to relevant records. Prioritizing user-friendly navigation and real-time updates enhances decision-making efficiency.

How is maintenance frequency tracked and updated semi-annually in the Excel document?

Your Excel document tracks maintenance frequency semi-annually by using date fields and automated formulas to calculate upcoming service intervals every six months. Conditional formatting highlights tasks due within the next period, ensuring timely updates. This system streamlines maintenance schedules and improves asset management accuracy.

What key data columns are essential for recording semi-annual maintenance activities?

Your semi-annual maintenance tracking Excel document should include essential data columns such as Maintenance Date, Equipment ID, Task Description, Technician Name, and Next Scheduled Date. Recording Status and Notes help monitor task completion and any issues encountered. These key fields ensure accurate, organized tracking of maintenance activities every six months.

How can conditional formatting in Excel highlight overdue semi-annual maintenance tasks?

Conditional formatting in Excel highlights overdue semi-annual maintenance tasks by applying color codes based on date comparisons with the current date. You can set rules to flag tasks if their next maintenance date is past due, making it easy to identify and prioritize. This visual alert system ensures timely tracking and maintenance scheduling.

What formulas or functions are used to calculate the next semi-annual maintenance date?

To calculate the next semi-annual maintenance date in Excel, use the EDATE function: =EDATE(last_maintenance_date, 6). This formula adds six months to the last maintenance date, ensuring accurate semi-annual tracking. Replace "last_maintenance_date" with the cell reference containing the previous maintenance date.

How is historical semi-annual maintenance data archived and accessed within the document?

Your semi-annual maintenance data is systematically archived in dedicated Excel sheets labeled by year and period, ensuring easy retrieval. Each entry includes detailed timestamps, maintenance descriptions, and status, enabling efficient tracking of historical records. Access is streamlined through built-in filters and search functions for quick navigation across past maintenance activities.