The Semi-annually Maintenance Schedule Excel Template for Facilities provides an organized and efficient way to plan and track maintenance tasks every six months. It helps facility managers ensure timely inspections, repairs, and upkeep, reducing downtime and extending equipment lifespan. Customizable features allow easy adaptation to specific facility needs and improve overall maintenance workflow.

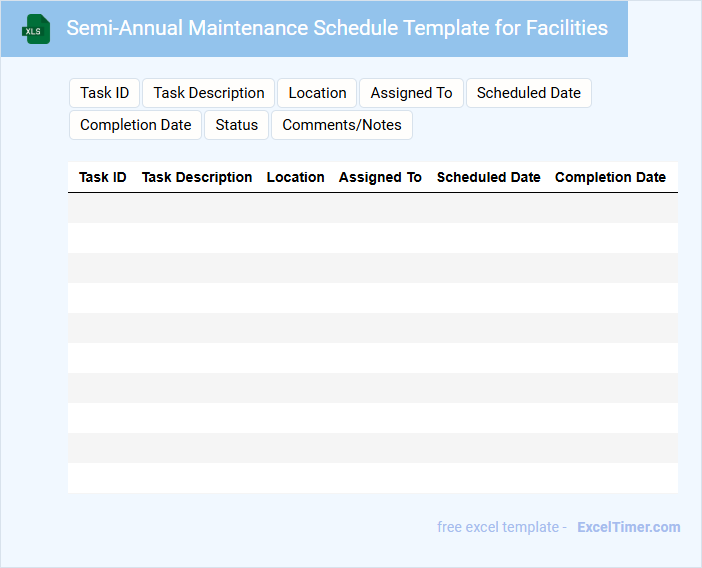

Semi-Annual Maintenance Schedule Template for Facilities

A Semi-Annual Maintenance Schedule Template for facilities typically outlines planned maintenance activities to ensure the smooth operation of equipment and infrastructure. It includes detailed timelines, assigned responsibilities, and specific tasks to be completed every six months.

This document helps facility managers track routine inspections, repairs, and preventive measures to avoid unexpected breakdowns. It is important to incorporate priority levels and any regulatory compliance requirements.

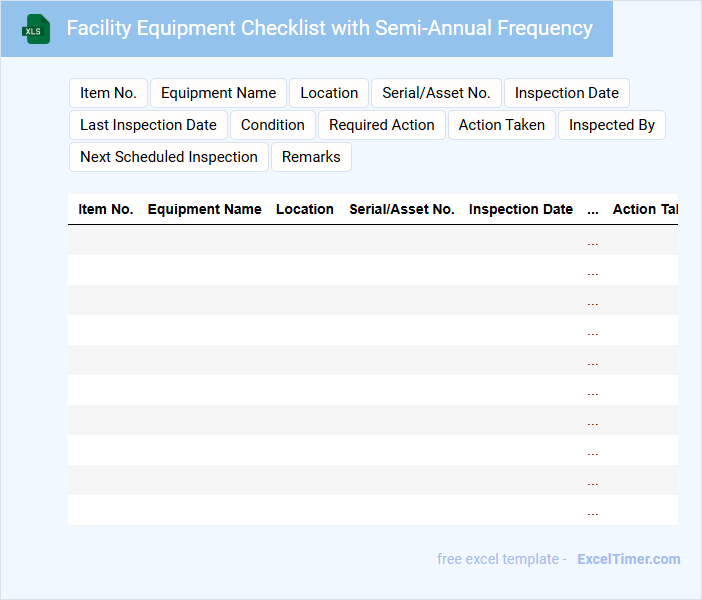

Facility Equipment Checklist with Semi-Annual Frequency

Facility Equipment Checklist with Semi-Annual Frequency typically contains a structured list of equipment inspections and maintenance tasks to be performed every six months to ensure operational efficiency and safety.

- Comprehensive Inspection Items: Detailed points covering all critical components and systems of the facility equipment.

- Scheduled Maintenance Tasks: Specific actions required to prevent breakdowns and prolong equipment lifespan.

- Compliance and Safety Notes: Guidelines to ensure adherence to regulatory standards and workplace safety protocols.

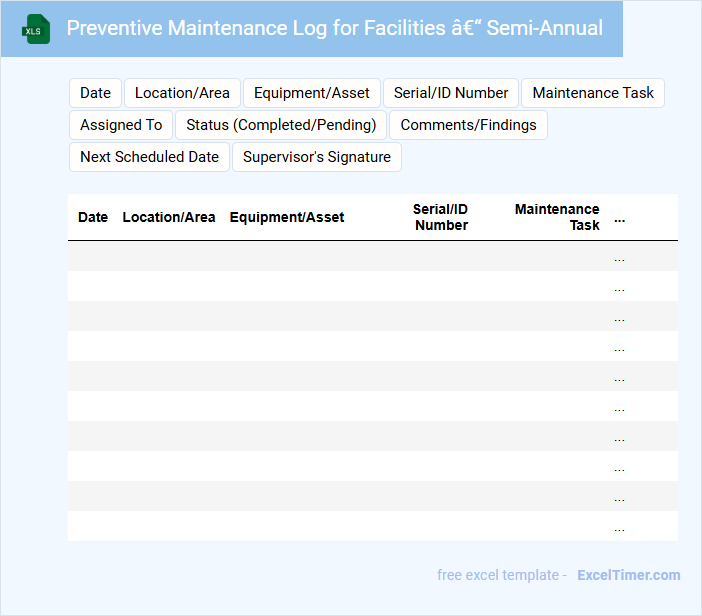

Preventive Maintenance Log for Facilities – Semi-Annual

A Preventive Maintenance Log for facilities is a detailed record that tracks all scheduled maintenance activities performed semi-annually. It ensures the longevity and efficiency of equipment by documenting inspections, repairs, and replacements systematically.

This document typically includes dates, tasks completed, responsible personnel, and any issues discovered during maintenance. Regular updates and accurate entries are crucial for effective facility management and compliance with safety standards.

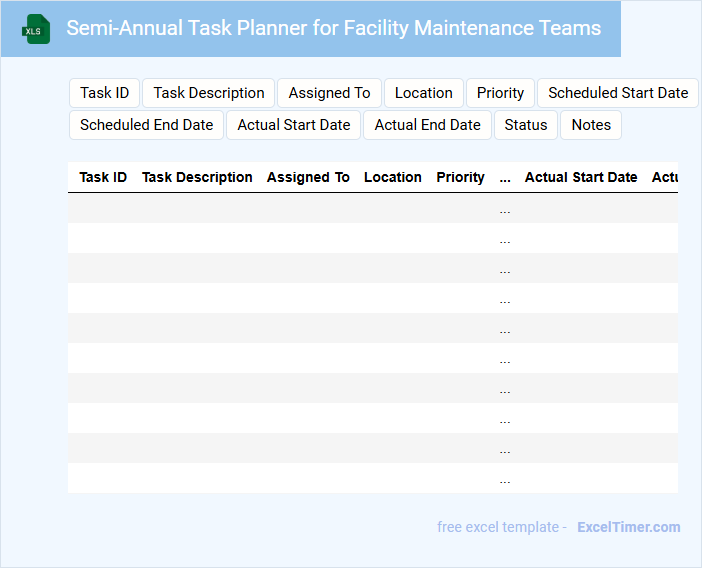

Semi-Annual Task Planner for Facility Maintenance Teams

A Semi-Annual Task Planner for Facility Maintenance Teams typically outlines scheduled maintenance activities and resource allocation for a six-month period.

- Comprehensive Scheduling: Ensure all critical equipment and systems have assigned maintenance dates to prevent unexpected breakdowns.

- Resource Management: Allocate personnel and materials efficiently to optimize maintenance operations without disruptions.

- Review and Adjustment: Regularly update the planner based on completed tasks and emerging facility needs to maintain accuracy and relevance.

Asset Maintenance Tracker with Semi-Annual Schedule

An Asset Maintenance Tracker is a crucial document designed to monitor the upkeep of physical assets over time. It typically contains details such as asset identification, maintenance schedules, and history of repairs or inspections.

For a Semi-Annual Schedule, the document emphasizes biannual checks to ensure asset longevity and performance. Regular updates and accurate record-keeping are essential to prevent unexpected breakdowns and costly repairs.

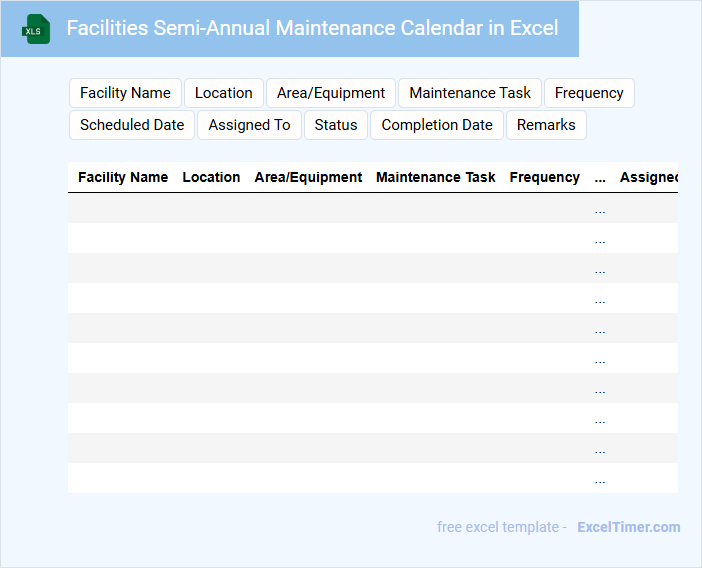

Facilities Semi-Annual Maintenance Calendar in Excel

Facilities Semi-Annual Maintenance Calendar in Excel is typically a document used to schedule and track routine maintenance activities to ensure operational efficiency.

- Maintenance Tasks: Lists all necessary maintenance activities to be performed semi-annually.

- Scheduling: Provides specific dates or timeframes for each maintenance task to be completed.

- Tracking and Status: Includes columns for recording progress, completion status, and any issues encountered during maintenance.

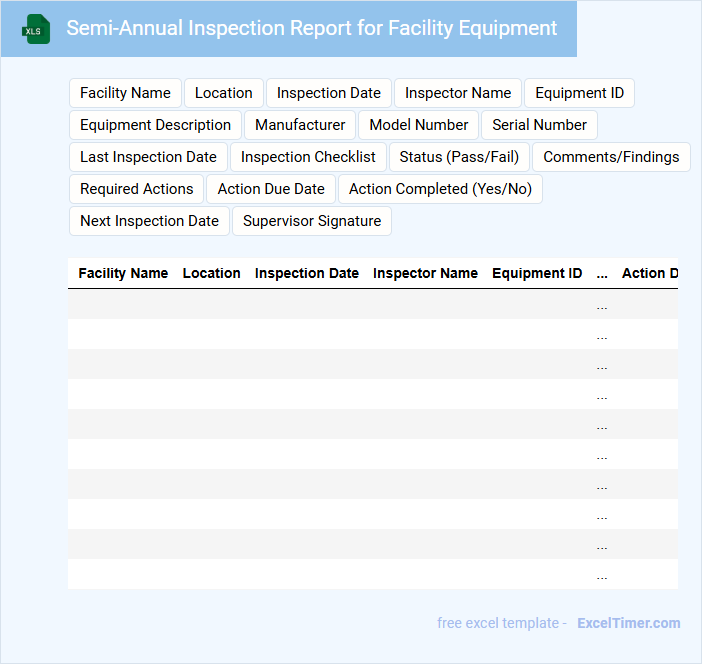

Semi-Annual Inspection Report for Facility Equipment

The Semi-Annual Inspection Report for Facility Equipment documents the detailed evaluation of machinery and systems conducted every six months. It highlights the condition, performance, and any detected issues to ensure operational efficiency.

This document typically includes inspection dates, equipment status, identified defects, and recommended maintenance actions. A crucial element is the accurate recording of safety concerns to prevent potential hazards.

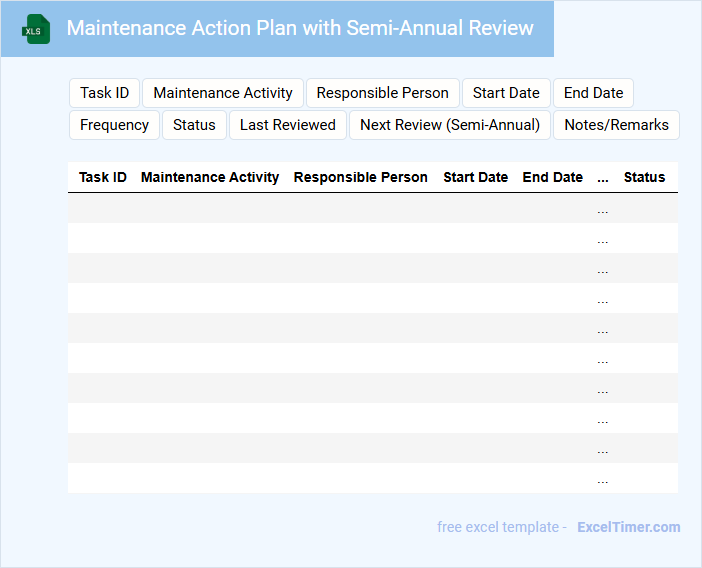

Maintenance Action Plan with Semi-Annual Review

A Maintenance Action Plan with Semi-Annual Review typically contains detailed schedules for routine maintenance tasks, responsibilities assigned to personnel, and metrics for assessing equipment performance. It ensures systematic upkeep to prevent unexpected breakdowns and prolong asset life. Regular semi-annual reviews help update the plan based on operational feedback and emerging issues.

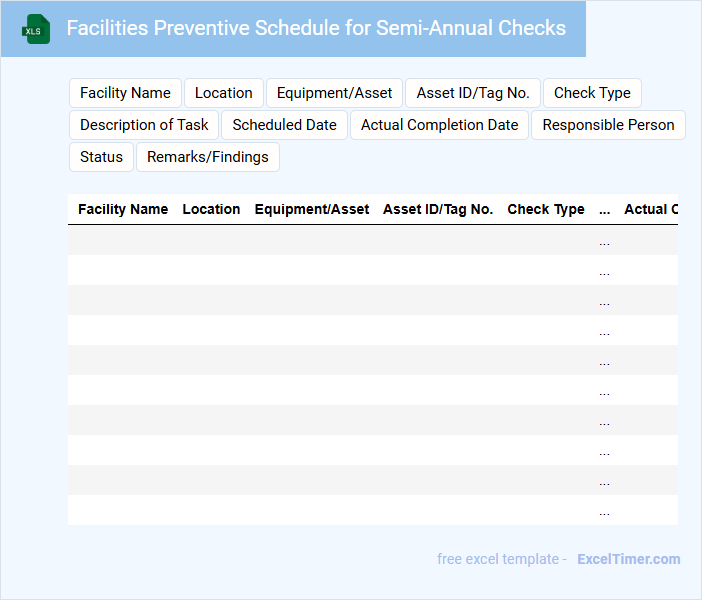

Facilities Preventive Schedule for Semi-Annual Checks

Facilities Preventive Schedule for Semi-Annual Checks is a document outlining planned maintenance activities to ensure optimal functionality and safety of equipment and infrastructure.

- Comprehensive list of equipment and areas to be inspected.

- Detailed timeline for scheduling and completing inspections.

- Clear assignment of responsibilities for maintenance personnel.

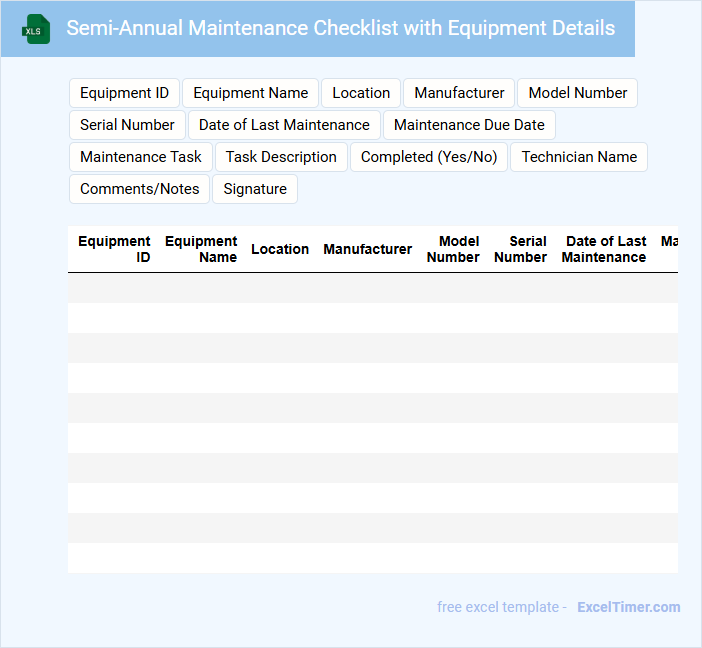

Semi-Annual Maintenance Checklist with Equipment Details

A Semi-Annual Maintenance Checklist typically includes a detailed list of tasks to be performed on equipment every six months to ensure optimal functionality and safety. It contains equipment details such as model numbers, serial numbers, and specific maintenance requirements tailored to each item. Including a section for notes and signatures is important to document completed work and any issues encountered during inspections.

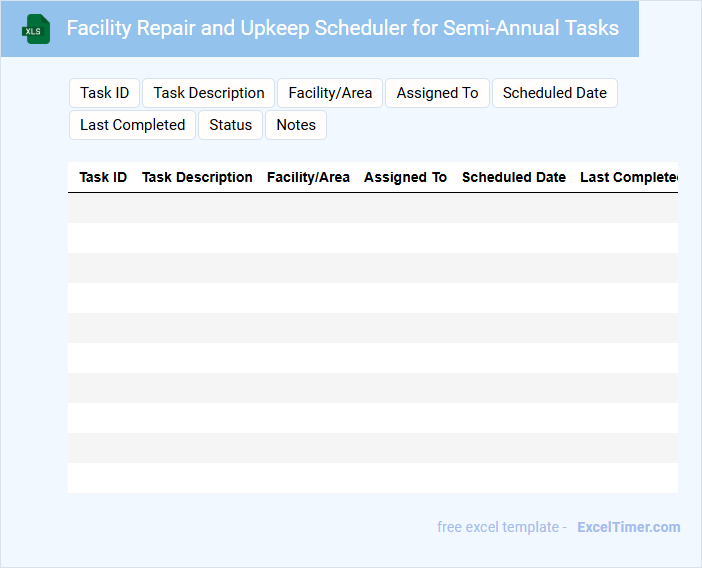

Facility Repair and Upkeep Scheduler for Semi-Annual Tasks

Facility Repair and Upkeep Scheduler for Semi-Annual Tasks is a document designed to organize and track maintenance activities occurring twice a year to ensure operational efficiency. It helps prioritize tasks and allocate resources effectively.

- Include a detailed checklist of all semi-annual maintenance tasks with assigned deadlines.

- Incorporate responsible personnel or team members for each specific task.

- Provide space for notes on completed work, issues found, and necessary follow-ups.

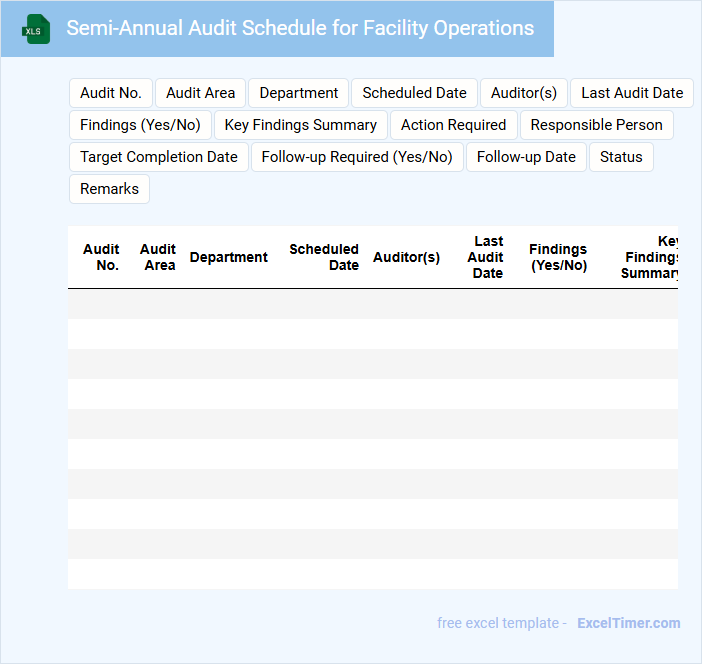

Semi-Annual Audit Schedule for Facility Operations

What does a Semi-Annual Audit Schedule for Facility Operations typically contain? This document usually outlines the planned dates and scope of audits conducted twice a year to assess the efficiency and compliance of facility operations. It includes key checkpoints, responsible personnel, and expected outcomes to ensure continuous improvement and regulatory adherence.

Why is it important to include specific audit criteria and responsible team members in the schedule? Defining clear audit criteria ensures that evaluations are consistent and focused on critical operational areas. Assigning responsible team members promotes accountability and facilitates timely completion of audit activities, driving effective facility management.

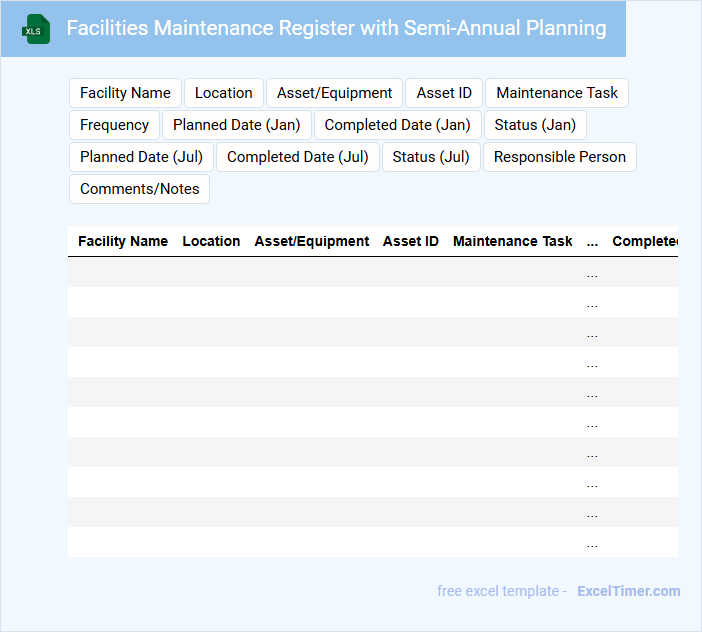

Facilities Maintenance Register with Semi-Annual Planning

The Facilities Maintenance Register is a crucial document that records all maintenance activities, schedules, and repairs for physical assets. It ensures that all upkeep tasks are planned and tracked systematically to avoid unexpected failures. Proper documentation helps in auditing and compliance.

The Semi-Annual Planning aspect focuses on organizing maintenance tasks every six months to keep facilities operating efficiently. This helps prioritize urgent repairs and allocate resources effectively. Regular reviews of the register improve maintenance strategies and budget forecasting.

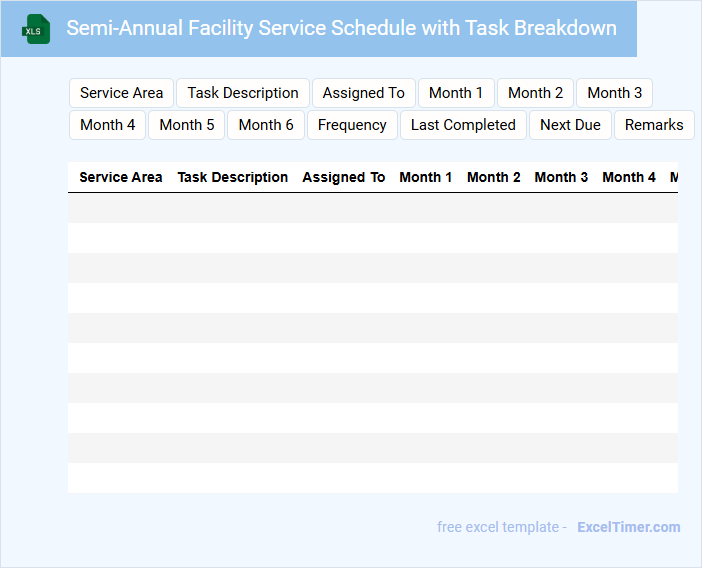

Semi-Annual Facility Service Schedule with Task Breakdown

A Semi-Annual Facility Service Schedule with Task Breakdown is a document that outlines maintenance activities planned every six months to ensure operational efficiency and safety. It provides detailed tasks categorized for systematic execution.

- Include specific maintenance tasks and responsible personnel for accountability.

- Schedule dates and deadlines to track progress and compliance effectively.

- List required tools and materials to prepare resources in advance.

Work Order Tracker for Facilities with Semi-Annual Focus

A Work Order Tracker for facilities is a document designed to monitor and manage maintenance tasks systematically. It typically contains records of work orders, including descriptions, statuses, assigned personnel, and deadlines. Emphasizing a semi-annual focus ensures scheduled upkeep and timely resolution of recurring issues.

What key components should be included in a semi-annual maintenance schedule for facilities in an Excel document?

A semi-annual maintenance schedule in Excel should include key components such as Task Description, Assigned Personnel, Scheduled Dates, Frequency, Priority Level, and Status Tracking. Incorporate columns for Equipment or Facility Area, Required Materials, and Comments to ensure comprehensive maintenance tracking. Use conditional formatting and filters to optimize task visibility and deadline management.

How can conditional formatting in Excel help highlight overdue maintenance tasks in a semi-annual schedule?

Conditional formatting in Excel can automatically highlight overdue maintenance tasks by comparing scheduled maintenance dates against the current date. By setting rules to color-code cells with dates past due, facility managers can quickly identify which tasks require immediate attention. This visual aid enhances proactive upkeep in a semi-annual maintenance schedule, minimizing equipment downtime.

Which Excel features best support tracking completed versus pending maintenance activities for each facility?

Excel features like Tables and Conditional Formatting enable efficient tracking of completed versus pending maintenance activities by visually distinguishing status updates. PivotTables summarize progress across multiple facilities, offering quick insights into scheduled and completed semi-annual tasks. Data Validation restricts input to predefined status options, ensuring consistent and accurate maintenance records.

What is the optimal way to organize facility locations, equipment types, and assigned personnel in a semi-annual maintenance ?

Organize your semi-annual maintenance schedule by creating separate columns for facility locations, equipment types, and assigned personnel to ensure clarity and efficient tracking. Use filters and drop-down lists in Excel to streamline data entry and improve accessibility. Incorporate color-coded status indicators to quickly monitor maintenance progress and upcoming tasks.

How can Excel formulas be employed to automatically calculate the next due date for semi-annual maintenance tasks?

Excel formulas can automatically calculate the next due date for semi-annual maintenance by adding 6 months to the last maintenance date using the EDATE function, e.g., =EDATE(A2,6). This formula ensures accurate tracking by accounting for varying month lengths and leap years. Combining this with conditional formatting highlights upcoming or overdue maintenance tasks for efficient facility management.