The Monthly Production Report Excel Template for Manufacturing Units streamlines tracking of daily output, efficiency, and downtime, enabling accurate performance analysis. It features customizable fields for quantities produced, machine utilization, and quality control metrics to enhance productivity monitoring. Using this template helps managers make data-driven decisions and improve overall manufacturing processes.

Monthly Production Report Excel Template for Manufacturing Units

A Monthly Production Report Excel Template for Manufacturing Units typically contains detailed data on production output, efficiency, and quality metrics to monitor and optimize manufacturing processes.

- Production Data: Records daily or monthly units produced to track overall output and identify trends.

- Quality Metrics: Includes defect rates and compliance checks to ensure product standards are met.

- Efficiency Indicators: Measures machine utilization and labor productivity to improve operational performance.

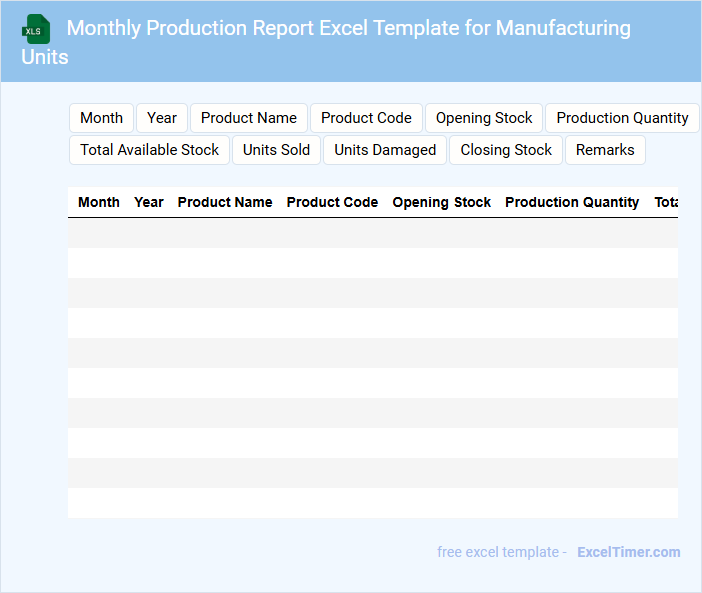

Production Output Tracking Sheet for Manufacturing Units

A Production Output Tracking Sheet is a crucial document used in manufacturing units to monitor and record the quantity of products produced within a specific timeframe. It typically contains data such as production dates, batch numbers, machine or line details, and output quantities. This sheet helps ensure efficiency, identify bottlenecks, and maintain quality control in the production process.

Manufacturing Units Monthly Production Log with Summary

Manufacturing Units Monthly Production Log with Summary is a detailed record documenting the daily production activities and output of a manufacturing unit over a month. It helps in tracking productivity, identifying bottlenecks, and planning future production schedules.

- Include daily production quantities along with machine or line details.

- Summarize total output, downtime, and efficiency metrics at the end of the month.

- Record any production issues or maintenance activities impacting output.

Excel Template for Monthly Production Analysis of Manufacturing

An Excel Template for Monthly Production Analysis is designed to systematically organize and track manufacturing outputs over a specified period. It typically includes sections for input data, production targets, actual production, and efficiency metrics.

This document is essential for identifying trends, bottlenecks, and areas for process improvement in manufacturing operations. Regular updates and accurate data entry are crucial for maximizing its effectiveness.

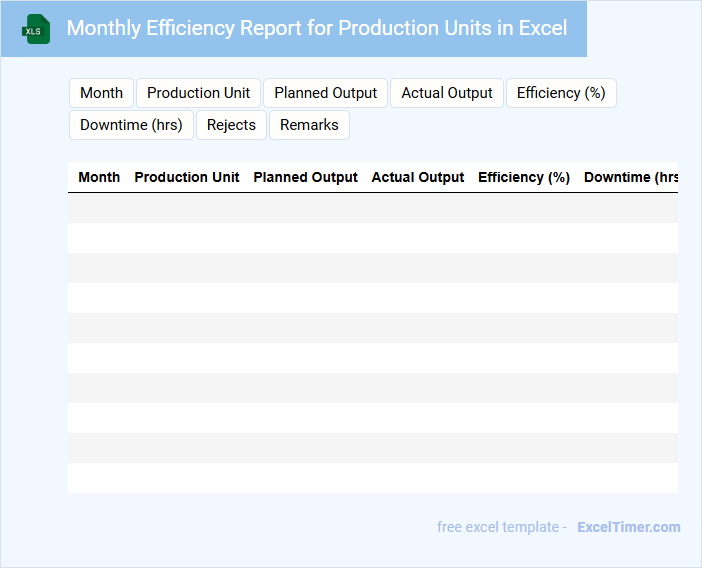

Monthly Efficiency Report for Production Units in Excel

The Monthly Efficiency Report for Production Units in Excel typically contains data on operational performance, resource utilization, and productivity metrics. It is designed to track key performance indicators (KPIs) such as output rate, downtime, and efficiency percentages. This document helps managers identify trends, bottlenecks, and opportunities for improvement in manufacturing processes.

Important elements to include are clearly defined metrics, visual charts for quick analysis, and a summary of actionable insights. Ensuring data accuracy and timely updates will improve decision-making and accountability. Additionally, incorporating comparisons to previous months or targets enhances the report's strategic value.

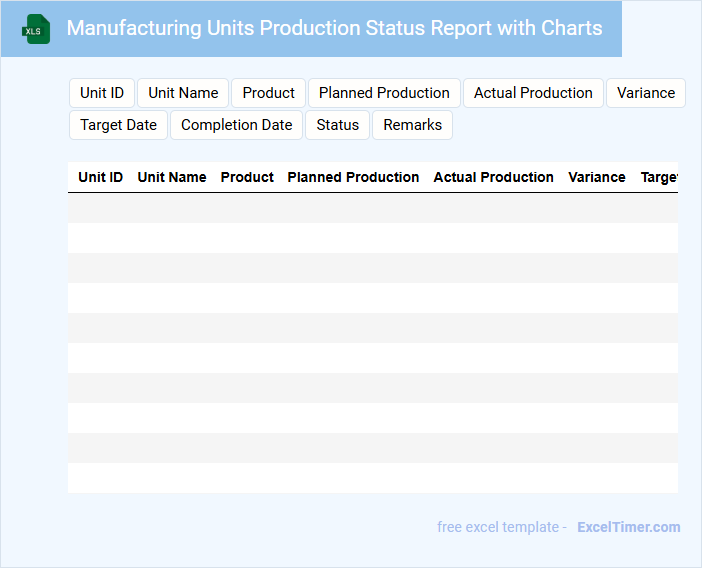

Manufacturing Units Production Status Report with Charts

A Manufacturing Units Production Status Report with Charts typically provides an overview of production performance, efficiency, and output levels within a manufacturing unit. It helps stakeholders track progress and identify bottlenecks through visual data representation.

- Include clear and concise production metrics highlighting target vs. actual output.

- Use charts to visualize trends, downtime causes, and productivity variations.

- Ensure real-time or regularly updated data to maintain report accuracy and relevance.

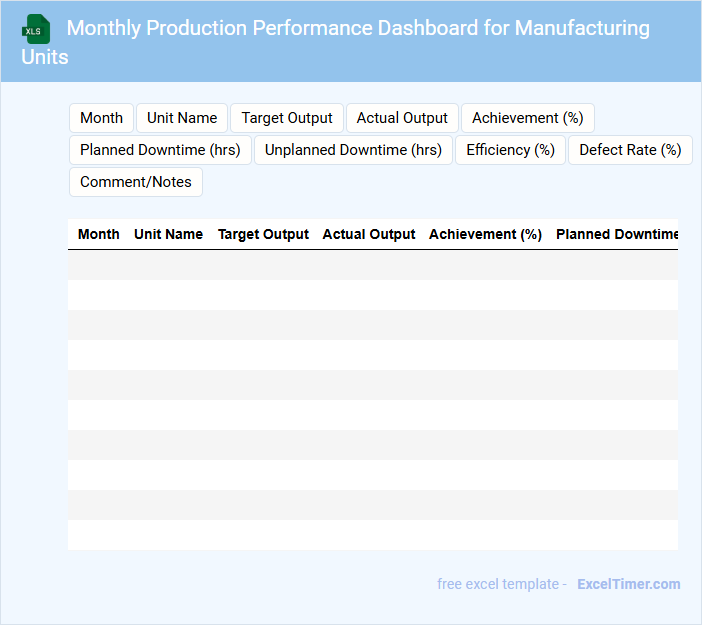

Monthly Production Performance Dashboard for Manufacturing Units

A Monthly Production Performance Dashboard typically contains key metrics such as total output, downtime, efficiency rates, and quality control statistics. It provides a clear overview to help manufacturing units monitor their productivity and identify areas for improvement.

Essential elements include real-time data visualization, trend analysis, and performance comparisons against set targets. Incorporating actionable insights ensures timely decision-making and optimizes production processes.

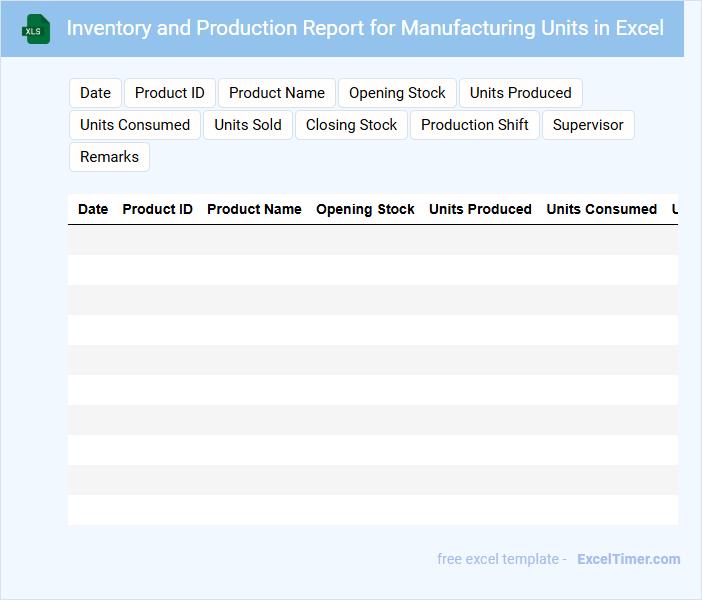

Inventory and Production Report for Manufacturing Units in Excel

An Inventory and Production Report for Manufacturing Units in Excel typically contains detailed records of raw materials, production output, and stock levels to ensure efficient management.

- Accurate data entry: Ensures all inventory and production figures are correctly logged for reliable reporting.

- Regular updates: Maintains current stock and production status to avoid discrepancies and delays.

- Clear categorization: Separates raw materials, work-in-progress, and finished goods for better tracking and analysis.

Machine-wise Monthly Production Report for Manufacturing Plants

A Machine-wise Monthly Production Report for Manufacturing Plants details the output and efficiency of each machine over the course of a month, helping to track productivity and identify issues. This document is essential for optimizing manufacturing processes and ensuring consistent quality control.

- Include accurate machine identification and operational hours.

- Record production quantities alongside any downtime or maintenance activities.

- Highlight trends or deviations in performance for proactive management.

Excel Logbook for Monthly Output Tracking of Manufacturing Units

An Excel Logbook for Monthly Output Tracking of Manufacturing Units typically contains detailed records of production volumes, machine performance data, and workforce efficiency metrics. This document helps in monitoring daily and monthly output to ensure targets are met consistently.

It is essential to include columns for dates, shift details, units produced, downtime reasons, and quality control checks to maintain comprehensive tracking. Regularly updating and reviewing this logbook supports timely decision-making and continuous process improvement.

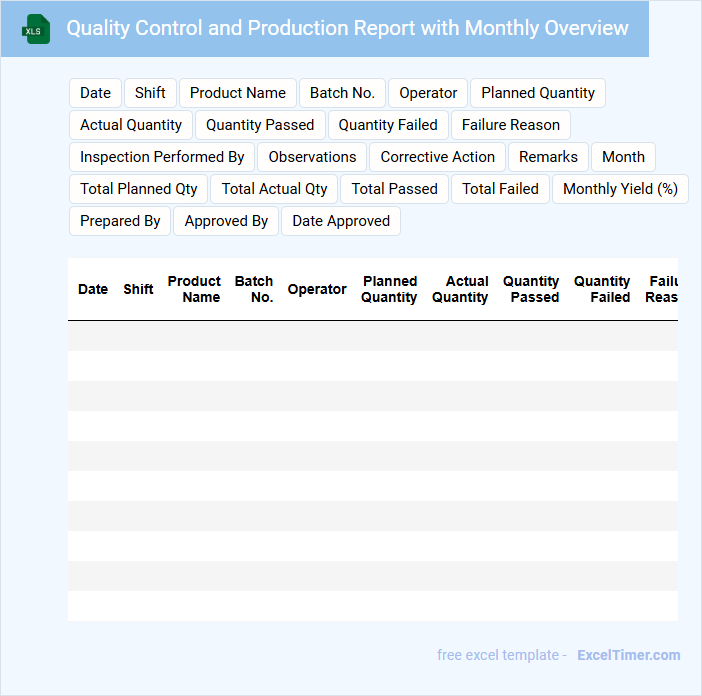

Quality Control and Production Report with Monthly Overview

A Quality Control and Production Report with Monthly Overview typically contains detailed records of production activities, quality assessments, and any deviations identified during the month. It summarizes key metrics such as defect rates, compliance with standards, and output volumes to ensure transparency and continuous improvement. This document serves as a critical tool for tracking performance trends and making informed operational decisions.

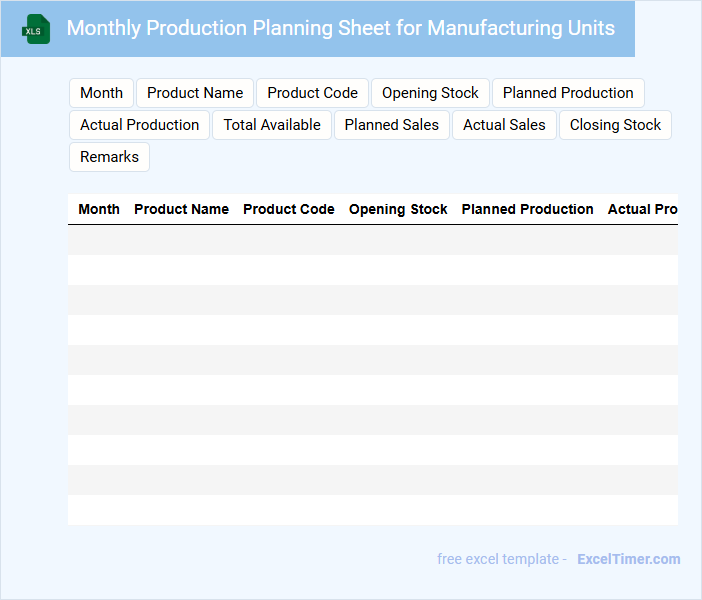

Monthly Production Planning Sheet for Manufacturing Units

A Monthly Production Planning Sheet typically contains detailed schedules of manufacturing activities, including target production volumes, resource allocation, and timelines. It serves as a crucial tool for coordinating various departments to meet monthly output goals efficiently.

Important elements to include are accurate inventory levels, machine availability, and workforce assignments to avoid bottlenecks. Regular updates and clear communication channels are essential to ensure flexibility and timely adjustments during production cycles.

Excel Tracker for Production Downtime of Manufacturing Units

An Excel Tracker for Production Downtime of Manufacturing Units is a document used to record and monitor periods when production is halted. It helps in identifying downtime causes and improving overall efficiency.

- Include timestamps for accurate downtime recording.

- Track reasons for each downtime event to identify patterns.

- Summarize data visually using charts for quick analysis.

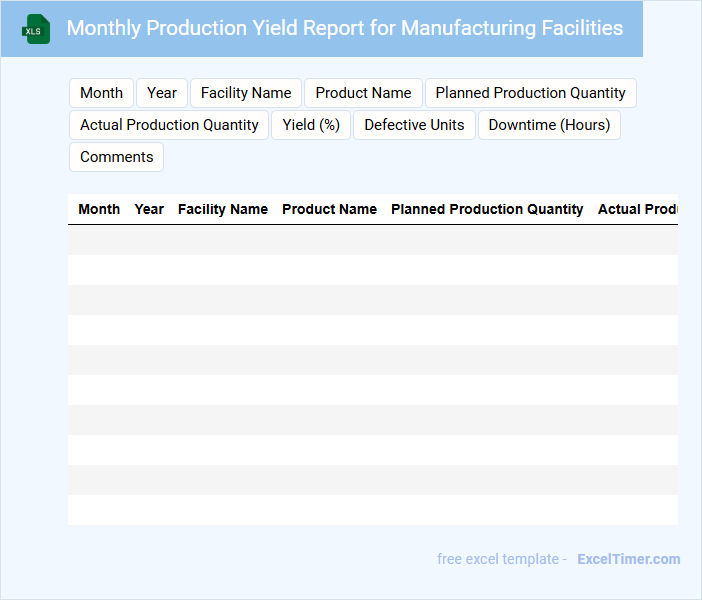

Monthly Production Yield Report for Manufacturing Facilities

A Monthly Production Yield Report for Manufacturing Facilities typically contains detailed data on production output, quality metrics, and process efficiency for the past month. It helps in monitoring performance and identifying areas for improvement in manufacturing operations.

- Include key production volume figures and yield percentages to track efficiency.

- Highlight any deviations from target outputs or quality standards.

- Provide actionable recommendations based on data analysis for process optimization.

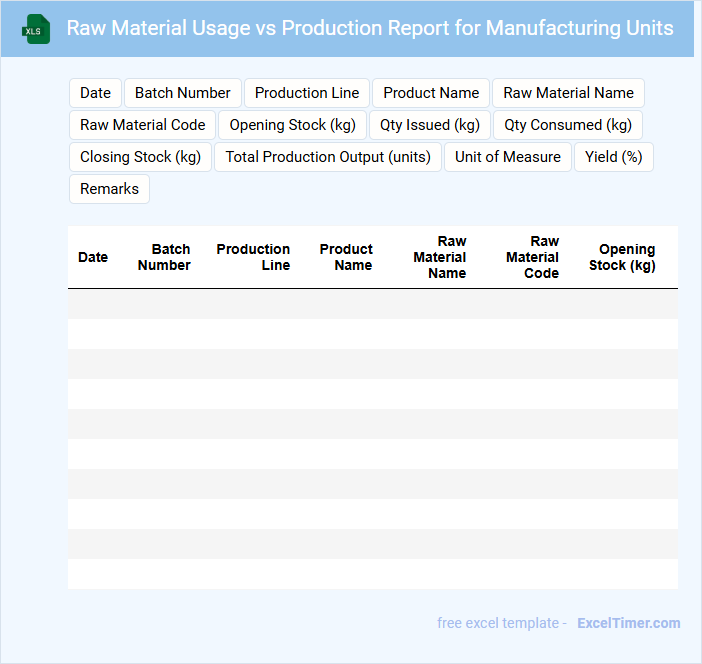

Raw Material Usage vs Production Report for Manufacturing Units

The Raw Material Usage vs Production Report is a crucial document in manufacturing units that tracks the quantity of raw materials consumed against the amount of finished goods produced. It helps in identifying discrepancies, waste, and efficiency in the production process. This report is essential for inventory management, cost control, and process optimization.

What key data fields should be included in a Monthly Production Report for manufacturing units?

A Monthly Production Report for manufacturing units should include key data fields such as Production Volume, Manufacturing Date, Product ID, Unit Cost, Downtime Hours, and Quality Metrics like Defect Rate. It should also track Labor Hours, Machine Utilization, and Inventory Levels to analyze efficiency and resource allocation. Capturing these fields enables comprehensive performance evaluation and operational decision-making.

How can Excel formulas be used to automatically calculate total production output and defect rates?

Excel formulas like SUM can be used to automatically calculate your total production output by adding daily or weekly production values. Defect rates can be computed using formulas that divide the number of defective units by total units produced and multiply by 100 for a percentage. Using these formulas streamlines data analysis and enhances accuracy in your Monthly Production Report for Manufacturing Units.

What methods in Excel help visualize production trends across different months?

Excel offers powerful methods like PivotTables and PivotCharts to visualize production trends across months by summarizing large datasets efficiently. Line charts and bar graphs dynamically display monthly production variations and highlight patterns over time. Conditional formatting can also be applied to cells to visually emphasize increases or decreases in production metrics.

How can the report track and compare planned versus actual production using conditional formatting?

Your Monthly Production Report in Excel can track and compare planned versus actual production by applying conditional formatting rules that highlight discrepancies. Use color scales or data bars to visually indicate whether actual production meets, exceeds, or falls short of planned targets. This method enables quick identification of performance gaps for each manufacturing unit on a monthly basis.

What security or data protection features should be applied to safeguard monthly production data in Excel?

Apply password protection to restrict access to the Monthly Production Report Excel file and use Excel's built-in encryption to secure sensitive manufacturing data. Utilize worksheet and workbook protection to prevent unauthorized alterations of production figures, formulas, and key metrics. Implement regular backups and restrict file sharing permissions to maintain data integrity and confidentiality within manufacturing units.