The Annually Maintenance Schedule Excel Template for Facilities Managers provides a streamlined way to plan, track, and manage maintenance tasks throughout the year. This template helps ensure timely inspections, repairs, and preventive maintenance, reducing downtime and extending the lifespan of equipment. Accurate scheduling enhances operational efficiency and supports budget management for facility upkeep.

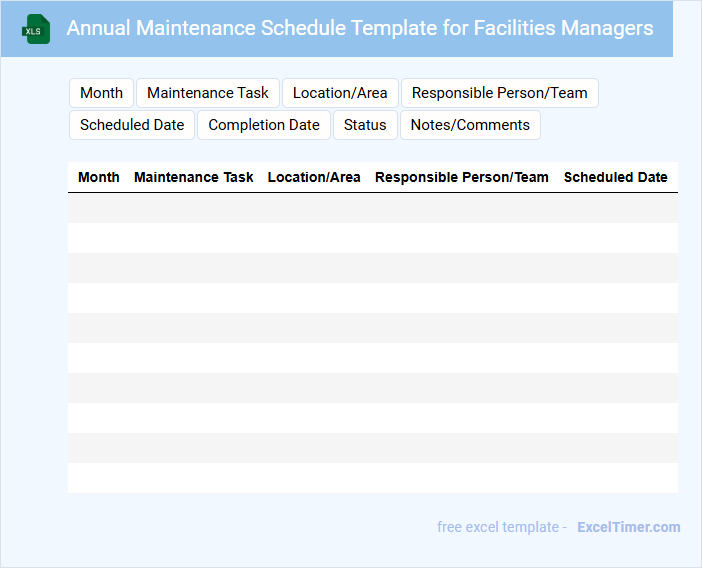

Annual Maintenance Schedule Template for Facilities Managers

What information is typically included in an Annual Maintenance Schedule Template for Facilities Managers? This document usually contains detailed timelines for routine inspections, preventive maintenance tasks, and equipment servicing throughout the year. It helps facilities managers organize resources efficiently and ensure the safety and functionality of building systems.

What is an important factor to consider when using an Annual Maintenance Schedule Template? Prioritizing tasks based on equipment criticality and regulatory compliance ensures maintenance efforts focus on high-impact areas. Additionally, regularly updating the schedule based on observed equipment performance helps maintain operational efficiency.

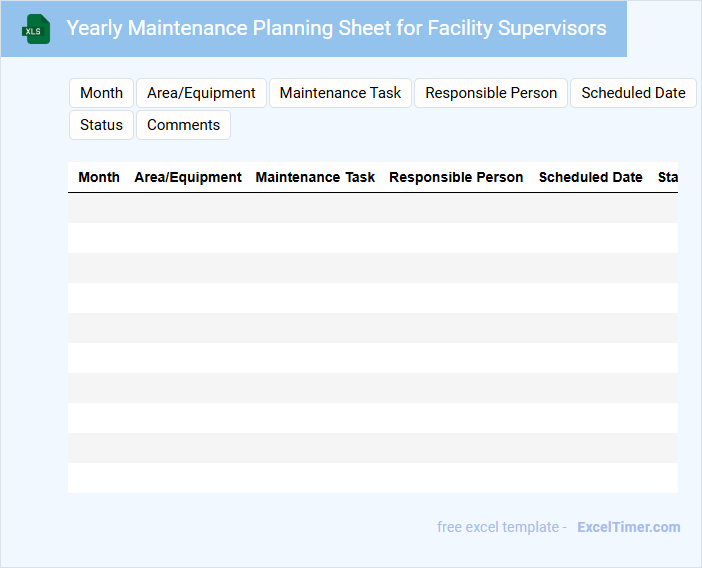

Yearly Maintenance Planning Sheet for Facility Supervisors

The Yearly Maintenance Planning Sheet is a crucial document that outlines scheduled maintenance tasks for facility supervisors to ensure operational efficiency. It typically contains a detailed list of equipment, maintenance dates, and responsible personnel. This document helps in tracking maintenance activities and preventing unexpected breakdowns.

Key elements to include are clear timelines, priority levels for each task, and allocated resources. Additionally, incorporating space for notes on completed work or issues encountered enhances the planning process. Ensuring the sheet is regularly updated and accessible promotes better facility management.

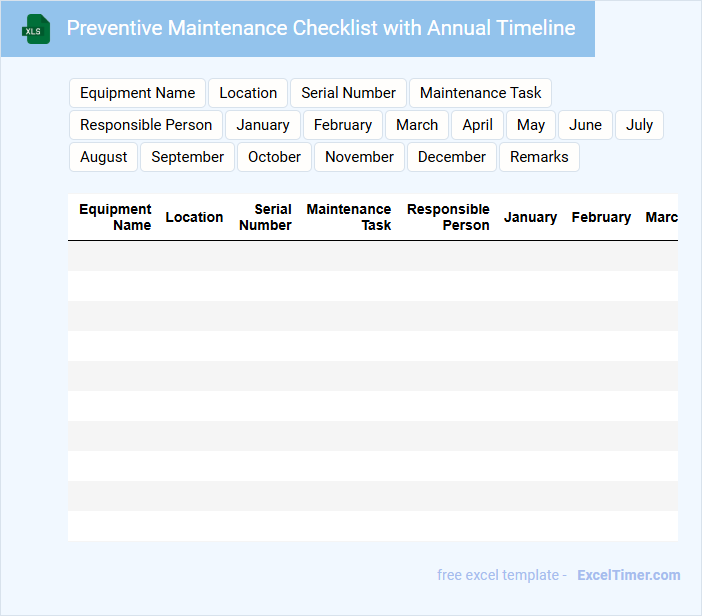

Preventive Maintenance Checklist with Annual Timeline

What typically does a Preventive Maintenance Checklist with Annual Timeline contain? This type of document usually includes a detailed list of maintenance tasks scheduled throughout the year to ensure the optimal functioning and longevity of equipment or systems. It also outlines specific timelines for inspections, repairs, and replacements to prevent unexpected breakdowns and maintain safety standards.

What is an important consideration when creating a Preventive Maintenance Checklist with Annual Timeline? It is crucial to prioritize tasks based on equipment criticality and manufacturer recommendations to allocate resources effectively. Additionally, incorporating clear deadlines and responsible personnel assignments enhances accountability and ensures timely completion of maintenance activities.

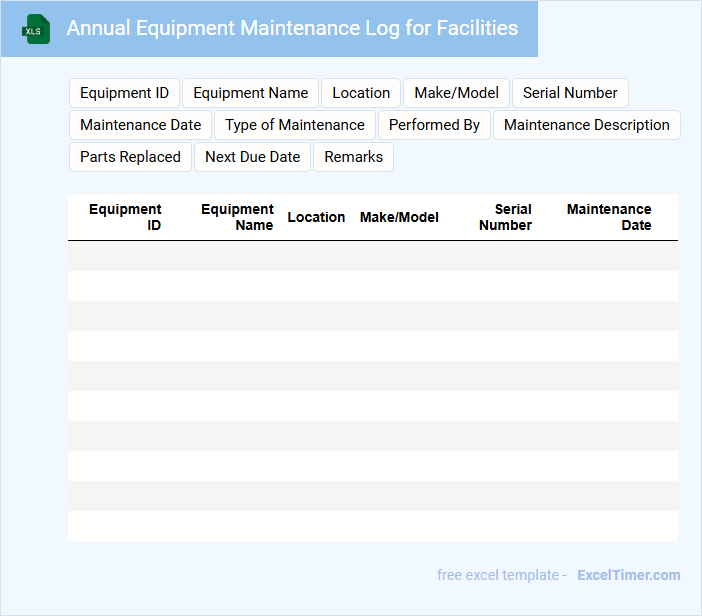

Annual Equipment Maintenance Log for Facilities

An Annual Equipment Maintenance Log for Facilities is a comprehensive record that details all scheduled maintenance activities performed on equipment throughout the year. This document typically contains dates of service, types of maintenance conducted, and any parts replaced or repaired to ensure optimal equipment performance. Maintaining an accurate log helps in tracking equipment reliability, preventing costly breakdowns, and ensuring compliance with safety standards.

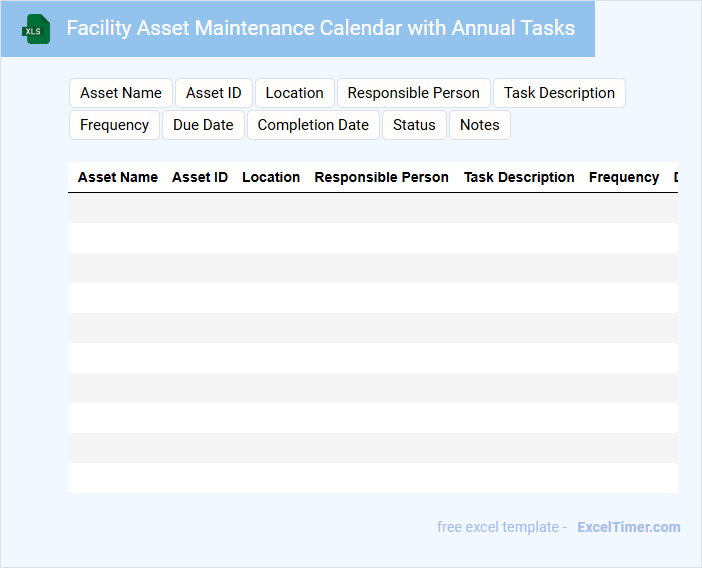

Facility Asset Maintenance Calendar with Annual Tasks

The Facility Asset Maintenance Calendar is a crucial document that outlines scheduled maintenance tasks and timelines for facility assets. It typically includes annual tasks, preventive maintenance activities, and important deadlines to ensure operational efficiency. To optimize its effectiveness, the calendar should highlight priority tasks and integrate clear responsibilities.

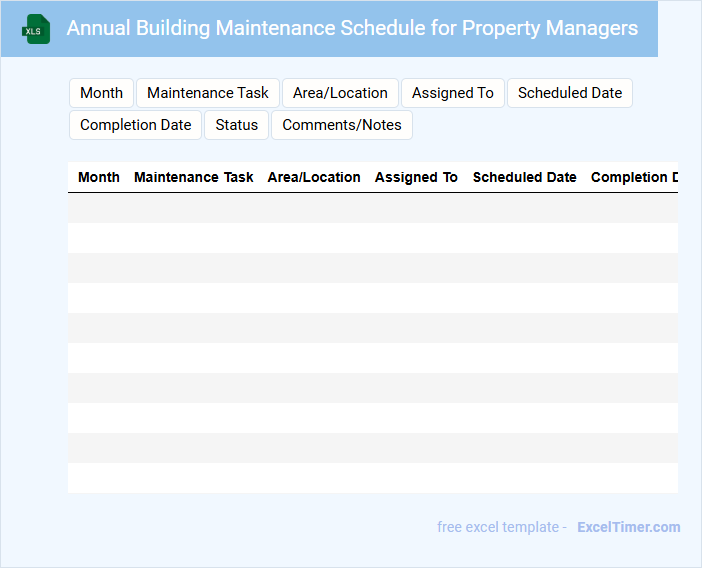

Annual Building Maintenance Schedule for Property Managers

What information is typically included in an Annual Building Maintenance Schedule for Property Managers? This type of document usually outlines scheduled inspections, routine maintenance tasks, and critical repairs needed throughout the year to ensure building safety and functionality. It provides a detailed timeline and resource allocation to help property managers efficiently oversee property upkeep.

Why is it important for property managers to prioritize this maintenance schedule? Prioritizing the schedule helps in preventing costly emergency repairs and extends the lifespan of building components. It also ensures compliance with safety regulations and enhances tenant satisfaction by maintaining a safe and comfortable environment.

Yearly Facilities Maintenance Tracker with Checklist

A Yearly Facilities Maintenance Tracker with Checklist is a comprehensive document used to systematically plan and record all maintenance activities throughout the year. It typically contains scheduled tasks, responsible personnel, deadlines, and status updates to ensure efficient facility management. This type of document helps prevent equipment failures and extends the lifespan of facility assets.

Important elements to include are detailed checklists for each facility area, prioritized tasks based on urgency, and a section for notes or issues encountered during maintenance. Incorporating reminders for regulatory compliance and safety inspections can improve overall operational safety. Additionally, using clear timelines and assigning accountability enhances tracking and follow-up processes.

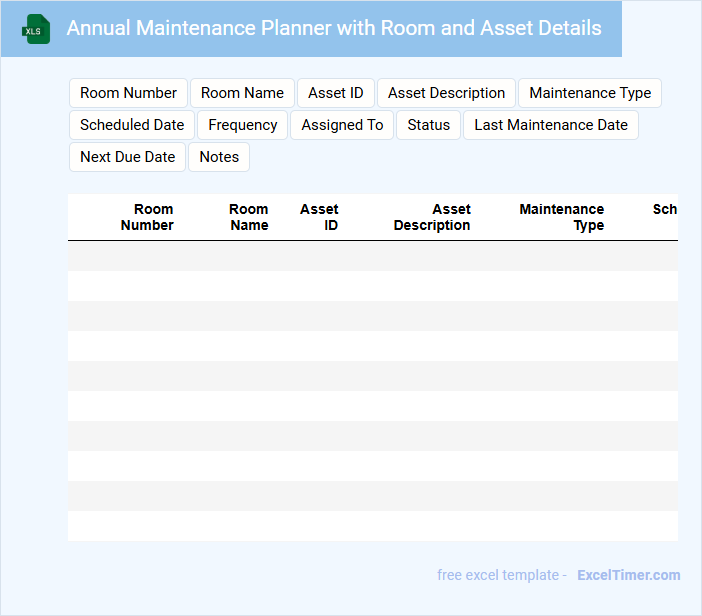

Annual Maintenance Planner with Room and Asset Details

An Annual Maintenance Planner is a document designed to organize and schedule maintenance activities throughout the year. It typically contains detailed timelines, tasks, and responsible personnel for upkeep. Including Room and Asset Details ensures that maintenance is targeted and efficient.

This document usually lists asset names, locations, conditions, and any special requirements for each room. A well-structured planner improves resource allocation and reduces downtime. Regularly updating asset information is crucial for accuracy and operational success.

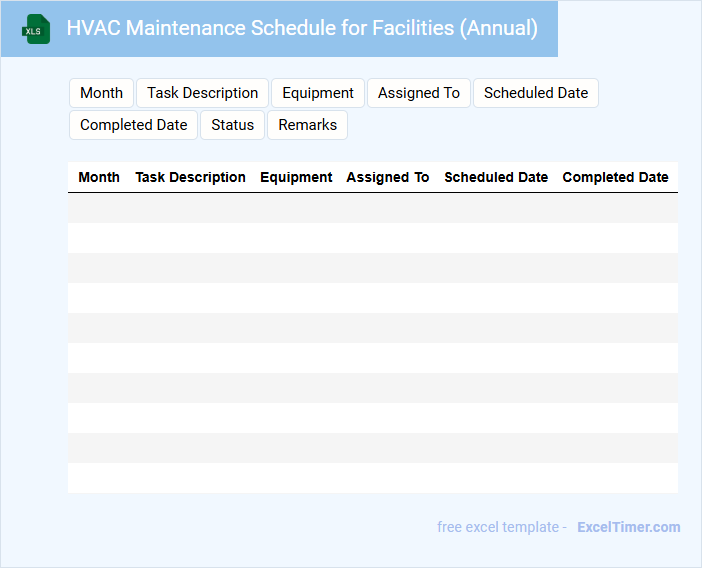

HVAC Maintenance Schedule for Facilities (Annual)

What information is typically included in an HVAC Maintenance Schedule for Facilities (Annual)? This document usually outlines the specific tasks, timelines, and responsible personnel for maintaining heating, ventilation, and air conditioning systems throughout the year. It helps ensure system efficiency, reduce downtime, and extend equipment lifespan by planning regular inspections, cleaning, and repairs.

Why is it important to prioritize certain tasks within an HVAC Maintenance Schedule? Prioritizing critical components such as filters, coils, and refrigerant levels helps prevent system failures and costly emergency repairs. Emphasizing energy efficiency and safety checks also supports optimal facility comfort and regulatory compliance.

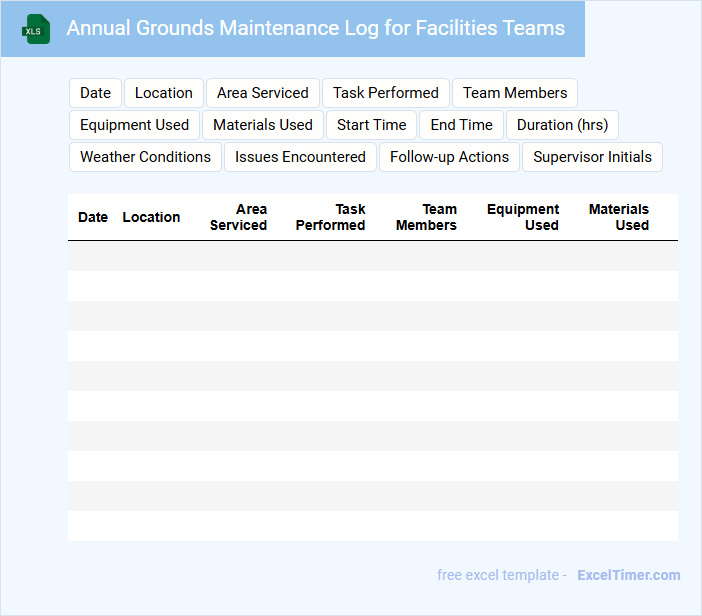

Annual Grounds Maintenance Log for Facilities Teams

What is usually contained in an Annual Grounds Maintenance Log for Facilities Teams? This type of document typically includes detailed records of all maintenance activities performed on the grounds throughout the year, such as landscaping, irrigation checks, pest control, and seasonal clean-ups. It serves as a comprehensive reference to ensure consistent upkeep, track labor and materials used, and plan future maintenance schedules for optimal facility appearance and safety.

What important considerations should be made when maintaining this log? Ensuring accurate, timely entries with clear dates, descriptions, and responsible personnel is crucial for accountability and effective management. Additionally, including sections for notes on observed issues or improvements helps teams proactively address potential problems and maintain high standards of facility grounds care.

Facility Maintenance Work Order Tracker with Annual Overview

A Facility Maintenance Work Order Tracker is a document designed to record and manage routine and urgent maintenance tasks within a facility. It typically contains detailed entries of work orders, assigned personnel, completion dates, and cost tracking. An annual overview helps in analyzing maintenance trends and planning preventive measures effectively.

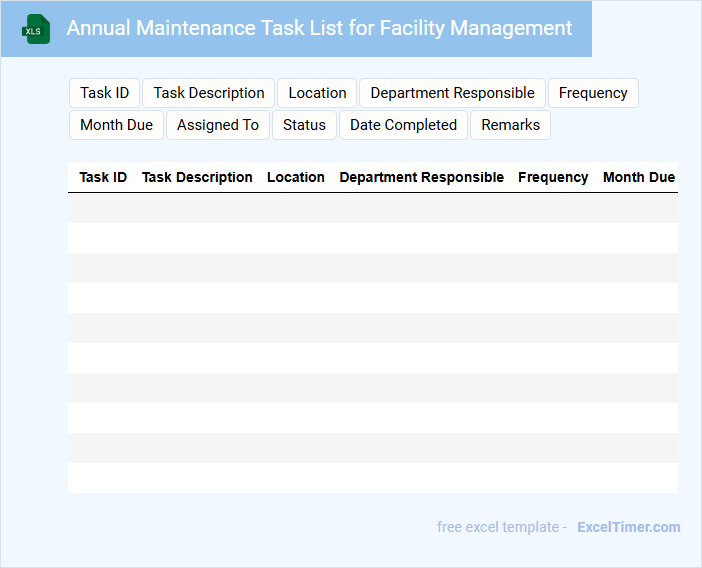

Annual Maintenance Task List for Facility Management

What does an Annual Maintenance Task List for Facility Management typically contain? This document usually includes a detailed schedule of routine inspections, repairs, and servicing activities necessary to ensure the facility's operational efficiency and safety throughout the year. It acts as a strategic tool to organize and prioritize maintenance tasks, helping managers allocate resources effectively and prevent costly breakdowns.

What is an important consideration when creating this list? It is crucial to incorporate comprehensive documentation of equipment specifications, maintenance intervals, and responsible personnel to enhance accountability and streamline workflow. Additionally, regularly updating the task list based on past performance and emerging facility needs ensures optimal maintenance outcomes and prolongs asset lifespan.

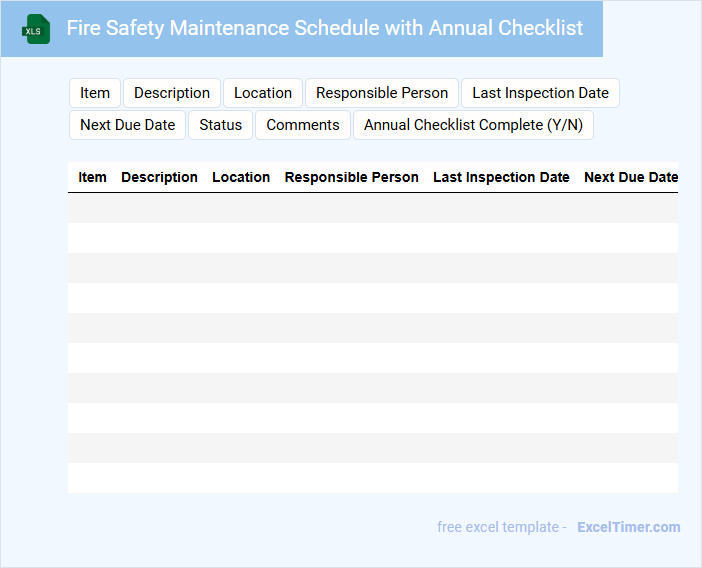

Fire Safety Maintenance Schedule with Annual Checklist

A Fire Safety Maintenance Schedule with an annual checklist is a crucial document designed to ensure the continuous readiness and safety of fire protection systems. It typically contains detailed timelines for routine inspections, maintenance tasks, and testing of fire alarms, extinguishers, and sprinkler systems. Including an annual checklist ensures all safety components are thoroughly reviewed and compliant with regulations.

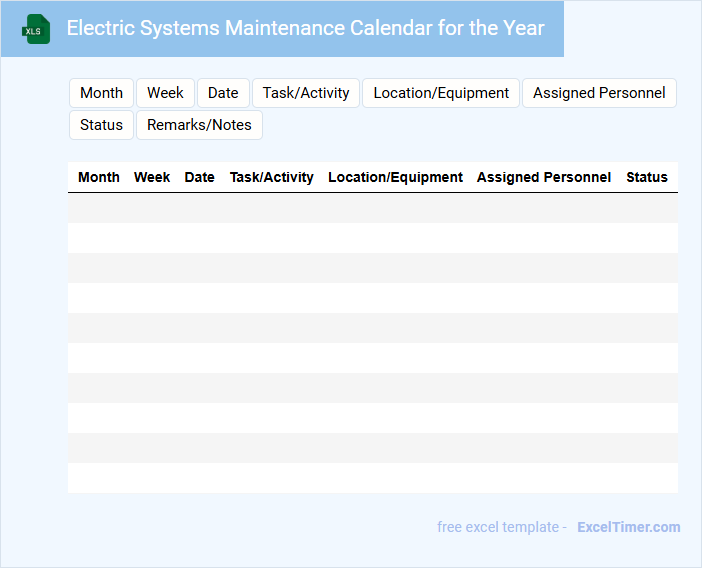

Electric Systems Maintenance Calendar for the Year

The Electric Systems Maintenance Calendar is a crucial document that outlines the scheduled inspections and maintenance activities for electrical systems throughout the year. It typically contains dates for routine checks, safety tests, and equipment servicing to ensure optimal performance and prevent breakdowns. Including clear timelines and responsible personnel is essential for effective management and accountability.

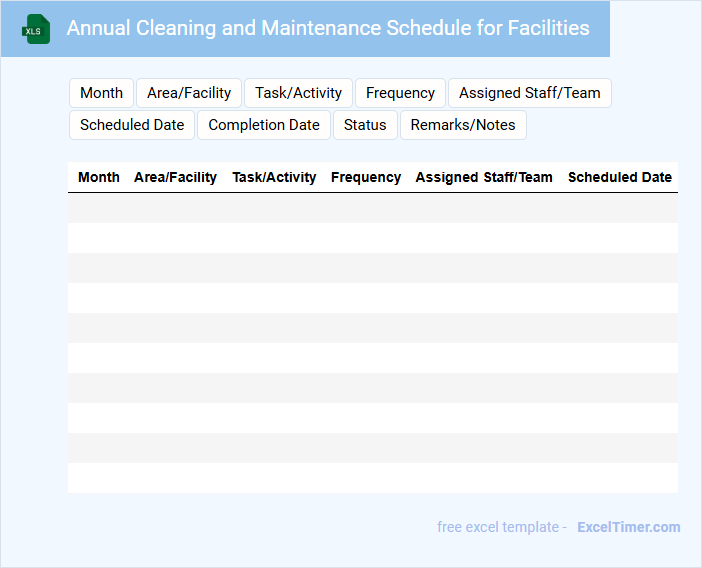

Annual Cleaning and Maintenance Schedule for Facilities

What is typically included in an Annual Cleaning and Maintenance Schedule for Facilities? This document usually contains a detailed timeline and checklist of cleaning tasks and maintenance activities required throughout the year to ensure optimal facility operation and safety. It outlines responsibilities, frequency, and methods for each task to help maintain cleanliness and prevent equipment failures.

Why is it important to have a clear and comprehensive schedule? A well-structured schedule helps in minimizing downtime, reducing repair costs, and maintaining a healthy environment for occupants. Prioritizing critical areas and periodic inspections ensures that all maintenance needs are consistently met and compliance standards are upheld.

What key components must be included in an annual maintenance schedule for facilities?

An annual maintenance schedule for facilities must include detailed asset inventories, routine inspection dates, and preventive maintenance tasks to ensure optimal operation. Your schedule should prioritize safety checks, equipment calibration, and cleaning protocols tailored to each facility's specific needs. Comprehensive documentation and compliance with regulatory standards are essential for effective facility management.

How does prioritizing tasks improve the efficiency of an annual maintenance plan?

Prioritizing tasks in your annual maintenance schedule ensures critical facility systems receive timely attention, minimizing downtime and costly repairs. It streamlines workflow by allocating resources effectively, improving response times and overall productivity. This targeted approach helps Facilities Managers optimize maintenance efforts, extending equipment lifespan and reducing operational risks.

What methods are best for tracking and documenting completed maintenance activities annually?

Using a centralized Excel document with date-stamped entries and dropdown status menus ensures accurate tracking of annual maintenance activities for facilities managers. Incorporating color-coded conditional formatting highlights completed versus pending tasks, enhancing visual oversight. Integrating timestamps and user notes within the spreadsheet improves documentation accuracy and accountability for each maintenance action.

How should facilities managers align maintenance frequency with equipment manufacturer recommendations?

Facilities managers should align maintenance frequency with equipment manufacturer recommendations by reviewing the annual maintenance schedule provided in the Excel document. Your schedule must reflect specific intervals and procedures to ensure compliance and optimal equipment performance. Regular updates based on manufacturer guidelines prevent costly downtime and extend asset lifespan.

What role does budgeting play in developing an effective annual facilities maintenance schedule?

Budgeting allocates essential financial resources to prioritize and plan maintenance tasks, ensuring all critical facility systems are regularly serviced and operational. Accurate budget planning helps you avoid unexpected repair costs and extends the lifespan of equipment through timely upkeep. Effective budgeting directly impacts the reliability and efficiency of your annual maintenance schedule for facilities.