The Annually Production Schedule Excel Template for Manufacturing Units streamlines the planning process by allowing manufacturers to organize and track production activities efficiently throughout the year. This template enhances resource allocation, minimizes downtime, and improves overall operational efficiency. Key features include customizable timelines, capacity planning, and real-time progress updates to support informed decision-making.

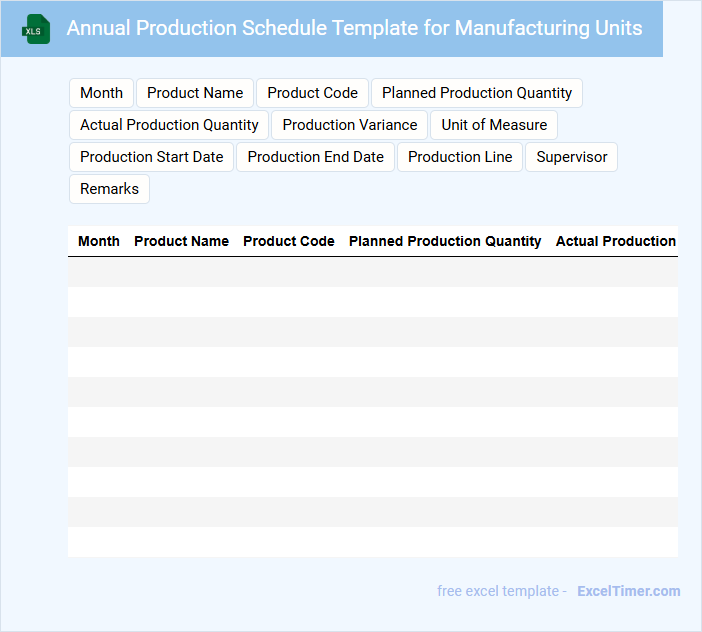

Annual Production Schedule Template for Manufacturing Units

An Annual Production Schedule Template for Manufacturing Units is a structured document used to plan and organize the production activities over a year. It ensures efficient resource allocation and timely delivery of products.

- Include clear timelines and milestones for each production phase.

- Incorporate capacity planning to optimize resource use and avoid bottlenecks.

- Track inventory levels and material requirements regularly to prevent delays.

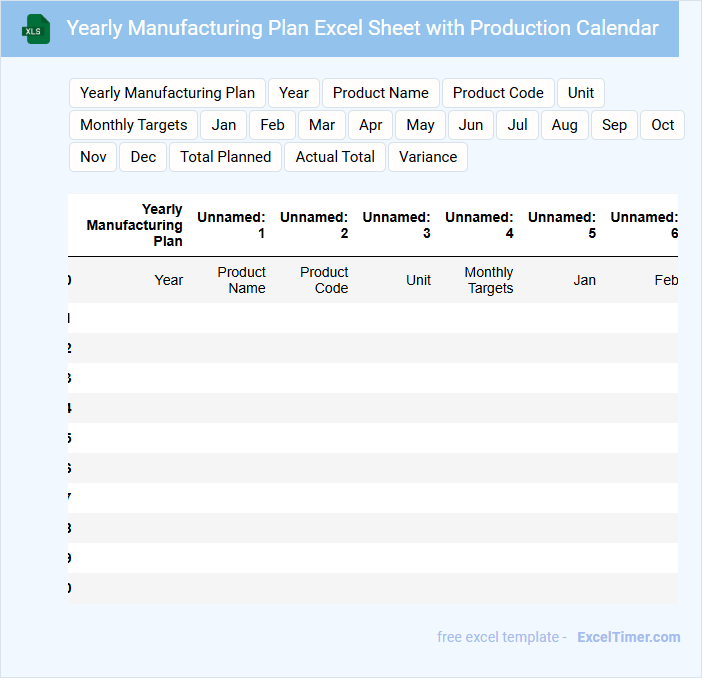

Yearly Manufacturing Plan Excel Sheet with Production Calendar

A Yearly Manufacturing Plan Excel Sheet with a production calendar typically contains detailed scheduling of production activities, inventory management data, and resource allocation for the entire year. It helps in foreseeing potential bottlenecks, planning workforce shifts, and maintaining optimal stock levels. This document is essential for aligning production goals with delivery timelines and financial forecasts.

Excel Template for Annual Output Tracking of Manufacturing Units

What information is typically contained in an Excel Template for Annual Output Tracking of Manufacturing Units? This document usually includes structured data entries such as monthly production volumes, unit-wise output, and efficiency metrics. It is designed to provide a comprehensive overview of manufacturing performance over the year, enabling trend analysis and operational assessment.

What important considerations should be kept in mind when using this template? Ensuring accurate data input and consistency across units is crucial for reliable tracking. Additionally, incorporating key performance indicators (KPIs) and automatic calculations enhances decision-making and streamlines reporting processes.

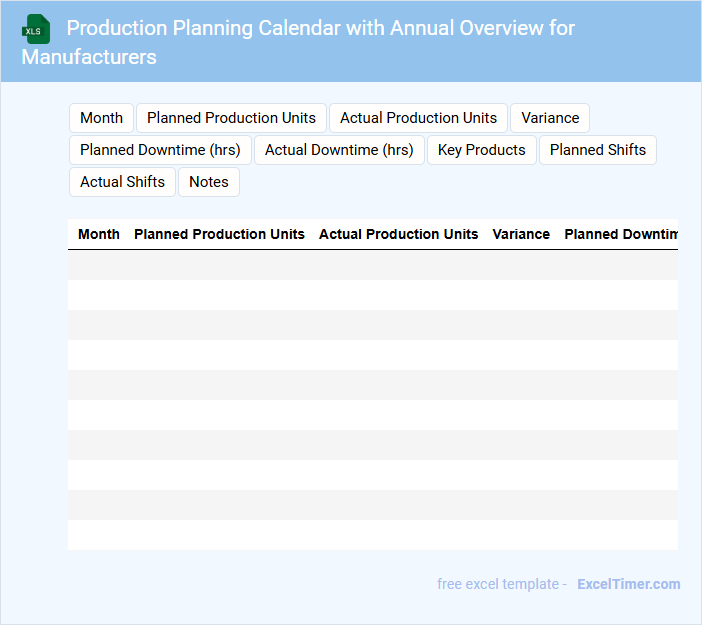

Production Planning Calendar with Annual Overview for Manufacturers

A Production Planning Calendar with Annual Overview for Manufacturers is a document that outlines the schedule and key milestones for manufacturing activities throughout the year. It helps in coordinating resources, managing deadlines, and ensuring smooth workflow across production phases.

- Include important production deadlines and maintenance periods to avoid downtime.

- Highlight inventory restocking dates to prevent material shortages.

- Incorporate buffer times for unexpected delays or quality control checks.

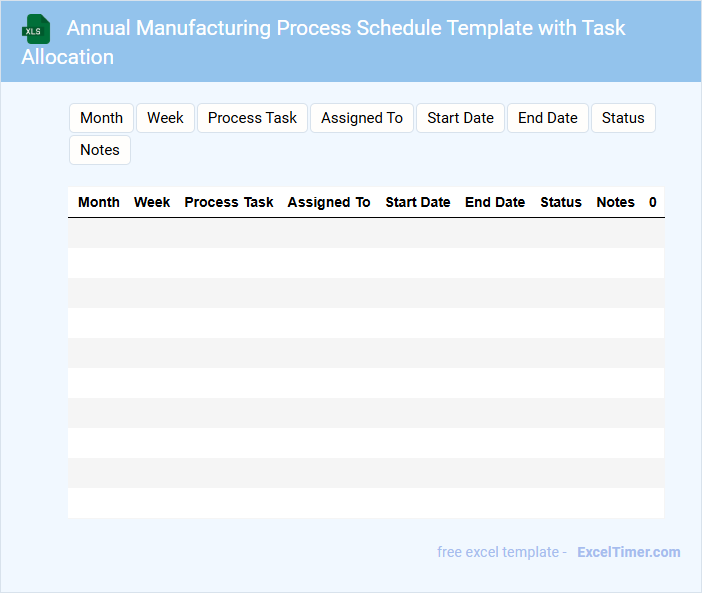

Annual Manufacturing Process Schedule Template with Task Allocation

An Annual Manufacturing Process Schedule Template typically contains a detailed timeline of production activities, key milestones, and precise task allocation to ensure smooth workflow throughout the year. It helps organize manufacturing phases, resource management, and deadline tracking effectively. This document is essential for optimizing operational efficiency and minimizing downtime.

One important aspect of this template is the clear task allocation, which assigns responsibilities to specific team members or departments to enhance accountability and coordination. Including buffer times for potential delays and integrating quality control checkpoints are also crucial. These measures contribute to maintaining consistent production quality and timely project completion.

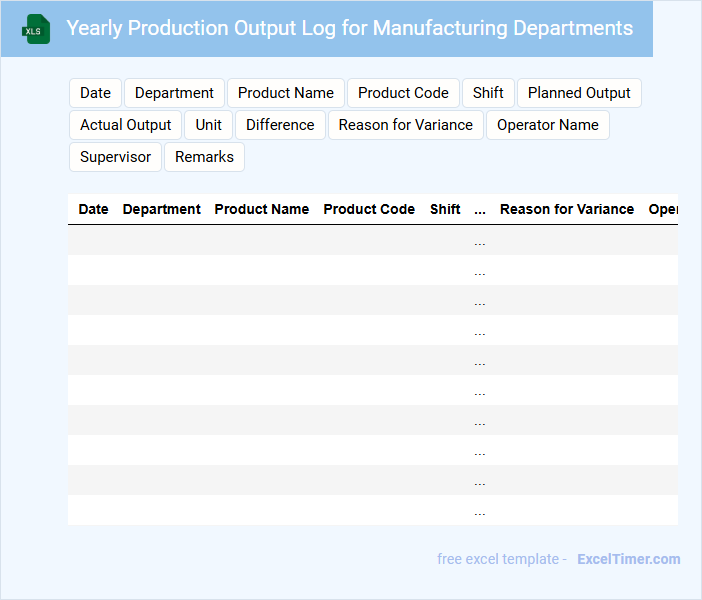

Yearly Production Output Log for Manufacturing Departments

The Yearly Production Output Log is a crucial document that records the total production quantities achieved by various manufacturing departments throughout the year. It typically includes data on product types, quantities, production dates, and any deviations from targets.

This log helps in tracking performance trends and identifying areas for improvement in manufacturing efficiency. For optimal use, it is important to maintain accurate entries and update the log regularly to ensure reliable production analysis.

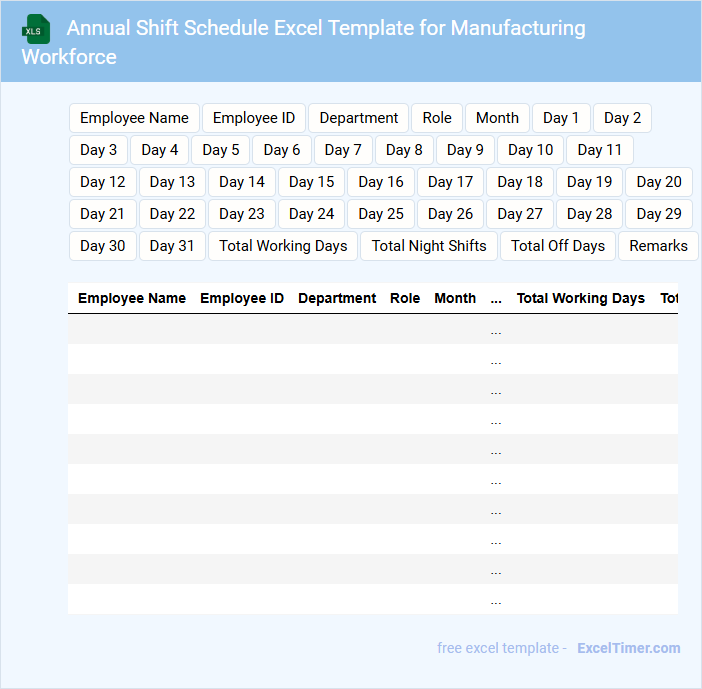

Annual Shift Schedule Excel Template for Manufacturing Workforce

What information is typically included in an Annual Shift Schedule Excel Template for a manufacturing workforce? This document usually contains detailed shift timings, employee names, and assigned workdays to ensure smooth operations throughout the year. It helps to track attendance, manage labor resources effectively, and plan for peak production periods.

Why is it important to include rest days and overtime tracking in this template? Including rest days ensures compliance with labor laws and promotes employee well-being, while overtime tracking helps monitor additional work hours and manage payroll expenses efficiently. Both elements are critical for maintaining a balanced workforce and optimizing productivity.

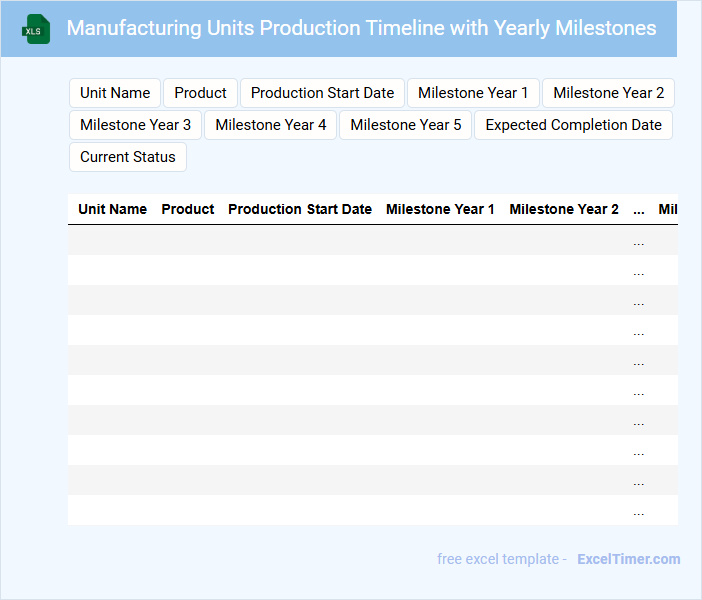

Manufacturing Units Production Timeline with Yearly Milestones

A Manufacturing Units Production Timeline with Yearly Milestones document typically outlines key production activities and achievements over a set period to track progress and plan future operations.

- Production Targets: Clearly define annual production goals to measure performance effectively.

- Milestone Dates: Include specific dates for critical project phases and deliverables.

- Resource Allocation: Highlight essential resources and capacity planning required for each milestone.

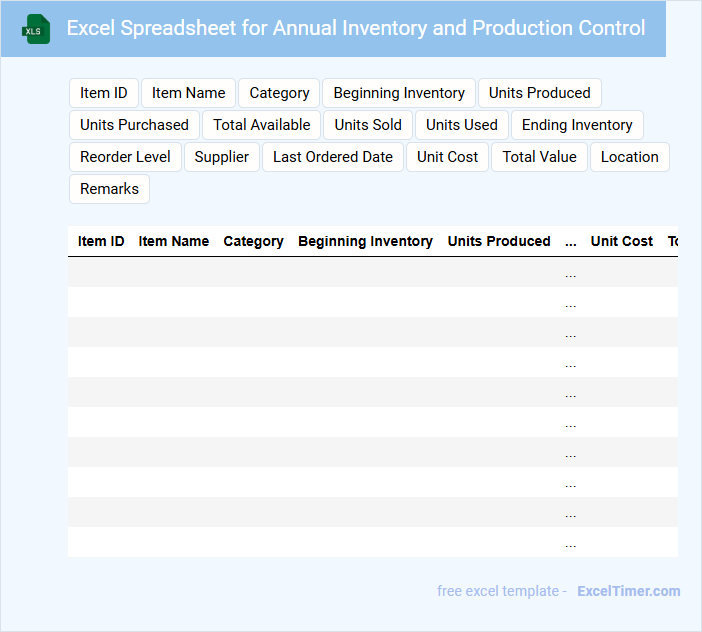

Excel Spreadsheet for Annual Inventory and Production Control

What information is typically contained in an Excel Spreadsheet for Annual Inventory and Production Control? This document usually includes detailed records of inventory levels, production schedules, and supply chain data to monitor and manage resources effectively throughout the year. It helps businesses track stock quantities, production output, and identify trends for optimizing operations.

Why is it important to include accurate data and clear labeling in this spreadsheet? Accurate data ensures reliable reporting and decision-making, while clear labeling enhances usability and reduces errors during data entry or analysis. Maintaining consistency in units and timestamps also improves the effectiveness of inventory and production control processes.

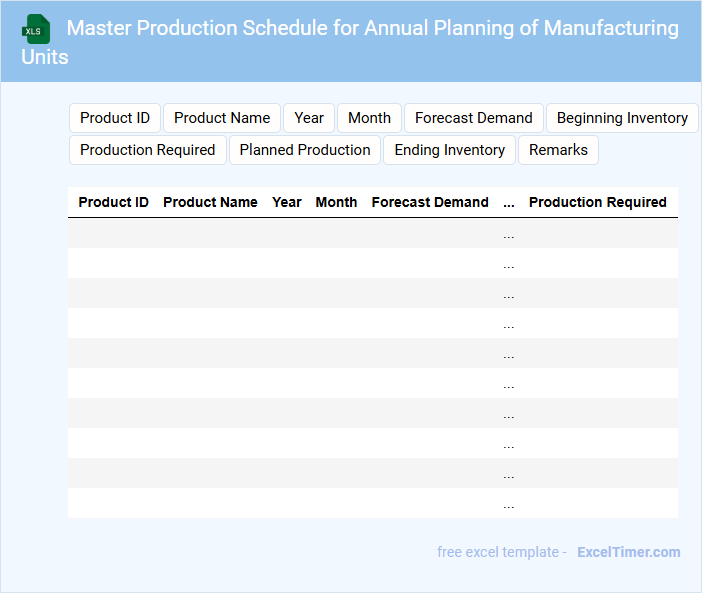

Master Production Schedule for Annual Planning of Manufacturing Units

The Master Production Schedule for Annual Planning of Manufacturing Units is a detailed plan that outlines the quantities and timing of finished products to be manufactured over a year.

- Demand Forecasting: Accurately predict customer demand to align production capacity and resource allocation effectively.

- Resource Planning: Ensure all raw materials, labor, and equipment are available to meet the scheduled production targets.

- Schedule Flexibility: Incorporate contingency plans to accommodate unexpected changes or disruptions in production.

Annual Work Order Tracker with Production Status for Factories

What information is typically included in an Annual Work Order Tracker with Production Status for Factories? This document usually contains detailed records of all work orders issued throughout the year, including order dates, descriptions, quantities, and deadlines. It also tracks the production status of each order, enabling factories to monitor progress, identify bottlenecks, and ensure timely completion of manufacturing tasks.

What key elements should be prioritized in such a tracker? It's important to include real-time updates on production stages, clear assignment of responsibilities, and integration with inventory and supply chain data. These features help enhance transparency, optimize resource allocation, and support efficient factory management.

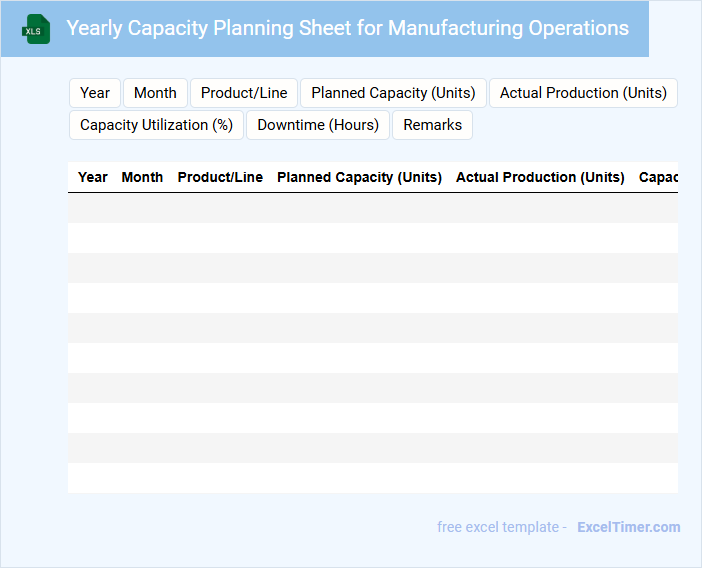

Yearly Capacity Planning Sheet for Manufacturing Operations

Yearly Capacity Planning Sheets for Manufacturing Operations typically contain detailed projections and assessments of production capabilities to ensure efficient resource allocation.

- Production Targets: Clearly define monthly and annual output goals based on market demand and historical data.

- Resource Allocation: Identify and allocate machinery, labor, and raw materials to meet capacity requirements.

- Contingency Planning: Include plans for potential bottlenecks or disruptions to maintain smooth operations.

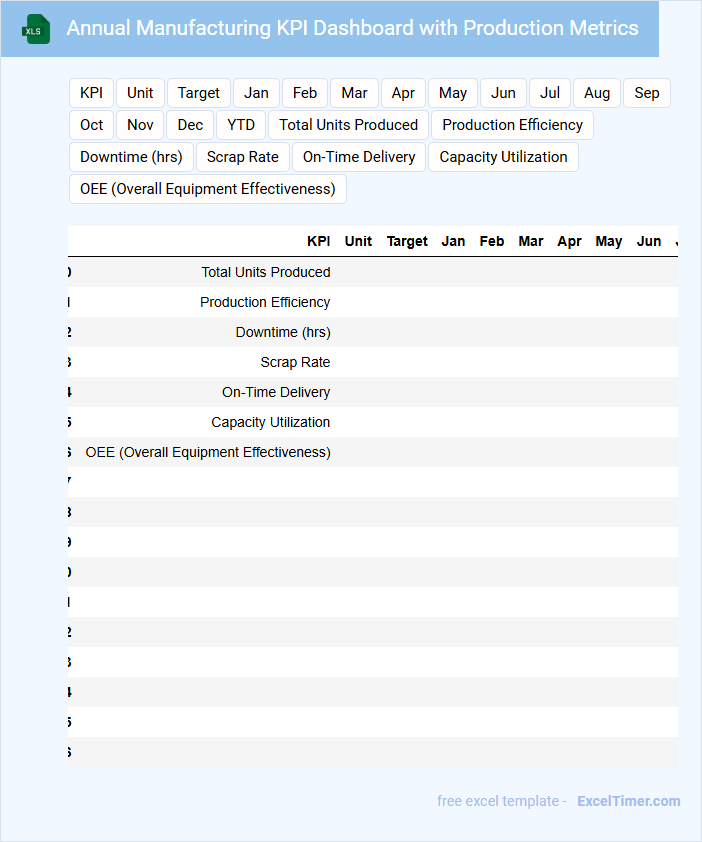

Annual Manufacturing KPI Dashboard with Production Metrics

An Annual Manufacturing KPI Dashboard with Production Metrics typically contains key performance indicators that track factory efficiency, production output, and quality control metrics over the year. This document helps stakeholders quickly assess operational performance and identify areas for improvement. Essential elements include machine downtime, production volume, defect rates, and on-time delivery statistics to provide a comprehensive overview of manufacturing effectiveness.

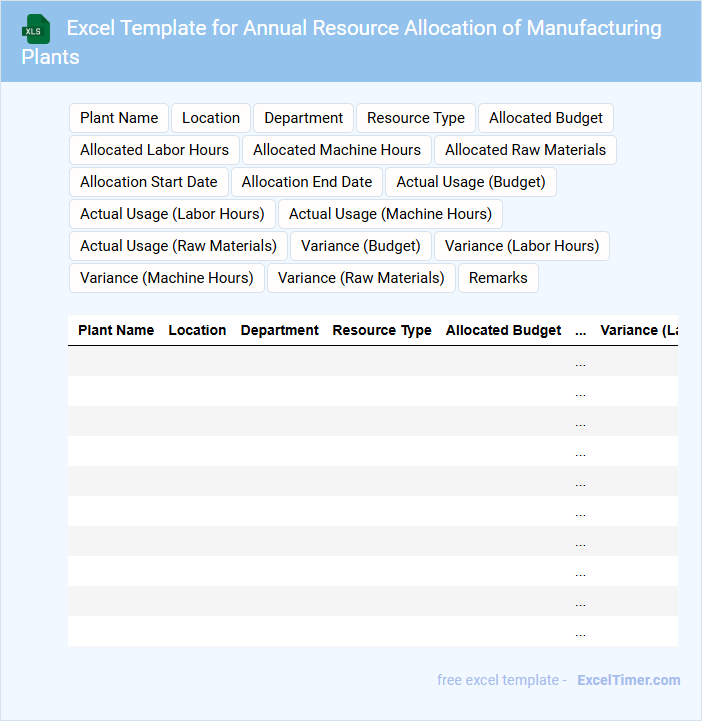

Excel Template for Annual Resource Allocation of Manufacturing Plants

This Excel template is designed to facilitate the annual planning and allocation of resources across manufacturing plants. It helps in organizing data related to budget, personnel, and machinery to optimize operational efficiency.

- Include detailed budget forecasts for each plant to ensure accurate financial planning.

- Track personnel allocation to balance workforce distribution effectively.

- Incorporate machinery usage schedules to maximize equipment productivity.

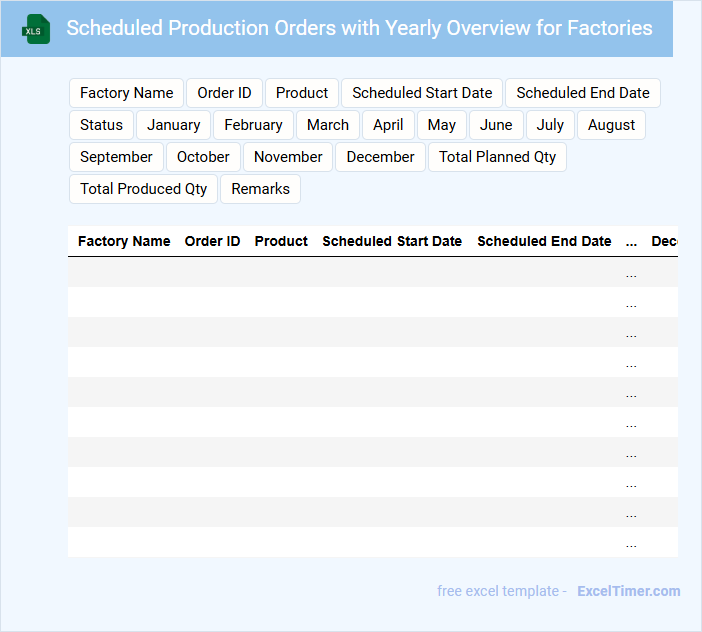

Scheduled Production Orders with Yearly Overview for Factories

Scheduled Production Orders with Yearly Overview for Factories document the planned manufacturing activities across the entire year, providing a comprehensive timeline of production schedules. This schedule includes important details such as order quantities, production dates, and factory assignments to ensure efficient workflow. It is essential for coordinating resources, meeting deadlines, and optimizing factory output.

What key data fields should be included in an Annually Production Schedule for manufacturing units in Excel?

An Annually Production Schedule for manufacturing units in Excel should include key data fields such as Product Name, Production Quantity, Monthly Production Targets, Machine Allocation, Shift Timings, and Resource Requirements. Incorporate fields for Planned Start and End Dates, Inventory Levels, and Quality Control Checkpoints to ensure smooth operations. Your schedule must also track Production Costs and Efficiency Metrics to optimize manufacturing performance.

How can dependencies between different production lines or products be represented within the schedule?

Dependencies between production lines or products can be represented using linked task fields or dependency columns within the Excel schedule, such as "Predecessor" or "Start-to-Finish" relationships. Utilizing Gantt charts or conditional formatting helps visualize these dependencies clearly. This approach ensures accurate timing and coordination across manufacturing units.

Which Excel functions or formulas are essential for calculating monthly and annual totals in the production schedule?

Your Annually Production Schedule for Manufacturing Units benefits from essential Excel functions like SUM to calculate monthly totals and SUMPRODUCT for annual totals across multiple products. Using SUMIF helps you aggregate data based on specific criteria, enhancing accuracy and efficiency. These formulas ensure precise tracking of production volumes throughout the year.

What methods can be used in Excel to visualize production targets versus actual outputs throughout the year?

Excel offers various methods to visualize production targets versus actual outputs, including line charts, bar charts, and combo charts that clearly compare monthly or quarterly data. Conditional formatting can highlight variances directly within your data tables, enhancing quick identification of discrepancies. Using PivotTables with slicers provides dynamic, interactive views of your annual production schedule for deeper analysis.

How should resource allocation and capacity constraints be managed and updated within the annual schedule document?

Manage resource allocation and capacity constraints by integrating real-time production data and machine availability metrics into your annual schedule document. Regularly update resource inputs and output forecasts to reflect changes in labor shifts, equipment maintenance, and material supply. Use automated formulas and conditional formatting in Excel to highlight bottlenecks and optimize production flow efficiently.